Komatsu CD30R-1 Crawler Carrier Shop Manual SEBM015701

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM015701

- Format: PDF

- Size: 9.5MB

- Number of Pages: 208

Category: Komatsu Shop Manual PDF

-

Model List:

- CD30R-1 Crawler Carrier

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF OIL AND COOLANT CAPACITIES

- 4. STRUCTURE AND FUNCTION

- 4.1. RADIATOR AND OIL COOLER

- 4.2. DAMPER COUPLING

- 4.3. ENGINE CONTROL

- 4.4. POWER TRAIN SYSTEM DIAGRAM

- 4.5. SWING CIRCLE

- 4.6. SWING MACHINERY

- 4.7. TRACK FRAME

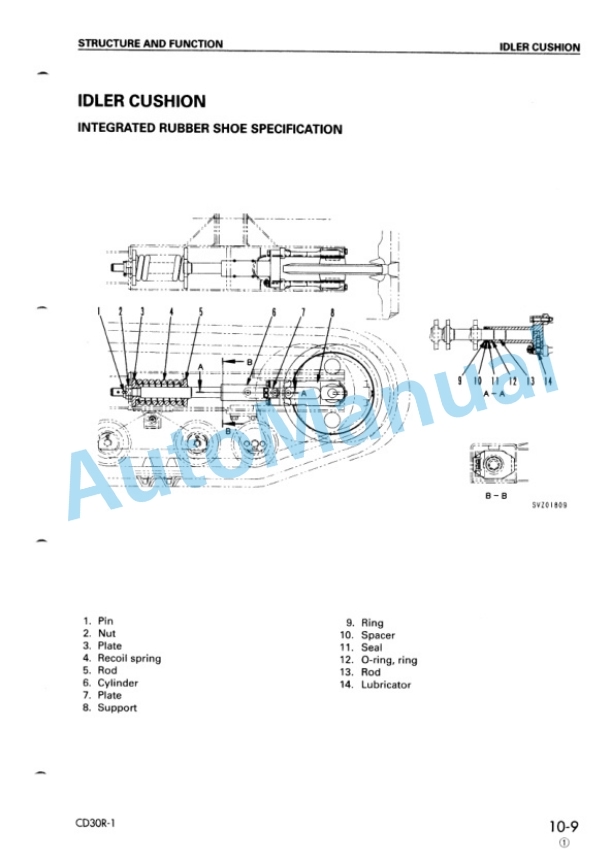

- 4.8. IDLER CUSHION

- 4.9. TRACK ROLLER BOGIE

- 4.10. TRACK SHOE

- 4.11. HYDRAULIC PIPING DRAWING

- 4.12. CENTER SWIVEL JOINT

- 4.13. VALVE CONTROL

- 4.14. SWING PPC VALVE

- 4.15. SOLENOID VALVE

- 4.16. WORK EQUIPMENT

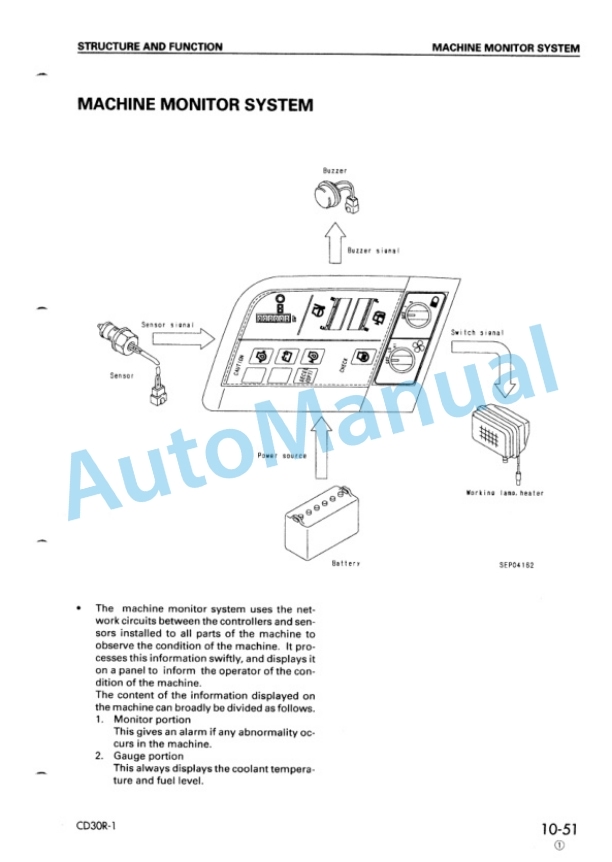

- 4.17. MACHINE MONITOR SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.4. TESTING AND ADJUSTING

- 5.4.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.4.2. MEASURING ENGINE SPEED

- 5.4.3. MEASURING EXHAUST COLOR

- 5.4.4. ADJUSTING VALVE CLEARANCE

- 5.4.5. MEASURING COMPRESSION PRESSURE

- 5.4.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.4.7. MEASURING ENGINE OIL PRESSURE

- 5.4.8. TESTING AND ADJUSTING FAN BELT TENSION

- 5.4.9. ADJUSTING FUEL CONTROL LEVER AND PEDAL

- 5.4.10. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN TRAVEL CIRCUIT

- 5.4.11. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING CIRCUIT

- 5.4.12. TESTING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE

- 5.4.13. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 5.4.14. MEASURING PPC VALVE OUTPUT PRESSURE (FOR SWING)

- 5.4.15. ADJUSTING PPC VALVE (FOR SWING)

- 5.4.16. TESTING TRAVEL DEVIATION

- 5.4.17. MEASURING OIL LEAKAGE

- 5.4.18. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.4.19. TESTING AND ADJUSTING TRACK SHOE TENSION

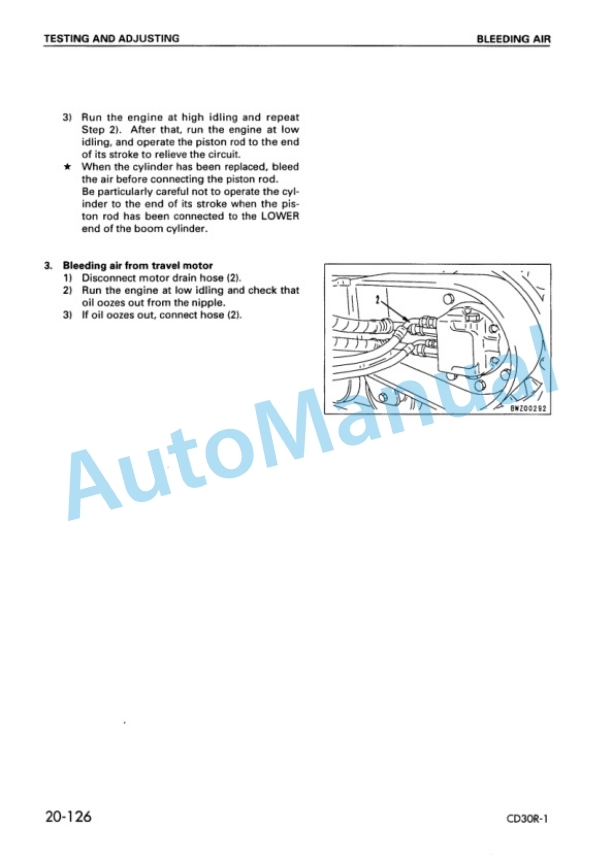

- 5.4.20. BLEEDING AIR

- 5.5. TROUBLESHOOTING

- 5.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.5.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.5.6. CONNECTOR ARRANGEMENT DIAGRAM

- 5.5.7. CONNECTOR TABLE FOR CONNECTOR PIN NUMBERS

- 5.5.8. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.5.9. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 5.5.9.1. EMODE RELATED ELECTRICAL CIRCUIT DIAGRAM

- 5.5.9.2. E1 ENGINE DOES NOT START

- 5.5.9.2.1. WHEN STARTING MOTOR DOES NOT TURN (STARTING SYSTEM)

- 5.5.9.2.2. WHEN STARTING MOTOR TURNS (ENGINE STOP SOLENOID SYSTEM)

- 5.5.9.3. E2 ENGINE DOES NOT STOP

- 5.5.9.4. E3 TRAVEL SPEED DOES NOT INCREASE EVEN TRAVEL BOOST PEDAL IS DEPRESSED

- 5.5.9.4.1. DOES NOT HI

- 5.5.9.4.2. DOES NOT LO

- 5.5.9.5. E4 DOES NOT SWING

- 5.5.9.6. E5 SWING BRAKE HAS NO EFFECT (THERE IS EXCESSIVE HYDRAULIC DRIFT)

- 5.5.10. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

- 5.5.10.1. TABLE OF FAILURE MODES AND CAUSES

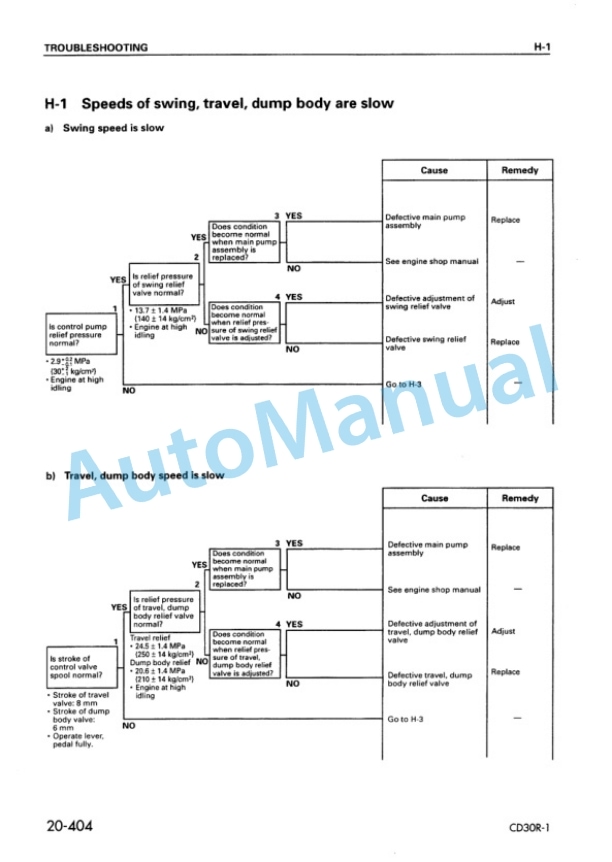

- 5.5.10.2. H1 SPEEDS OF SWING, TRAVEL, DUMP BODY ARE SLOW

- 5.5.10.2.1. SWING SPEED IS SLOW

- 5.5.10.2.2. TRAVEL, DUMP BODY SPEED IS SLOW

- 5.5.10.3. H2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS

- 5.5.10.4. H3 SWING, TRAVEL, DUMP BODY DO NOT MOVE, OR SPEED IS EXTREMELY SLOW

- 5.5.10.4.1. SWING DOES NOT MOVE, OR SPEED IS EXTREMELY SLOW

- 5.5.10.4.2. TRAVEL, DUMP BODY DO NOT MOVE, OR SPEED IS EXTREMELY SLOW

- 5.5.10.5. H4 SWING, TRAVEL, DUMP BODY LACK POWER

- 5.5.10.6. H5 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)

- 5.5.10.7. H6 DUMP BODY SPEED IS SLOW, OR LACKS POWER

- 5.5.10.8. H7 EXCESSIVE HYDRAULIC DRIFT (DUMP BODY)

- 5.5.10.9. H8 DEVIATES TO ONE SIDE WHEN TRAVELING

- 5.5.10.10. H9 LACKS POWER WHEN TRAVELING (OR SPEED IS SLOW)

- 5.5.10.11. H10 TRAVEL SPEED DOES NOT SWITCH

- 5.5.10.12. H11 TRAVEL DOES NOT MOVE (ONE SIDE ONLY)

- 5.5.10.13. H12 TRAVEL LEVER IS HEAVY

- 5.5.10.14. H13 DOES NOT SWING

- 5.5.10.14.1. DOES NOT SWING IN EITHER DIRECTION

- 5.5.10.14.2. DOES NOT SWING IN ONE DIRECTION (LEFT OR RIGHT)

- 5.5.10.15. H14 SWING SWING SPEED IS SLOW OR ACCELERATION IS POOR

- 5.5.10.16. H15 EXCESSIVE SHOCK WHEN STOPPING SWING

- 5.5.10.17. H16 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING

- 5.5.10.18. H17 EXCESSIVE HYDRAULIC DRIFT OF SWING

- 5.5.11. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 5.5.11.1. MONITOR SYSTEM ELECTRICAL CIRCUIT DIAGRAM

- 5.5.11.2. M1 WHEN STARTING SWITCH IS TURNED ON, NO DISPLAY IS GIVEN

- 5.5.11.3. M2 WHEN STARTING SWITCH IS TURNED ON, EVEN WHEN SELF CHECK IS COMPLETED (ALL LAMPS LIGHT UP FOR 3 SECONDS), LAMPS DO NOT GO OUT

- 5.5.11.4. M3 WHEN STARTING SWITCH IS TURNED ON, SOME SELF CHECK LAMPS DO NOT LIGHT UP FOR 3 SECONDS

- 5.5.11.4.1. NO GAUGE LAMPS LIGHT UP (FUEL, COOLANT TEMPERATURE)

- 5.5.11.4.2. CAUTION LAMPS (ENGINE OIL PRESSURE, BATTERY CHARGE), PILOT LAMP (PREHEATING) DO NOT LIGHT UP

- 5.5.11.5. M4 DURING SELF CHECK (ALL LAMPS LIGHT UP FOR 3 SECONDS), EVEN IF STARTING SWITCH IS TURNED TO START, SELF CHECK IS NOT COMPLETED FOR 3 SECONDS

- 5.5.11.6. M5 WHEN STARTING SWITCH IS ON (ENGINE STOPPED), ENGINE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP

- 5.5.11.7. M6 WHEN STARTING SWITCH IS ON (ENGINE STOPPED), CHARGE CAUTION LAMP DOES NOT LIGHT UP

- 5.5.11.8. M7 WHEN STARTING SWITCH IS TURNED TO HEAT, PREHEATING PILOT LAMP DOES NOT LIGHT UP

- 5.5.11.9. M8 WHEN ENGINE IS RUNNING, ENGINE OIL PRESSURE CAUTION LAMP LIGHTS UP

- 5.5.11.10. M9 WHEN ENGINE IS RUNNING, CHARGE CAUTION LAMP LIGHTS UP

- 5.5.11.11. M10 ABNORMALITY IN COOLANT TEMPERATURE GAUGE

- 5.5.11.11.1. LEVEL DOES NOT RISE FROM SEGMENT C

- 5.5.11.11.2. LEVEL DOES NOT GO DOWN FROM SEGMENT H, OR ALL SEGMENT GO OUT

- 5.5.11.11.3. COOLANT TEMPERATURE DOES NOT MATCH GAUGE DISPLAY

- 5.5.11.12. M11 ABNORMALITY IN FUEL GAUGE

- 5.5.11.12.1. LEVEL DOES NOT RISE FROM SEGMENT E OR ALL SEGMENTS GO OUT

- 5.5.11.12.2. LEVEL DOES NOT GO DOWN FROM SEGMENT F

- 5.5.11.12.3. FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY

- 5.5.11.13. M12 DEFECTIVE OPERATION OF ALARM BUZZER

- 5.5.11.13.1. BUZZER DOES NOT SOUND

- 5.5.11.13.2. BUZZER CONTINUES TO SOUND AND DOES NOT STOP

- 5.5.11.14. M13 WHEN ENGINE IS RUNNING, SERVICE METER DOES NOT ADVANCE

- 5.5.11.14.1. WHEN CHARGE CAUTION LAMP DOES NOT LIGHT UP

- 5.5.11.14.2. WHEN CHARGE CAUTION LAMP LIGHTS UP

- 5.5.11.14.3. PILOT LAMP DOES NOT FLASH (SERVICE METER IS ACTUATED)

- 5.5.11.15. M14 NIGHT LIGHTING DOES NOT LIGHT UP

- 5.5.11.15.1. GAUGE LIGHTING DOES NOT LIGHT UP

- 5.5.11.15.2. SERVICE METER LIGHTING DOES NOT LIGHT UP

- 6. MAINTENANCE STANDARD

- 6.1. SWING MACHINERY

- 6.2. SWING CIRCLE

- 6.3. TRACK FRAME, RECOIL SPRING

- 6.4. IDLER

- 6.5. CARRIER ROLLER

- 6.6. TRACK ROLLER BOGIE

- 6.7. CENTER SWIVEL JOINT

- 6.8. SWING PPC VALVE

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM

- 7.2. ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00