Komatsu CD110R-1 Crawler Carrier Shop Manual SEBM021902

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM021902

- Format: PDF

- Size: 43.0MB

- Number of Pages: 384

Category: Komatsu Shop Manual PDF

-

Model List:

- CD110R-1 Crawler Carrier

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. GENERAL ASSEMBLY DRAWING

- 1.2. SPECIFICATIONS

- 1.3. WEIGHT TABLE

- 1.4. TABLE OF OIL AND COOLANT CAPACITIES

- 2. STRUCTURE AND FUNCTION

- 2.1. RADIATOR AND OIL COOLER

- 2.2. DAMPER COUPLING

- 2.3. ENGINE CONTROL

- 2.4. POWER TRAIN

- 2.5. SWING CIRCLE

- 2.6. SWING MACHINERY

- 2.7. TRACK ROLLER BOGIE

- 2.8. SPROCKET

- 2.9. TRACK SHOE

- 2.10. HYDRAULIC COMPONENT LAYOUT

- 2.11. HYDRAULIC TANK

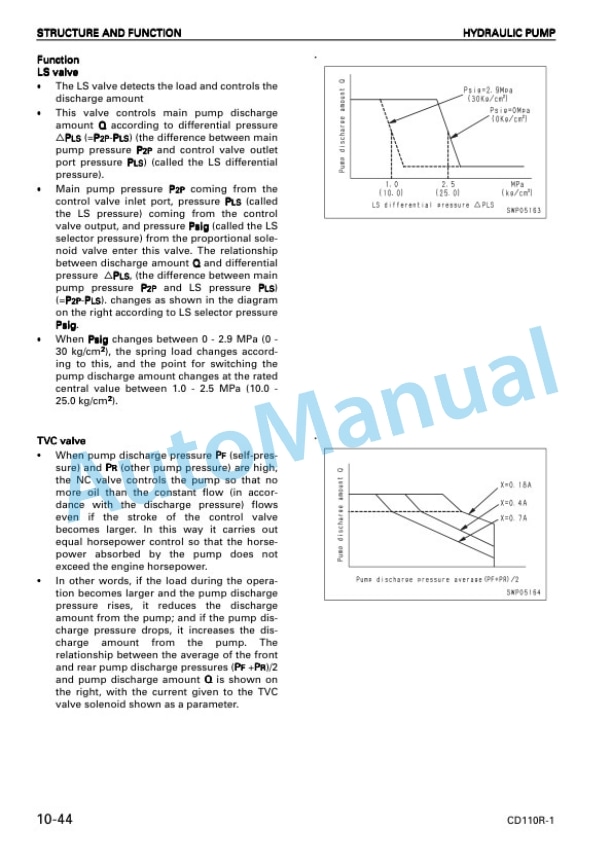

- 2.12. HYDRAULIC PUMP

- 2.13. HYDRAULIC CONTROL VALVE

- 2.14. CLSS

- 2.15. SWING MOTOR

- 2.16. CENTER SWIVEL JOINT

- 2.17. TRAVEL MOTOR

- 2.18. CONTROL PUMP

- 2.19. VALVE CONTROL

- 2.20. BODY PPC VALVE

- 2.21. SWING PPC VALVE

- 2.22. TRAVEL PPC VALVE

- 2.23. SOLENOID VALVE

- 2.24. VARIABLE BACK PRESSURE VALVE

- 2.25. DUMP CYLINDER

- 2.26. WORK EQUIPMENT

- 2.27. MACHINE MONITOR SYSTEM

- 3. TESTING AND ADJUSTING

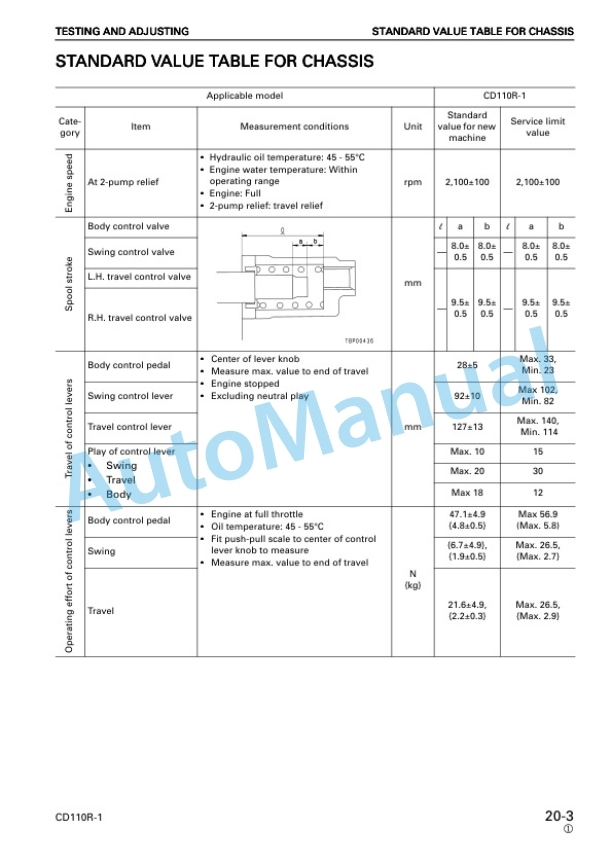

- 3.1. STANDARD VALUE TABLES

- 3.1.1. STANDARD VALUE TABLE FOR ENGINE

- 3.1.2. STANDARD VALUE TABLE FOR CHASSIS

- 3.1.3. STANDARD VALUE TABLE FOR ELECTRIC PARTS

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 3.2.2. MEASURING ENGINE SPEED

- 3.2.3. MEASURING EXHAUST COLOR

- 3.2.4. ADJUSTING VALVE CLEARANCE

- 3.2.5. MEASURING COMPRESSION PRESSURE

- 3.2.6. MEASURING BLOWBY PRESSURE

- 3.2.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.2.8. MEASURING ENGINE OIL PRESSURE

- 3.2.9. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 3.2.10. TESTING AND ADJUSTING WATER PUMP TENSION

- 3.2.11. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 3.2.12. MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)

- 3.2.13. ADJUSTING FUEL CONTROL CABLE

- 3.2.14. ADJUSTING ENGINE STOP MOTOR CABLE

- 3.2.15. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN TRAVEL CIRCUIT

- 3.2.16. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN BODY AND SWING CIRCUIT

- 3.2.17. TESTING AND ADJUSTING TVC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)

- 3.2.18. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTION INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

- 3.2.19. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN CONTROL PUMP CICUIT

- 3.2.20. TESTING OUTPUT PRESSURE OF SOLENOID VALVE

- 3.2.21. MEASURING PPC VALVE OUTPUT PRESSURE

- 3.2.22. ADJUSTING SWING PPC VALVE

- 3.2.23. TESTING TRAVEL DEVIATION

- 3.2.24. MEASURING OIL LEAKAGE

- 3.2.25. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 3.2.26. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 3.2.27. TESTING AND ADJUSTING TRACK SHOE TENSION

- 3.2.28. BLEEDING AIR

- 3.3. TROUBLESHOOTING

- 3.3.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.3.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 3.3.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 3.3.4. CHECKS BEFORE TROUBLESHOOTING

- 3.3.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 3.3.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 3.3.7. METHOD OF USING JUDGMENT TABLE

- 3.3.8. METHOD OF USING TROUBLESHOOTING CHARTS

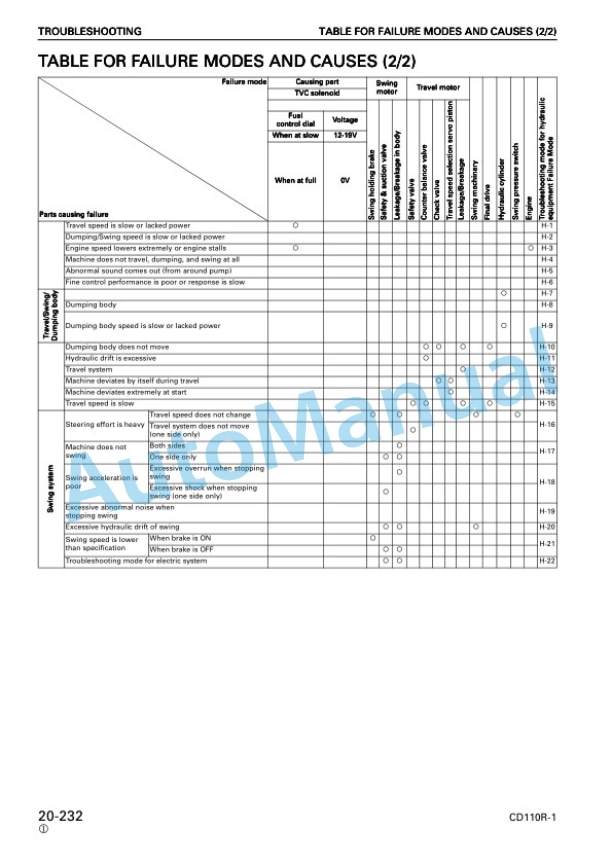

- 3.3.9. TABLE OF FAILURE MODES AND CAUSES (1/2)

- 3.3.10. TABLE OF FAILURE MODES AND CAUSES (2/2)

- 3.3.11. TROUBLESHOOTING FOR ELECTRIC SYSTEM (E MODE)

- 3.3.12. TROUBLESHOOTIGN OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 3.3.13. TROUBLESHOOTING OF MONITOR SYSTEM (M MODE)

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. METHOD OF USING MANUAL

- 4.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 4.3. SPECIAL TOOL LIST

- 4.4. SKETCHES OF SPECIAL TOOLS

- 4.5. AFTERCOOLER ASSEMBLY

- 4.5.1. REMOVAL

- 4.5.2. INSTALLATION

- 4.6. HYDRAULIC OIL COOLER

- 4.6.1. REMOVAL

- 4.6.2. INSTALLATION

- 4.7. RADIATOR ASSEMBLY

- 4.7.1. REMOVAL

- 4.7.2. INSTALLATION

- 4.8. MAIN PUMP ASSEMBLY

- 4.8.1. REMOVAL

- 4.8.2. INSTALLATION

- 4.9. ENGINE AND MAIN PUMP

- 4.10. SWING MACHINERY AND SWING MOTOR

- 4.10.1. DISASSEMBLY

- 4.10.2. ASSEMBLY

- 4.11. SWING MACHINERY

- 4.11.1. DISASSEMBLY

- 4.11.2. ASSEMBLY

- 4.12. CENTER SWIVEL JOINT

- 4.12.1. REMOVAL

- 4.12.2. INSTALLATION

- 4.12.3. DISASSEMBLY

- 4.12.4. ASSEMBLY

- 4.13. WORK EQUIPMENT CONTROL VALVE

- 4.13.1. REMOVAL

- 4.13.2. INSTALLATION

- 4.13.3. DISASSEMBLY

- 4.13.4. ASSEMBLY

- 4.14. TRAVEL CONTROL VALVE ASSEMBLY

- 4.14.1. REMOVAL

- 4.14.2. INSTALLATION

- 4.14.3. DISASSEMBLY

- 4.14.4. ASSEMBLY

- 4.15. FINAL DRIVE AND TRAVEL MOTOR

- 4.15.1. REMOVAL

- 4.15.2. INSTALLATION

- 4.16. FINAL DRIVE ASSEMBLY

- 4.16.1. DISASSEMBLY

- 4.16.2. ASSEMBLY

- 4.17. DUMP CONTROL PPC VALVE

- 4.17.1. DISASSEMBLY

- 4.17.2. ASSEMBLY

- 4.18. TRAVEL PPC VALVE

- 4.18.1. DISASSEMBLY

- 4.18.2. ASSEMBLY

- 4.19. SWING PPC VALVE

- 4.20. FUEL TANK ASSEMBLY

- 4.20.1. REMOVAL

- 4.20.2. INSTALLATION

- 4.21. AIR CONDITIONER UNIT ASSEMBLY

- 4.22. REVOLVING FRAME ASSEMBLY

- 4.22.1. REMOVAL

- 4.22.2. INSTALLATION

- 4.23. SWING CIRCLE ASSEMBLY

- 4.23.1. REMOVAL

- 4.23.2. INSTALLATION

- 4.24. RUBBER SHOE ASSEMBLY

- 4.25. IDLER CUSHION SPRING ASSEMBLY

- 4.25.1. DISASSEMBLY

- 4.25.2. ASSEMBLY

- 4.26. TRACK ROLLER ASSEMBLY

- 4.26.1. DISASSEMBLY

- 4.26.2. ASSEMBLY

- 4.27. DUMP BODY ASSEMBLY

- 4.27.1. REMOVAL

- 4.27.2. INSTALLATION

- 5. OTHERS

- 5.1. HYDRAULIC CIRCUIT DIAGRAM

- 5.2. ELECTRIC CIRCUIT DIAGRAM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00