Komatsu EC Series Air Compressor Shop Manual SEBM0680A10

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM0680A10

- Format: PDF

- Size: 109.7MB

- Number of Pages: 1050

Category: Komatsu Shop Manual PDF

-

Model List:

- EC Series Air Compressor

- 0.0.0.1. GENERAL LOCATIONS

- 0.0.0.2. SPECIFICATIONS

- 0.0.0.3. ENGINE LOCATIONS

- 0.0.0.4. ENGINE SPECIFICATIONS

- 0.0.0.5. ENGINE DIMENSIONS

- 0.0.0.6. GENERAL DIMENSIONS

- 0.0.0.7. WEIGHT TABLE

- 0.0.0.8. SERIAL NUMBERS, WATER AND OIL FILLING AND DRAINING POINT

- 1. ENGINE

- 1.1. TESTING AND ADJUSTING

- 1.1.1. TESTING AND ADJUSTING

- 1.1.1.1. STANDARD VALUES FOR TESTING AND ADJUSTING

- 1.1.1.2. TESTING AND ADJUSTING TOOL LIST

- 1.1.1.3. TESTING AND ADJUSTING

- 1.1.1.4. INTAKE AND EXHAUST SYSTEM

- 1.1.1.5. ENGINE BODY

- 1.1.1.6. LUBRICATION SYSTEM

- 1.1.1.7. KOMATSU ENGINE FUEL SYSTEM

- 1.1.1.8. CUMMINS ENGINE FUEL SYSTEM

- 1.1.1.9. COOLING SYSTEM

- 1.2. DISASSEMBLY AND ASSEMBLY

- 1.2.1. DISASSEMBLY AND ASSEMBLY

- 1.2.2. EC35Z, ZS

- 1.2.2.1. STARTING MOTOR ASSEMBLY

- 1.2.2.2. ALTERNATOR ASSEMBLY

- 1.2.2.3. FUEL INJECTION PUMP ASSEMBLY

- 1.2.2.4. NOZZLE HOLDER ASSEMBLY

- 1.2.2.5. WATER PUMP ASSEMBLY

- 1.2.2.6. CYLINDER HEAD ASSEMBLY

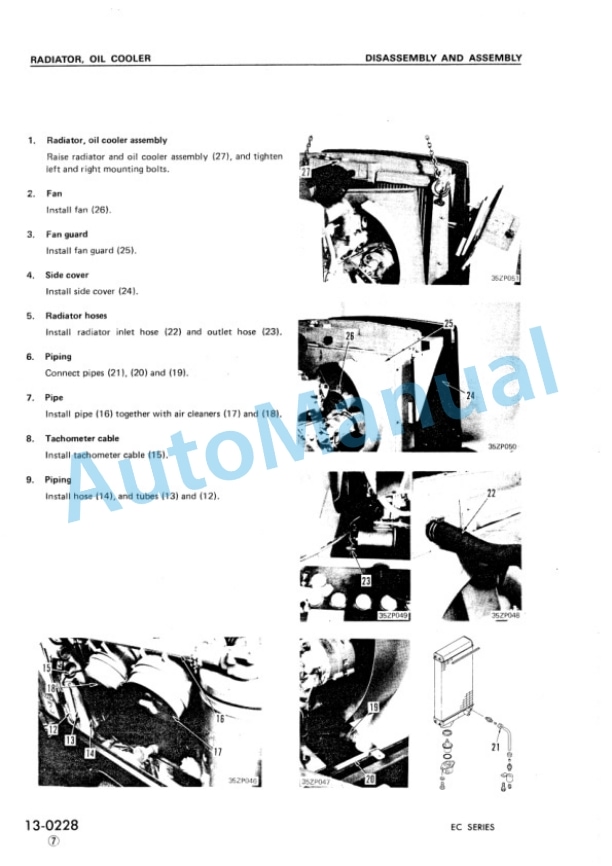

- 1.2.2.7. RADIATOR, OIL COOLER ASSEMBLY

- 1.2.2.8. ENGINE, COMPRESSOR ASSEMBLY

- 1.2.3. EC50Z, ZS3

- 1.2.3.1. STARTING MOTOR ASSEMBLY

- 1.2.3.2. ALTERNATOR ASSEMBLY

- 1.2.3.3. OIL COOLER ASSEMBLY

- 1.2.3.4. FUEL INJECTION PUMP ASSEMBLY

- 1.2.3.5. WATER PUMP ASSEMBLY

- 1.2.3.6. NOZZLE HOLDER ASSEMBLY

- 1.2.3.7. CYLINDER HEAD ASSEMBLY

- 1.2.3.8. RADIATOR AND COMPRESSOR OIL COOLER ASSEMBLY

- 1.2.3.9. ENGINE, COMPRESSOR ASSEMBLY

- 1.2.3.10. ENGINE ASSEMBLY AND COMPRESSOR ASSEMBLY

- 1.2.3.11. COMPRESSOR ASSEMBLY

- 1.2.4. EC50Z, ZS5

- 1.2.4.1. STARTING MOTOR ASSEMBLY

- 1.2.4.2. ALTERNATOR ASSEMBLY

- 1.2.4.3. FUEL INJECTION PUMP ASSEMBLY

- 1.2.4.4. WATER PUMP ASSEMBLY

- 1.2.4.5. NOZZLE HOLDER ASSEMBLY

- 1.2.4.6. CYLINDER HEAD ASSEMBLY

- 1.2.4.7. ENGINE, COMPRESSOR ASSEMBLY

- 1.2.4.8. ENGINE ASSEMBLY AND COMPRESSOR ASSEMBLY

- 1.2.4.9. RADIATOR, OIL COOLER ASSEMBLY

- 1.2.5. EC75Z, ZS2

- 1.2.5.1. STARTING MOTOR ASSEMBLY

- 1.2.5.2. ALTERNATOR ASSEMBLY

- 1.2.5.3. OIL COOLER ASSEMBLY

- 1.2.5.4. FUEL INJECTION PUMP ASSEMBLY

- 1.2.5.5. WATER PUMP ASSEMBLY

- 1.2.5.6. NOZZLE HOLDER ASSEMBLY

- 1.2.5.7. CYLINDER HEAD ASSEMBLY

- 1.2.5.8. RADIATOR AND OIL COOLER ASSEMBLY

- 1.2.5.9. ENGINE, COMPRESSOR ASSEMBLY

- 1.2.6. EC105Z, ZS

- 1.2.6.1. STARTING MOTOR ASSEMBLY

- 1.2.6.2. ALTERNATOR ASSEMBLY

- 1.2.6.3. FUEL INJECTION PUMP ASSEMBLY

- 1.2.6.4. OIL COOLER ASSEMBLY

- 1.2.6.5. NOZZLE HOLDER ASSEMBLY

- 1.2.6.6. TURBOCHARGER ASSEMBLY

- 1.2.6.7. WATER PUMP ASSEMBLY

- 1.2.6.8. CYLINDER HEAD ASSEMBLY

- 1.2.6.9. RADIATOR, OIL COOLER ASSEMBLY

- 1.2.6.10. ENGINE, COMPRESSOR ASSEMBLY

- 1.2.6.11. RADIATOR AND OIL COOLER

- 1.2.6.12. ENGINE ASSEMBLY

- 1.2.7. EC170Z, ZS1 EC210Z1

- 1.2.7.1. STARTING MOTOR ASSEMBLY

- 1.2.7.2. ALTERNATOR ASSEMBLY

- 1.2.7.3. OIL COOLER ASSEMBLY

- 1.2.7.4. FUEL INJECTION PUMP ASSEMBLY

- 1.2.7.5. WATER PUMP ASSEMBLY

- 1.2.7.6. NOZZLE HOLDER ASSEMBLY

- 1.2.7.7. TURBOCHARGER ASSEMBLY (EC170Z, ZS1)

- 1.2.7.8. TURBOCHARGER ASSEMBLY (EC210Z1)

- 1.2.7.9. AFTERCOOLER ASSEMBLY

- 1.2.7.10. CYLINDER HEAD ASSEMBLY (EC170Z, ZS1)

- 1.2.7.11. CYLINDER HEAD ASSEMBLY (EC210Z1)

- 1.2.7.12. RADIATOR AND OIL COOLER ASSEMBLY

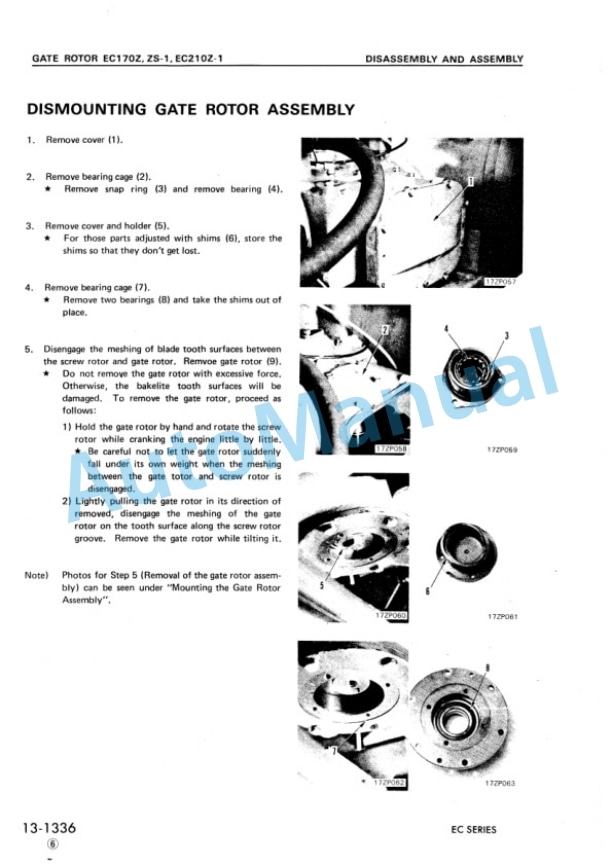

- 1.2.7.13. GATE ROTOR ASSEMBLY

- 1.2.7.14. ENGINE, COMPRESSOR ASSEMBLY

- 1.2.8. EC260Z1

- 1.2.8.1. STARTING MOTOR ASSEMBLY

- 1.2.8.2. ALTERNATOR ASSEMBLY

- 1.2.8.3. OIL COOLER ASSEMBLY

- 1.2.8.4. FUEL INJECTION PUMP ASSEMBLY

- 1.2.8.5. WATER PUMP ASSEMBLY

- 1.2.8.6. NOZZLE HOLDER ASSEMBLY

- 1.2.8.7. TURBOCHARGER ASSEMBLY

- 1.2.8.8. CYLINDER HEAD ASSEMBLY

- 1.2.8.9. RADIATOR, OIL COOLER ASSEMBLY

- 1.2.8.10. GATE ROTOR ASSEMBLY

- 1.2.8.11. ENGINE, COMPRESSOR ASSEMBLY

- 2. COMPRESSOR

- 2.1. STRUCTURE AND FUNCTION

- 2.1.1. STRUCTURE AND FUNCTION

- 2.1.1.1. GENERAL

- 2.1.1.2. ROTARY COMPRESSOR

- 2.1.1.3. ZSCREW COMPRESSOR

- 2.2. TESTING AND ADJUSTING

- 2.2.1. TESTING AND ADJUSTING

- 2.2.1.1. ROTARY COMPRESSOR

- 2.2.1.2. ZSCREW COMPRESSOR

- 2.2.1.3. ADJUSTING A ZSCREW TYPE (ONEUNIT TYPE) COMPRESSOR

- 2.3. DISASSEMBLY AND ASSEMBLY

- 2.3.1. DISASSEMBLY AND ASSEMBLY

- 2.3.1.1. EC35Z, ZS

- 2.3.1.2. EC35V, VS

- 2.3.1.3. EC50Z, ZS1, 2

- 2.3.1.4. EC50Z3 1000115652 EC50ZS3 1000110561

- 2.3.1.5. EC50Z3 15653 EC50ZS3 10362

- 2.3.1.6. EC50V, VS

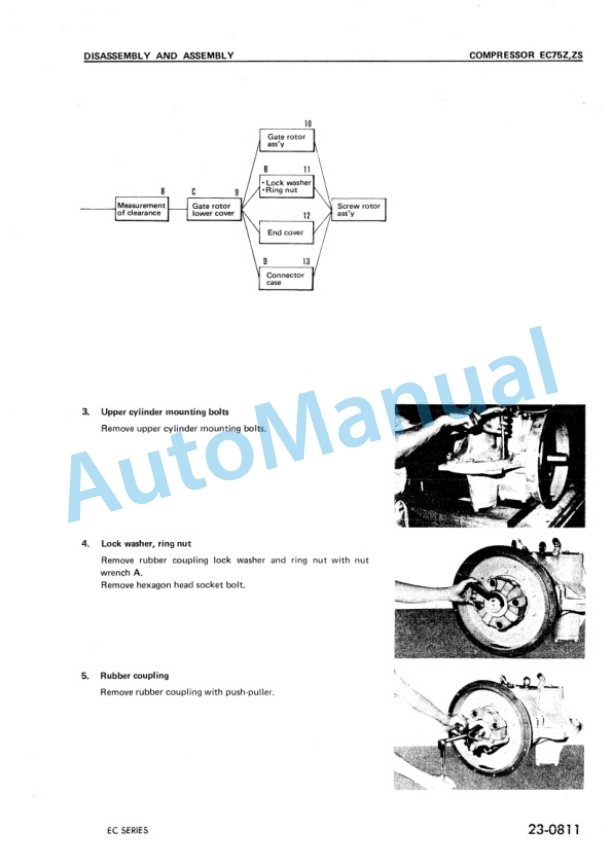

- 2.3.1.7. EC75Z, ZS

- 2.3.1.8. EC105Z, ZS

- 2.3.1.9. EC SERIES

- 2.3.1.10. EC75Z, ZS2

- 2.3.1.11. EC170V

- 2.3.1.12. EC170Z, ZS1 EC210Z1

- 2.3.1.13. EC260Z1

- 2.4. MAINTENANCE STANDARD

- 2.4.1. MAINTENANCE STANDARD

- 2.4.1.1. ROTARY TYPE COMPRESSOR

- 2.4.1.2. OIL PUMP

- 2.4.1.3. ZSCREW TYPE COMPRESSOR

- 3. REGULATOR

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. STRUCTURE AND FUNCTION

- 3.1.2. OPERATION OF REGULATOR

- 3.1.3. VOLUME REGULATOR

- 3.1.4. SPEED REGULATOR

- 3.1.5. STRUCTURE AND FUNCTION VOLUME REGULATOR

- 3.1.6. SPEED REGULATOR

- 3.1.7. LOADING VALVE

- 3.1.8. MAGNETIC VALVE (OPTION )

- 3.1.9. THREEWAY COCK (OPTION )

- 3.1.10. OPERATION DIAGRAM OF REGULATORS

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TESTING AND ADJUSTING

- 3.2.1.1. TESTING AND ADJUSTING TABLE

- 3.2.1.2. ADJUSTING OF REGULATOR

- 3.2.1.3. CHECKING THE SAFETY VALVE AND TESTING THE MINIMUM PRESSURE VALVE AND AUTOMATIC BLOWOFF VALVE

- 3.2.2. TROUBLE SHOOTING

- 3.2.2.1. GENERAL

- 3.2.2.2. TESTING

- 3.2.2.3. ROTRAY COMPRESSOR

- 3.2.2.4. ZSCREW COMPRESSOR

- 3.2.2.5. REGULATOR

- 3.3. MAINTENANCE STANDARD

- 3.3.1. MAINTENANCE STANDARD

- 3.3.1.1. VOLUME REGULATOR

- 4. LUBRICATION SYSTEM

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. STRUCTURE AND FUNCTION

- 4.1.1.1. GENERAL

- 4.1.1.2. RECEIVER TANK

- 4.1.1.3. OIL RECLAIMER

- 4.1.1.4. OIL FILTER

- 4.1.1.5. THERMOSTAT VALVE

- 4.1.1.6. OIL MANIFOLD

- 4.1.1.7. SLUICE VALVE

- 4.1.1.8. LUBRICATION OIL PIPING

- 4.2. TESTING AND ADJUSTING

- 4.2.1. TESTING AND ADJUSTING

- 4.2.1.1. TESTING THERMOSTAT VALVE

- 4.2.1.2. CHANGING OIL AND CLEANING COMPRESSOR

- 4.2.2. TROUBLE SHOOTING

- 4.2.2.1. LUBRICATION OIL (MAIN CAUSES AND CHECKING)

- 4.3. MAINTENANCE STANDARD

- 4.3.1. MAINTENANCE STANDARD

- 4.3.1.1. OIL MANIFOLD

- 5. AIR SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. STRUCTURE AND FUNCTION

- 5.1.1.1. GENERAL

- 5.1.1.2. MINIMUM PRESSURE VALVE

- 5.1.1.3. SAFETY VALVE

- 5.1.1.4. AUTOMATIC BLOWOFF VALVE

- 5.1.1.5. AIR PIPING

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TESTING AND ADJUSTING

- 5.2.1.1. CHECKING SAFETY VALVE AND MINIMUM PRESSURE VALVE AND AUTOMATIC BLOWOFF VALVE TESTS

- 6. OTHERS

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. STRUCTURE AND FUNCTION

- 6.1.1.1. EXPLANATION OF COMPONENT PARTS (EMERGENCY STOP, MONITORING DEVICES)

- 6.1.1.2. EMERGENCY STOP MONITORING DEVICES

- 6.1.1.3. EXPLANATION OF COMPONENT PARTS (AUTOMATIC START, EMERGENCY STOP AND MONITORING DEVICES)

- 6.1.1.4. ELECTRICAL CIRCUIT DIAGRAM

- 6.1.2. TROUBLESHOOTING

- 6.1.2.1. GENERAL

- 6.1.2.2. PRECAUTIONS IN TROUBLESHOOTING

- 6.1.2.3. EMERGENCY STOP MONITORING DEVICES (EC35Z, ZS1)

- 6.1.2.4. EMERGENCY STOP MONITORING DEVICES (EC75Z, ZS2, EC105Z,ZS1, EC170Z, ZS1, EC210Z1)

- 6.1.2.5. AUTOMATIC STARTING, EMERGENCY STOP AND MONITORING DEVICES (OPTION EC75ZS2, EC105ZS1,EC170ZS1)

- 6.1.2.6. TROUBLESHOOTING TABLE CLASSIFIED BY AUTOMATIC STARTING, EMERGENCY STOP AND MONITORING DEVICES (OPTION EC75ZS2, EC105ZS1,EC170ZS1)

- 6.2. TESTING AND ADJUSTING

- 6.2.1. TESTING AND ADJUSTING

- 6.2.1.1. TABLE OF EMERGENCY SYSTEMS

- 6.2.1.2. FUEL CUT SOLENOID

- 6.2.1.3. TESTING CIRCUIT OF EMERGENCY SYSTEM

- 6.2.1.4. CHECKING SENSORS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00