Komatsu D85MS-15 Demining Equipment Shop Manual SEN04305-02

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN04305-02

- Format: PDF

- Size: 34.6MB

- Number of Pages: 754

Category: Komatsu Shop Manual PDF

-

Model List:

- D85MS-15 Demining Equipment

- 1. Cover

- 2. Index and forword

- 2.1. Index,foreword and general information

- 2.1.0.1. HOW TO READ THE SHOP MANUAL

- 2.1.0.2. HOISTING INSTRUCTIONS

- 2.1.0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 2.1.0.4. COATING MATERIALS

- 2.1.0.5. STANDARD TIGHTENING TORQUE

- 2.1.0.6. ELECTRIC WIRE CODE

- 2.1.0.7. CONVERSION TABLE

- 2.1.0.8. UNITS

- 3. Specification

- 3.1. Specification and technical data

- 3.1.1. SPECIFICATION DRAWING

- 3.1.2. SPECIFICATIONS

- 3.1.3. WEIGHT TABLE

- 3.1.4. TABLE OF FUEL, COOLANT AND LUBRICANT

- 4. Structure, function and maintenance standard

- 4.1. POWER TRAIN

- 4.2. OVERALL DRAWING OF POWER TRAIN UNIT

- 4.3. HYDRAULIC PIPING OF POWER TRAIN

- 4.4. DAMPER, UNIVERSAL JOINT

- 4.5. TORQUE CONVERTER, PTO

- 4.6. SCAVENGING PUMP

- 4.7. TRANSMISSION CONTROL

- 4.8. TRANSMISSION

- 4.9. TRAMSMISSION ECMV

- 4.10. MAIN RELIEF VALVE

- 4.11. LUBRICATION RELIEF VALVE

- 4.12. POWER TRAIN PUMP, LUBRICATION PUMP

- 4.13. HSS SYSTEM

- 4.14. HYDRAULIC, HSS PUMP

- 4.15. HSS MOTOR

- 4.16. HSS OIL COOLER BYPASS VALVE

- 4.17. STEERING, BRAKE CONTROL

- 4.18. BEVEL, GEAR SHAFT, HSS, BRAKE

- 4.19. BRAKE VALVE

- 4.20. BRAKE ECMV

- 4.21. PARKING BRAKE VALVE

- 4.22. SUDDEN BRAKE PREVENTION VALVE

- 4.23. WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM

- 4.24. EPC CONTROL PIPING DIAGRAM

- 4.25. WORK EQUIPMENT CONTROL

- 4.26. COOLING FAN PUMP

- 4.27. COOLING FAN MOTOR

- 4.28. HYDRAULIC TANK

- 4.29. ACCUMLATOR

- 4.30. WORK EQUIPMENT LOCK VALVE

- 4.31. HYDRAULIC CYLINDER

- 4.32. PISTON VALVE

- 4.33. PCCS lever (FOR ROTOR LIFT, TILT)

- 4.34. PCCS LEVER (FOR STEERING)

- 4.35. CONTROL VALVE

- 4.36. SELF PRESSURE REDUCING VALVE

- 4.37. CYLINDER STAY

- 4.38. ROTOR

- 4.39. CAB MOUNT

- 4.41. AIR CONDITIONER

- 4.42. ENGINE CONTROL

- 4.43. ENGINE CONTROL SYSTEM

- 4.44. DECELERATION POTENTIOMETER

- 4.45. CRI ENGINE CONTROL SYSTEM

- 4.46. MONITOR SYSTEM

- 4.47. MACHINE MONITOR

- 4.48. SENSORS

- 4.49. PALM COMAND CONTROL SYSTEM

- 5. Testing and adjustment

- 5.1. Standard value table, testing, adjustmet and troubleshooting

- 5.1.1. STANDARD VALUE TABLE FOR ENGINE

- 5.1.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.1.3. TESTING AND ADJUSTMENT

- 5.1.3.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.1.3.2. MEASURING ENGINE SPEED

- 5.1.3.3. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.1.3.4. MEASURING EXHAUST TEMPERATURE

- 5.1.3.5. MEASURING EXHAUST GAS COLOR

- 5.1.3.6. ADJUSTING VALVE CLEARANCE

- 5.1.3.7. MEASURING COMPRESSION PRESSURE

- 5.1.3.8. MEASURING BLOWBY PRESSURE

- 5.1.3.9. MEASURING ENGINE OIL PRESSURE

- 5.1.3.10. HANDLING OF FUEL SYSTEM DEVICES

- 5.1.3.11. RELEASING RESIDUAL PRESSURE FROM FUEL SYSTEM

- 5.1.3.12. MEASURING FUEL PRESSURE

- 5.1.3.13. BLEEDING AIR FROM FUEL CIRCUIT

- 5.1.3.14. REDUCED CYLINDER MODE OPERATION FOR ENGINE

- 5.1.3.15. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.1.3.16. TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION

- 5.1.3.17. ADJUSTING FUEL CONTROL DIAL AND DECELERATOR PEDAL

- 5.1.3.18. MEASURING POWER TRAIN OIL PRESSURE

- 5.1.3.19. ADJUSTING TRANSMISSION SPEED SENSOR

- 5.1.3.20. SIMPLE METHOD OF TESTING BRAKE PERFORMANCE

- 5.1.3.21. ADJUSTING BRAKE PEDAL

- 5.1.3.22. EMERGENCY ESCAPE METHOD WHEN POWER TRAIN HAS TROUBLE

- 5.1.3.23. ADJUSTING CLEARANCE OF IDLER

- 5.1.3.24. INSPECTING WEAR OF SPROCKET

- 5.1.3.25. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.1.3.26. TESTING AND ADJUSTING WORK EQUIPMENT AND HSS OIL PRESSURE

- 5.1.3.27. TESTING CONTROL CIRCUIT MAIN PRESSURE

- 5.1.3.28. Measuring work equipment lock solenoid valve output pressure

- 5.1.3.29. TESTING PARTS WHICH CAUSE HYDRAULIC DRIFT OF ROTOR

- 5.1.3.30. MEASURING INTERNAL LEAKAGE OF WORK EQUIPMENT CYLINDER

- 5.1.3.31. BLEEDING AIR FROM WORK EQUIPMENT CYLINDER

- 5.1.3.32. RELEASING RESIDUAL PRESSURE IN WORK EQUIPMENT CYLINDER

- 5.1.3.33. ADJUSTING SAFETY LOCK LEVER

- 5.1.3.34. MEASURING FAN MOTOR SPEED

- 5.1.3.35. MEASURING FAN PUMP CIRCUIT PRESSURE

- 5.1.3.36. BLEEDING AIR FROM FAN PUMP

- 5.1.3.37. ADJUSTING ROTOR

- 5.1.3.38. TESTING AND ADJUSTING OF OPERATORS CAB

- 5.1.3.39. SPECIAL FUNCTIONS OF MONITOR PANEL (EMMS)

- 5.1.3.40. HANDLING OF HIGHVOLTAGE CIRCUIT OF ENGINE CONTROLLER

- 5.1.3.41. ADJUSTMENT METHOD OF REPLACED CONTROLLER

- 5.1.3.42. PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRIC SYSTEM

- 5.1.3.43. Pm CLINIC SERVICE

- 5.1.3.44. UNDERCARRIAGE TROUBLESHOTTING REPORT

- 5.1.4. TROUBLESHOOTING

- 5.1.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.1.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.1.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.1.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.1.4.5. CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING

- 5.1.4.6. TYPES AND LOCATIONS OF CONNECTORS

- 5.1.4.7. CONNECTOR ARRANGEMENT DRAWING

- 5.1.4.8. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.1.4.9. TBRANCH BOX AND TBRANCH TABLE

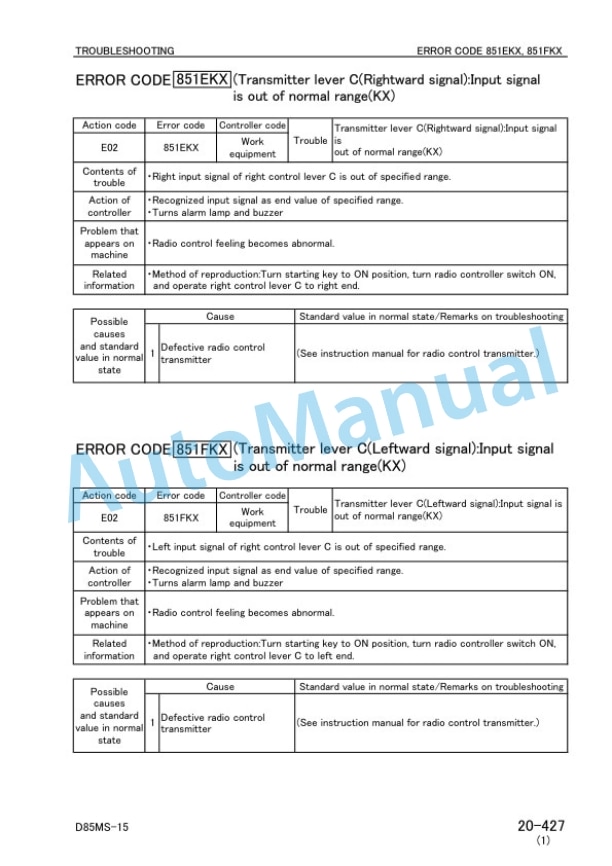

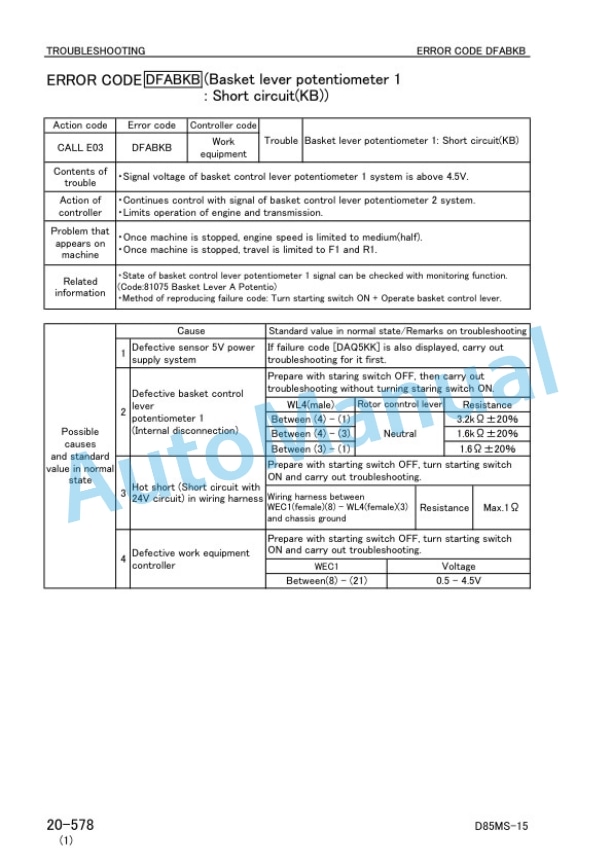

- 5.1.4.10. TROUBLESHOOTING WHEN ERROR CODE IS DISPLAYED (ERROR CODE)

- 6. Others

- 6.1. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 6.2. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 6.3. ELECTRICAL CIRCUIT DIAGRAM (1/8)

- 6.4. ELECTRICAL CIRCUIT DIAGRAM (2/8)

- 6.5. ELECTRICAL CIRCUIT DIAGRAM (3/8)

- 6.6. ELECTRICAL CIRCUIT DIAGRAM (4/8)

- 6.7. ELECTRICAL CIRCUIT DIAGRAM (5/8)

- 6.8. ELECTRICAL CIRCUIT DIAGRAM (6/8)

- 6.9. ELECTRICAL CIRCUIT DIAGRAM (7/8)

- 6.10. ELECTRICAL CIRCUIT DIAGRAM (8/8)

- 6.11. CAB ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00