Komatsu D31EX-21, D31PX-21, D37EX-21, D37PX-21, D39EX-21, D39PX-21 Bull Dozer Shop Manual SEBM035005

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM035005

- Format: PDF

- Size: 37.6MB

- Number of Pages: 745

Category: Komatsu Shop Manual PDF

-

Model List:

- D31EX-21 Bull Dozer

- D31PX-21 Bull Dozer

- D37EX-21 Bull Dozer

- D37PX-21 Bull Dozer

- D39EX-21 Bull Dozer

- D39PX-21 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

- 4.1. COOLING SYSTEM

- 4.2. ENGINE CONTROL

- 4.3. POWER TRAIN

- 4.4. POWER TRAIN SYSTEM

- 4.5. DAMPER

- 4.6. HST HYDRAULIC EQUIPMENT ARRANGEMENT DIAGRAM

- 4.7. STEERING, BRAKE CONTROL

- 4.8. SOLENOID VALVE

- 4.9. TOWING VALVE

- 4.10. FINAL DRIVE

- 4.11. HST PUMP

- 4.12. SAFETYSUCTION VALVE

- 4.13. CHARGE SAFETY VALVE

- 4.14. CHARGE PUMP

- 4.15. TOWING VALVE

- 4.16. HST MOTOR

- 4.17. ELECTRIC LEVER (FOR STEERING)

- 4.18. FRAME ASSEMBLY

- 4.19. TRACK FRAME, RECOIL SPRING

- 4.20. ARRANGEMENT OF HYDRAULIC EQUIPMENT FOR WORK EQUIPMENT

- 4.21. WORK EQUIPMENT CONTROL

- 4.22. HYDRAULIC TANK, FILTER

- 4.23. PPC LOCK VALVE

- 4.24. ACCUMULATOR

- 4.25. HYDRAULIC PUMP

- 4.26. WORK EQUIPMENT CYLINDER

- 4.27. CONTROL VALVE

- 4.28. CLSS

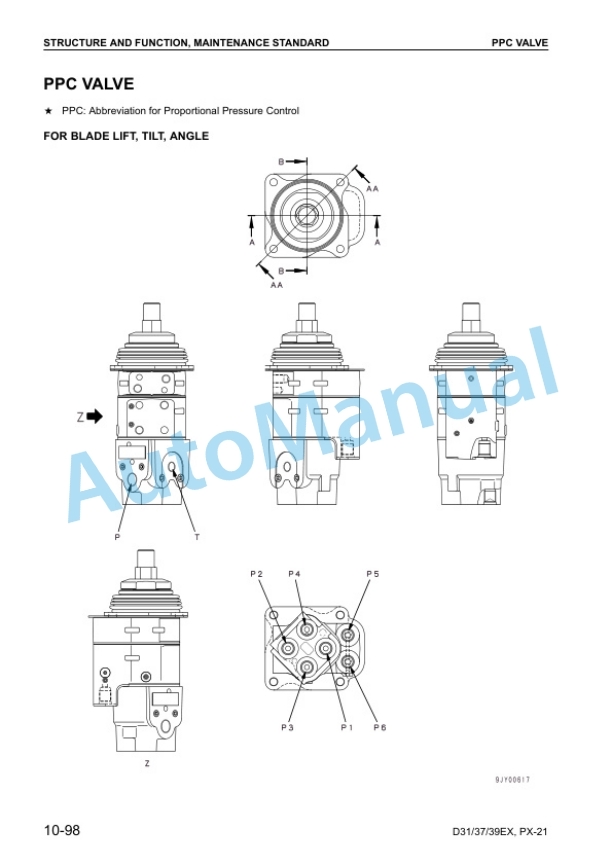

- 4.29. PPC VALVE

- 4.30. WORK EQUIPMENT

- 4.31. CUTTING EDGE, END BIT

- 4.32. RIPPER

- 4.33. CAB RELATED

- 4.34. ENGINE CONTROL

- 4.35. HST CONTROL SYSTEM

- 4.36. GEAR SHIFT CONTROL SYSTEM

- 4.37. PARING BRAKE CONTROL SYSTEM

- 4.38. COMPONENT EQUIPMENT OF SYSTEM

- 4.39. MONITOR SYSTEM

- 4.40. MONITOR PANEL

- 4.41. SENSORS

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. LIST OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.3.2. SKETCH OF SPECIAL TOOL

- 5.3.3. MEASURING ENGINE SPEED

- 5.3.4. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.3.5. MEASURING EXHAUST TEMPERATURE

- 5.3.6. MEASURING EXHAUST GAS COLOR

- 5.3.7. ADJUSTING VALVE CLEARANCE

- 5.3.8. MEASURING COMPRESSION PRESSURE

- 5.3.9. MEASURING BLOWBY PRESSURE

- 5.3.10. MEASURING ENGINE OIL PRESSURE

- 5.3.11. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.3.12. BLEEDING AIR FROM FUEL CIRCUIT

- 5.3.13. ADJUSTING ENGINE STOP SOLENOID LINKAGE

- 5.3.14. ADJUSTING ENGINE SPEED SENSOR

- 5.3.15. REPLACEMENT OF FAN BELT

- 5.3.16. TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION (WITH CAB)

- 5.3.17. ADJUSTING FUEL CONTROL LEVER AND DECELERATOR PEDAL

- 5.3.18. TESTING AND ADJUSTING HST OIL PRESSURE

- 5.3.19. MEASURING HST SOLENOID VALVE OUTLET PRESSURE

- 5.3.20. TESTING TRAVEL DEVIATION

- 5.3.21. ADJUSTING HST MOTOR SPEED SENSOR

- 5.3.22. ADJUSTING PARKING BRAKE LEVER

- 5.3.23. PROCEDURE OF SIMPLE TEST OF BRAKE PERFORMANCE

- 5.3.24. ADJUSTING BRAKE PEDAL LINKAGE

- 5.3.25. METHOD OF RELEASING PARKING BRAKE (PROCEDURE FOR EMERGENCY ESCAPE)

- 5.3.26. TESTING AND ADJUSTING IDLER CLEARANCE

- 5.3.27. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.3.28. TESTING AND ADJUSTING WORK EQUIPMENT OIL PRESSURE

- 5.3.29. MEASURING WORK EQUIPMENT PPC VALVE OUTPUT PRESSURE

- 5.3.30. ADJUSTING PLAY OF WORK EQUIPMENT PPC VALVE

- 5.3.31. ADJUSTING WORK EQUIPMENT LOCK LEVER

- 5.3.32. MEASURING LEAKAGE IN WORK EQUIPMENT CYLINDER

- 5.3.33. RELEASING RESIDUAL PRESSURE IN HYDRAULIC CIRCUIT

- 5.3.34. BLEEDING AIR FROM HYDRAULIC CIRCUIT

- 5.3.35. ADJUSTING PLAY OF BLAD CENTER BALL

- 5.3.36. PROCEDURE FOR TESTING DIODES

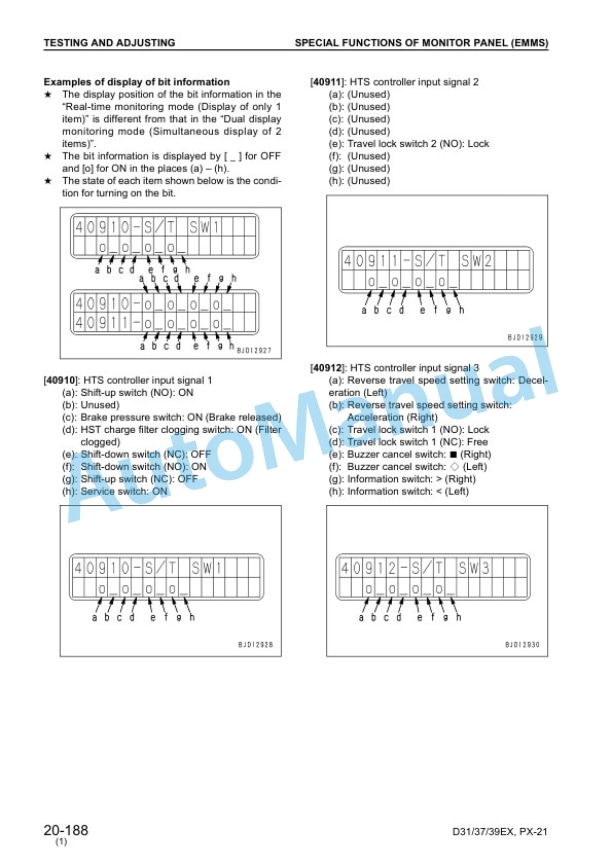

- 5.3.37. SPECIAL FUNCTIONS OF MONITOR PANEL (EMMS)

- 5.3.38. PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRIC SYSTEM

- 5.3.39. PMCLINIC

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.4.3. HANDLING OF ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENT

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CLASSIFICATION AND PROCEDURE FOR TROUBLESHOOTING

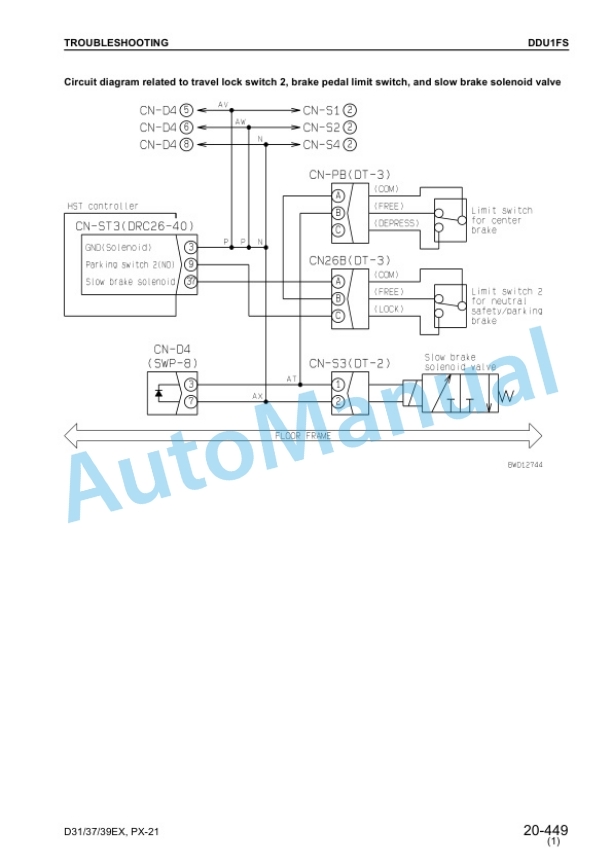

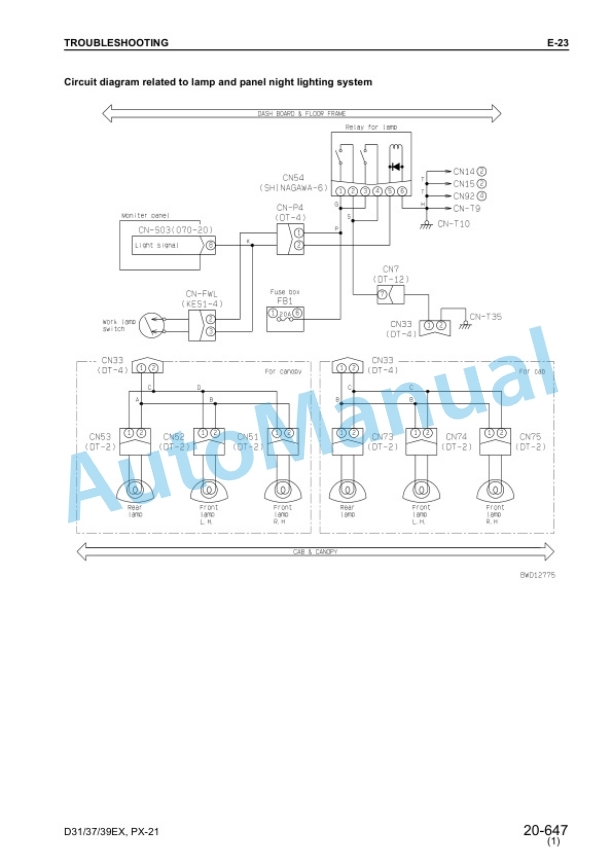

- 5.4.6. CONNECTOR ARRANGEMENT DRAWING AND ELECTRIC CIRCUIT DIAGRAM OF EACH SYSTEM

- 5.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.4.8. TBRANCH BOX AND TBRANCH ADAPTER TABLE

- 5.4.9. TROUBLESHOOTING WHEN ERROR CODE IS DISPLAYED

- 5.4.10. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 5.4.11. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 5.4.12. TROUBLESHOOTING OF ENGINE (S MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO READ THIS MANUAL

- 6.2. COATING MATERIALS LIST

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 6.6. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.7. REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL

- 6.8. REMOVAL AND INSTALLATION OF ENGINE REAR SEAL

- 6.9. REMOVAL AND INSTALLATION OF RADIATOR GUARD ASSEMBLY

- 6.10. DISASSEMBLY AND ASSEMBLY OF RADIATOR, OIL COOLER, AND CHARGE AIR COOLER ASSEMBLIES

- 6.11. REMOVAL AND INSTALLATION OF ENGINE AND HST PUMP ASSEMBLY

- 6.12. REMOVAL AND INSTALLATION OF DAMPER

- 6.13. SPREADING AND INSTALLATION OF TRACK SHOE ASSEMBLY

- 6.14. REMOVAL AND INSTALLATION OF HST MOTOR AND FINAL DRIVE ASSEMBLY

- 6.15. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 6.16. REMOVAL AND INSTALLATION OF IDLER AND RECOIL SPRING ASSEMBLY

- 6.17. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.18. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 6.19. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.20. DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 6.21. REMOVAL AND INSTALLATION OF HST PUMP ASSEMBLY

- 6.22. REMOVAL AND INSTALLATION OF MAIN CONTROL VALVE ASSEMBLY

- 6.23. DISASSEMBLY AND ASSEMBLY OF MAIN CONTROL VALVE ASSEMBLY

- 6.24. REMOVAL AND INSTALLATION OF BLADE ASSEMBLY

- 6.25. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLIES

- 6.26. REMOVAL AND INSTALLATION OF OPERATORS SEAT FRAME ASSEMBLY

- 6.27. REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY

- 6.28. REMOVAL AND INSTALLATION OF HYDRAULIC TANK ASSEMBLY

- 6.29. REMOVAL AND INSTALLATION OF HST CONTROLLER ASSEMBLY

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM(1/2)

- 7.2. HYDRAULIC CIRCUIT DIAGRAM(2/2)

- 7.3. ELECTRICAL CIRCUIT DIAGRAM(1/4)

- 7.4. ELECTRICAL CIRCUIT DIAGRAM(2/4)

- 7.5. ELECTRICAL CIRCUIT DIAGRAM(3/4)

- 7.6. ELECTRICAL CIRCUIT DIAGRAM(4/4)

- 7.7. AIR CONDITIONER CIRCUIT DIAGRAM

Rate this product

You may also like