Komatsu D575A-2 Bull Dozer Shop Manual SEBM015600K

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM015600K

- Format: PDF

- Size: 23.1MB

- Number of Pages: 154

Category: Komatsu Shop Manual PDF

-

Model List:

- D575A-2 Bull Dozer

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. COATING MATERIALS

- 0.4. STANDARD TIGHTENING TORQUE

- 0.5. ELECTRIC WIRE CODE

- 0.6. CONVERSION TABLE

- 1. STRUCTURE AND FUNCTION

- 1.1. TRANSMISSION CONTROL

- 1.2. STEERING CLUTCH, BRAKE CONTROL

- 1.3. HYDRAULIC CIRCUIT SCHEMATICS FOR COOLING FAN DRIVE WORK EQUIPMENT

- 1.4. HYDRAULIC CIRCUIT DIAGRAM FOR COOLING FAN DRIVE AND WORK EQUIPMENT

- 1.5. OPERATION OF WORK EQUIPMENT CONTROL CIRCUIT

- 1.6. WORK EQUIPMENT EPC VALVE

- 1.7. RIPPER SSC CONTROLLER (LE TYPE)

- 1.8. BLADE CONTROLLER (LX TYPE)

- 1.9. ACTUAL ELECTRIC WIRING DIAGRAM (1/2)

- 1.9.1. ACTUAL ELECTRIC WIRING DIAGRAM (1/2)ACTUAL ELECTRIC WIRING DIAGRAM (2/2)

- 1.10. ELECTRICAL CIRCUIT DIAGRAM (1/3)

- 1.10.1. ELECTRICAL CIRCUIT DIAGRAM (2/3)

- 1.10.2. ELECTRICAL CIRCUIT DIAGRAM (3/3)

- 1.11. ENGINE STARTING SYSTEM

- 1.12. MODE SELECTION SYSTEM

- 1.13. ENGINE CONTROL SYSTEM

- 1.14. ELPC CONTROLLER

- 1.15. ELPC ACTUATOR

- 1.16. FUEL CONTROL DIAL

- 2. TESTING AND ADJUSTING

- 2.1. TESTING AND ADJUSTING ELPC VALVE POTENTTIOMETER

- 2.2. ADJUSTING FUEL CONTROL

- 2.3. PROCEDURE FOR CLEARING MEMORY

- 2.4. TROUBLESHOOTING

- 2.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 2.4.4. CHECKS BEFORE TROUBLESHOOTING

- 2.4.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 2.4.6. CONNECTOR ARRANGEMENT DIAGRAM (1/3)

- 2.4.6.1. CONNECTOR ARRANGEMENT DIAGRAM (2/3)

- 2.4.6.2. CONNECTOR ARRANGEMENT DIAGRAM (3/3)

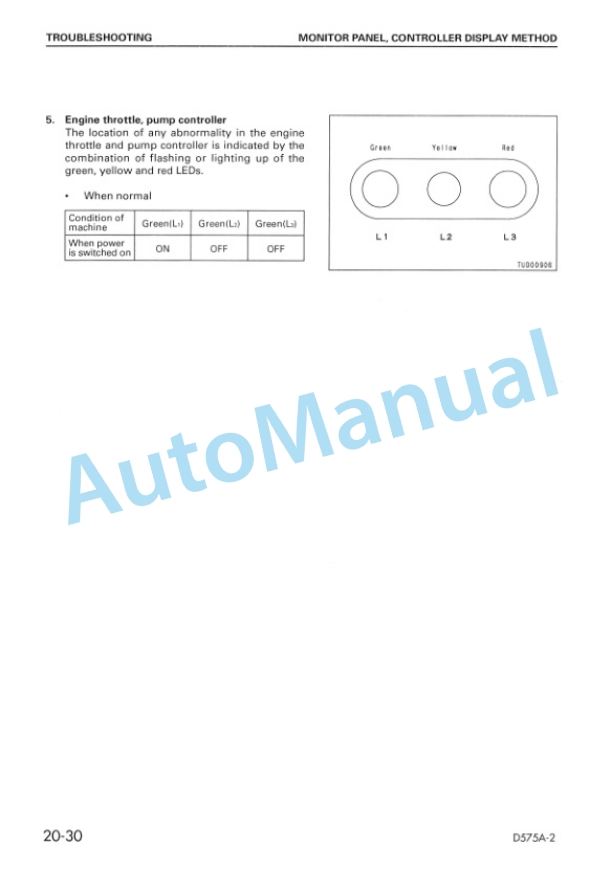

- 2.4.7. MONITOR PANEL, CONTROLLER DISPLAY METHOD

- 2.4.8. EMERGENCY SWITCH

- 2.4.9. ENGINE SYSTEM TROUBLESHOOTING

- 2.4.10. MONTOR AND MISCELLANEOUS TROUBLESHOOTING

- 2.4.11. POWER SOURCE TROUBLESHOOTING

- 2.4.12. BLADE SYSTEM TROUBLESHOOTING

- 2.4.13. RIPPER SYSTEM TROUBLESHOOTING

- 2.4.14. ERROR CODE TABLE

- 3. MAINTENANCE STANDARD

- 3.1. EPC SOLENOID VALVE

- 3.2. WORK EQUIPMENT CYLINDER

- 3.3. VARIABLE MULTIPLE LONG SHANK RIPPER

- 4. OTHERS

- 4.1. ELECTRIC CIRCUIT DIAGRAM (1/3)

- 4.2. ELECTRIC CIRCUIT DIAGRAM (2/3)

- 4.3. ELECTRIC CIRCUIT DIAGRAM (3/3)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00