Komatsu 95-2 Series Diesel Engine Shop Manual SEBM018803

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM018803

- Format: PDF

- Size: 9.0MB

- Number of Pages: 180

Category: Komatsu Shop Manual PDF

-

Model List:

- 95-2 Series Diesel Engine

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. APPLICABLE MACHINE

- 1.2. SPECIFICATIONS

- 1.3. WEIGHT TABLE

- 1.4. OVERALL DRAWING

- 1.5. ENGINE PERFORMANCE CURVE

- 2. STRUCTURE AND FUNCTION

- 2.1. GENERAL STRUCTURE

- 2.1.1. GENERAL STRUCTURE

- 2.2. INTAKE AND EXHAUST SYSTEM

- 2.2.1. INTAKE AND EXHAUST SYSTEM

- 2.2.2. AIR CLEANER

- 2.3. ENGINE BODY

- 2.3.1. CYLINDER HEAD

- 2.3.2. CYLINDER BLOCK

- 2.3.3. MAIN CIRCULATION SYSTEM

- 2.3.4. TIMING GEAR

- 2.3.5. VALVE SYSTEM

- 2.3.6. FLYWHEEL AND FLYWHEEL HOUSING

- 2.4. LUBRICATION SYSTEM

- 2.4.1. LUBRICATION SYSTEM CHART

- 2.4.2. OIL PUMP

- 2.4.3. OIL FILTER

- 2.4.4. OIL FILTER MOUNT

- 2.5. FUEL SYSTEM

- 2.5.1. FUEL SYSTEM CHART

- 2.5.2. FUEL INJECTION PUMP

- 2.5.3. FUEL INJECTION NOZZLE

- 2.5.4. FUEL FILTER

- 2.5.5. ENGINE CUT SOLENOID

- 2.6. COOLING SYSTEM

- 2.6.1. COOLING SYSTEM CHART

- 2.6.2. WATER PUMP

- 2.6.3. FAN DRIVE AND THERMOSTAT

- 2.7. ELECTRICAL SYSTEM

- 2.7.1. STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM

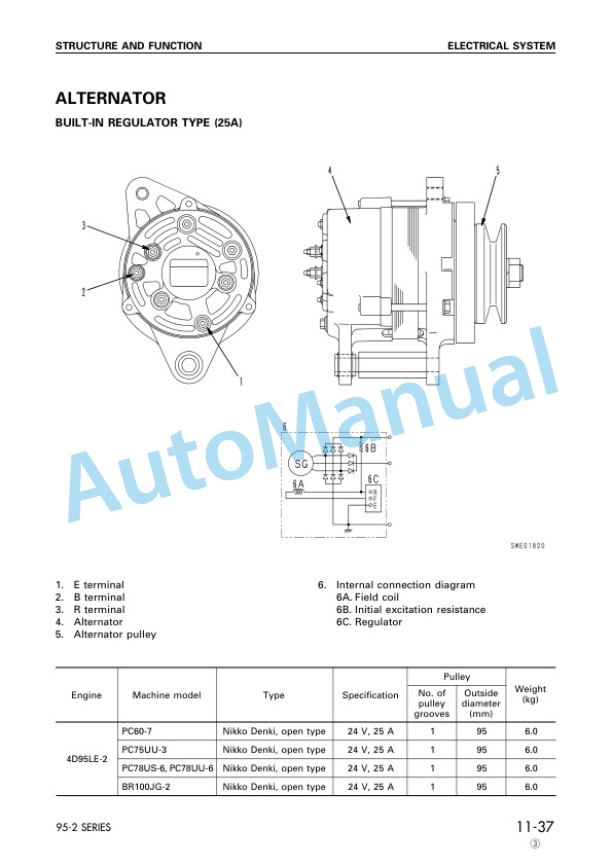

- 2.7.2. ALTERNATOR

- 2.7.3. STARTING MOTOR

- 2.7.4. ENGINE STARTING DEVICE

- 3. TESTING AND ADJUSTING

- 3.1. TESTING AND ADJUSTING

- 3.1.1. ADJUSTING VALVLE CLEARANCE

- 3.1.2. MEASURING COMPRESSION PRESSURE

- 3.1.3. ADJUSTING FUEL INJECTION PRESSURE

- 3.1.4. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.1.5. ADJUSTING FUEL CUT SOLENOID

- 3.2. FUEL INJECTION PUMP CALIBRATION DATA

- 3.3. PERFORMANCE TEST

- 3.3.1. RUNIN STANDARD

- 3.3.2. PERFORMANCE TEST CRITERIA

- 3.4. TROUBLESHOOTING

- 3.4.1. METHOD OF USING TROUBLESHOOTING CHARTS

- 3.4.2. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.4.3. S1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)

- 3.4.4. S2 ENGINE DOES NOT START

- 3.4.4.1. ENGINE DOES NOT TURN

- 3.4.4.2. ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)

- 3.4.4.3. EXHAUST SMOKE COMES OUT, BUT ENGINE DOES NOT START (FUEL IS NOT BEING INJECTED)

- 3.4.5. S3 ENGINE DOES NOT PICK UP SMOOTHLY

- 3.4.6. S4 ENGINE STOPS DURING OPERATIONS

- 3.4.7. S5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)

- 3.4.8. S6 ENGINE LACK OUTPUT (NO POWER)

- 3.4.9. S7 EXHAUST GAS IS BLACK

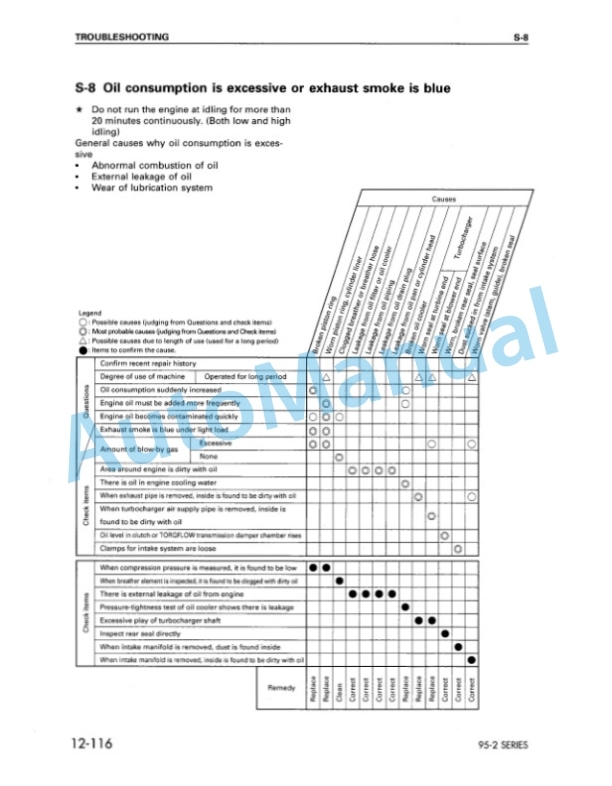

- 3.4.10. S8 OIL CONSUMPTION IS EXCESSIVE, OR EXHAUST GAS IS BLUE

- 3.4.11. S9 OIL BECOMES CONTAMINATED QUICKLY

- 3.4.12. S10 FUEL CONSUMPTION IS EXCESSIVE

- 3.4.13. S11 OIL IS IN COOLING WATER

- 3.4.14. S12 OIL PRESSURE CAUTION LAMP LIGHTS UPS (DROP IN OIL PRESSURE)

- 3.4.15. S13 OIL LEVEL RISES (WATER, FUEL IN OIL )

- 3.4.16. S14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)

- 3.4.17. S15 ABNORMAL NOISE IS MADE

- 3.4.18. S16 VIBRATION IS EXCESSIVE

- 3.5. TESTING AND ADJUSTING TOOL LIST

- 3.6. TESTING AND ADJUSTING DATA

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. SPECIAL TOOL LIST

- 4.2. OVERALL DISASSEMBLY OF 4D95LC2

- 4.2.1. PREPARATORY WORK

- 4.2.2. ALTERNATOR, FAN PULLEY

- 4.2.3. STARTING MOTOR, ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK

- 4.2.4. WATER PUMP

- 4.2.5. FUEL INJECTION TUBE, GLOW PLUG

- 4.2.6. INJECTION NOZZLE

- 4.2.7. FUEL INJECTION PUMP

- 4.2.8. INTAKE MANIFOLD

- 4.2.9. EXHAUST MANIFOLD

- 4.2.10. HEAD COVER

- 4.2.11. ROCKER ARM

- 4.2.12. PUSH ROD, CYLINDER HEAD MOUNTING BOLT

- 4.2.13. CYLINDER HEAD COVER

- 4.2.14. PTO SHAFT

- 4.2.15. OIL PAN

- 4.2.16. OIL SUCTION PIPE

- 4.2.17. CRANKSHAFT PULLEY

- 4.2.18. GEAR CASE COVER

- 4.2.19. OIL PUMP, IDLER GEAR

- 4.2.20. CAMSHAFT ASSEMBLY

- 4.2.21. FLYWHEEL

- 4.2.22. FLYWHEEL HOUSING

- 4.2.23. PISTION, CONNECTING ROD ASSEMBLY

- 4.2.24. MAIN CAP

- 4.2.25. CRANKSHAFT

- 4.2.26. TAPPET

- 4.2.27. CYLINDER BLOCK ASSEMBLY

- 4.3. OVERALL ASSEMBLY

- 4.3.1. CYLINDER BLOCK ASSEMBLY

- 4.3.2. TAPPET

- 4.3.3. CRANKSHAFT

- 4.3.4. MAIN CAP

- 4.3.5. FLYWHEEL HOUSING

- 4.3.6. FLYWHEEL

- 4.3.7. CAMSHAFT ASSEMBLY

- 4.3.8. OIL PUMP, IDLER GEAR

- 4.3.9. GEAR CASE COVER

- 4.3.10. CRANKSHAFT PULLEY

- 4.3.11. OIL SUCTION PIPE

- 4.3.12. OIL PAN

- 4.3.13. PTO SHAFT

- 4.3.14. FUEL INJECTION PUMP

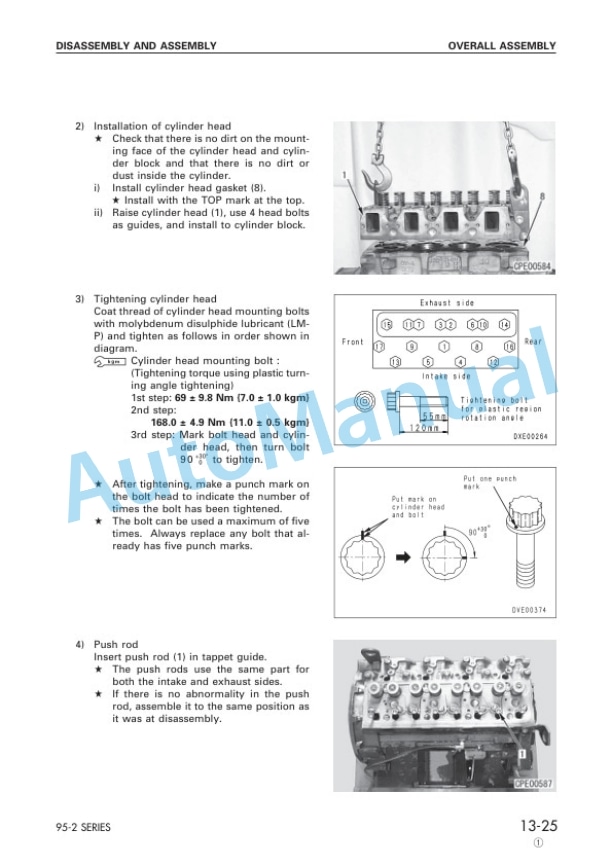

- 4.3.15. CYLINDER HEAD ASSEMBLY

- 4.3.16. ADJUSTMENT OF VALVE CLEARANCE

- 4.3.17. HEAD COVER

- 4.3.18. EXHAUST MANIFOLD

- 4.3.19. INTAKE MANIFOLD

- 4.3.20. INJECTION NOZZLE

- 4.3.21. FUEL INJECTION TUBE, GLOW PLUG

- 4.3.22. WATER PUMP

- 4.3.23. STARTING MOTOR. ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK

- 4.3.24. ALTERNATOR, FAN PULLEY

- 4.3.25. ENGINE ASSEMBLY

- 4.3.26. FAN, EXHAUST PIPE, MUFFLER, ENGINE OIL TUBES, BLOCK, COVER

- 5. MAINTENANCE STANDARD

- 5.1. CYLINDER HEAD

- 5.2. VALVE AND VALVE GUIDE

- 5.3. ROCKER ARM SHAFT, PUSH ROD AND TAPPET

- 5.4. PISTION, PISTON RING AND PISTION PIN

- 5.5. CONNECTING ROD

- 5.6. FLYWHEEL AND FLYWHEEL HOUSING

- 5.7. OIL PUMP

- 5.8. REGULATOR VALVE

- 5.9. WATER PUMP AND THERMOSTAT

- 6. REPAIR AND REPLACEMENT OF PARTS

- 6.1. CYLINDER HEAD SECTION

- 6.1.1. GRINDING CYLINDER HEAD MOUNTING SURFACE

- 6.1.2. REPLACING VALVE GUIDE

- 6.1.3. GRINDING VALVE

- 6.2. CYLINDER BLOCK SECTION

- 6.2.1. REPLACING CAMSHAFT BUSHING

- 6.2.2. REPLACING CRANKSHAFT GEAR

- 6.2.3. REPLACING CAM GEAR

- 6.2.4. REPLACING FLYWHEEL RING GEAR

- 6.2.5. PROCEDURE FOR PRESSURE TEST

- 6.2.6. CYLINDER LINER (SPECIAL RESTORATION PART)

- 6.2.7. MACHINING DRAWING FOR CYLINDER BLOCK BORE

- 6.2.8. ADDITIONAL MACHINING OF CAM JOURNAL

- 6.2.9. GRINDING CRANKSHAFT

- 6.2.10. REPLACING CONNECTING ROD SMALL END BUSHING

Rate this product

You may also like