Komatsu Component Of Engine Shop Manual SEBECOMP009

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBECOMP009

- Format: PDF

- Size: 61.3MB

- Number of Pages: 648

Category: Komatsu Shop Manual PDF

-

Model List:

- Component Of Engine

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. TURBOCHARGER

- 1.1. CONTENTS

- 1.2. INTRODUCTION

- 1.3. GENERAL

- 1.3.1. TURBOCHARGER MODEL NO.

- 1.3.2. SPECIFICATIONS

- 1.4. STRUCTURE AND FUNCTION

- 1.4.1. GENERAL STRUCTURE

- 1.4.2. STRUCTURE AND FUNCTION

- 1.5. DISASSEMBLY AND ASSEMBLY

- 1.5.1. GENERAL

- 1.5.1.1. DISASSEMBLY

- 1.5.1.2. ASSEMBLY

- 1.6. MAINTENANCE STANDARD AND INSPECTION OF PARTS

- 1.6.1. MAINTENANCE STANDARD

- 1.6.1.1. KTR100

- 1.6.1.2. KTR110

- 1.6.1.3. KTR130

- 1.6.1.4. KTR150

- 1.6.2. INSPECTION OF PARTS

- 2. AIR COMPRESSOR

- 2.1. CONTENTS

- 2.2. GENERAL

- 2.2.1. SPECIFICATIONS

- 2.3. STRUCTURE AND FUNCTION

- 2.3.1. GENERAL STRUCTURE

- 2.3.2. CROSSSECTIONAL DRAWING OF THE CYLINDER HEAD

- 2.3.3. STRUCTURE

- 2.3.4. FUNCTION

- 2.3.5. OPERATION OF UNLOADER VALVE

- 2.4. TESTING AND ADJUSTING

- 2.4.1. PERFORMANCE TEST

- 2.5. DISASSEMBLY AND ASSEMBLY

- 2.5.1. TIGHTENING TORQUE

- 2.5.2. DISASSEMBLY AND ASSEMBLY

- 2.5.2.1. (S)6D95L1 SERIES

- 2.5.2.2. S6D1051 SERIES

- 2.5.2.3. S(A)6D1101 SERIES

- 2.5.2.4. (SA)6D1251 SERIES

- 2.5.2.5. S6D1051,S6D1101 SERIES

- 2.5.2.6. S6D1251 SERIES

- 2.5.2.7. S6D1401 SERIES

- 2.5.2.8. S6D1401, SA6D1401 SERIES

- 2.5.2.9. S6D1701

- 2.5.2.10. S6D1701 SERIES

- 2.5.2.11. S6D1701 SERIES

- 2.5.2.12. SA12V1401 SERIES

- 2.5.2.13. SA12V1401 SERIES

- 2.5.2.14. SA8V1701, SA12V1701 SERIES

- 2.5.2.15. SA8V1701, SA12V1701 SERIES

- 2.5.2.16. SA8V1701, SA12V1701 SERIES

- 2.6. MAINTENANCE STANDARD AND INSPECTION OF PARTS

- 2.6.1. MAINTENANCE STANDARD

- 2.6.1.1. SERIES

- 2.6.1.2. SERIES

- 2.6.1.3. SERIES

- 2.6.1.4. SERIES

- 2.6.1.5. SERIES

- 2.6.1.6. SERIES

- 2.6.1.7. SERIES

- 2.6.1.8. SERIES

- 2.6.1.9. SERIES

- 2.6.1.10. SERIES

- 2.6.1.11. SERIES

- 2.6.1.12. SERIES

- 2.6.1.14. SERIES

- 2.6.1.15. SERIES

- 2.6.1.16. SERIES

- 2.6.2. INSPECTION OF PARTS

- 2.6.3. PERIODIC INSPECTION

- 3. FUEL INJECTION PUMP

- 3.1. FUEL INJECTION PUMP PE(S)A TYPE

- 3.1.1. CONTENTS

- 3.1.2. GENERAL

- 3.1.2.1. FUEL INJECTION SYSTEM OUTLINE

- 3.1.2.2. PRINCIPAL SPECIFICATIONS

- 3.1.3. STRUCTURE

- 3.1.3.1. CONSTRUCTION AND OPERATION

- 3.1.4. TESTING AND ADJUSTING

- 3.1.4.1. SPECIAL TOOLS

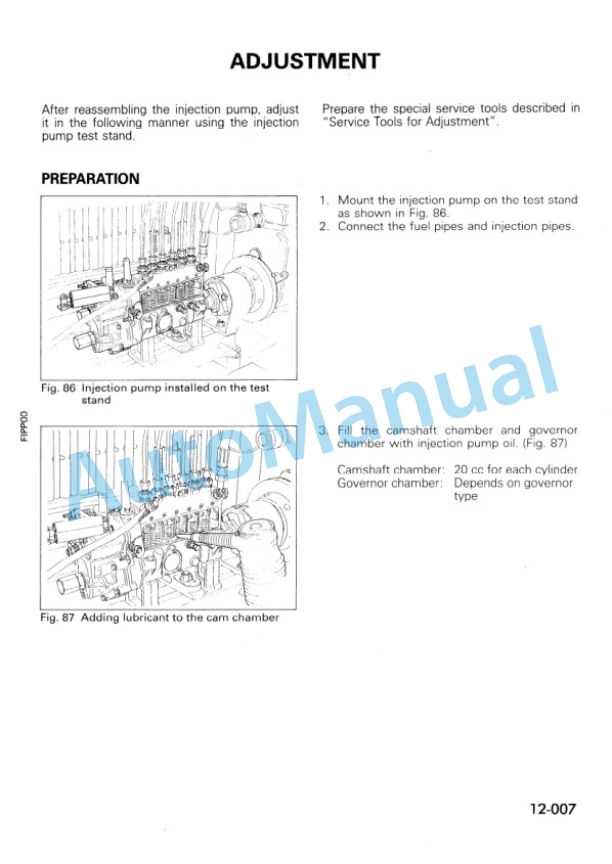

- 3.1.4.2. ADJUSTMENT

- 3.1.4.3. PRECAUTIONS

- 3.1.5. DISASSEMBLY AND ASSEMBLY

- 3.1.5.1. SPECIAL TOOLS

- 3.1.5.2. EXPLODED VIEW OF PEA PUMP

- 3.1.5.3. EXPLODED VIEW OF THE SUPPLY PUMPS

- 3.1.5.4. DISASSEMBLY

- 3.1.5.5. INSPECTION

- 3.1.5.6. REASSEMBLY

- 3.1.6. MAINTENANCE STANDARD

- 3.1.6.1. TIGHTENING TORQUE

- 3.1.7. OTHERS

- 3.1.7.1. TROUBLESHOOTING

- 3.1.7.2. EXPLANATION OF PART NUMBERS

- 3.2. FUEL INJECTION PUMP PE(S)P TYPE

- 3.2.1. CONTENTS

- 3.2.2. GENERAL

- 3.2.2.1. FUEL INJECTION SYSTEM OUTLINE

- 3.2.2.2. PRINCIPAL SPECIFICATIONS

- 3.2.2.3. INJECTION QUANTITY CHARACTERISTICS

- 3.2.3. STRUCTURE AND FUNCTION

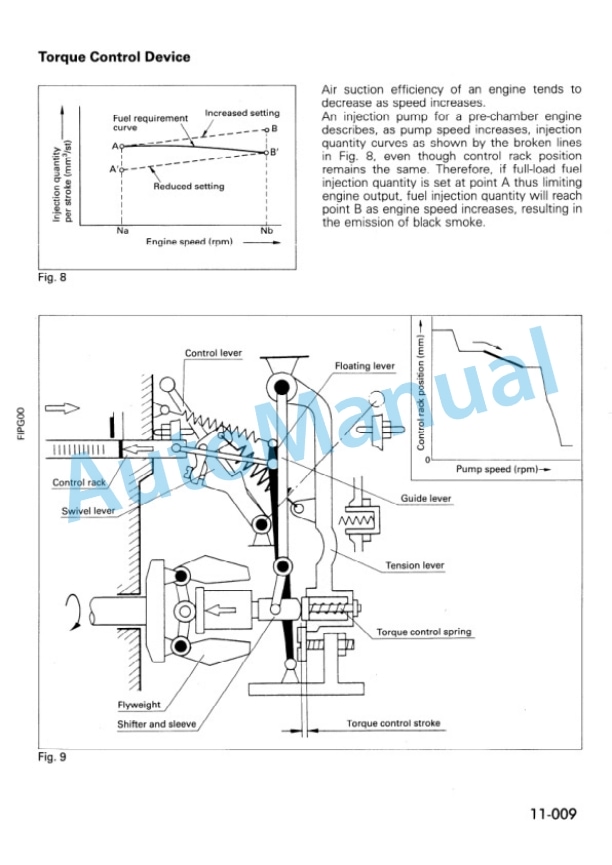

- 3.2.3.1. CONTRUCTION AND OPERATION

- 3.2.4. TESTING AND ADJUSTING

- 3.2.4.1. SERVICE TOOLS FOR ADJUSTMENT

- 3.2.4.2. ADJUSTMENT

- 3.2.4.3. PRECAUTIONS

- 3.2.4.4. TROUBLESHOOTING

- 3.2.5. DISASSEMBLY AND ASSEMBLY

- 3.2.5.1. SPECIAL TOOLS

- 3.2.5.2. EXPLODED VIEW OF THE PEP PUMP AND SUPPLY PUMP

- 3.2.5.3. DISASSEMBLY

- 3.2.5.4. INSPECTION

- 3.2.5.5. REASSEMBLY

- 3.2.6. MAINTENANCE STANDARD

- 3.2.6.1. TIGHTENING TORQUES

- 3.2.7. OTHERS

- 3.2.7.1. EXPLANATION OF PART NUMBERS

- 3.3. FUEL INJECTION PUMP KFE TYPE

- 3.3.1. CONTENTS

- 3.3.2. GENERAL

- 3.3.2.1. SPECIFICATIONS

- 3.3.2.2. GENERAL VIEW

- 3.3.3. STRUCTURE AND FUNCTION

- 3.3.3.1. STRUCTURE

- 3.3.3.2. OPERATION

- 3.3.4. TESTING AND ADJUSTING

- 3.3.4.1. SPECIAL TOOLS OF ADJUSTING

- 3.3.4.2. PREPARATION

- 3.3.4.3. PRESTROKE AJUSTMENT

- 3.3.4.4. ADJUSTMENT OF FUEL INJECTION VOLUME

- 3.3.4.5. GOVERNOR PERFORMANCE CHECK

- 3.3.4.6. PRESTROKE OIL PRESSURE CHECK

- 3.3.4.7. FIGURE OF SPECIAL TOOLS

- 3.3.5. DISASSEMBLY AND ASSEMBLY

- 3.3.5.1. SPECIAL TOOLS FOR DISASSEMBLY AND ASSEMBLY

- 3.3.5.2. DISASSEMBLY

- 3.3.5.3. ASSEMBLY

- 3.3.5.4. FIGURE OF SPECIAL TOOLS

- 3.3.6. MAINTENANCE STANDARD

- 3.3.6.1. ADJUSTING FUEL INJECTION PUMP

- 3.3.6.2. ADJUSTING ELECTRONIC GOVERNOR

- 3.3.7. REPAIRS AND REPLACEMENT OF PARTS

- 3.3.7.1. PARTS INSPECTION

- 3.3.7.2. JUDGEMENT STANDARD FOR REUSE

- 4. FUEL INJECTION PUMP GOVERNOR

- 4.1. FUEL INJECTION PUMP GOVERNOR RSV

- 4.1.1. CONTENTS

- 4.1.2. GENERAL

- 4.1.2.1. FEATURES

- 4.1.3. STRUCTURE AND FUNCTION

- 4.1.3.1. CONSTRUCTION

- 4.1.3.2. OPERATION

- 4.1.4. TESTING AND ADJUSTION

- 4.1.4.1. SPECIAL TOOLS

- 4.1.4.2. ADJUSTMENT

- 4.1.4.3. PRECAUTIONS

- 4.1.5. DISASSEMBLY AND ASSEMBLY

- 4.1.5.1. SPECIAL TOOLS

- 4.1.5.2. EXPLODED VIEW OF THE RSV GOVERNOR

- 4.1.5.3. DISASSEMBLY

- 4.1.6. MAINTENANCE STANDARD

- 4.1.6.1. TIGHTENING TORQUE

- 4.1.7. OTHERS

- 4.1.7.1. EXPLANATION OF PART NUMBERS

- 4.2. FUEL INJECTION PUMP GOVERNOR RSUV(D)Z

- 4.2.1. CONTENTS

- 4.2.2. GENERAL

- 4.2.2.1. FEATURES

- 4.2.3. TESTING AND ADJUSTING

- 4.2.3.1. SPECIAL TOOLS

- 4.2.3.2. ADJUSTMENT

- 4.2.3.3. PRECAUTIONS

- 4.2.4. DISASSEMBLY AND ASSEMBLY

- 4.2.4.1. SPECIAL TOOLS

- 4.2.4.2. EXPLODED VIEW OF THE RSUV GOVERNOR

- 4.2.4.3. DISASSEMBLY

- 4.2.4.4. INSPECTION

- 4.2.4.5. REASSEMBLY

- 4.2.5. MAINTENANCE STANDARD

- 4.2.5.1. TIGHTENING TORQUES

- 5. FUEL SUPPLY PUMP (COMMON RAIL TYPE)

- 5.1. CONTENTS

- 5.2. DISASSEMBLY AND ASSEMBLY

- 5.2.1. SPECIAL TOOL LIST

- 5.2.2. CONSUMABLE PARTS LIST

- 5.2.3. SKETCHES OF SPECIAL TOOLS

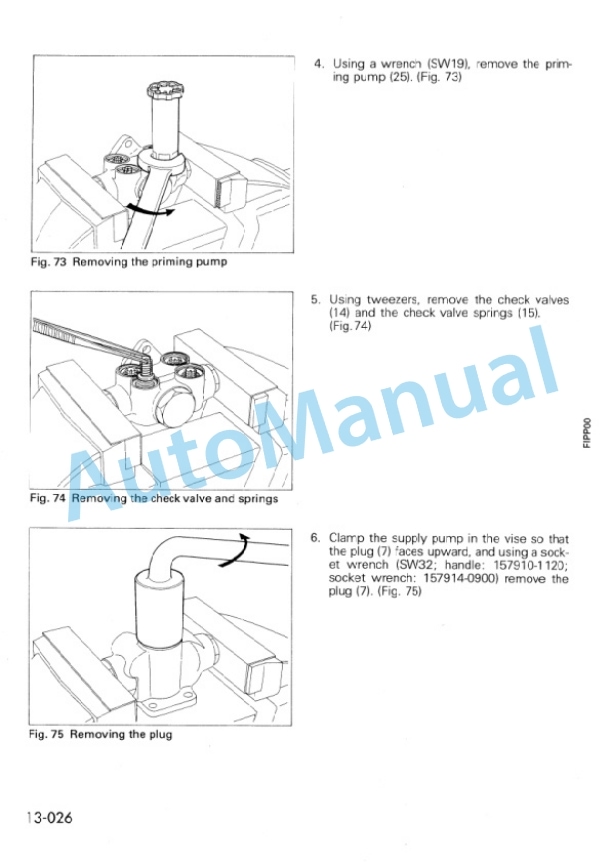

- 5.2.4. DISASSEMBLY OF FUEL SUPPLY PUMP

- 5.2.5. ASSEMBLY OF FUEL SUPPLY PUMP

- 5.2.5.1. TIGHTENING TORQUE TABLE

- 5.3. PERFORMANCE TEST

- 5.3.1. SPECIAL TOOLS LIST

- 5.3.2. SKETCHES OF SPECIAL TOOLS

- 5.3.3. PERFORMANCE TEST ON FUEL SUPPLY PUMP

- 5.3.3.1. PREPARATION

- 5.3.3.2. BENCH SETTING

- 5.3.3.3. ELECTRICAL WIRING

- 5.3.3.4. PERFORMANCE TEST

- 5.4. STRUCTURE AND FUNCTION

- 5.4.1. GENERAL STRUCTURE

- 5.4.2. STRUCTURE AND FUNCTION

- 5.5. DISASSEMBLY AND ASSEMBLY

- 5.5.1. STANDARD VALUES AND TIGHTENING TORQUE TABLE

- 5.5.2. , 105, 108, AND 110 SERIES GENERAL DISASSEMBLY

- 5.5.2.1. GENERAL DISASSEMBLY

- 5.5.2.2. GENERAL DISASSEMBLY

- 5.5.3. ,12V140 SERIES

- 5.5.3.1. GENERAL DISASSEMBLY

- 5.5.3.2. GENERAL ASSEMBLY

- 5.5.4.1. GENERAL DISASSEMBLY

- 5.5.4.2. GENERAL ASSEMBLY

- 5.5.5. SERIES

- 5.5.5.1. GENERAL DISASSEMBLY

- 5.5.5.2. GENERAL ASSEMBLY

- 5.5.6. SERIES

- 5.5.6.1. GENERAL DISASSEMBLY

- 5.5.6.2. GENERAL DISASSEMBLY

- 5.6. MAINTENANCE STANNDARD AND INSPECTION

- 5.6.1. MAINTENANCE STANDARD

- 5.6.2. PARTS INSPECTION AND EVALUATION CRITERIA

- 5.6.3. CONTENTS OF REPAIRS AND MATRIX FOR REQUIRED PARTS KIT

- 5.6.4. SPECIFICATIONS

- 5.6.5. PUMP CONFIGURATION

- 5.7. DISASSEMBLY AND ASSEMBLY

- 5.7.1. DISASSEMBLY OF FUEL PUMP ASSEMBLY

- 5.7.2. ASSEMBLY OF FUEL PUMP ASSEMBLY

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00