Komatsu BR100JG-2 Series Shop Manual SEBM027804

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM027804

- Format: PDF

- Size: 26.8MB

- Number of Pages: 397

Category: Komatsu Shop Manual PDF

-

Model List:

- BR100JG-2 Series

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. Specification drawing

- 3.2. Specification

- 3.3. Weight table

- 3.4. Table of oil and Coolant Capacities

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. RADIATOR, OIL COOLER

- 4.2. PTO (COUPLING)

- 4.3. POWER TRAIN DIAGRAM

- 4.4. DRIVE SYSTEMS FOR EACH COMPONENT

- 4.5. HYDRAULIC EQUIPMENT LAYOUT DRAWING

- 4.6. HYDRAULIC TANK

- 4.7. HYDRAULIC PUMP

- 4.8. CONTROL VALVE

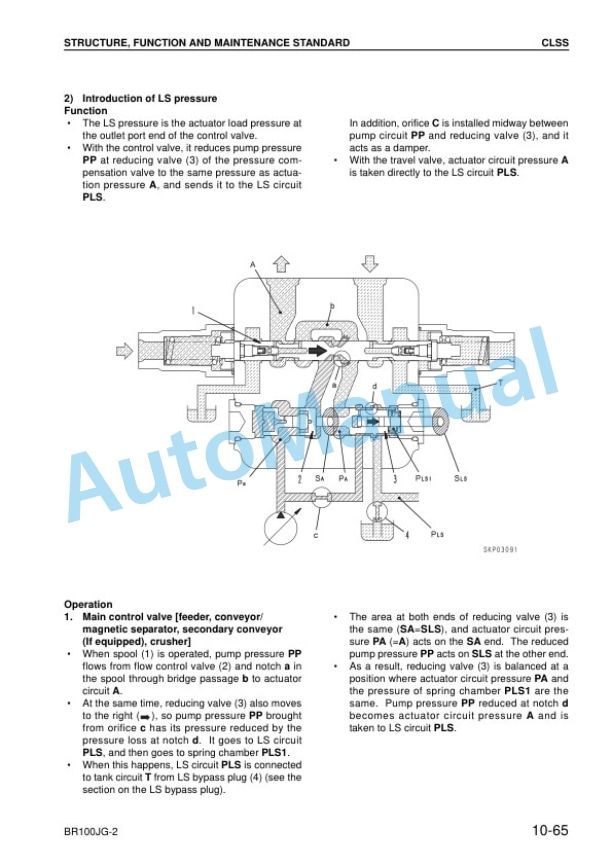

- 4.9. CLSS

- 4.10. SELF PRESSURE REDUCING VALVE

- 4.11. TRAVEL MOTOR

- 4.12. CRUSHER MOTOR

- 4.13. MAGNETIC SEPARATOR MOTOR

- 4.14. FEEDER MOTOR

- 4.15. TRAVEL PPC VALVE

- 4.16. ON/OFF VALVE

- 4.17. EPC VALVE

- 4.18. WORK EQUIPMENT

- 4.19. CRUSHER GENERAL VIEW

- 4.20. JAW CRUSHER ASSEMBLY

- 4.21. GRIZZLY FEEDER

- 4.22. VIBRATOR

- 4.23. PRIMARY BELT CONVEYOR

- 4.24. PRIMARY BELT CONVEYOR ASSEMBLY

- 4.25. MAGNETIC SEPARATOR

- 4.26. ENGINE CONTROL SYSTEM

- 4.27. LX CONTROLLER

- 4.28. MACHINE MONITOR SYSTEM

- 4.29. FEEDER AUTOMATIC CONTROL SYSTEM WHEN THERE IS CRUSHER OVERLOAD

- 4.30. EMERGENCY STOP SYSTEM FOR CONVEYOR, OPTION OVERLOAD

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE

- 5.1.1. STANDARD VALUE TABLE FOR ENGINE

- 5.1.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TOOLS FOR TESTING AND ADJUSTING

- 5.2.2. MEASURING ENGINE SPEED

- 5.2.3. MEASURING EXHAUST COLOR

- 5.2.4. ADJUSTING VALVE CLEARANCE

- 5.2.5. MEASURING COMPRESSION PRESSURE

- 5.2.6. MEASURING BLOWBY PRESSURE

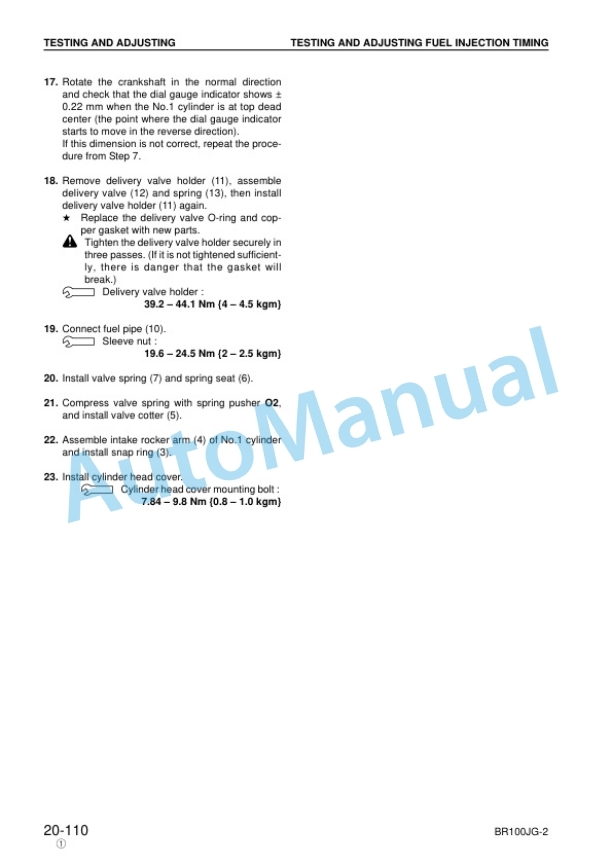

- 5.2.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.2.8. MEASURING ENGINE OIL PRESSURE

- 5.2.9. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.2.10. ADJUSTING FUEL CUT SOLENOID LINKAGE

- 5.2.11. ADJUSTING FUEL CONTROL LINKAGE

- 5.2.12. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT CIRCUIT

- 5.2.13. MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE

- 5.2.14. ADJUSTING PC VALVE

- 5.2.15. MEASURING CONTROL CIRCUIT OIL PRESSURE

- 5.2.16. MEASURING PPC, EPC VALVE OUTPUT PRESSURE

- 5.2.17. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 5.2.18. TESTING TRAVEL DEVIATION

- 5.2.19. MEASURING TRAVEL MOTOR OIL LEAKAGE

- 5.2.20. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.2.21. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.2.22. BLEEDING AIR FROM HYDRAULIC CIRCUIT

- 5.2.23. TESTING AND ADJUSTING CRUSHER RELATED PARTS

- 5.3. TROUBLESHOOTING

- 5.3.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.3.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.3.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.3.4. CHECKS BEFORE TROUBLESHOOTING

- 5.3.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.3.6. CONNECTOR ARRANGMENT DIAGRAM (1/5)

- 5.3.7. E MODE SYSTEM ELECTRICAL CIRCUIT DIAGRAM

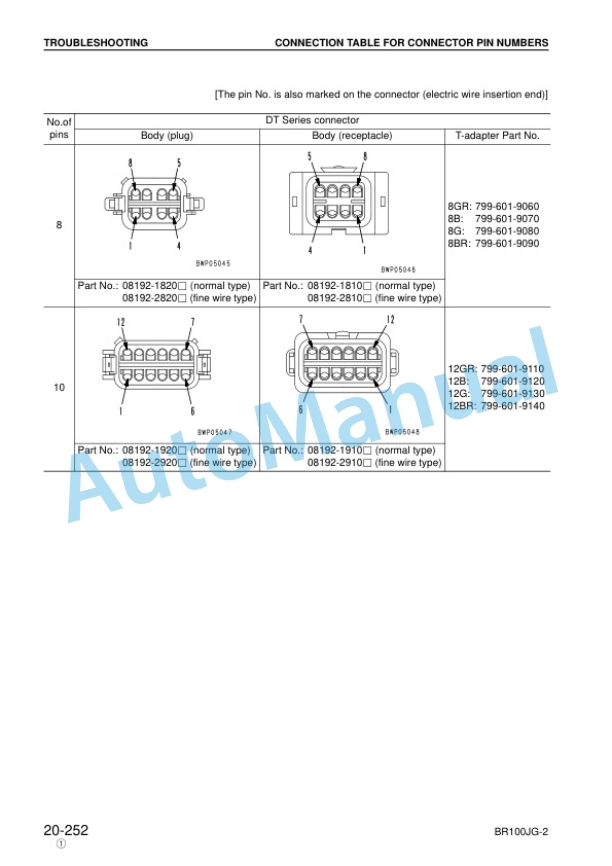

- 5.3.8. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.3.9. TADAPTER TABLE

- 5.3.10. CATEGORIES OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

- 5.3.11. POSSIBLE FAILURE AND TROUBLESHOOTING NO.

- 5.3.12. TROUBLESHOOTING FOR ELECTRICAL SYSTEM (E MODE)

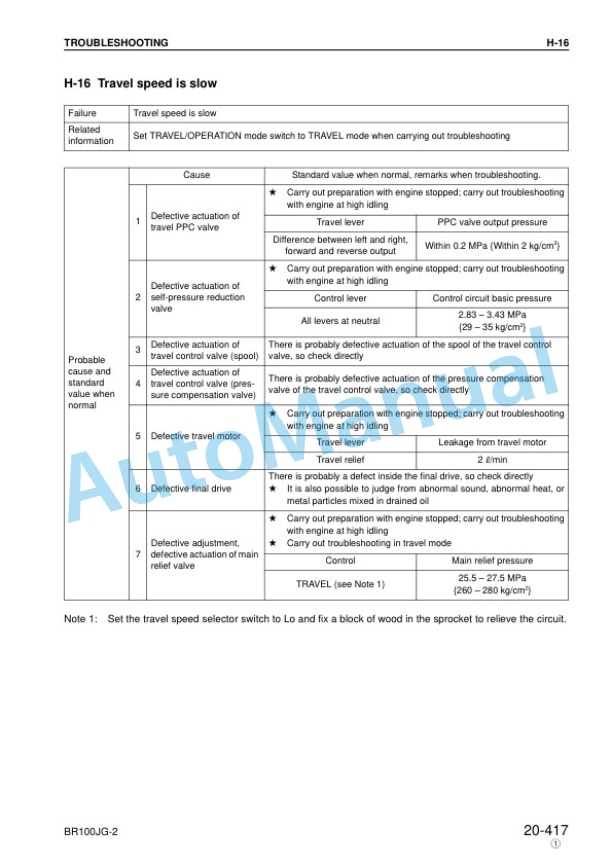

- 5.3.13. TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

- 5.3.14. TROUBLESHOOTING FOR MONITOR SYSTEM (M MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. REMOVAL and INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 6.5. REMOVAL and INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.6. REMOVAL and INSTALLATION OF ENGINE, MAIN PUMP ASSEMBLY

- 6.7. REMOVAL and INSTALLATION OF RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 6.8. REMOVAL and INSTALLATION OF FUEL TANK ASSEMBLY

- 6.9. REMOVAL and INSTALLATION OF FINAL DRIVE ASSEMBLY

- 6.10. DISASSEMBLY and ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.11. ASSEMBLY OF IDLER ASSEMBLY

- 6.12. ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.13. REMOVAL and INSTALLATION OF TRACK SHOE ASSEMBLY

- 6.14. REMOVAL OF MAIN PUMP

- 6.15. REMOVAL and INSTALLATION OF CONTROL VALVE ASSEMBLY

- 6.16. DISASSEMBLY and ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 6.17. REMOVAL and INSTALLATION OF CONVEYOR MOTOR ASSEMBLY

- 6.18. REMOVAL and INSTALLATION OF MAGNETIC SEPARATOR MOTOR ASSEMBLY

- 6.19. REMOVAL and INSTALLATION OF FEEDER MOTOR ASSEMBLY

- 6.20. REMOVAL and INSTALLATION OF CRUSHER MOTOR ASSEMBLY

- 6.21. REMOVAL and INSTALLATION OF CONVEYOR ASSEMBLY

- 6.22. REMOVAL and INSTALLATION OF FEEDER ASSEMBLY

- 6.23. REMOVAL AND INSTALLATION OF CRUSHER ASSEMBLY

- 6.24. DISASSEMBLY AND ASSEMBLY OF CRUSHER ASSEMBLY

- 6.25. REMOVAL and INSTALLATION OF COUNTERWEIGHT

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM

- 7.2. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 7.3. ELECTRICAL CIRCUIT DIAGRAM (2/2)

Rate this product

You may also like