Komatsu CD110R-2 Shop Manual SEBM030003

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM030003

- Format: PDF

- Size: 31.3MB

- Number of Pages: 383

Category: Komatsu Shop Manual PDF

-

Model List:

- CD110R-2

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL,COOLANT AND LUBRICANTS

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. DAMPER

- 4.2. COOLING SYSTEM

- 4.3. POWER TRAIN

- 4.4. SWING CIRCLE

- 4.5. SWING MACHINERY

- 4.6. TRACK FRAME

- 4.7. IDLER CHSHION

- 4.8. IDLER

- 4.9. TRACK ROLLER BOGIE

- 4.10. TRACK ROLLER

- 4.11. CARRIER ROLLER

- 4.12. SPROCKET

- 4.13. TRACK SHOE

- 4.14. HYDRAULIC COMPONENT LAYOUT

- 4.15. FLOW COMPENSATION VALVE

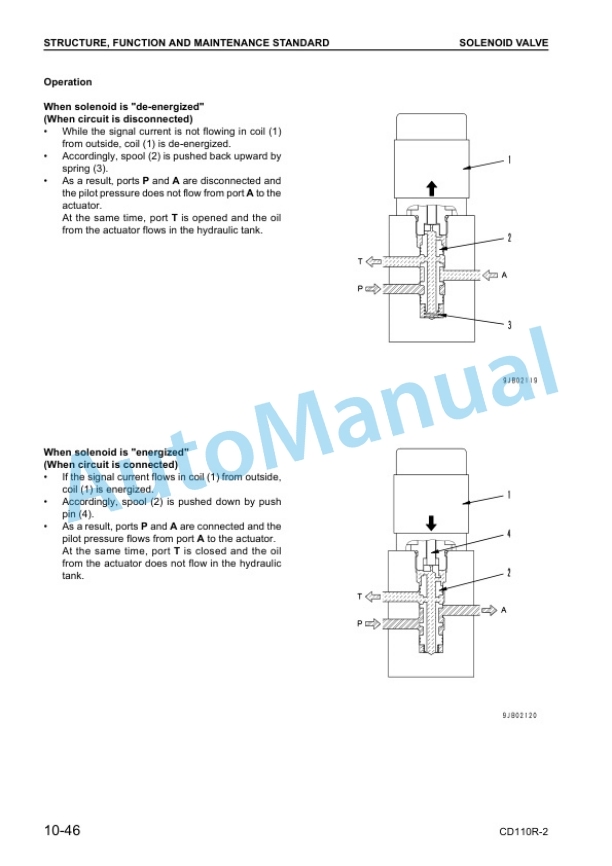

- 4.16. SOLENOID VALVE

- 4.17. EPC VALVE

- 4.18. ACCUMULATOR

- 4.19. CENTER SWIVEL JOINT

- 4.20. DUMP CYLINDER

- 4.21. CONTROL VALVE

- 4.22. SWING MOTOR

- 4.23. SWING PPC VALVE

- 4.24. TRAVEL PPC VALVE

- 4.25. BODY PPC VALVE

- 4.26. WORK EQUIPMENT

- 4.27. AIR CONDITIONER PIPING

- 4.28. ELECTRIC CONTROL SYSTEM

- 4.29. SYSTEM COMPONENTS

- 4.30. MONITOR SYSTEM

- 4.31. SENSORS

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 5.3.2. TESTING ENGINE SPEED

- 5.3.3. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.3.4. MEASURING EXHAUST GAS COLOR

- 5.3.5. ADJUSTING VALVE CLEARANCE

- 5.3.6. MEASURING COMPRESSION PRESSURE

- 5.3.7. MEASURING BLOWBY PRESSURE

- 5.3.8. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.3.9. MEASURING ENGINE OIL PRESSURE

- 5.3.10. ADJUSTING ENGINE STOP SOLENOID

- 5.3.11. TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE

- 5.3.12. ADJUSTING OF ENGINE SPEED SENSOR

- 5.3.13. INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

- 5.3.14. EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM

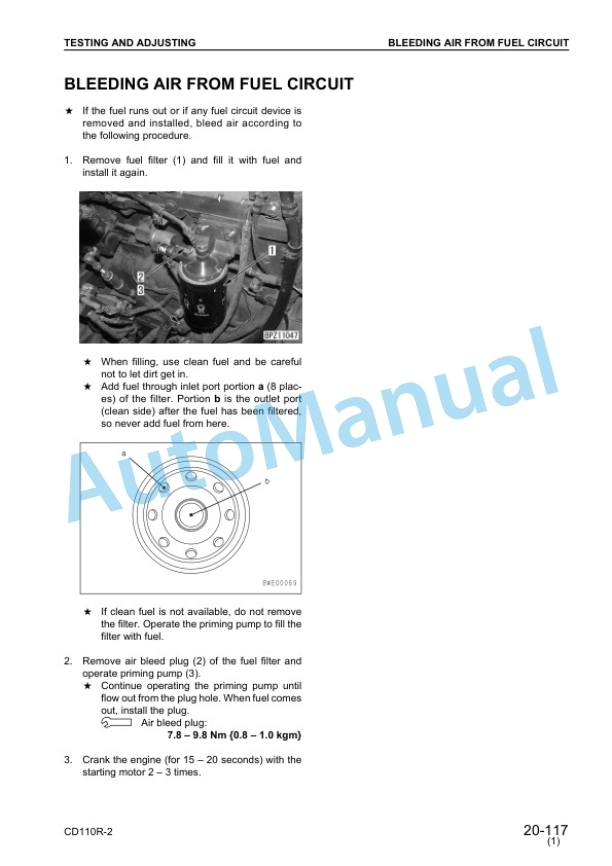

- 5.3.15. BLEEDING AIR FROM FUEL CIRCUIT

- 5.3.16. MEASURING CLEARANCE OF SWING CIRCLE BEARING

- 5.3.17. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.3.18. TESTING HST OIL PRESSURE

- 5.3.19. TESTING AND ADJUSTING WORK EQUIPMENT AND SWING CIRCUIT PRESSURE

- 5.3.20. TESTING CONTROL PUMP CIRCUIT PRESSURE

- 5.3.21. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 5.3.22. ADJUSTING SWING PPC VALVE

- 5.3.23. TESTING TRAVEL DEVIATION

- 5.3.24. MEASURING OIL LEAKAGE

- 5.3.25. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.3.26. BLEEDING AIR FROM EACH PART

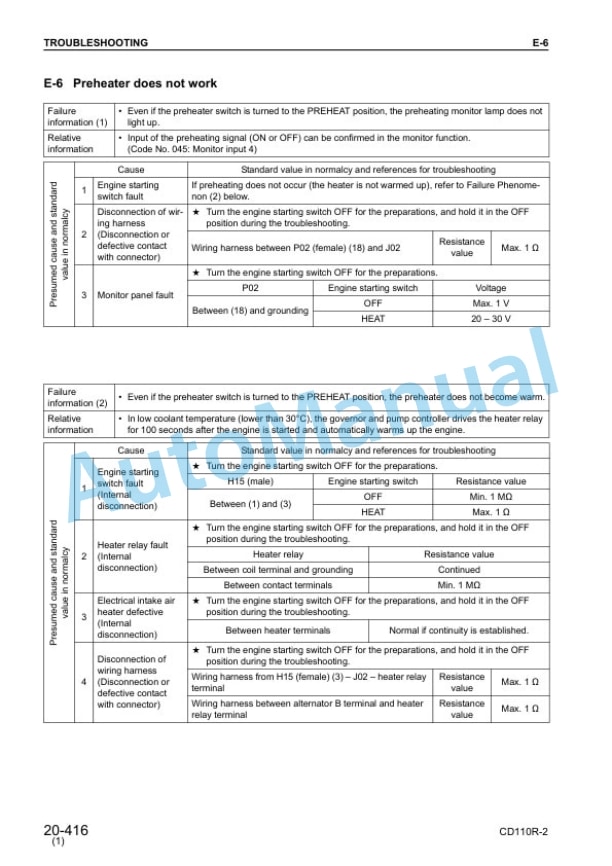

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 5.4.6. CONNECTOR ARRANGEMENT AND ELECTRIC CIRCUIT DIAGRAM OF EACH SYSTEM

- 5.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.4.8. TADAPTERBOXES AND TADAPTER TABLE

- 5.4.9. EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM

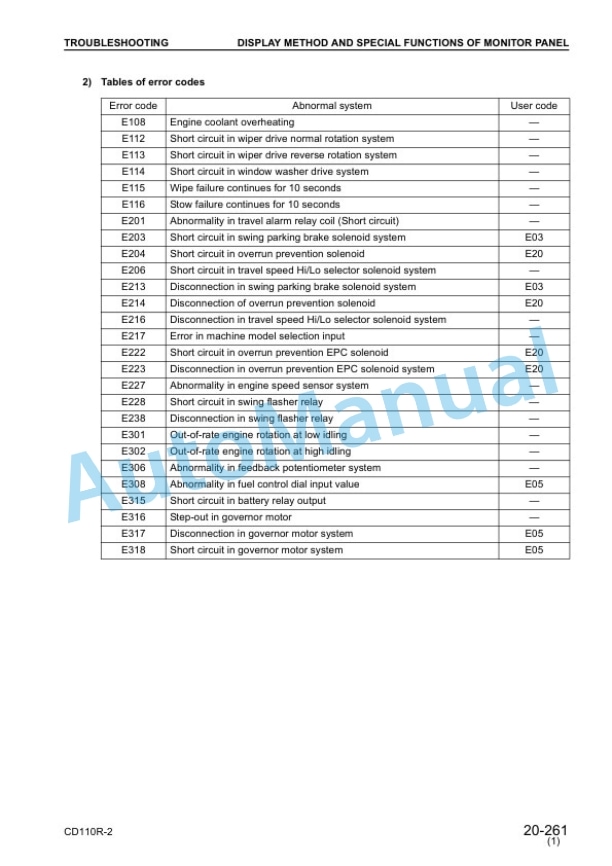

- 5.4.10. DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 5.4.11. TROUBLESHOOTING WHEN ERROR CODE ELECTRICAL SYSTEM IS INDICATED

- 5.4.12. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EMODE)

- 5.4.13. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (HMODE)

- 5.4.14. TROUBLESHOOTING OF ENGINE (S MODE)

- 6. OTHERS

- 6.1. HYDRAULIC CIRCUIT DIAGRAM

- 6.2. ELECTRIC CIRCUIT DIAGRAM (1/4)

- 6.3. ELECTRIC CIRCUIT DIAGRAM (2/4)

- 6.4. ELECTRIC CIRCUIT DIAGRAM (3/4)

- 6.5. ELECTRIC CIRCUIT DIAGRAM (4/4)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00