Komatsu FB10EX-11, FB14EX-11, FB15EX-11, FB18EX-11, FB15EXG-11, FB18EXG-11, FB20EX-11, FB25EX-11, FB20EXG-11, FB25EXG Shop Manual

$40.00

- Type Of Manual: Shop Manual

- Format: PDF

- Size: 12.5MB

- Number of Pages: 423

Category: Komatsu Shop Manual PDF

-

Model List:

- FB10EX-11 Electric Lift Truck

- FB14EX-11 Electric Lift Truck

- FB15EX-11 Electric Lift Truck

- FB18EX-11 Electric Lift Truck

- FB15EXG-11 Electric Lift Truck

- FB18EXG-11 Electric Lift Truck

- FB20EX-11 Electric Lift Truck

- FB25EX-11 Electric Lift Truck

- FB20EXG-11 Electric Lift Truck

- FB25EXG-11 Electric Lift Truck

- FB30-11 Electric Lift Truck

- 1. BBB11E103

- 1.1. SECTION INDEX

- 1.2. FOREWORD

- 1.2.1. PRECAUTIONS WHEN PERFORMING THE SERVICE WORK

- 1.2.2. DESCRIPTION OF THE SYMBOLS

- 1.3. GENERAL AND SPECIFICATIONS

- 1.3.1. Outside view and specifications

- 1.3.2. Periodic replacement of consumable parts

- 1.3.3. Safety items for maintenance

- 1.3.4. Standard tightening torque for bolts

- 1.3.5. Standard tightening torque for pipe joints

- 1.3.6. How to use loctite

- 1.3.7. Conversion table

- 1.4. TESTING AND ADJUSTING

- 1.4.1. Service data (1.0 1.75 ton models)

- 1.4.2. Service data (2.0 3.0 ton models)

- 1.4.3. How to operate lift interrupt function

- 1.4.4. How to reset electrolyte level indicator function

- 1.4.5. How to start hour meter

- 1.4.6. Operation of meter panel

- 1.4.7. Adjusting lowering speed of fork

- 1.4.8. Battery

- 1.4.9. Fuse

- 1.4.10. Transfer case

- 1.4.11. Stationary charger

- 1.4.12. Brake pedal

- 1.4.13. Wheel brake

- 1.4.14. Adjusting parking brake lever

- 1.4.15. Hydraulic tank

- 1.4.16. Rear axle (Steering axle)

- 1.4.17. Mast (1.0 1.75 ton models)

- 1.4.18. Mast (2.0 3.0 ton models)

- 1.4.19. Fork carriage (1.0 1.75 ton models)

- 1.4.20. Fork carriage (2.0 3.0 ton models)

- 1.4.21. Measuring hydraulic drift of hydraulic cylinder and hydraulic drift of leaning forward

- 1.4.22. Bleeding air

- 1.5. REMOVAL AND INSTALLATION

- 1.5.1. Arrangement of units

- 1.5.2. Weight of each unit (1.0 1.75 ton models)

- 1.5.3. Weight of each unit (2.0 3.0 ton models)

- 1.5.4. General disassembly and assembly drawing

- 1.5.5. Mast

- 1.5.6. Lift cylinder

- 1.5.7. Power train (Front axle Transfer Drive motor)

- 1.5.8. Rear axle

- 1.5.9. Battery

- 1.5.10. EPS actuator

- 1.5.11. Steering gear box

- 1.5.12. Hydraulic pump Pump motor

- 1.6. DISASSEMBLY AND ASSEMBLY

- 1.6.1. Transfer (1.0 1.75 ton models)

- 1.6.2. Transfer (2.0 2.5 ton models)

- 1.6.3. Transfer (3.0 ton model)

- 1.6.4. Differential (1.0 1.75 ton models)

- 1.6.5. Differential (2.0 3.0 ton models)

- 1.6.6. Front axle (1.0 1.75 ton models)

- 1.6.7. Front axle (2.0 2.5 ton models)

- 1.6.8. Front axle (3.0 ton model)

- 1.6.9. Brake master cylinder

- 1.6.10. Damping cylinder

- 1.6.11. Wheel brake (1.0 1.75 ton models)

- 1.6.12. Wheel brake (2.0 2.5 ton models)

- 1.6.13. Wheel brake (3.0 ton model)

- 1.6.14. Steering gear box

- 1.6.15. EPS actuator

- 1.6.16. Rear axle (1.0 1.75 ton models)

- 1.6.17. Rear axle (2.0 3.0 ton models)

- 1.6.18. Lift cylinder

- 1.6.19. Tilt cylinder

- 1.6.20. Hydraulic pump

- 1.6.21. Control valve (Proportional solenoid valve spec.)

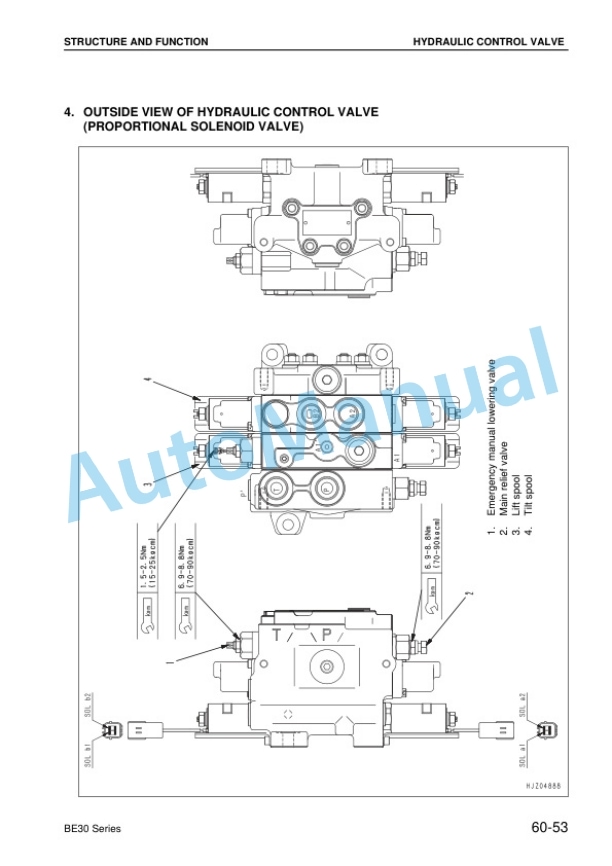

- 1.6.22. Control valve (Manual valve spec.)

- 1.6.23. DRIVE MOTOR

- 1.6.24. PUMP MOTOR

- 1.7. MAINTENANCE STANDARD

- 1.7.1. Transfer

- 1.7.2. Differential (1.0 1.75 ton models)

- 1.7.3. Differential (2.0 3.0 ton models)

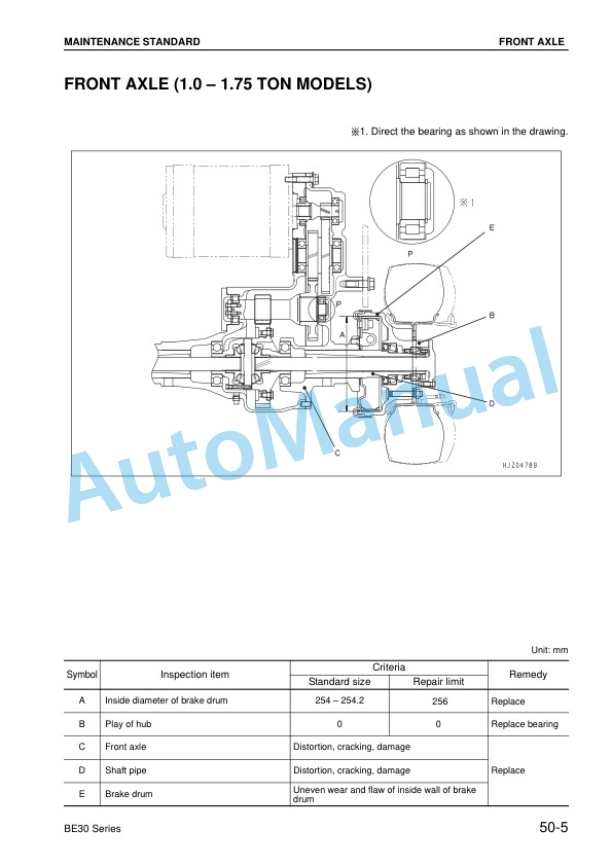

- 1.7.4. Front axle (1.0 1.75 ton models)

- 1.7.5. Front axle (2.0 2.5 ton models)

- 1.7.6. Front axle (3.0 ton model)

- 1.7.7. Brake master cylinder

- 1.7.8. Damping cylinder

- 1.7.9. Wheel brake (1.0 1.75 ton models)

- 1.7.10. Wheel brake (2.0 2.5 ton models)

- 1.7.11. Wheel brake (3.0 ton model)

- 1.7.12. Rear axle (1.0 1.75 ton models)

- 1.7.13. Rear axle (2.0 3.0 ton models)

- 1.7.14. Lift cylinder

- 1.7.15. Tilt cylinder

- 1.7.16. Control valve (Proportional solenoid valve spec.)

- 1.7.17. Control valve (Manual valve spec.)

- 1.7.18. Hydraulic pump

- 1.7.19. Mast, fork carriage, and fork (1.0 1.75 ton models)

- 1.7.20. Mast, fork carriage, and fork (2.0 3.0 ton models)

- 1.7.21. Drive motor (1.0 2.5 ton models)

- 1.7.22. Drive motor (3.0 ton model)

- 1.7.23. Pump motor (1.0 1.75 ton models)

- 1.7.24. Pump motor (2.0 3.0 ton models)

- 1.7.25. Power steering motor

- 1.8. STRUCTURE AND FUNCTION

- 1.8.1. Power train

- 1.8.2. Travel system

- 1.8.3. Braking device

- 1.8.4. Steering system

- 1.8.5. Hydraulic system

- 1.8.6. Hydraulic control valve (Proportional solenoid valve spec.)

- 1.8.7. Work equipment

- 1.8.8. Power connector for optional devices

- 1.8.9. Control unit

- 1.8.10. Operating device (Meter panel, switches, etc.)

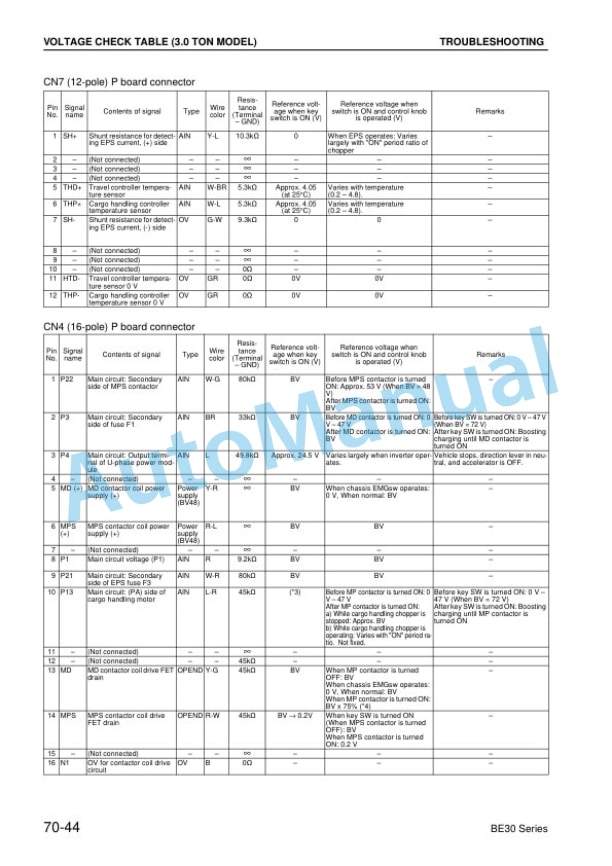

- 1.9. TROUBLESHOOTING

- 1.9.1. Controller

- 1.9.2. Main controller

- 1.9.3. Electric circuit diagram

- 1.9.4. Sub controller

- 1.9.5. Troubleshooting

- 1.9.6. Selfdiagnosis logic table (1.0 3.0 ton models)

- 1.9.7. Drive motor

- 1.9.8. CHARGER

- 1.10. YEARLY INSPECTION CRITERIA

- 1.10.1. Starting motor and pump motor

- 1.10.2. Battery

- 1.10.3. Controller

- 1.10.4. Power train

- 1.10.5. Travel system

- 1.10.6. Steering system

- 1.10.7. Brake system

- 1.10.8. Cargo handling system

- 1.11. BACK COVER

Rate this product

You may also like