Komatsu AE50, AM50 Series Forklift Truck Shop Manual BBA12E1-11

$40.00

- Type Of Manual: Shop Manual

- Manual ID: BBA12E1-11

- Format: PDF

- Size: 21.9MB

- Number of Pages: 464

Category: Komatsu Shop Manual PDF

-

Model List:

- AE50 Series Forklift Truck

- AM50 Series Forklift Truck

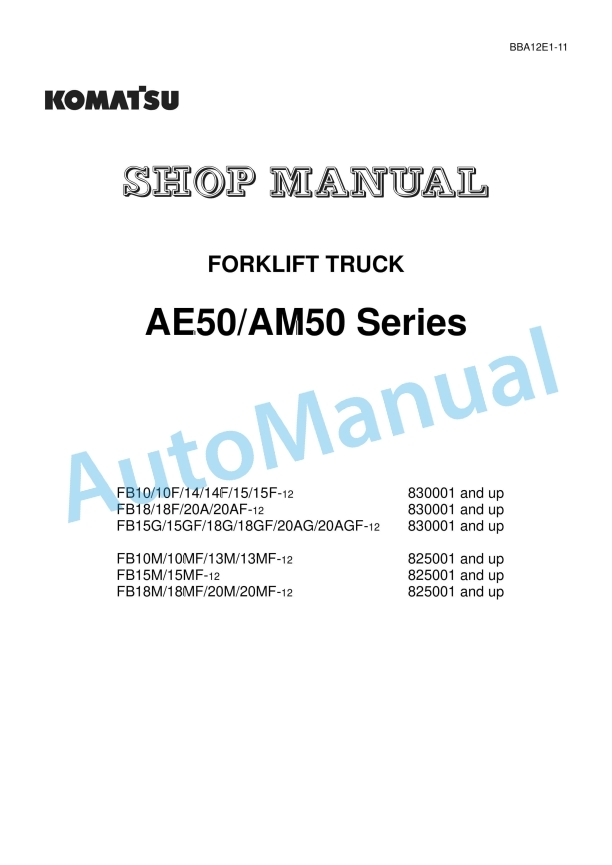

- 1. COVER

- 2. FOREWORD

- 2.1. SECTION INDEX

- 3. GENERAL AND SPECIFICATIONS

- 3.1. OUTSIDE VIEW

- 3.2. SPECIFICATIONS

- 3.3. PERIODIC REPLACEMENT OF CONSUMABLE PARTS

- 3.4. SAFETY ITEMS FOR MAINTENANCE

- 3.5. STANDARD TIGHTENING TORQUE FOR BOLTS

- 3.6. STANDARD TIGHTENING TORQUE FOR PIPE JOINTS

- 3.7. HOW TO USE LOCTITE

- 4. TESTING AND ADJUSTING

- 4.1. SERVICE DATA

- 4.2. METHOD OF RELEASING THE PRESSURE IN THE HYDRAULIC PIPING

- 4.3. LIFT INTERRUPT FUNCTION

- 4.4. HOW TO START UP THE HOUR METER

- 4.5. SEATBELT INTERLOCK FUNCTION

- 4.6. LIFTING HEIGHT TRAVEL SPEED LIMIT

- 4.7. METER PANEL

- 4.8. OPERATION OF METER PANEL

- 4.9. BATTERY

- 4.10. FUSE

- 4.11. TRANSFER CASE

- 4.12. VEHICLE MOUNTED TYPE CHARGER

- 4.13. INSTALLATION TYPE CHARGER

- 4.14. ADJUSTMENT OF WET TYPE BRAKE AND PARKING BRAKE

- 4.15. WET TYPE BRAKE

- 4.16. HYDRAULIC OIL TANK

- 4.17. MAST

- 4.18. LIFTING HEIGHT DETECTION SENSOR

- 4.19. FINGER BAR

- 4.20. NATURALLY DESCENDING AMOUNT OF HYDRAULIC OIL CYLINDER, MEASUREMENT OF NATURALLY FORWARD TILTING AMOUNT

- 4.21. AIR BLEEDING

- 4.22. LIST OF LUBRICANT AND GREASE

- 5. REMOVAL AND INSTALLATION

- 5.1. UNIT LOCATION DIAGRAM

- 5.2. UNIT MASS

- 5.3. DRAWING OF DISASSEMBLY/ASSEMBLY

- 5.4. HYDRAULIC PUMP AND PUMP MOTOR

- 5.5. VEHICLE MOUNTED CHARGER

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. DRIVE AXLE

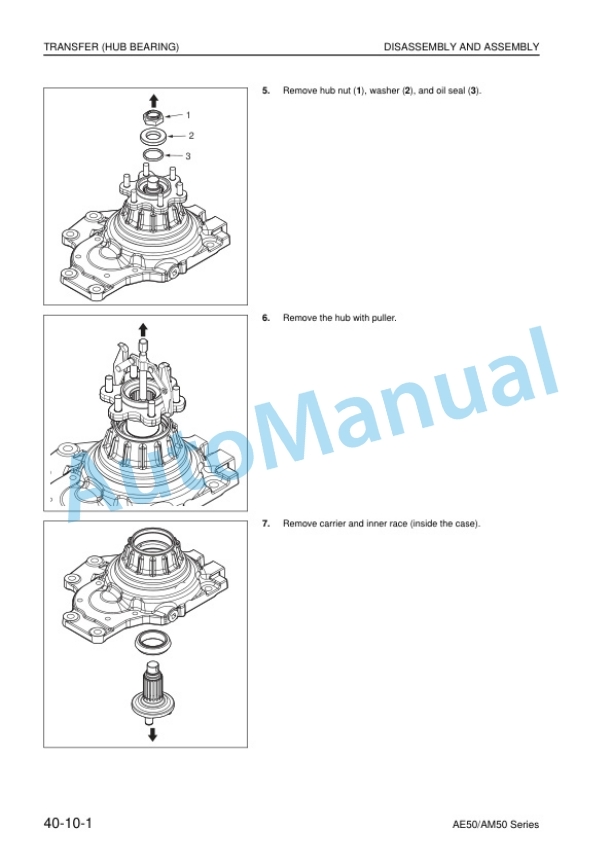

- 6.2. TRANSFER

- 6.3. BRAKE WHEEL CYLINDER

- 6.4. BRAKE MASTER CYLINDER

- 6.5. STEERING GEAR BOX

- 6.6. ORBITROL

- 6.7. POWER STEERING CYLINDER

- 7. MAINTENANCE STANDARD

- 7.1. DRIVE AXLE

- 7.2. BRAKE MASTER CYLINDER

- 7.3. MAST, FINGER BAR, FORK

- 7.4. DRIVE MOTOR

- 7.5. PUMP MOTOR

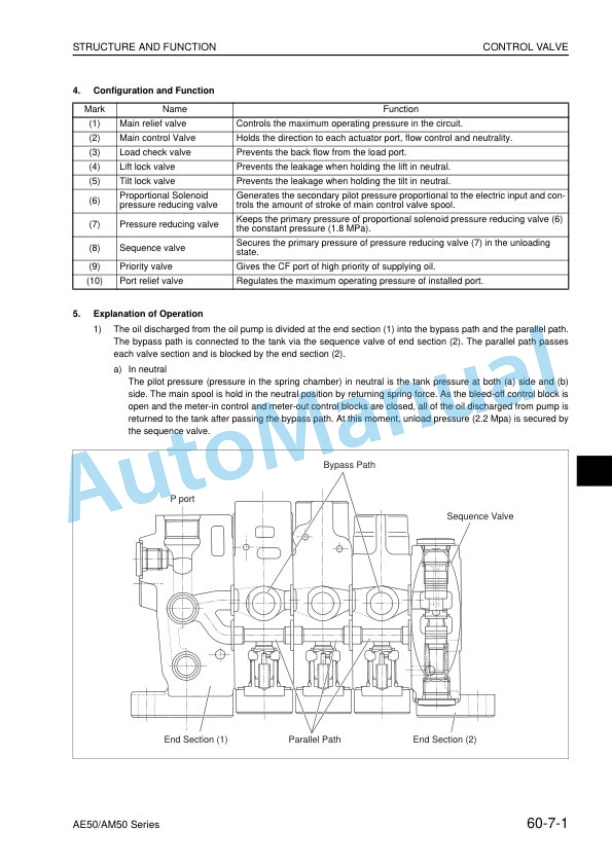

- 8. STRUCTURE AND FUNCTION

- 8.1. BRAKE

- 8.2. HYDRAULIC CIRCUIT DIAGRAM

- 8.3. CONTROL VALVE

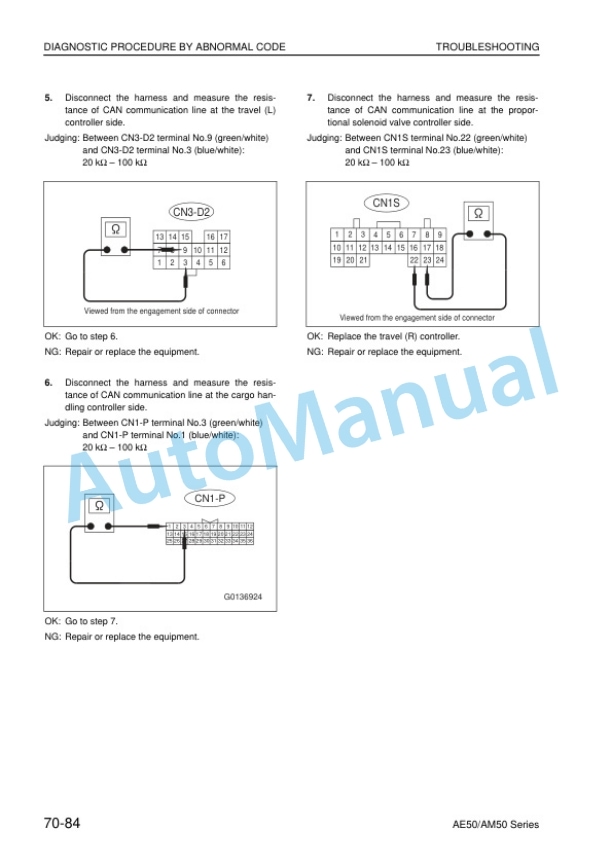

- 9. TROUBLESHOOTING

- 9.1. DIAGNOSIS TOOL

- 9.2. CONFIGURATION PARTS, SENSOR, UNIT LOCATION DRAWING

- 9.3. LOCATION DRAWING

- 9.4. HARNESS LIST

- 9.5. LOCATION OF CPU BOARD CONNECTOR

- 9.6. OVERVIEW OF ABNORMAL CODE

- 9.7. PREPARATION FOR VOLTAGE CHECK AND CURRENT CHECK

- 9.8. INPUT/OUTPUT SIGNAL OF CONTROLLER

- 9.9. ABNORMAL CODE LIST

- 9.10. DIAGNOSTIC PROCEDURE BY ABNORMAL CODE (ALA CODE)

- 9.11. DIAGNOSTIC PROCEDURE BY ABNORMAL CODE (ERR CODE)

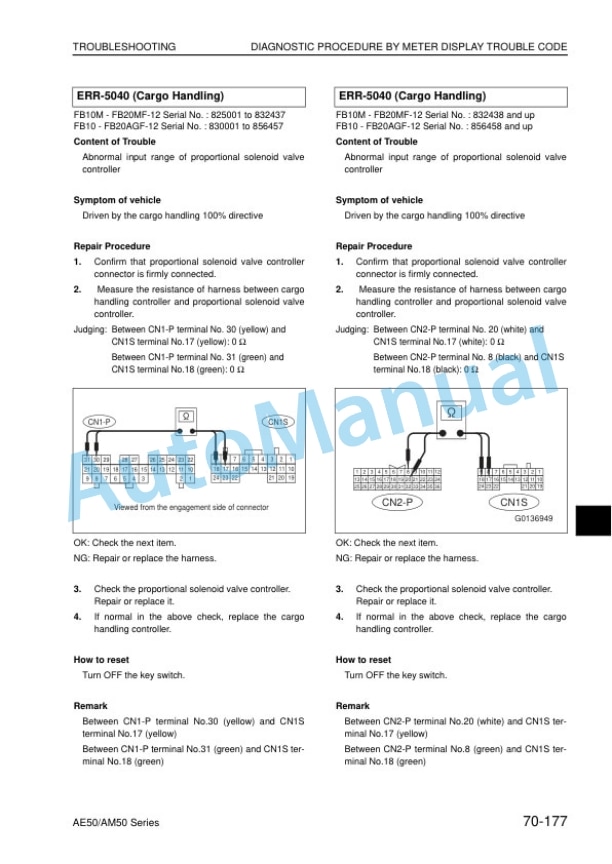

- 9.12. DIAGNOSTIC PROCEDURE BY METER DISPLAY TROUBLE CODE

- 9.13. TROUBLE WITHOUT ABNORMAL DISPLAY

- 9.14. PROPORTIONAL SOLENOID VALVE CONTROLLER

- 9.15. ADJUSTMENT PROCEDURE OF TILT AUTOMATIC HORIZONTAL (OPTION)

- 9.16. METER PANEL

- 10. YEARLY INSPECTION CRITERIA

- 10.1. MOTOR

- 10.2. CONTROL EQUIPMENT

- 10.3. CHARGE CONTROL UNIT

- 10.4. BATTERY

- 10.5. POWER TRANSFER EQUIPMENT

- 10.6. TRAVELING EQUIPMENT

- 10.7. STEERING EQUIPMENT

- 10.8. BRAKING EQUIPMENT

- 10.9. CARGO HANDLING EQUIPMENT

- 10.10. HYDRAULIC EQUIPMENT

- 10.11. BODY, SAFETY EQUIPMENT, ETC

- 10.12. TOTAL TEST

- 11. CONVERSION TABLE

- 11.1. MILLIMETERS TO INCHES

- 11.2. INCHES TO MILLIMETERS

- 11.3. CUBIC METERS TO CUBIC YARDS

- 11.4. CUBIC YARDS TO CUBIC METERS

- 11.5. LITER TO U.S. GALLON

- 11.6. GALLON TO LITER

- 11.7. LITER TO U.K. GALLON

- 11.8. GALLON TO LITER

- 11.9. KILOGRAM TO POUND

- 11.10. POUND TO KILOGRAM

- 11.11. KG/CM2 TO IB/IN2

- 11.12. KGM TO FT IB

- 11.13. TEMPERATURE

- 12. APPENDIX

- 12.1. A9799310 (INPUT CAP PRESSFITTING JIG)

- 12.2. A9799320 (INPUT OIL SEAL PRESSFITTING JIG)

- 12.3. A9799330 (INPUT HUB BEARING PRESSFITTING JIG)

- 12.4. A9799710(INPUT GEAR/BEARING PRESSFITTING JIG)

- 12.5. A9799720 (MULTIPLE DISC ALIGNMENT JIG)

- 12.6. A9799730 (MULTIPLE HOLDER CLEARANCE ALIGNING JIG)

- 12.7. A9799740 (3 WHEEL REAR AXLE PRESSFITTING JIG)

- 12.8. A9799760 (3 WHEEL REAR AXLE SENSOR ALIGNMENT JIG)

- 12.9. SERVICE TOOL CONFIGURATION

- 12.10. ELECTRIC WIRING DIAGRAM (BUILD IN CHARGER)

- 12.11. ELECTRIC WIRING DIAGRAM (BUILD IN CHARGER)

- 12.12. ELECTRIC WIRING DIAGRAM (BUILD IN CHARGER)

- 12.13. ELECTRIC WIRING DIAGRAM (MACHINE WITH SEATBELT INTERLOCK SYSTEM AND HIGH MAST TRAVEL SPEED LIMIT SYSTEM

- 12.14. ELECTRIC WIRING DIAGRAM (1/2) (MACHINE WITH SEATBELT INTERLOCK SYSTEM AND HIGH MAST TRAVEL SPEED LIMIT SYSTEM)

- 12.15. ELECTRIC WIRING DIAGRAM (2/2) (MACHINE WITH SEATBELT INTERLOCK SYSTEM AND HIGH MAST TRAVEL SPEED LIMIT SYSTEM)

- 12.16. ELECTRIC WIRING DIAGRAM (STATIONARY CHARGER)

- 12.17. ELECTRIC WIRING DIAGRAM (STATIONARY CHARGER)

- 12.18. ELECTRIC WIRING DIAGRAM (STATIONARY CHARGER)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00