Komatsu D275A-5 Galeo Bull Dozer Operation and Maintenance Manual SEAM044801T

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM044801T

- Format: PDF

- Size: 7.5MB

- Number of Pages: 276

-

Model List:

- D275A-5 Galeo Bull Dozer

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. FRONT/REAR,LEFT/RIGHT DIRECTIONS OF MACHINE

- 2.4. NECESSARY INFORMATION

- 2.4.1. MACHINE SERIAL NO.PLATE AND POSITION

- 2.4.2. ENGINE SERIAL NO.PLATE AND POSITION

- 2.4.3. BLADE SERIAL NO.PLATE POSITION

- 2.4.4. RIPPER SERIAL NO.PLATE POSITION

- 2.4.5. POSITION OF SERVICE METER

- 2.4.6. TABLE TO ENTER SERIAL NO. AND DISTRIBUTORN

- 2.4.7. POSITIONS OF SAFETY PICTOGRAMS

- 2.4.8. SAFETY LABELS

- 2.4.9. GENERAL PRECAUTIONS

- 2.4.10. PRECAUTIONS FOR OPERATION

- 2.4.11. PRECAUTIONS FOR MAINTENANCE

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. GENERAL VIEW OF MACHINE

- 3.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

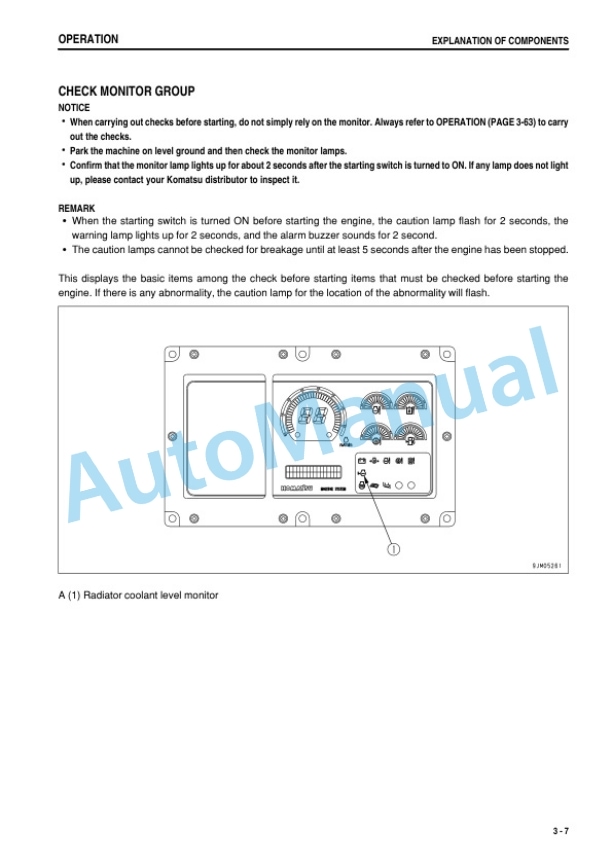

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. FRONT PANEL

- 3.2.2. SWITCH

- 3.2.3. CONTROL LEVERS,PEDALS

- 3.2.4. SASH GLASS INTERMEDIATE LOCK

- 3.2.5. DOOR POCKET

- 3.2.6. ASHTRAY

- 3.2.7. TOOL BOX

- 3.2.8. CAR STEREO, HANDLING

- 3.2.9. AIR CONDITIONER,HANDLING

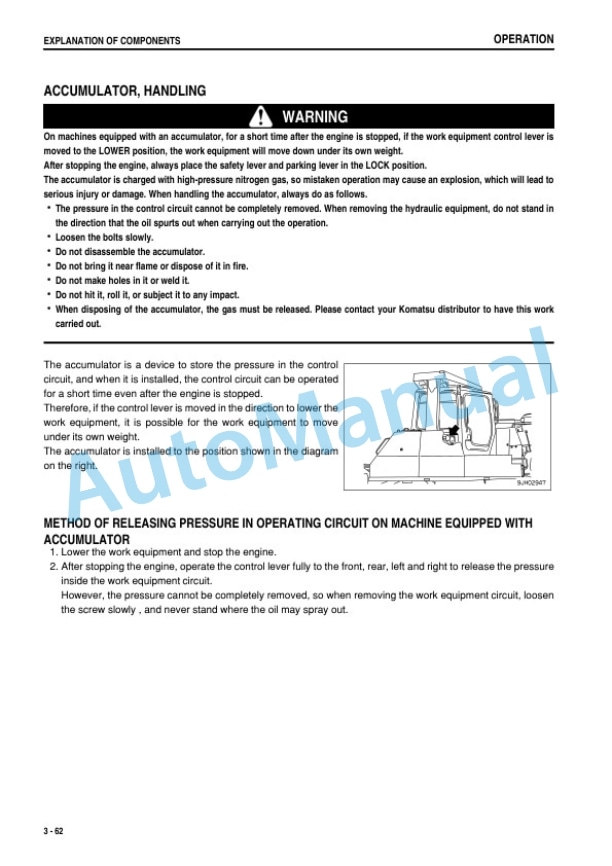

- 3.2.10. ACCUMULATOR,HADLING

- 3.3. OPERATION

- 3.3.1. CHECK BEFORE STARTING ENGINE,ADJUST

- 3.3.2. STARTING ENGINE

- 3.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 3.3.4. STOPPING ENGINE

- 3.3.5. CHECK AFTER STOPPING ENGINE

- 3.3.6. MOVING MACHINE OFF

- 3.3.7. STOPPING MACHINE

- 3.3.8. SHIFTING GEAR

- 3.3.9. SHIFTING BETWEEN FOEWARD AND REVERSE

- 3.3.10. STEERIG MACHINE

- 3.3.11. PRECAUTIONS FOR OPERATION

- 3.3.12. PARKING MACHINE

- 3.3.13. CHECK AFTER FINISHING WORK

- 3.3.14. LOCKNG

- 3.3.15. WORK POSSIBLE USING BULLDOZER

- 3.3.16. RIPPER OPERATION

- 3.3.17. OPERATING METHOD FOR RIPPING OPERATIONS

- 3.3.18. ADJUSTING POSTURE OF WORK EQUIPMENT

- 3.3.19. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 3.4. TRANSPORTATION

- 3.4.1. TRANSPORTATION PROCEDURE

- 3.4.2. LOADING,UNLOADING WORK

- 3.4.3. PRECAUTIONS FOR LOADING

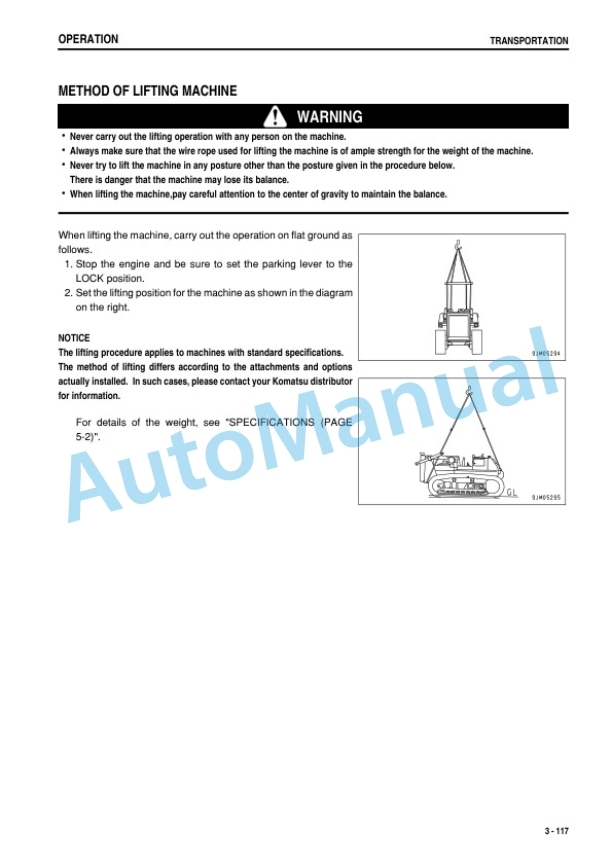

- 3.4.4. METHOD OF LIFTING MACHINE

- 3.4.5. PRECAUTIONS FOR TRANSPORTATION

- 3.4.6. TRAVELING ON ROADS

- 3.4.7. REMOVAL OF CAB

- 3.4.8. INSTALLATION OF CAB

- 3.5. COLD WEATHER OPERATION

- 3.5.1. PRECAUTONS FOR LOW TEMPERATURE

- 3.5.2. AFTER COMPLETION OF WORK

- 3.5.3. AFTER COLD WEATHER

- 3.6. LONGTERM STORAGE

- 3.6.1. BEFORE STORAGE

- 3.6.2. DURING STORAGE

- 3.6.3. AFTER STORAGE

- 3.7. TROUBLESHOOTING

- 3.7.1. AFTER RUNNING OUT OF FUEL

- 3.7.2. METHOD OF TOWING MACHINE

- 3.7.3. IF BATTERY IS DISCHARGED

- 3.7.4. OTHER TROUBLE

- 4. MAINTENANCE

- 4.1. GUIDES TO MAINTENANCE

- 4.2. OUTLINES OF SERVICE

- 4.2.1. HANDLING OIL,FUEL,COOLANT,AND PERFORMING OIL CLINIC

- 4.2.2. OUTLINE OF ELECTRIC SYSTEM

- 4.3. WEAR PARTS LIST

- 4.3.1. WEAR PARTS LIST

- 4.4. USE OF FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 4.4.1. PROPER SELECTION OF FUEL,COOLANT AND LUBRECANTS

- 4.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 4.5.1. TORQUE LIST

- 4.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 4.6.1. SAFETY CRITICAL PARTS

- 4.7. MAINTENANCE SCHEDULE CHART

- 4.7.1. MAINTENANCE SCHEDULE CHART

- 4.8. SERVICE PROCEDURE

- 4.8.1. INITIAL 250 HOURS SERVICE(ONLY AFTER THE FIRST 250 HOURS)

- 4.9. WHEN REQUIRED

- 4.9.1. CLEAN INSIDE OF COOLING SYSTEM

- 4.9.2. CHECK,CLEAN AND RELACE AIR CLEANER ELEMENT

- 4.9.3. CHECK TRACK TENSION

- 4.9.4. CHECK AND TIGHTEN TRACK SHOE BOLTS

- 4.9.5. ADJUST IDLER CEARANCE

- 4.9.6. REVERSE AND REPLACE THE END BITS AND CUTTING EDGES

- 4.9.7. CLEAN,CHECK RADIATOR FINS

- 4.9.8. CLEAN FUEL TANK STRAINER

- 4.9.9. DRAIN WATER AND SEDIMENT IN FUEL TANK

- 4.9.10. CLEAN STEERING CLUTCH CASE BREATHER

- 4.9.11. REPLACE AIE CONDITIONER BELT

- 4.9.12. CLEAN,CHECK HYDRAULIC COOLER FINS

- 4.9.13. CHECK UNDERCARRIAGE OIL

- 4.9.14. CLEAN AIR CONDITIONER AIR FILTER(FRESH/RECIRC FILTER)

- 4.9.15. CHECK,ADJUST AIR CONDITIONER

- 4.9.16. LUBRICATE DOOR HINGE

- 4.9.17. CHECK DOOR LATCH

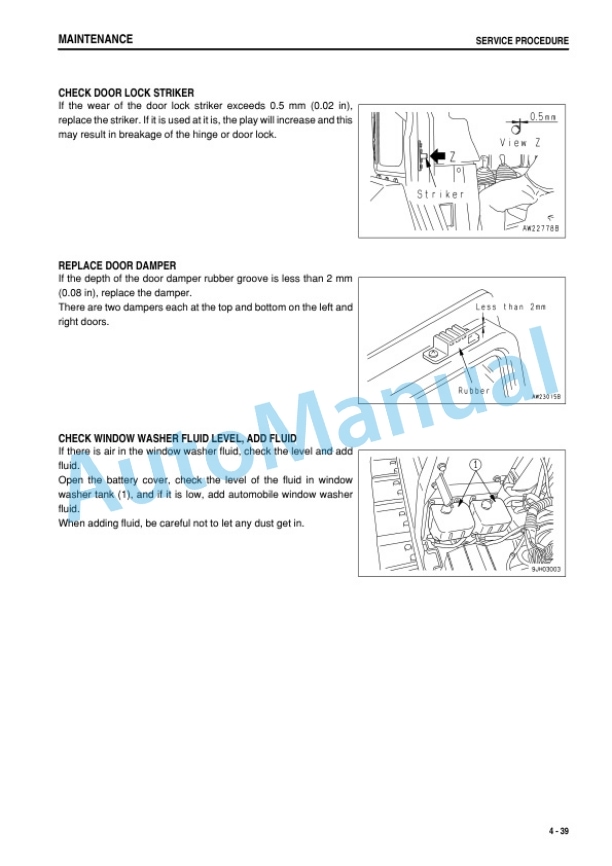

- 4.9.18. CHECK DOOR LOCK STRIKER

- 4.9.19. REPLACE DOOR DAMPER

- 4.9.20. CHECK WINDOW WASHER FLUID LEVEL,ADD FLUID

- 4.9.21. REPLACE WIPER BLADE

- 4.9.22. BLEEDING AIR IN HYDRAULIC SYSTEM

- 4.9.23. CHECK ELECTRICAL INTAKE AIR HEATER

- 4.9.24. LUBRICATING

- 4.10. CHECK BEFORE STARTING

- 4.11. EVERY 250 HOURS SERVICE

- 4.11.1. LUBRICATING

- 4.11.2. CHECK ALTERNATOR DRIVE BELT TENSION,ADJUST

- 4.11.3. CHECK LEVEL OF BATTERY ELECTROLYTE

- 4.11.4. CHECK BRAKE PERFORMANCE

- 4.11.5. CHECK OIL LEVEL IN DAMPER CASE,ADD OIL

- 4.12. EVERY 500 HOURS SERVICE

- 4.12.1. CHANGE OIL IN ENGINE OIL PAN,REPLACE ENGINE OIL FILTER CARTRIDGE

- 4.12.2. REPLACE FUEL FILTER CARTRIDGE

- 4.12.3. REPLACE POWER TRAIN OIL FILTER ELEMENT,STEERING LUBRICATING OIL FILTER ELEMENT

- 4.12.4. CHECK OIL LEVEL IN FINAL DRIVE CASE,ADD OIL

- 4.12.5. REPLACE HYDRAULIC TANK BREATHER ELEMENT

- 4.13. EVERY 1000 HOURS SERVICE

- 4.13.1. CHANGE OIL IN POWER TRAIN CASE,WASH STRAINERS(POWER TRAIN PUMP STRAINER,SCAVENGING PUMP STRAINER)

- 4.13.2. CHECK, CLEAN FUEL STRAINER

- 4.13.3. CHECK FOR LOOSE ROPS MOUNT BOLTS

- 4.13.4. REPLACE MAIN CORROSION RESISTOR CARTRIDGE AND SUB CORROSION RESISTOR CARTRIDGE

- 4.13.5. CHECK TIGHTENING PARTS OF TURBOCHARGER

- 4.14. EVERY 2000 HOURS SERVICE

- 4.14.1. CHANGE OIL IN HYDRAULIC TANK,REPLACE HYDRAULIC OIL FILTER ELEMENT,CLEAN HYDRAULIC TANK STRAINER

- 4.14.2. CHANGE OIL FINAL DRIVE CASE

- 4.14.3. CHANGE OIL IN DAMPER CASE,CLEAN DAMPER BREATHER

- 4.14.4. CHECK PIVOT BEARING OIL LEVEL,ADD OIL

- 4.14.5. CHECK OIL LEVEL IN RECOIL SPRING,ASSIST CYLINDER CASE,ADD OIL

- 4.14.6. CLEAN ENGINE BREATHER ELEMENT

- 4.14.7. CHECK ALTERNATOR,STARTING MOTOR

- 4.14.8. CHECK INJECTOR

- 4.15. EVERY 4000 HOURS SERVICE

- 4.15.1. CHECK WATER PUMP

- 4.15.2. CHECK VIBRATION DAMPER

- 4.15.3. CLEAN,CHECK TURBOCHARGER

- 4.15.4. CHECK PLAY OF TURBOCHARGER ROTOR

- 4.15.5. CHECK ENGINE VALVE CLEARANCE,ADJUST

- 4.15.6. CHECKING FOR LOOSENESS OF HIGHPRESSURE CLAMP,HARDENING OF RUBBER

- 4.15.7. CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP,HARDENING OF RUBBER

- 4.15.8. REPLACE INJECTOR ASSEMBLY

- 4.15.9. CHECK MAIN FRAME,WORK EQUIPMENT(BLADE,RIPPER)

- 4.16. EVERY 8000 HOURS SERVICE

- 4.16.1. REPLACE HIGHPRESSURE PIPING CLAMP

- 4.16.2. REPLACE FUEL SPLAY PREVENTION CAP

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 6. ATTACHMENTS,OPTIONS

- 6.1. GENERAL PRECAUTIONS

- 6.1.1. PRECAUTIONS RELATED TO SAFETY

- 6.2. SELECTION OF TRACK SHOE

- 6.2.1. SELECTION OF TRACK SHOES

- 6.3. PROCEDURE FOR SELECTING RIPPER POINT

- 6.3.1. PROCEDURE FOR SELECTING RIPPER POINT

- 6.4. CAP WITHLOCK,HANDLING

- 6.4.1. METHOD OF OPENING AND CLOSING CAP WITH LOCK

- 6.5. EFECTIVE METHOD OF OPERATION FOR DUAL TILT DOZER

- 6.5.1. BLADE CONDITION

- 6.5.2. DOZING WORK

- 6.5.3. LEVELING(SPREADING) OPERATION

- 6.5.4. DITCHING OPERATION

- 6.5.5. BOULDER RAISING OPERATION

- 6.5.6. SIDECUTTING OPERATIONS

- 6.5.7. HORIZONTAL DOZING OPERATIONS FROM SIDE SLOPE(ROUGH GROUND)

- 6.6. SHOE SLIP CONTROL

- 6.6.1. MODE SELECTION SWITCH PANEL(SHOE SLIP CONTROL)

- 6.6.2. EFECTIVE USE OF MODE SELECTION SYSTEM

- 6.6.3. IF MODE SELECTION SYSTEM FLASHES

- 7. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200