Komatsu D475A-5 Bull Dozer Shop Manual SEBM033710

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM033710

- Format: PDF

- Size: 75.4MB

- Number of Pages: 1221

Category: Komatsu Shop Manual PDF

-

Model List:

- D475A-5 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. RADIATOR AND OIL COOLER

- 4.2. ENGINE MOUNT

- 4.3. POWER TRAIN

- 4.4. POWER TRAIN HYDRAULIC EQUIPMENT ARRANGEMENT DIAGRAM

- 4.5. DAMPER AND UNIVERSAL JOINT

- 4.6. POWER TRAIN UNIT

- 4.7. TORQUE CONVERTER AND PTO

- 4.8. TORQUE CONVERTER VALVE

- 4.9. TORQUE CONVERTER LOCKUP CONTROL SYSTEM

- 4.10. SCAVENGING PUMP

- 4.11. TRANSMISSION CONTROL

- 4.12. TRANSMISSION

- 4.13. TRANSMISSION ECMV

- 4.14. TRANSMISSION CLUTCH ECMV

- 4.15. PRIORITY VALVE

- 4.16. LUBRICATING OIL RELIEF VALVE

- 4.17. POWER TRAIN, LUBRICATION PUMP

- 4.18. STEERING, BRAKE CONTROL

- 4.19. FINAL DRIVE

- 4.20. STEERING UNIT

- 4.21. STEERING ECMV

- 4.22. STEERING CLUTCH ECMV, STEERING BRAKE ECMV

- 4.23. PARKING BRAKE VALVE

- 4.24. SUDDEN STOP PREVENTION VALVE

- 4.25. TRACK ROLLER BOGIE

- 4.26. TRACK SHOE

- 4.27. MAIN FRAME

- 4.28. SUSPENSION

- 4.29. WORK EQUIPMENT HYDRAULIC EQUIPMENT ARRANGEMENT DIAGRAM

- 4.30. PPC CONTROL PIPING DIAGRAM

- 4.31. WORK EQUIPMENT CONTROL

- 4.32. WORK EQUIPMENT PUMP

- 4.33. COOLING FAN PUMP

- 4.34. COOLING FAN MOTOR

- 4.35. PPC VALVE

- 4.36. ELECTRIC LEVER (STEERING)

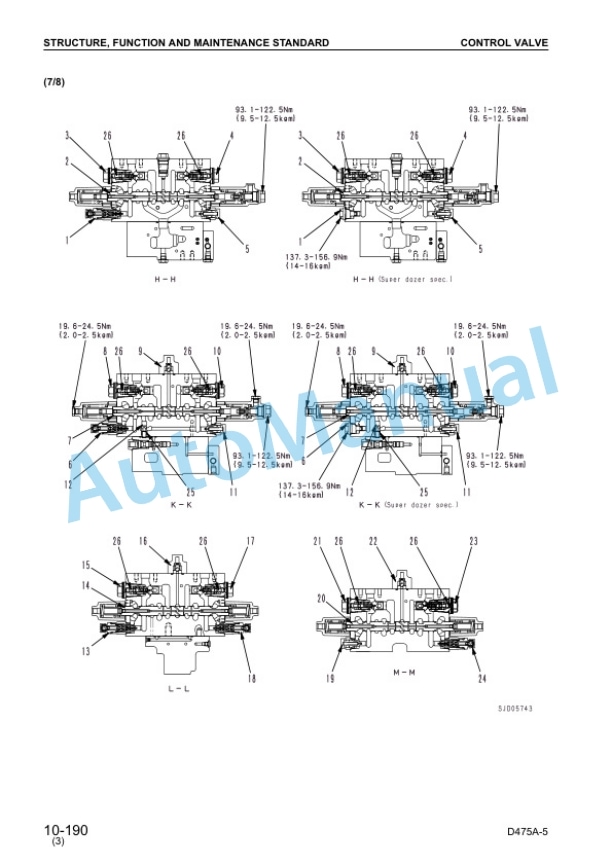

- 4.37. CONTROL VALVE

- 4.38. MAIN RELIEF VALVE

- 4.39. CLSS

- 4.40. UNLOAD VALVE

- 4.41. INTRODUCTION OF LS PRESSURE (LS SHUTTLE VALVE)

- 4.42. LS BYPASS PLUG

- 4.43. PRESSURE COMPENSATION VALVE

- 4.44. BLADE LIFT VALVE

- 4.45. MERGE DIVIDER VALVE

- 4.46. SELF PRESSURE REDUCING VALVE

- 4.47. PILOT SOLENOID VALVE

- 4.48. HYDRAULIC TANK

- 4.49. ACCUMULATOR

- 4.50. WORK EQUIPMENT CYLINDER

- 4.51. PISTON VALVE

- 4.52. QUICK DROP VALVE

- 4.53. BLADE CONTROL KNOB

- 4.54. PITCH AND DUAL SOLENOID VALVE

- 4.55. PIN PULLER HYDRAULIC CIRCUIT DIAGRAM

- 4.56. PIN PULLER SOLENOID VALVE

- 4.57. CYLINDER STAY

- 4.58. BLADE

- 4.59. RIPPER EQUIPMENT

- 4.60. CAB MOUNT

- 4.62. AIR CONDITIONER

- 4.63. ENGINE CONTROL

- 4.64. ENGINE CONTROL SYSTEM

- 4.65. DECELERATION POTENTIOMETER

- 4.66. ENGINE CONTROL SYSTEM WITH ELECTRONIC ENGINE THROTTLE CONTROLLER

- 4.67. FULE INJECTION PUMP WITH ELECTRONIC GOVERNOR

- 4.68. MONITOR SYSTEM

- 4.69. MONITOR PANEL

- 4.70. SENSORS

- 4.71. MODE SELECTION SYSTEM

- 4.72. ELECTRICAL EQUIPMENT

- 4.73. STEERING ELECTRONIC CONTROL SYSTEM

- 4.74. VHMS CONTROLLER

- 4.75. SENSORS

- 4.76. COMMUNICATION (ORB ORBCOMM) CONTROLLER/ANTENNA

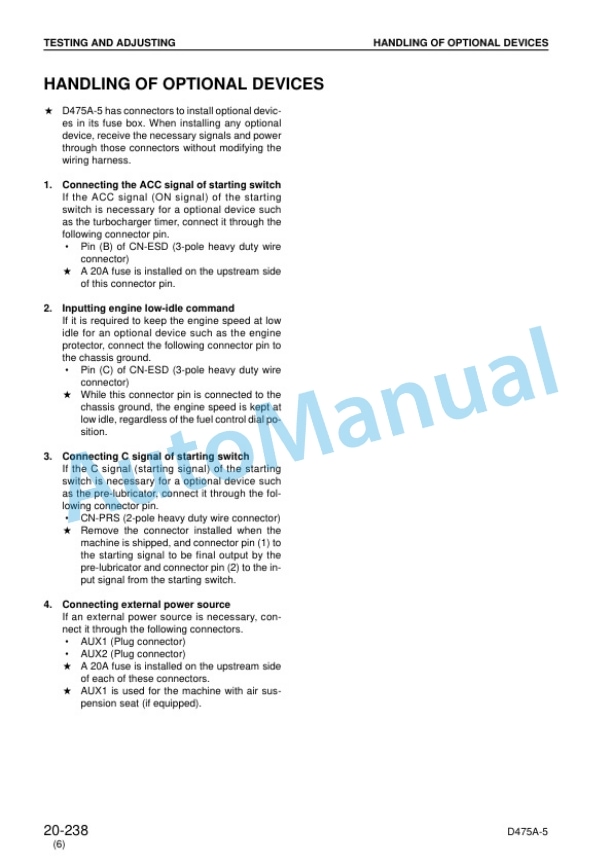

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TESTING AND ADJUSTING

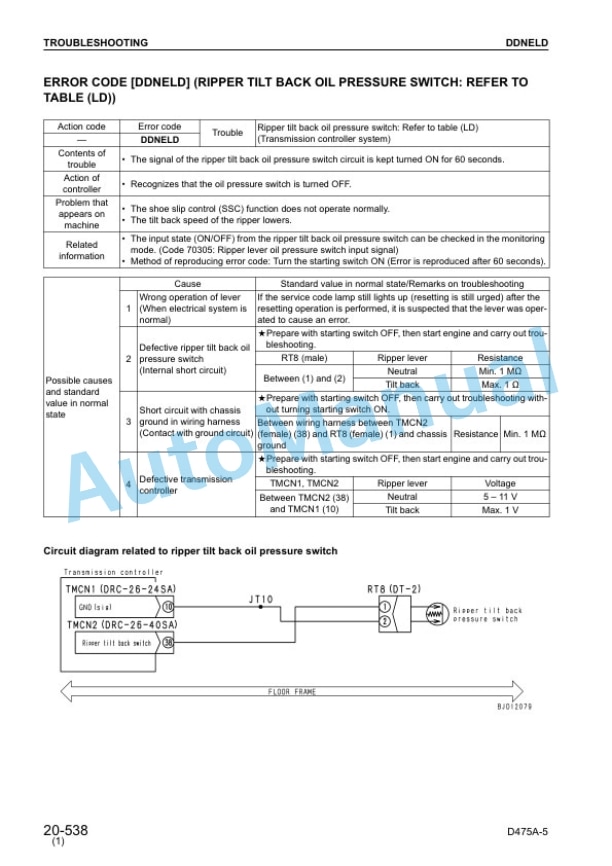

- 5.4. TROUBLESHOOTING

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. REMOVAL AND INSTALLATION OF ENGINE OIL COOLER ASSEMBLY

- 6.6. REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 6.7. REMOVAL AND INSTALLATION OF AFTERCOOLER CORE ASSEMBLY

- 6.8. REMOVAL AND INSTALLATION OF NOZZLE HOLDER ASSEMBLY

- 6.9. REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL

- 6.10. REMOVAL AND INSTALLATION OF ENGINE REAR SEAL

- 6.11. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.12. REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY

- 6.13. REMOVAL AND INSTALLATION OF MAIN RADIATOR ASSEMBLY

- 6.14. REMOVAL AND INSTALLATION OF SUB RADIATOR ASSEMBLY

- 6.15. REMOVAL AND INSTALLATION OF RADIATOR GUARD ASSEMBLY

- 6.16. REMOVAL AND INSTALLATION OF FAN MOTOR PUMP

- 6.17. REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY

- 6.18. REMOVAL AND INSTALLATION OF DAMPER ASSEMBLY

- 6.19. DISASSEMBLY AND ASSEMBLY OF DAMPER ASSEMBLY

- 6.20. REMOVAL AND INSTALLATION OF POWER TRAIN UNIT ASSEMBLY

- 6.21. REMOVAL AND INSTALLATION OF PTO, TORQUE CONVERTER ASSEMBLY

- 6.22. DISCONNECTION AND CONNECTION OF PTO, TORQUE CONVERTER ASSEMBLY

- 6.23. DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY

- 6.24. DISASSEMBLY AND ASSEMBLY OF PTO ASSEMBLY

- 6.25. REMOVAL AND INSTALLATION OF TORQFLOW TRANSMISSION ASSEMBLY

- 6.26. DISASSEMBLY AND ASSEMBLY OF TORQFLOW TRANSMISSION ASSEMBLY

- 6.27. DISASSEMBLY AND ASSEMBLY OF STEERING CASE ASSEMBLY

- 6.28. DISASSEMBLY AND ASSEMBLY OF STEERING CLUTCH, BRAKE ASSEMBLY

- 6.29. DISASSEMBLY AND ASSEMBLY OF TRANSFER GEAR HOUSING ASSEMBLY

- 6.30. REMOVAL AND INSTALLATION OF POWER TRAIN PUMP ASSEMBLY

- 6.31. REMOVAL AND INSTALLATION OF SCAVENGING PUMP ASSEMBLY

- 6.32. REMOVAL AND INSTALLATION OF TORQUE CONVERTER OIL COOLER

- 6.33. REMOVAL AND INSTALLATION OF TORQUE CONVERTER VALVE ASSEMBLY

- 6.34. DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER VALVE ASSEMBLY

- 6.35. REMOVAL AND INSTALLATION OF TRANSMISSION CONTROL VALVE ASSEMBLY

- 6.36. DISASSEMBLY AND ASSEMBLY OF TRANSMISSION CONTROL VALVE ASSEMBLY (ECMV ASSEMBLY)

- 6.37. REMOVAL AND INSTALLATION OF STEERING CONTROL VALVE ASSEMBLY

- 6.38. DISASSEMBLY AND ASSEMBLY OF STEERING CONTROL VALVE ASSEMBLY

- 6.39. REMOVAL AND INSTALLATION OF FINAL DRIVE ASSEMBLY

- 6.40. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 6.41. REMOVAL AND INSTALLATION OF TRACK FRAME ASSEMBLY

- 6.42. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 6.43. REMOVAL AND INSTALLATION OF RECOIL SPRING ASSEMBLY

- 6.44. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.45. REMOVAL AND INSTALLATION OF TRACK ROLLER ASSEMBLY

- 6.46. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.47. REMOVAL AND INSTALLATION OF CARRIER ROLLER ASSEMBLY

- 6.48. DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 6.49. REMOVAL AND INSTALLATION OF BOGIE ASSEMBLY

- 6.50. DISASSEMBLY AND ASSEMBLY OF BOGIE ASSEMBLY

- 6.51. REMOVAL AND INSTALLATION OF NO.1 BOGIE ASSEMBLY

- 6.52. EXPANSIO AND INSTALLATION OF TRACK SHOE ASSEMBLY

- 6.53. OVERALL DISASSEMBLY AND OVERALL ASSEMBLY OF TRACK SHOE

- 6.54. PRESSFITTING JIG DIMENSION TABLE FOR LINK PRESS

- 6.55. FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK

- 6.56. DISASSEMBLY AND ASSEMBLY OF MASTER LINK

- 6.57. REMOVAL AND INSTALLATION OF PIVOT SHAFT ASSEMBLY

- 6.58. REMOVAL AND INSTALLATION OF EQUALIZER BAR

- 6.59. DISASSEMBLY AND ASSEMBLY OF EQUALIZER BAR BUSHING

- 6.60. REMOVAL AND INSTALLATION OF HYDRAULIC PUMP ASSEMBLY

- 6.61. REMOVAL AND INSTALLATION OF HYDRAULIC VALVE ASSEMBLY

- 6.62. DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE

- 6.63. DISASSEMBLY AND ASSEMBLY OF MERGE DIVIDER VALVE AND SELF PRESSURE REDUCING VALVE ASSEMBLY

- 6.64. REMOVAL AND INSTALLATION OF PPC RELIEF VALVE ASSEMBLY

- 6.65. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 6.66. DISASSEMBLY AND ASSEMBLY OF RIPPER PIN PULLER CYLINDER ASSEMBLY

- 6.67. REMOVAL AND INSTALLATION OF BLADE ASSEMBLY

- 6.68. DISASSEMBLY AND ASSEMBLY OF GIANT RIPPER ASSEMBLY

- 6.69. REMOVAL AND INSTALLATION OF ROPS GUARD

- 6.70. REMOVAL AND INSTALLATION OF OPERATORS CAB ASSEMBLY

- 6.71. REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY

- 6.72. REMOVAL AND INSTALLATION OF CONTROLLER ASSEMBLY

- 6.73. REMOVAL AND INSTALLATION OF AIR CONDITIONER CONDENSER ASSEMBLY

- 6.74. REMOVAL AND INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY

- 6.75. REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT

- 6.76. REMOVAL AND INSTALLATION OF HOOD ASSEMBLY

- 6.77. REMOVAL AND INSTALLATION OF FAN DRIVE ASSEMBLY

- 6.78. REMOVAL AND INSTALLATION OF FAN MOTOR ASSEMBLY

- 7. OTHERS

- 7.1. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 7.2. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (1/3)

- 7.3. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (2/3)

- 7.4. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (3/3)

- 7.5. ELECTRICAL CIRCUIT DIAGRAM (1/8)

- 7.6. ELECTRICAL CIRCUIT DIAGRAM (2/8)

- 7.7. ELECTRICAL CIRCUIT DIAGRAM (3/8)

- 7.8. ELECTRICAL CIRCUIT DIAGRAM (4/8)

- 7.9. ELECTRICAL CIRCUIT DIAGRAM (5/8)

- 7.10. ELECTRICAL CIRCUIT DIAGRAM (6/8)

- 7.11. ELECTRICAL CIRCUIT DIAGRAM (7/8)

- 7.12. ELECTRICAL CIRCUIT DIAGRAM (8/8)

- 7.13. ELECTRICAL CIRCUIT DIAGRAM OF INSIDE CAB

Rate this product

You may also like