Komatsu D155A-5 Bull Dozer Shop Manual SEBM023302

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM023302

- Format: PDF

- Size: 28.8MB

- Number of Pages: 722

Category: Komatsu Shop Manual PDF

-

Model List:

- D155A-5 Bull Dozer

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. General

- 1.1. Specification drawing

- 1.2. Specifications

- 1.3. Weight table

- 1.4. Table of fuel, coolant and lubricants

- 2. Structure and function

- 2.1. Radiator

- 2.2. Oil cooler

- 2.3. Engine control

- 2.4. Power train

- 2.5. Power train system

- 2.6. Power train unit mount

- 2.7. Overall drawing of power train unit

- 2.8. Power train hydraulic piping diagram

- 2.9. Power train hydraulic system drawing

- 2.10. Damper, universal joint

- 2.11. Torque converter, PTO

- 2.12. Transmission control

- 2.13. Transmission

- 2.14. Transmission control valve

- 2.15. Main relief valve

- 2.16. Lubrication relief valve

- 2.17. Steering, brake control

- 2.18. Bevel gear shaft, steering clutch, steering brake

- 2.19. Steering control valve

- 2.20. Reducing valve

- 2.21. Scavenging pump strainer

- 2.22. Power train pump strainer

- 2.23. Power train oil filter

- 2.24. Final drive

- 2.25. Radiator guard

- 2.26. Main frame, underguard

- 2.27. Track frame

- 2.28. Recoil spring

- 2.29. Track roller bogie

- 2.30. Suspension

- 2.31. Work equipment hydraulic piping diagram

- 2.32. PPC control piping diagram

- 2.33. Work equipment control

- 2.34. Work equipment hydraulic system diagram

- 2.35. Hydraulic tank and filter

- 2.36. PPC charge valve

- 2.37. Accumulator

- 2.38. PPC lock valve

- 2.39. PPC valve

- 2.40. Main control valve

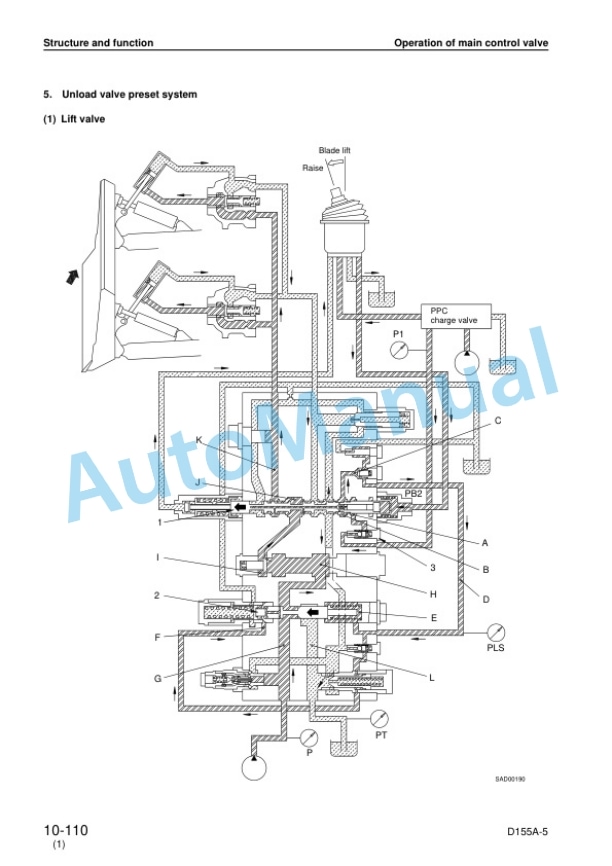

- 2.41. Operation of main control valve

- 2.42. Operation of work equipment control circuit

- 2.43. Piston valve

- 2.44. Quick drop valve

- 2.45. Cylinder stay

- 2.46. Work equipment

- 2.47. Pin puller switch

- 2.48. Pin puller solenoid valve

- 2.49. Tilt/pitch selector switch

- 2.50. Pitch solenoid valve

- 2.51. Cab mount

- 2.53. Air conditioner

- 2.54. Electrical wiring diagram

- 2.55. Machine monitor system

- 2.56. Sensors

- 2.57. Engine starting system

- 3. Testing and adjusting

- 3.1. Standard value tables

- 3.1.1. Standard value table for engine related parts

- 3.1.2. Standard value table for chassis related parts

- 3.1.3. Standard value table for machine monitor

- 3.2. Testing and adjusting

- 3.2.1. Tools for testing, adjusting, and troubleshooting

- 3.2.2. Measuring engine speed

- 3.2.3. Measuring exhaust color

- 3.2.4. Adjusting valve clearance

- 3.2.5. Measuring compression pressure

- 3.2.6. Measuring blowby

- 3.2.7. Measuring engine oil pressure

- 3.2.8. Testing and adjusting fuel injection timing

- 3.2.9. Testing and adjusting alternator belt tension

- 3.2.10. Measuring exhaust temperature

- 3.2.11. Measuring air supply pressure (boost pressure)

- 3.2.12. Measuring torque converter stall speed

- 3.2.13. Measuring torque converter stall hydraulic pump relief (full stall) speed

- 3.2.14. Adjusting fuel control linkage

- 3.2.15. Adjusting decelerator pedal

- 3.2.16. Adjusting joystick (steering, directional, gear shift lever), parking lever linkage

- 3.2.17. Adjusting brake pedal linkage

- 3.2.18. Adjusting work equipment control linkage

- 3.2.19. Testing and adjusting work equipment control circuit pressure

- 3.2.20. Measuring PPC valve output pressure

- 3.2.21. Adjusting PPC valve

- 3.2.22. Measuring onoff solenoid valve output pressure

- 3.2.23. Measuring power train oil pressure

- 3.2.24. Testing and adjusting work equipment main relief pressure

- 3.2.25. Bleeding air from hydraulic cylinders

- 3.2.26. Releasing remaining pressure in hydraulic circuit

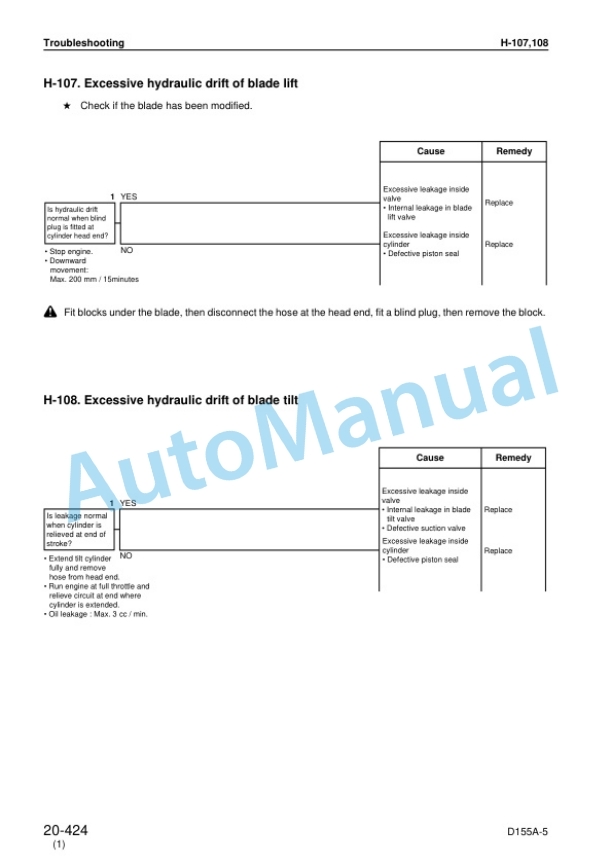

- 3.2.27. Checking location of cause of hydraulic drift of blade and ripper

- 3.2.28. Measuring leakage inside cylinder

- 3.2.29. Adjusting semiUtiltdozer

- 3.2.30. Adjusting clearance of idler

- 3.2.31. Simple procedure for testing brake performance

- 3.3. Troubleshooting

- 3.3.1. Points to remember when troubleshooting

- 3.3.2. Sequence of events in troubleshooting

- 3.3.3. Points to remember when carrying out maintenance

- 3.3.4. Checks before troubleshooting

- 3.3.5. Type of connector and position of installation

- 3.3.6. Connector arrangement diagram

- 3.3.7. Connection table for connector pin numbers

- 3.3.8. Method of using troubleshooting charts

- 3.3.9. Troubleshooting of electrical system (E mode)

- 3.3.10. Troubleshooting of hydraulic and mechanical systems (H mode)

- 3.3.11. Troubleshooting of machine monitor system (M mode)

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. METHOD OF USING MANUAL

- 4.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 4.3. SPECIAL TOOL LIST

- 4.4. SPECIAL TOOL SKETCH

- 4.5. ENGINE OIL COOLER CORE

- 4.5.1. REMOVAL

- 4.5.2. INSTALLATION

- 4.6. FUEL INJECTION PUMP

- 4.7. ENGINE FRONT SEAL

- 4.7.1. REMOVAL

- 4.7.2. INSTALLATION

- 4.8. ENGINE REAR SEAL

- 4.9. AIR CONDITIONER COMPRESSOR

- 4.9.1. REMOVAL

- 4.9.2. INSTALLATION

- 4.10. AIR CONDITIONER CONDENSER

- 4.11. RADIATOR, OIL COOLER, GUARD

- 4.12. HYDRAULIC COOLER

- 4.13. POWER TRAIN UNIT

- 4.14. TORQUE CONVERTER

- 4.14.1. DISASSEMBLY

- 4.14.2. ASSEMBLY

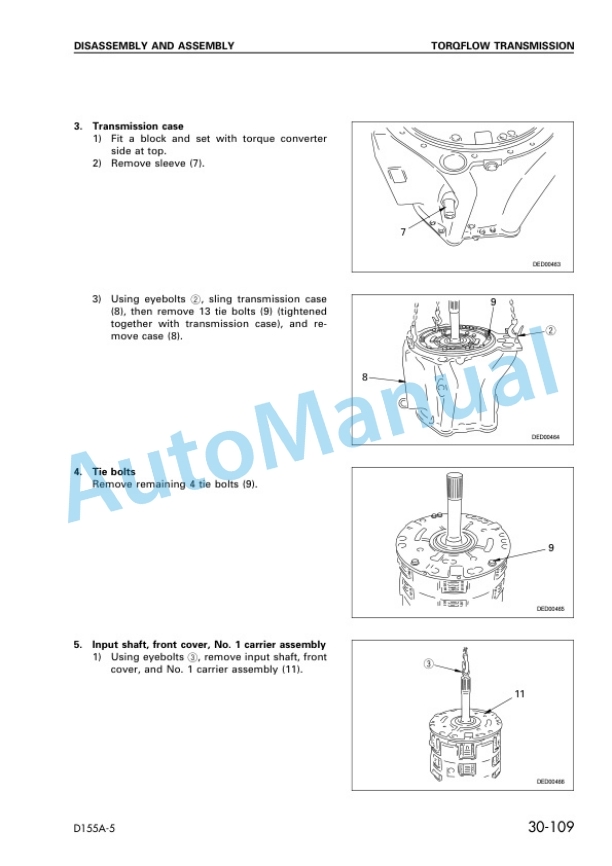

- 4.15. TORQFLOW TRANSMISSION

- 4.16. POWER TRAIN, LUBRICATION PUMP

- 4.16.1. REMOVAL

- 4.16.2. INSTALLATION

- 4.17. SCAVENGING PUMP

- 4.17.1. REMOVAL

- 4.17.2. INSTALLATION

- 4.18. POWER TRAIN MAIN RELIEF VALVE

- 4.18.1. REMOVAL

- 4.18.2. INSTALLATION

- 4.18.3. DISASSEMBLY

- 4.18.4. ASSEMBLY

- 4.19. TRANSMISSION CONTROL VALVE

- 4.20. STEERINGCONTROL VALVE

- 4.20.1. CHECKING BEFORE REMOVAL

- 4.20.2. REMOVAL (NORMAL)

- 4.20.3. REMOVAL (WHEN THERE IS ABNORMALITY INSIDE TRACK FRAME)

- 4.20.4. INSTALLATION

- 4.20.5. OVERALL DISASSEMBLY

- 4.20.6. OVERALL ASSEMBLY

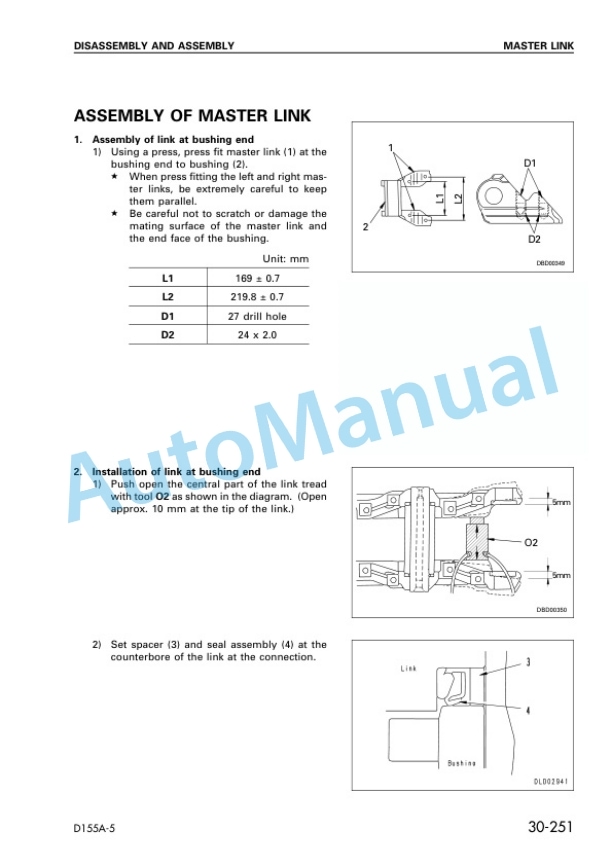

- 4.21. PRESSFITTING JIG DIMENSION TABLE FOR LINK PRESS

- 4.22. EQUALIZER BAR SIDE BUSHING

- 4.23. HYDRAULIC, PPC PUMP

- 4.23.1. REMOVAL

- 4.23.2. INSTALLATION

- 4.24. MAIN CONTROL VALVE

- 4.24.1. REMOVAL

- 4.24.2. INSTALLATION

- 4.24.3. DISASSEMBLY

- 4.24.4. ASSEMBLY

- 4.25. PPC CHARGE VALVE

- 4.25.1. REMOVAL

- 4.25.2. INSTALLATION

- 4.25.3. DISASSEMBLY

- 4.25.4. ASSEMBLY

- 4.26. BLADE PPC VALVE

- 4.26.1. REMOVAL

- 4.26.2. INSTALLATION

- 4.27. RIPPER PPC VALVE

- 4.27.1. REMOVAL

- 4.27.2. INSTALLATION

- 4.28. BLADE PPC VALVE

- 4.28.1. DISASSEMBLY

- 4.28.2. ASSEMBLY

- 4.29. BLADE LIFT CYLINDER

- 4.29.1. REMOVAL

- 4.29.2. INSTALLATION

- 4.30. BLADE TILT CYLINDER

- 4.30.1. REMOVAL

- 4.30.2. INSTALLATION

- 4.31. RIPPER LIFT CYLINDER

- 4.31.1. REMOVAL

- 4.31.2. INSTALLATION

- 4.32. RIPPER TILT CYLINDER

- 4.32.1. REMOVAL

- 4.32.2. INSTALLATION

- 4.33. HYDRAULIC CYLINDER

- 4.34. MULTISHANK RIPPER

- 5. Maintenance standard

- 5.1. Engine mount

- 5.2. Power train unit mount

- 5.3. Damper, universal joint

- 5.4. Torque converter, PTO

- 5.5. Transmission

- 5.6. Transmission control valve

- 5.7. Main relief valve

- 5.8. Bevel gear shaft, steering clutch, steering brake

- 5.9. Steering control valve

- 5.10. Scavenging pump

- 5.11. Power train pump, lubrication pump

- 5.12. Final drive

- 5.13. Main frame

- 5.14. Track frame

- 5.15. Recoil spring

- 5.16. Track roller bogie

- 5.17. Idler

- 5.18. Track roller

- 5.19. Carrier roller

- 5.20. Recoil spring

- 5.21. Track shoe (Dry type track)

- 5.22. Track shoe (Sealed and Lubricated Track)

- 5.23. Suspension

- 5.24. Hydraulic, PPC charge pump

- 5.25. PPC charge valve

- 5.26. PPC valve

- 5.27. Main control valve

- 5.28. Work equipment cylinder

- 5.29. Quick drop valve

- 5.30. Cylinder stay

- 5.31. Work equipment

- 6. Others

- 6.1. Hydraulic circuit diagram

- 6.1.1. Power train hydraulic circuit diagram

- 6.1.2. Work equipment hydraulic circuit diagram

- 6.2. Electrical circuit diagram

- 6.2.1. ELECTRICAL CIRCUIT DIAGRAM

- 6.2.2. Cab electrical circuit diagram

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00