Komatsu Auto Greasing System Hydraulic Excavator Operation and Maintenance Manual UEAM001401

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: UEAM001401

- Format: PDF

- Size: 2.3MB

- Number of Pages: 53

-

Model List:

- Auto Greasing System Hydraulic Excavator

- 1. LUBRICATION SYSTEM

- 1.1. Safety Instructions

- 1.1.1. Appropriate Use

- 1.1.2. General Safety Instructions

- 1.1.3. Regulations for Prevention of Accidents

- 1.1.4. Operation, Repair and Maintenance

- 1.1.5. Installation

- 1.2. Progressive Metering Devices Model SSV

- 1.2.1. Suitable Lubricants

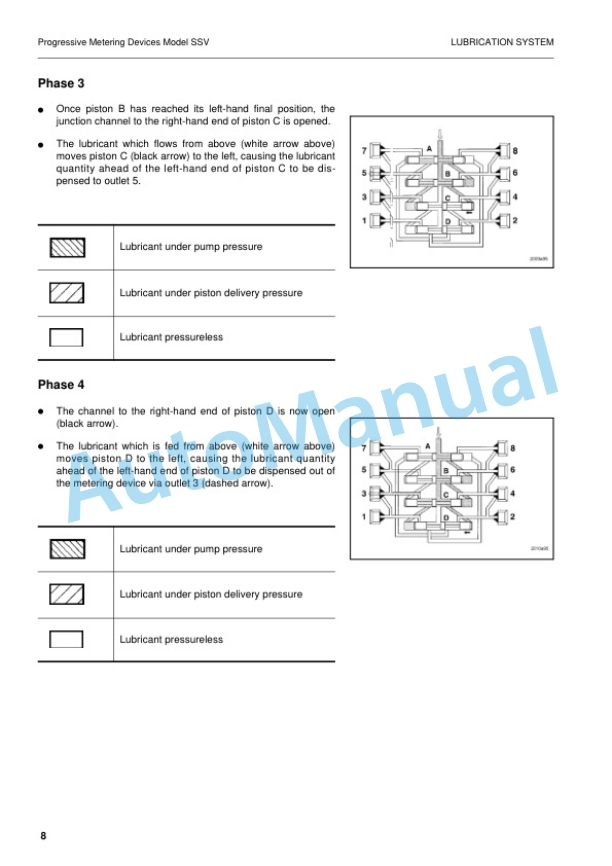

- 1.2.2. Lubricant Distribution within the Metering Device

- 1.2.3. Monitoring of the Operation

- 1.2.3.1. Systemdependent monitoring

- 1.2.3.2. Visual monitoring

- 1.2.3.3. Electrical monitoring (microprocessor control)

- 1.2.4. Determining the Lubricant Output by Combining Outlets

- 1.2.4.1. Screwtype fittings (main metering device and secondary metering devices)

- 1.2.4.2. Tube Fittings, Pushin Type (main metering device)

- 1.2.5. Tube Fittings, PlugType (secondary metering devices)

- 1.2.5.1. Single lubricant output

- 1.2.5.2. Double or multiple lubricant output

- 1.2.5.3. Fig 14 Single, double and triple lubricant output

- 1.2.6. Lubricant Metering Devices SSV 14 up to SSV 22

- 1.2.7. Tube fittings, Screwtype

- 1.2.7.1. Main and secondary metering device

- 1.2.8. Tube Fittings, Pushin Type

- 1.2.8.1. Metering Devices

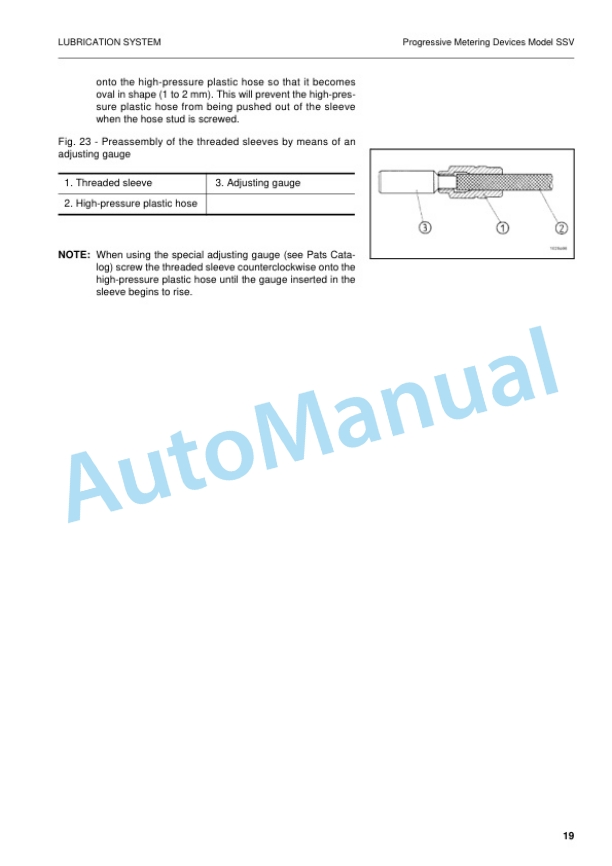

- 1.2.8.2. Connection of the Highpressure Plastic Hose and the Pressure Plastic Tube

- 1.2.9. Plastic tubes and highpressure plastic hoses

- 1.2.9.1. Plastic tube (? 6 x 1,5 mm)

- 1.2.9.2. Highpressure plastic hoses ? 8,6 x 2,3 mm

- 1.3. Troubleshooting

- 1.4. Technical Data

- 1.5. Tightening Torques

- 1.6. Lubricants

- 1.6.1. Recommended greases for centralised lubrication systems

- 2. Central Lubrication Pump

- 2.1. Safety Instructions

- 2.1.1. Appropriate Use

- 2.1.2. General Safety Instructions

- 2.1.3. Regulations for prevention of accidents

- 2.1.4. Operation, Maintenance and Repair

- 2.1.5. Installation

- 2.2. Central Lubrication Pump

- 2.2.1. Lowlevel control (Option)

- 2.2.2. Operation

- 2.2.2.1. Commissioning

- 2.3. Maintenance, Repair and Tests

- 2.3.1. Maintenance

- 2.3.1.1. To Fill Pump

- 2.3.2. Repair

- 2.3.2.1. Pump

- 2.3.2.2. Printed circuit boards

- 2.3.2.3. Replace the pump element

- 2.3.3. Tests

- 2.3.3.1. Test run / Triggering an additional lubrication

- 2.3.3.2. To check the system

- 2.3.3.3. To Check the Safety Valve

- 2.4. Troubleshooting

- 2.5. Technical Data

- 2.5.1. Connection Diagram

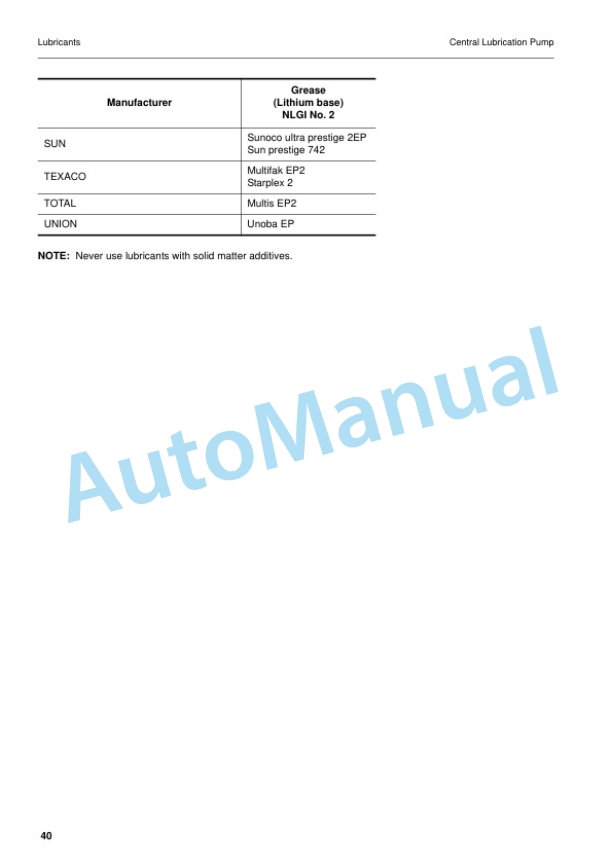

- 2.6. Lubricants

- 2.6.1. Lubricating greases for Automatic Grease Systems

- 3. Printed Circuit Board (standard system)

- 3.1. Applications

- 3.1.1. Mode of Operation

- 3.1.2. Time Setting

- 3.1.2.1. Fault indication

- 3.1.2.2. Repair

- 3.1.3. Operational Test / To Trigger an Additional Lubrication Cycle

- 3.2. Troubleshooting

- 3.3. Technical Data

- 3.3.1. Connection Diagram

- 3.3.2. Combinations of the jumper positions Survey

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001