Komatsu 930E-2 Dump Truck Operation and Maintenance Manual CEAM011600

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM011600

- Format: PDF

- Size: 2.4MB

- Number of Pages: 165

-

Model List:

- 930E-2 Dump Truck

- 1. MAIN MENU

- 2. COVER

- 3. FOREWARD

- 3.1. ALERTS PAGE

- 4. TABLE OF CONTENTS

- 4.1. TRUCK MODEL ILLUSTRATION

- 5. ABOUT THIS MANUAL

- 6. STANDARD CHARTS AND TABLES

- 7. SAFETY

- 7.1. Safety Rules

- 7.2. Safety Features

- 7.3. Clothing And Personal Items

- 7.4. Unauthorized Modification

- 7.5. Leaving The Operators Seat

- 7.6. Mounting And Dismounting

- 7.7. Fire Prevention For Fuel And Oil

- 7.8. Precautions With High Temperature Fluids

- 7.9. Asbestos Dust Hazard Prevention

- 7.10. Prevention Of Injury By Work Equipment

- 7.11. Fire Extinguisher And First Aid Kit

- 7.12. Precautions When Using ROPS

- 7.13. Precautions For Attachments

- 7.14. PRECAUTIONS DURING OPERATION

- 7.15. OPERATING THE MACHINE

- 7.16. TOWING

- 7.17. WORKING NEAR BATTERIES

- 8. PRECAUTIONS FOR MAINTENANCE

- 8.1. BEFORE PERFORMING MAINTENANCE

- 8.2. DURING MAINTENANCE

- 8.3. TIRES

- 8.4. ADDITIONAL JOB SITE RULES

- 9. WHEN REPAIRS ARE NECESSARY

- 10. SPECIAL PRECAUTIONS FOR WORKING ON A 930E TRUCK

- 10.1. Preliminary Procedures Before Welding Or Performing Maintenance

- 10.2. Normal Engine Shutdown Procedure

- 10.3. Engine Shutdown Procedure Before Welding Or Performing Maintenance

- 11. WARNINGS AND CAUTIONS

- 12. OPERATING INSTRUCTIONS

- 12.1. PREPARING FOR OPERATION

- 12.2. ENGINE STARTUP SAFETY PRACTICES

- 12.3. AFTER ENGINE HAS STARTED

- 12.4. MACHINE OPERATION SAFETY PRECAUTIONS

- 12.5. MACHINE OPERATION ON THE HAUL ROAD

- 12.6. STARTING ON A GRADE WITH A LOADED TRUCK

- 12.7. PASSING

- 12.8. LOADING

- 12.9. DUMPING

- 12.10. TOWING

- 12.11. SAFE PARKING PROCEDURES

- 12.12. NORMAL ENGINE SHUTDOWN PROCEDURE

- 12.13. DELAYED ENGINE SHUTDOWN PROCEDURE

- 12.14. SUDDEN LOSS OF ENGINE POWER

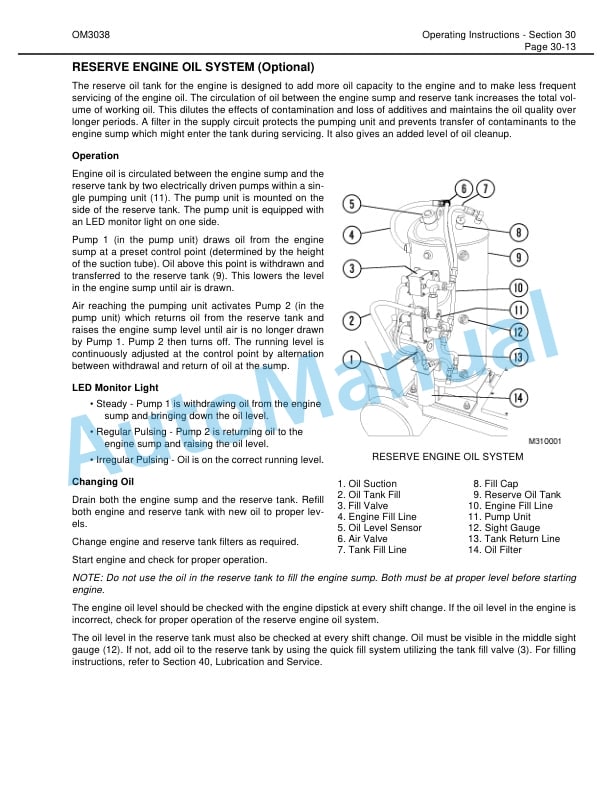

- 12.15. RESERVE ENGINE OIL SYSTEM (OPTIONAL)

- 13. OPERATOR CAB AND CONTROLS

- 13.1. STEERING WHEEL AND CONTROLS

- 13.2. DYNAMIC RETARDING

- 13.3. GRADE/SPEED RETARD CHART

- 13.4. INSTRUMENT PANEL

- 13.5. OVERHEAD PANEL AND DISPLAYS

- 13.6. CENTER CONSOLE

- 14. OPERATOR COMFORT

- 14.1. OPERATOR SEAT

- 14.2. HEATER/AIR CONDITIONER COMPARTMENT AND CONTROLS

- 15. INSTRUMENT PANEL AND INDICATOR LIGHTS

- 15.1. CONTROL SYMBOLS

- 15.2. INSTRUMENT PANEL

- 16. PANEL GAUGES, INDICATORS, AND CONTROLS

- 16.1. Key Switch

- 16.2. Engine Shutdown Switch With 5 Minute Idle Timer Delay

- 16.3. Fog Lights (Optional)

- 16.4. Ladder Light Switch

- 16.5. Manual Backup Switch

- 16.6. Panel Illumination Lights

- 16.7. Cab/Air Conditioner Vents

- 16.8. Rotating Beacon Light Switch (Optional)

- 16.9. Heated Mirror Switch (Optional)

- 16.10. Wheel Brake Lock Control

- 16.11. Parking Brake Control

- 16.12. Tachometer

- 16.13. Right Turn Signal Indicator

- 16.14. High Beam Indicator

- 16.15. Left Turn Signal Indicator

- 16.16. Speedometer/Payload Meter Display

- 16.17. Voltmeter

- 16.18. Engine Oil Pressure Gauge

- 16.19. Water Temperature Gauge

- 16.20. Fuel Gauge

- 16.21. AC Drive System Temperature Gauge

- 16.22. Hourmeter

- 16.23. Hydraulic Oil Temperature Gauge

- 16.24. Rest Switch

- 16.25. Light Switch

- 16.26. Windshield Wiper And Washer

- 16.27. Panel Light And DImmer

- 16.28. Payload Meter Switch

- 16.29. OVERHEAD STATUS/WARNING INDICATORS

- 16.30. STATUS/WARNING INDICATOR LIGHT SYMBOLS

- 17. LUBRICATION AND SERVICE

- 17.1. SERVICE CAPACITIES

- 17.2. HYDRAULIC TANK SERVICE

- 17.3. WHEEL MOTOR SERVICE

- 17.4. COOLANT LEVEL CHECK

- 17.5. RADIATOR FILLING PROCEDURE

- 17.6. RESERVE ENGINE OIL SYSTEM (OPTIONAL)

- 17.7. LUBRICATION CHART

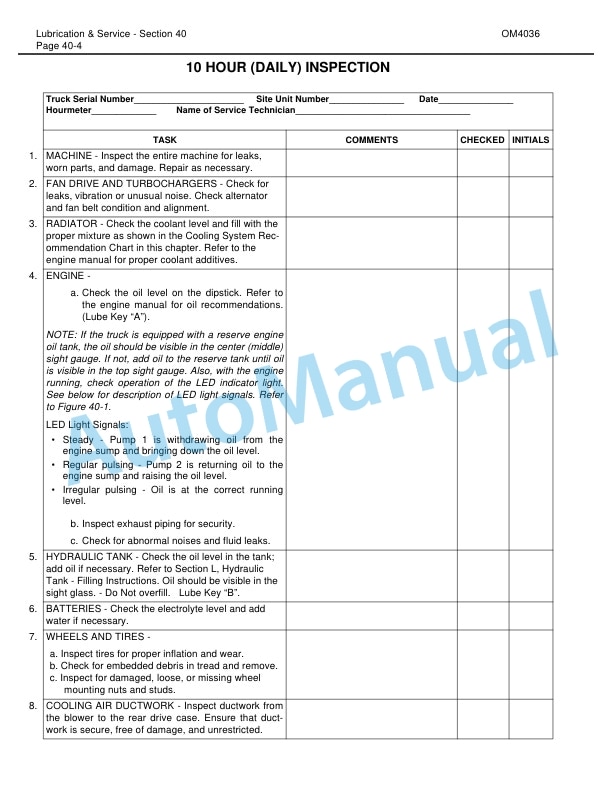

- 17.8. HOUR (DAILY) INSPECTION

- 17.9. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 17.10. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 17.11. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 17.12. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 17.13. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 17.14. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 17.15. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 18. AUTOMATIC LUBRICATION SYSTEM

- 18.1. GENERAL DESCRIPTION

- 18.2. SYSTEM COMPONENTS

- 18.3. SYSTEM OPERATION

- 18.4. GENERAL INSTRUCTIONS

- 18.5. LUBRICANT PUMP

- 18.6. INJECTOR OPERATION

- 18.7. SYSTEM CHECKOUT

- 18.8. SYSTEM TROUBLESHOOTING CHART

- 18.9. PREVENTATIVE MAINTENANCE PROCEDURES

- 19. MAJOR COMPONENT DESCRIPTION

- 20. PAYLOAD METER III TM

- 20.1. INDEX

- 20.2. OPERATION SECTION

- 20.3. COMPONENT DESCRIPTION

- 20.4. OPERATORS DISPLAY AND SWITCH

- 20.5. PAYLOAD OPERATION CALCULATION

- 20.6. SOURCES FOR PAYLOAD ERROR

- 20.7. HAUL CYCLE DATA

- 20.8. PC SOFTWARE OVERVIEW

- 20.9. DOWNLOADING DATA

- 20.10. PLMIII SYSTEM CONFIGURATION

- 20.11. DATA ANALYSIS

- 21. RADIO AM/FM STEREO CASSETTE

- 21.1. SETTING THE TIME

- 21.2. GENERAL RECEIVER FUNCTIONS

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E