Komatsu 95-3 Series Diesel Engine Shop Manual SEBM031002

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM031002

- Format: PDF

- Size: 6.2MB

- Number of Pages: 224

Category: Komatsu Shop Manual PDF

-

Model List:

- 95-3 Series Diesel Engine

- 0.1. OVERALL DRAWING

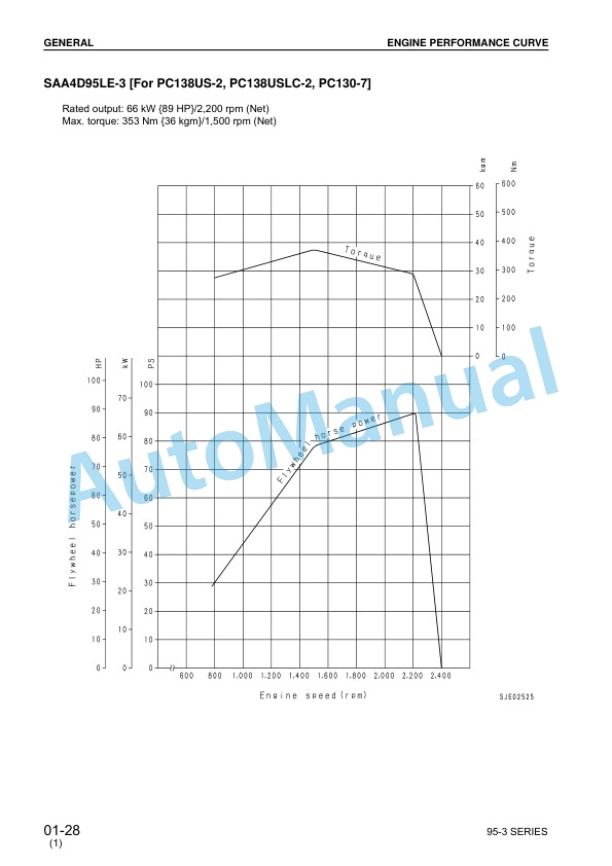

- 0.2. ENGINE PERFORMANCE CURVE

- 1. STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD

- 1.1. GENERAL STRUCTURE

- 1.2. INTAKE AND EXHAUST SYSTEM

- 1.3. MAIN CIRCULATION SYSTEM

- 1.4. CRANKSHAFT

- 1.5. PISTON, PISTON RING AND PISTON PIN

- 1.6. CONNECTING ROD

- 1.7. FLYWHEEL AND FLYWHEEL HOUSING

- 1.8. TIMING GEAR

- 1.9. VALVE SYSTEM

- 1.10. CAMSHAFT

- 1.11. ROCKER ARM SHAFT, PUSH ROD AND TAPPET

- 1.12. VALVE, VALVE GUIDE

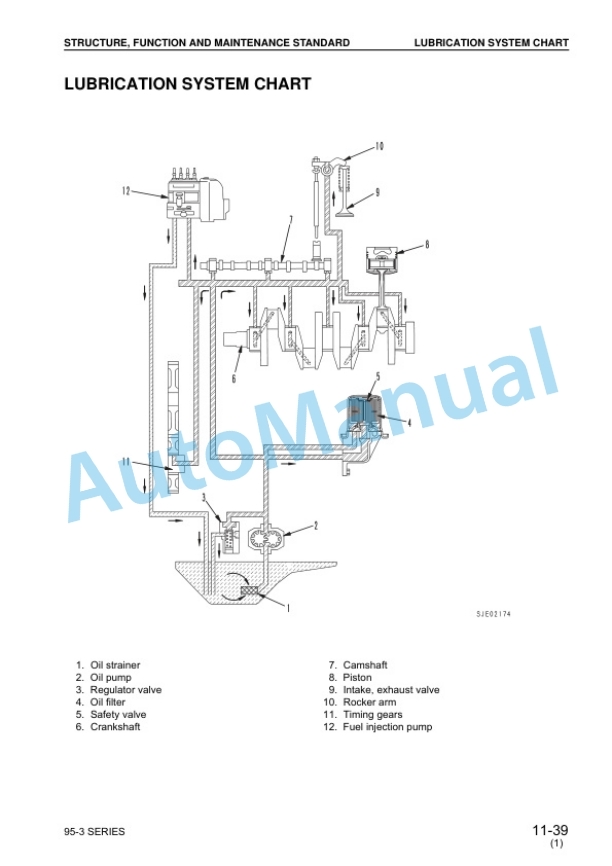

- 1.13. LUBRICATION SYSTEM CHART

- 1.14. OIL PUMP

- 1.15. REGULATOR VALVE

- 1.16. OIL FILTER MOUNT

- 1.17. OIL FILTER

- 1.18. FUEL SYSTEM CHART

- 1.19. FUEL INJECTION PUMP

- 1.20. BOOST COMPENSATOR

- 1.21. FUEL INJECTION NOZZLE

- 1.22. FUEL FILTER

- 1.23. FUEL CUT SOLENOID

- 1.24. COOLING SYSTEM CHART

- 1.25. WATER PUMP

- 1.26. FAN DRIVE AND THERMOSTAT

- 1.27. STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM

- 1.28. ALTERNATOR

- 1.29. STARTING MOTOR

- 1.30. ENGINE STARTING DEVICE

- 2. TESTING AND ADJUSTING

- 2.1. ADJUSTING VALVE CLEARANCE

- 2.2. MEASURING COMPRESSION PRESSURE

- 2.3. ADJUSTING FUEL INJECTION PRESSURE (CRACKING PRESSURE)

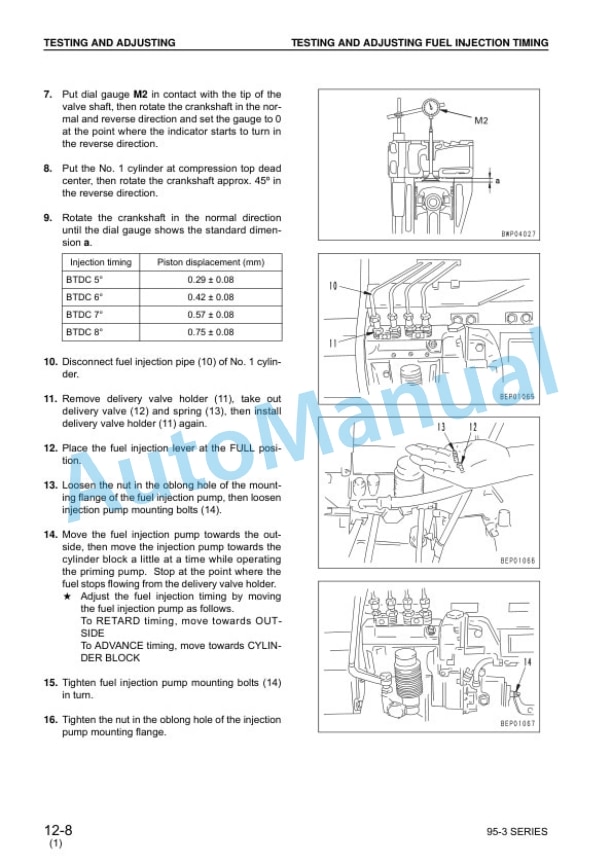

- 2.4. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 2.5. ADJUSTING FUEL CUT SOLENOID

- 2.6. FUEL INJECTION PUMP CALIBRATION DATA

- 2.7. PERFORMANCE TEST

- 2.8. PERFORMANCE TEST CRITERIA

- 2.9. TROUBLESHOOTING

- 2.9.1. METHOD OF USING TROUBLESHOOTING CHARTS

- 2.9.2. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.9.3. S1 Starting performance is poor (starting always takes time)

- 2.9.4. S2 Engine does not start

- 2.9.5. S3 Engine does not pick up smoothly (followup is poor)

- 2.9.6. S4 Engine stops during operations

- 2.9.7. S5 Engine does not rotate smoothly (hunting)

- 2.9.8. S6 Engine lacks output (no power)

- 2.9.9. S7 Exhaust smoke is black (incomplete combustion)

- 2.9.10. S8 Oil consumption is excessive or exhaust smoke is blue

- 2.9.11. S9 Oil becomes contaminated quickly

- 2.9.12. S10 Fuel consumption is excessive

- 2.9.13. S11 Oil is in cooling water, or water spurts back, or water level goes down

- 2.9.14. S12 Oil pressure caution lamp lights up (drop in oil pressure)

- 2.9.15. S13 Oil level rises (water, fuel in oil)

- 2.9.16. S14 Water temperature becomes too high (overheating)

- 2.9.17. S15 Abnormal noise is made

- 2.9.18. S16 Vibration is excessive

- 2.9.19. TESTING AND ADJUSTING TOOL LIST

- 2.9.20. TESTING AND ADJUSTING DATA

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. SPECIAL TOOL LIST

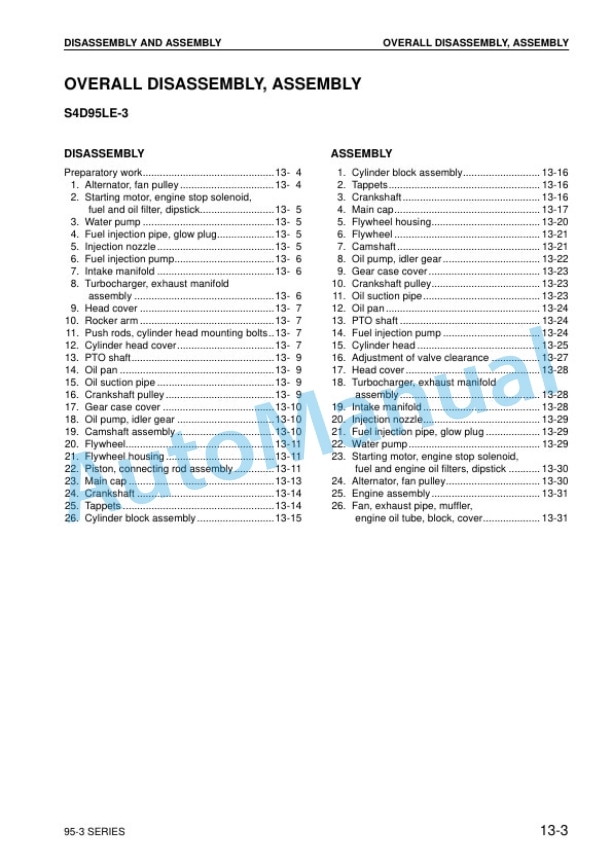

- 3.2. OVERALL DISASSEMBLY, ASSEMBLY

- 3.3. DISASSEMBLY

- 3.4. ASSEMBLY

- 4. REPAIR AND REPLACEMENT OF PARTS

- 4.1. GRINDING CYLINDER HEAD MOUNTING SURFACE

- 4.2. REPLACING VALVE GUIDE

- 4.3. GRINDING VALVE

- 4.4. REPLACING CAMSHAFT BUSHING

- 4.5. REPLACING CRANKSHAFT GEAR

- 4.6. REPLACING CAM GEAR

- 4.7. REPLACING FLYWHEEL RING GEAR

- 4.8. PROCEDURE FOR PRESSURE TEST

- 4.9. CYLINDER LINER (SPECIAL RESTORATION PART)

- 4.10. MACHINING DRAWING FOR CYLINDER BLOCK BORE

- 4.11. ADDITIONAL MACHINING OF CAM JOURNAL

- 4.12. GRINDING CRANKSHAFT

- 4.13. REPLACING CONNECTING ROD SMALL END BUSHING

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00