Komatsu D85A-21, D85E-21, D85P-21 Shop Manual SEBM01542110

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM01542110

- Format: PDF

- Size: 73.6MB

- Number of Pages: 676

Category: Komatsu Shop Manual PDF

-

Model List:

- D85A-21

- D85E-21

- D85P-21

- 1. MAIN MENU

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 4. ENGINE

- 4.1. TESTING AND ADJUSTING

- 4.1.1. STANDARDS FOR TESTING AND ADJUSTING

- 4.1.2. TESTING AND ADJUSTING TOOL LIST

- 4.1.3. ADJUSTING VALVE CLEARANCE

- 4.1.4. MEASURING COMPRESSION PRESSURE

- 4.1.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 4.1.6. MEASURING BLOWBY

- 4.1.7. MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)

- 4.1.8. MEASURING EXHAUST COLOR

- 4.1.9. MEASURING EXHAUST TEMPERATURE

- 4.1.10. MEASURING ENGINE OIL PRESSURE

- 4.1.11. MEASURING ENGINE SPEED

- 4.1.12. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 4.1.13. TROUBLESHOOTING

- 4.2. DISASSEMBLY AND ASSEMBLY

- 4.2.1. METHOD OF USING MANUAL

- 4.2.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 4.2.3. SPECIAL TOOL LIST

- 4.2.4. FUEL INJECTION PUMP

- 4.2.5. ENGINE OIL COOLER

- 4.2.6. D85A, E21 Serial No. 36534 and up, D85P21 Serial No. 3689 and up

- 4.2.7. AIR CONDITIONER COMPRESSOR

- 4.2.8. ENGINE OIL COOLER

- 4.2.9. WATER PUMP

- 4.2.10. FUEL INJECTION PUMP

- 4.2.11. ENGINE FRONT SEAL

- 4.2.12. ENGINE REAR SEAL

- 4.2.13. CYLINDER HEAD

- 4.2.14. RADIATOR, POWER TRAIN OIL COOLER

- 4.3. STRUCTURE AND FUNCTION

- 4.3.1. GENERAL

- 4.3.2. POWER TRAIN

- 4.3.3. POWER TRAIN HYDRAULIC PIPING

- 4.3.4. POWER TRAIN HYDRAULIC SYSTEM

- 4.3.5. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 4.3.6. TORQUE CONVERTER

- 4.3.7. TORQFLOW TRANSMISSION

- 4.3.8. TRANSMISSION CONTROL

- 4.3.9. TRANSMISSION CONTROL VALVE

- 4.3.10. TRANSMISSION LUBRICATION VALVE

- 4.3.11. TRANSMlSSlON PUMP

- 4.3.12. TRANSMISSION AND STEERING OIL STRAINER

- 4.3.13. TRANSMISSION AND STEERING OIL FILTER

- 4.3.14. BEVEL GEAR SHAFT AND STEERING CLUTCH

- 4.3.15. STEERING CONTROL

- 4.3.16. STEERING PUMP

- 4.3.17. STEERING MAIN RELIEF VALVE

- 4.3.18. STEERING AND BRAKE CONTROL VALVE

- 4.3.19. STEERING BRAKE

- 4.3.20. FINAL DRIVE

- 4.4. TESTING AND ADJUSTING

- 4.4.1. STANDARDS FOR TESTING AND ADJUSTING

- 4.4.2. TESTING AND ADJUSTING TOOL LIST

- 4.4.3. MEASURING TORQUE CONVERTER STALL SPEED

- 4.4.4. MEASURING OIL PRESSURE

- 4.4.5. ADJUSTING FUEL CONTROL LINKAGE

- 4.4.6. ADJUSTING GEAR SHIFT LEVER LINKAGE

- 4.4.7. ADJUSTING STEERING CLUTCH LINKAGE

- 4.4.8. ADJUSTING TRAVEL OF BRAKE PEDAL

- 4.4.9. ADJUSTING BRAKE PEDAL LINKAGE

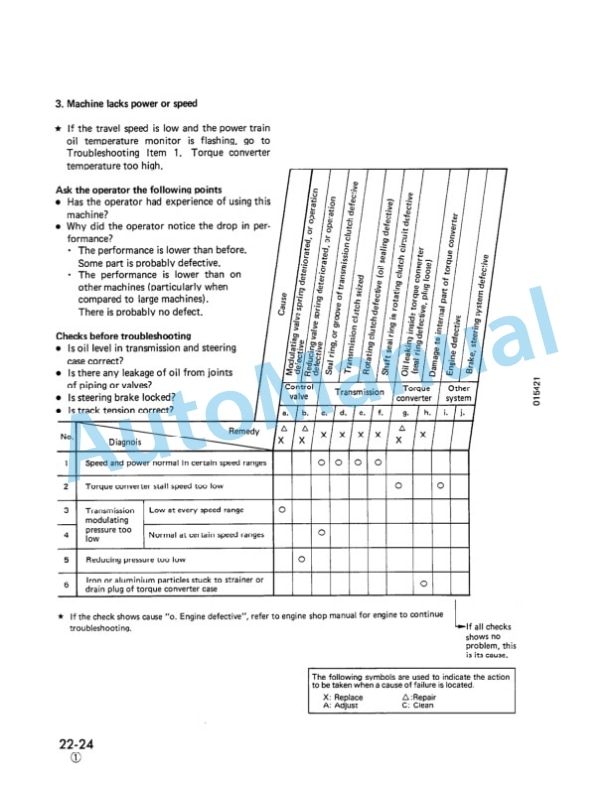

- 4.4.10. TROUBLESHOOTING

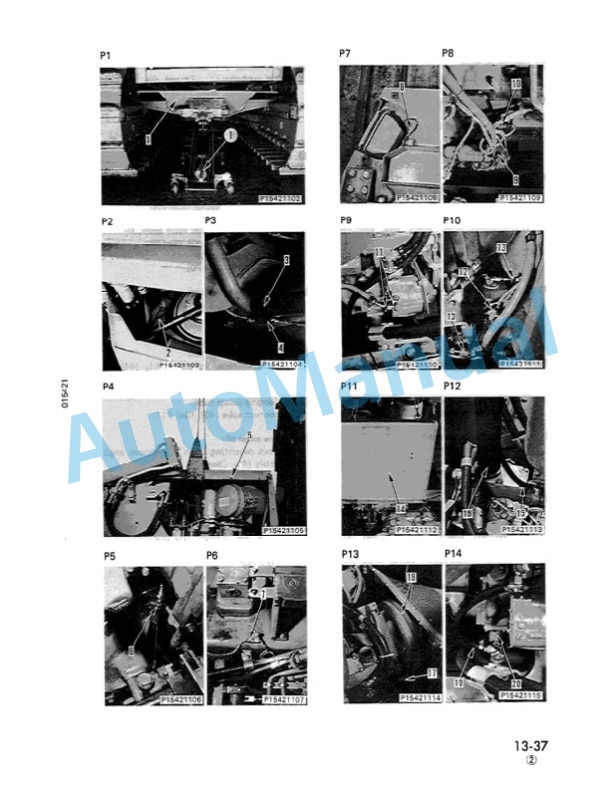

- 4.5. DISASSEMBLY AND ASSEMBLY

- 4.5.1. METHOD OF USING MANUAL

- 4.5.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 4.5.3. TORQUE CONVERTER

- 4.5.4. TORQUE CONVERTER RELIEF VALVE

- 4.5.5. TORQUE CONVERTER REGULATOR VALVE

- 4.5.6. TRANSMISSION CONTROL VALVE

- 4.5.7. TRANSMISSION LUBRICATION VALVE

- 4.5.8. BEVEL GEAR AND SHAFT

- 4.5.9. STEERING CLUTCH

- 4.5.10. BRAKE BOOSTER

- 4.5.11. STEERING RELIEF VALVE

- 4.5.12. STEERING BRAKE VALVE

- 4.5.13. TRANSMISSION PUMP

- 4.6. MAINTENANCE STANDARD

- 4.6.1. TORQUE CONVERTER

- 4.6.2. TORQFLOW TRANSMISSON

- 4.6.3. TRANSMISSION CONTROL VALVE

- 4.6.4. TRANSMISSION LUBRICATION VALVE

- 4.6.5. TRANSMISSION PUMP

- 4.6.6. BEVEL GEAR SHAFT

- 4.6.7. STEERING CLUTCH

- 4.6.8. STEERING PUMP

- 4.6.9. STEERING MAIN RELI EF VALVE

- 4.6.10. STEERING AND BRAKE CONTROL VALVE

- 4.6.11. STEERING BRAKE

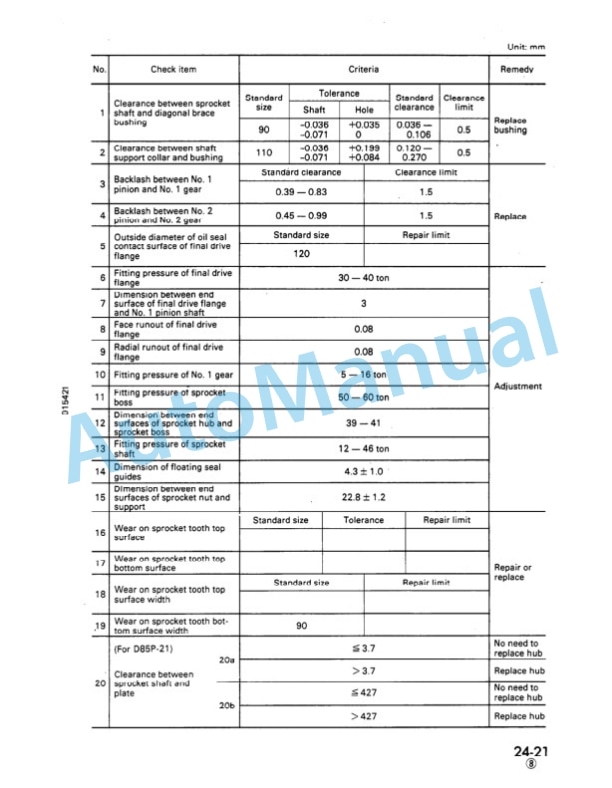

- 4.6.12. FINAL DRIVE

- 5. UNDERCARRIAGE

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. TRACK

- 5.1.2. TRACK GROUP

- 5.1.3. IDLER

- 5.1.4. IDLER CUSHION

- 5.1.5. TRACK ROLLER AND CARRIER ROLLER

- 5.1.6. SUSPENSION

- 5.2. DISASSEMBLY AND ASSEMBLY

- 5.2.1. METHOD OF USING MANUAL

- 5.2.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 5.2.3. CARRIER ROLLER

- 5.2.4. TRACK SHOE

- 5.2.5. TRUCK LINK

- 5.3. MAINTENANCE STANDARD

- 6. HYDRAULIC SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. HYDRAULIC PIPING

- 6.1.2. HYDRAULIC CONTROL

- 6.1.3. HYDRAULIC SYSTEM

- 6.1.4. HYDRAULIC CIRCUIT DIAGRAM

- 6.1.5. HYDRAULIC TANK

- 6.1.6. HYDRAULIC PUMP

- 6.1.7. BLADE CONTROL VALVE

- 6.1.8. HYDRAULIC LEVER OPERATION

- 6.1.9. HYDRAULIC CYLINDER

- 6.1.10. CYLINDERS STAY (D85A. E21)

- 6.1.11. CYLINDER YOKE (D85P21)

- 6.2. TESTING AND ADJUSTING

- 6.2.1. STANDARDS FOR TESTING AND ADJUSTING

- 6.2.2. TESTING AND ADJUSTING TOOL LIST

- 6.2.3. MEASURING OIL PRESSURE

- 6.2.4. ADJUSTING BLADE CONTROL LINKAGE

- 6.2.5. ADJUSTING RIPPER CONTROL LINKAGE

- 6.2.6. TROUBLESHOOTING

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. METHOD OF USING MANUAL

- 6.3.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3.3. HYDRAULIC PUMP

- 6.3.4. BLADE CONTROL VALVE

- 6.3.5. RIPPER CONTROL VALVE

- 6.3.6. BLADE LIFT CYLINDER

- 6.3.7. BLADE TILT CYLINDER

- 6.3.8. RIPPER CYLINDER

- 6.3.9. HYDRAULIC CYLINDER

- 6.3.10. BLADE RELIEF VALVE

- 6.3.11. RIPPER RELIEF VALVE

- 6.4. MAINTENANCE STANDARD

- 6.4.1. HYDRAULIC CONTROL VALVE

- 6.4.2. HYDRAULIC CYLINDER

- 6.4.3. CYLINDER STAY (D85A, E21)

- 6.4.4. CYLINDER YOKE (D85P21)

- 6.4.5. HYDRAULIC PUMP

- 7. WORK EQUIPMENT

- 7.1. DISASSEMBLY AND ASSEMBLY

- 7.1.1. METHOD OF USING MANUAL

- 7.1.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 7.2. MAINTENANCE STANDARD

- 7.2.1. STRAIGHT TILTDOZER

- 7.2.2. FIXED MULTISHANK RIPPER

- 8. ELECTRICAL SYSTEM

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. ELECTRICAL WIRING DIAGRAM

- 8.1.2. EVMS

- 8.2. TESTING AND ADJUSTING

- 8.2.1. TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE

- 8.2.2. TROUBLESHOOTING

- 9. OTHERS

- 9.1. STRUCTURE AND FUNCTION

- 9.1.1. AIR CONDITIONER

- 9.2. DISASSEMBLY AND ASSEMBLY

- 9.2.1. METHOD OF USING MANUAL

- 9.2.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 9.2.4. CAB, FLOOR FRAME

- 9.2.5. ROPS CAB

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00