Komatsu D575A-2 Super Dozer Shop Manual SEBM006506

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM006506

- Format: PDF

- Size: 50.4MB

- Number of Pages: 812

Category: Komatsu Shop Manual PDF

-

Model List:

- D575A-2 Super Dozer

- 1. MAIN MENU

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. RADIATOR, OIL COOLER, COOLING FAN

- 4.2. FUEL PIPING DRAWING

- 4.3. ENGINE CONTROL

- 4.4. INLINE SERVO VALVE

- 4.5. POWER TRAIN SYSTEM

- 4.6. POWER TRAIN SKELTON

- 4.7. POWER TRAIN HYDRAULIC PIPING

- 4.8. POWER TRAIN HYDRAULIC CIRCUIT SCHEMATICS

- 4.9. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 4.10. DAMPER

- 4.11. TORQUE CONVERTER, PTO

- 4.12. TORQUE CONVERTER VALVE

- 4.13. TORQUE CONVERTER FILTER

- 4.14. TRANSMISSION CONTROL

- 4.15. TRANSMISSION

- 4.16. TRANSMISSION CONTROL VALVE

- 4.17. STEERING CLUTCH, BRAKE CONTROL

- 4.18. STEERING CONTROL VALVE

- 4.19. STEERING CLUTCH, STEERING BRAKE

- 4.20. FINAL DRIVE

- 4.21. TRACK FRAME

- 4.22. RECOIL SPRING

- 4.23. TRACK ROLLER BOGIE

- 4.24. SUSPENSION

- 4.25. HYDRAULIC PIPING DIAGRAM FOR WORK EQUIPMENT

- 4.26. CENTRALIZED OIL PRESSURE DETECTION PIPING DIAGRAM

- 4.27. HYDRAULIC CIRCUIT SCHEMATICS FOR WORK EQUIPMENT

- 4.28. HYDRAULIC CIRCUIT DIAGRAM FOR WORK EQUIPMENT

- 4.29. HYDRAULIC TANK

- 4.30. ACCUMULATOR FOR WORK EQUIPMENT CIRCUIT

- 4.31. PITCH, TILT SELECTOR SOLENOID VALVE ASSEMBLY

- 4.32. PITCH BACK (PITCH DUMP) SOLENOID VALVE

- 4.33. PPC VALVE

- 4.34. ACCUMULATOR FOR PPC CIRCUIT

- 4.35. PPC RELIEF VALVE

- 4.36. MAIN CONTROL VALVE

- 4.37. PITCH SELECTOR SOLENOID VALVE

- 4.38. PITCH PRIORITY SOLENOID VALVE

- 4.39. PITCH ASSIST SOLENOID VALVE

- 4.40. BLADE CONTROL KNOB

- 4.41. PISTON VALVE FOR BLADE LIFT CYLINDER

- 4.42. QUICK DROP VALVE FOR BLADE LIFT CYLINDER

- 4.43. OPERATION OF WORK EQUIPMENT CONTROL CIRCUIT

- 4.44. CYLINDER STAY, YOKE

- 4.45. WORK EQUIPMENT

- 4.46. COUNTERWEIGHT

- 4.48. AIR CONDITIONER

- 4.49. ACTUAL ELECTRIC WIRING DIAGRAM

- 4.50. ELECTRICAL CIRCUIT DIAGRAM

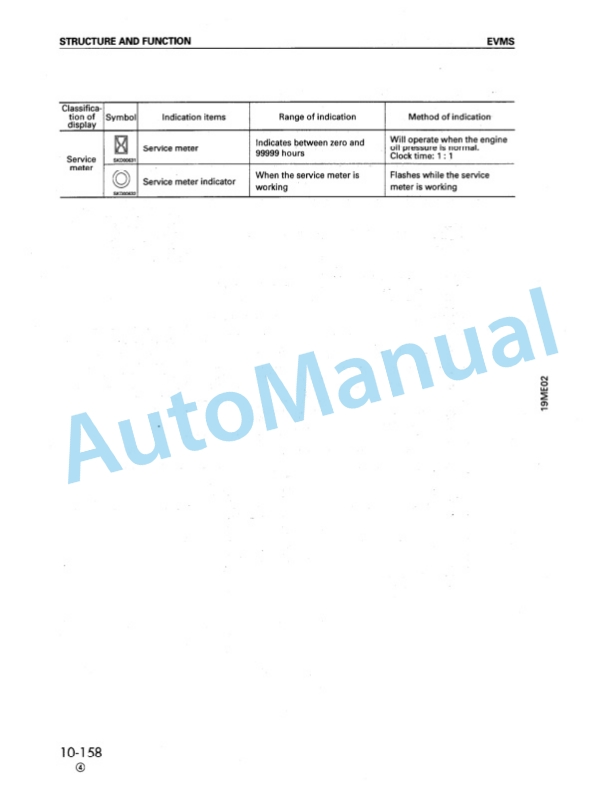

- 4.51. EVMS (Electronic Vehicle Monitoring System)

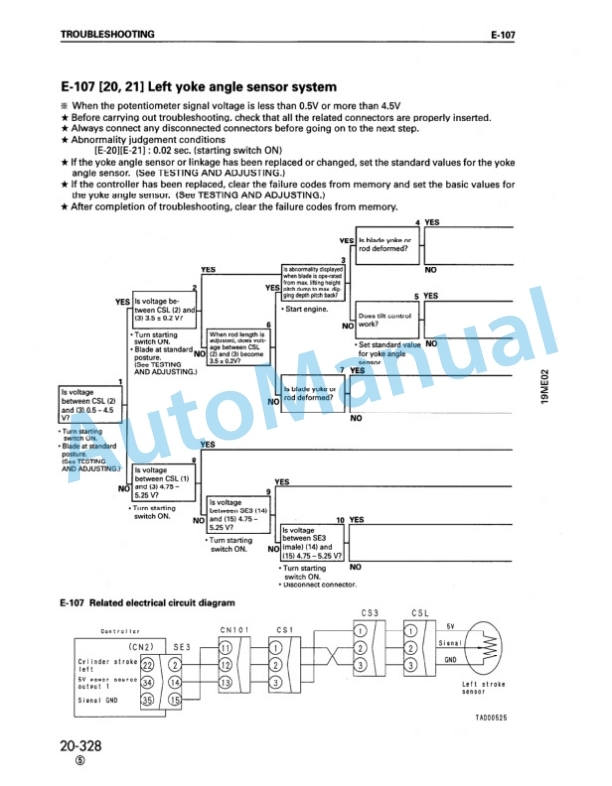

- 4.52. TORQUE CONVERTER LOCKUP, BLADE CONTROL SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS

- 5.4. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.5. ADJUSTING VALVE CLEARANCE

- 5.6. MEASURING COMPRESSION PRESSURE

- 5.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.8. ADJUSTING FUEL INJECTION PUMP RACK LINKAGE

- 5.9. MEASURING ENGINE OIL PRESSURE

- 5.10. MEASURING ENGINE SPEED

- 5.11. MEASURING EXHAUST COLOR

- 5.12. TESTING AND ADJUSTING FAN BELT TENSION

- 5.13. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.14. MEASURING EXHAUST TEMPERATURE

- 5.15. MEASURING BLOWBY

- 5.16. MEASURING COOLING FAN SPEED

- 5.17. MEASURING TORQUE CONVERTER STALL SPEED

- 5.18. MEASURING SPEED AT TORQUE CONVERTER STALL HYDRAULIC PUMP RELIEF (FULL STALL)

- 5.19. MEASURING POWER TRAIN OIL PRESSURE

- 5.20. PROCEDURE FOR SIMPLE TEST OF STEERING BRAKE PERFORMANCE

- 5.21. PROCEDURE FOR RELEASING STEERING BREAK

- 5.22. TESTING AND ADJUSTING WORK EQUIPMENT CIRCUIT PRESSURE (MAIN RELIEF AND PPC CIRCUIT)

- 5.23. MEASURING PPC VALVE OUTPUT PRESSURE

- 5.24. ADJUSTING WORK EQUIPMENT, PPC VALVE

- 5.25. RELEASING AIR REMAINING IN HYDRAULIC CIRCUIT ON PPC VALVE

- 5.26. BLEEDING AIR FROM HYDRAULIC CYLINDER

- 5.27. CHECKING LOCATION OF CAUSE OF HYDRAULIC DRIFT OF BLADE

- 5.28. MEASURING LEAKAGE INSIDE CYLINDER

- 5.29. ADJUSTING FUEL CONTROL LINKAGE

- 5.30. ADJUSTMENT OF GEARSHIFT LEVER LINKAGE

- 5.31. ADJUSTMENT OF STEERING LEVER LINKAGE

- 5.32. ADJUSTMENT OF BRAKE PEDAL LINKAGE

- 5.33. PROCEDURE FOR TESTING SENSORS

- 5.34. TROUBLESHOOTING

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. STARTING MOTOR

- 6.5. ALTERNATOR

- 6.6. ENGINE OIL COOLER

- 6.7. FUEL INJECTION PUMP

- 6.8. WATER PUMP

- 6.9. TURBOCHARGER

- 6.10. AFTERCOOLER CORE

- 6.11. POWER TRAIN OIL COOLER

- 6.12. HYDRAULIC COOLER

- 6.13. RADIATOR

- 6.14. FAN DRIVE SUPPORT

- 6.15. FAN DRIVE PULLEY

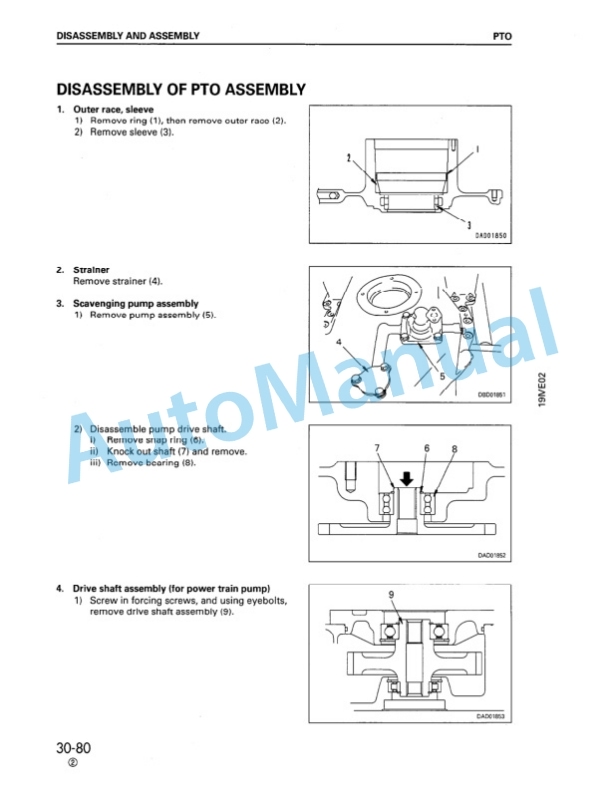

- 6.16. PTO, TORQUE CONVERTER

- 6.18. TORQUE CONVERTER

- 6.19. TORQFLOW TRANSMISSION

- 6.20. STEERING CLUTCH

- 6.21. STEERING BRAKE

- 6.22. TORQUE CONVERTER VALVE

- 6.23. TRANSMISSION CONTROL VALVE

- 6.24. STEERING CONTROL VALVE

- 6.25. POWER TRAIN PUMP

- 6.26. TRANSMISSION LUBRICATION PUMP

- 6.27. SCAVENGING PUMP

- 6.28. FINAL DRIVE

- 6.29. TRACK FRAME

- 6.30. RECOIL SPRING, TUBE

- 6.31. IDLER YOKE, CYLINDER

- 6.32. PRESSFITTING JIG DIMENSION TABLE FOR LINK PRESS

- 6.33. FIELD DISASSEMBLY OF ONE LINK

- 6.34. MASTER LINK

- 6.35. ADJUSTING TRACK SHOE TENSION

- 6.36. WORK EQUIPMENT PUMP

- 6.37. WORK EQUIPMENT ASSIST, CONTROL PUMP

- 6.38. BLADE VALVE

- 6.39. MAIN RELIEF VALVE

- 6.40. BLADE LIFT CYLINDER

- 6.41. BLADE PITCH CYLINDER

- 6.42. HYDRAULIC CYLINDER

- 6.43. BLADE PPC VALVE

- 6.44. OPERATORS COMPARTMENT FRAME

- 6.46. ROPS

- 6.47. COUNTERWEIGHT. FRAME

- 6.48. BLADE LIFT CYLINDER SUPPORT

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.2. DAMPER

- 7.3. TORQUE CONVERTER, PTO

- 7.4. TORQUE CONVERTER VALVE

- 7.5. TRANSMISSION

- 7.6. TRANSMISSION CONTROL VALVE

- 7.7. STEERING CONTROL VALVE

- 7.8. STEERING CLUTCH, STEERING BRAKE

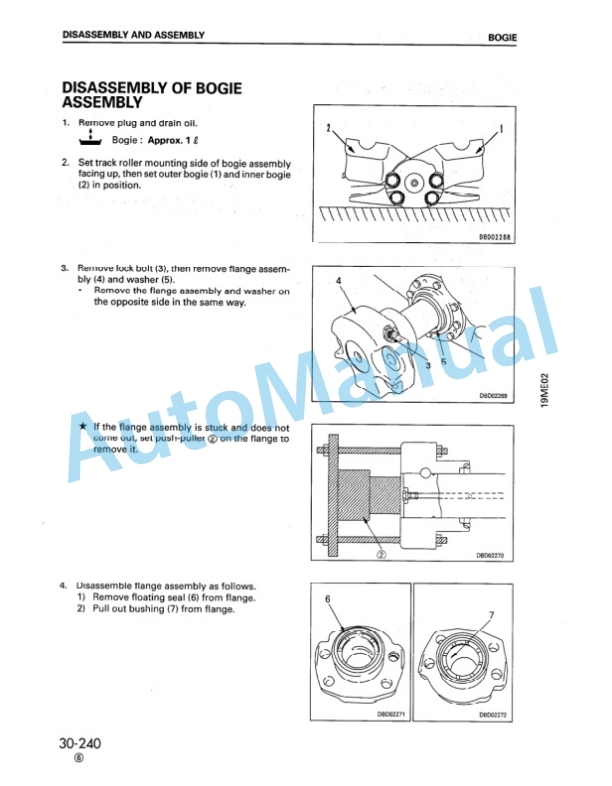

- 7.9. TRACK ROLLER BOGIE

- 7.10. TRACK SHOE

- 7.11. SUSPENSION

- 7.12. HYDRAULIC PUMP

- 7.13. PPC VALVE

- 7.14. MAIN CONTROL VALVE

- 7.15. WORK EQUIPMENT CYLINDER

- 7.16. CYLINDER STAY, YOKE

- 7.17. MAIN FRAME

- 7.18. WORK EQUIPMENT

- 7.19. COUNTERWEIGHT

- 8. OTHERS

- 8.1. POWER TRAIN HYDRAULIC PIPING

- 8.2. POWER TRAIN HYDRAULIC CIRCUIT SCHEMATICS

- 8.3. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 8.4. TRANSMISSION

- 8.5. HYDRAULIC PIPING DIAGRAM FOR WORK EQUIPMENT

- 8.6. HYDRAULIC CIRCUIT SCHEMATICS FOR WORK EQUIPMENT

- 8.7. HYDRAULIC CIRCUIT DIAGRAM FOR WORK EQUIPMENT

- 8.8. OPERATION OF WORK EQUIPMENT CONTROL CIRCUIT

- 8.9. AIR CONDITIONER

- 8.10. ACTUAL ELECTRICAL WIRING DIAGRAM (1/2)

- 8.11. ACTUAL ELECTRICAL WIRING DIAGRAM (2/2)

- 8.12. ELECTRICAL CIRCUIT DIAGRAM

- 8.13. AIR CONDITIONER ELECTRICAL CIRCUIT

- 8.14. TORQUE CONVERTER LOCKUP, BLADE CONTROL SYSTEM

- 8.15. LOCATION OF CONNECTOR, SENSOR

- 8.16. ELECTRICAL CIRCUIT DIAGRAM FOR WORK EQUIPMENT, LOCKUP CONTROLLER SYSTEM

- 8.17. ELECTRICAL CIRCUIT DIAGRAM FOR MONITOR SYSTEM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00