Komatsu FB20SH-4, FB25SH-4, FB30SH-4 Electric Lift Truck Shop Manual KO-SM015

$40.00

- Type Of Manual: Shop Manual

- Manual ID: KO-SM015

- Format: PDF

- Size: 9.3MB

- Number of Pages: 295

Category: Komatsu Shop Manual PDF

-

Model List:

- FB20SH-4 Electric Lift Truck

- FB25SH-4 Electric Lift Truck

- FB30SH-4 Electric Lift Truck

- 1. AJFORE

- 1.1. FOREWORD

- 2. AJGEN

- 2.1. GENERAL AND SPECIFICATIONS

- 2.2. Overall dimensions and specifications

- 2.3. Weight of main compnents

- 2.4. Standard tightening torque for bolts

- 2.5. Standard tightening torque for pipe joints

- 2.6. Periodical replacement of safetyassured parts

- 2.7. General locations

- 2.8. Instruments and controls

- 3. AJCONV

- 3.1. CONVERSION TABLE

- 3.2. Millimeters to Inches

- 3.3. Inches to Millimeters

- 3.4. Cubic meters to Cubic yards

- 3.5. Cubic yards to Cubic meters

- 3.6. Liter to U.S. Gallon

- 3.7. Gallon to Liter

- 3.8. Liter to U.K. Gallon

- 3.9. Gallon to Liter

- 3.10. Kilogram to Pound

- 3.11. Pound to Kilogram

- 3.12. Kg/cm2 to lb/in2

- 3.13. Kgm to Ft. lb

- 3.14. Temperature

- 4. AJDIS

- 4.1. DISASSEMBLY AND ASSEMBLY OF COMPONENTS

- 4.1.1. POWER TRAIN

- 4.1.1.1. Transfer

- 4.1.1.2. Wheel brake

- 4.1.1.3. Differential

- 4.1.1.4. Drive axle

- 4.1.2. BRAKE SYSTEM

- 4.1.2.1. Master cylinder

- 4.1.2.2. Wheel brake

- 4.1.2.3. Air vent

- 4.1.2.4. STEERING SYSTEM

- 4.1.2.5. Power steering valve

- 4.1.2.6. Steering axle

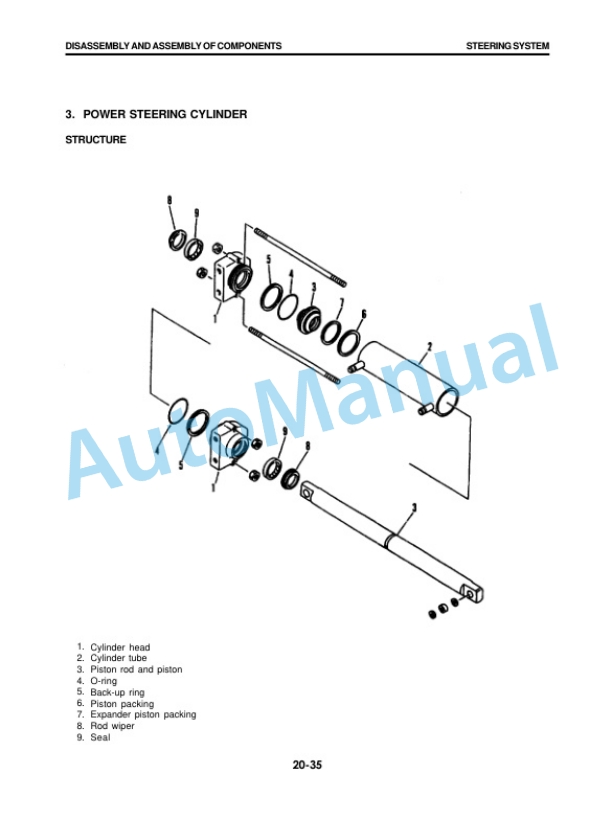

- 4.1.2.7. Power steering cylinder

- 4.1.3. HYDRAULIC SYSTEM

- 4.1.3.1. Hydraulic circuit diagram

- 4.1.3.2. Hydraulic pump

- 4.1.3.3. Control valve

- 4.1.3.4. Control valve lever

- 4.1.3.5. Lift cylinder (For STD type)

- 4.1.3.6. Tilt cylinder (For STD type)

- 4.1.3.7. Tilt cylinder (For USA type)

- 4.1.4. MAST

- 4.1.4.1. Mast (For STD type)

- 4.1.4.2. Mast (For USA type)

- 4.1.4.3. Lift chains

- 5. AJELEC

- 5.1. ELECTRICAL SYSTEM

- 5.1.1. ELECTRICAL COMPONENTS

- 5.1.2. Digital multimeter

- 5.1.3. BATTERY AND CASE (For USA)

- 5.1.3.1. Battery compartment

- 5.1.3.2. Notes on selecting a battery

- 5.1.3.3. Recommended batteries

- 5.1.4. MOTORS

- 6. AJREMOV

- 6.1. REMOVAL AND INSTALLATION OF UNITS

- 6.1.1. Locations of units

- 6.1.2. How to install units

- 6.1.3. Removal and installation flowchart

- 6.1.4. Removal and installation of units

- 6.1.4.1. Mast (For Tochigi plant product)

- 6.1.4.2. Mast (For K. F. M. product)

- 6.1.4.3. Power train (Front axle Transfer Traction motor)

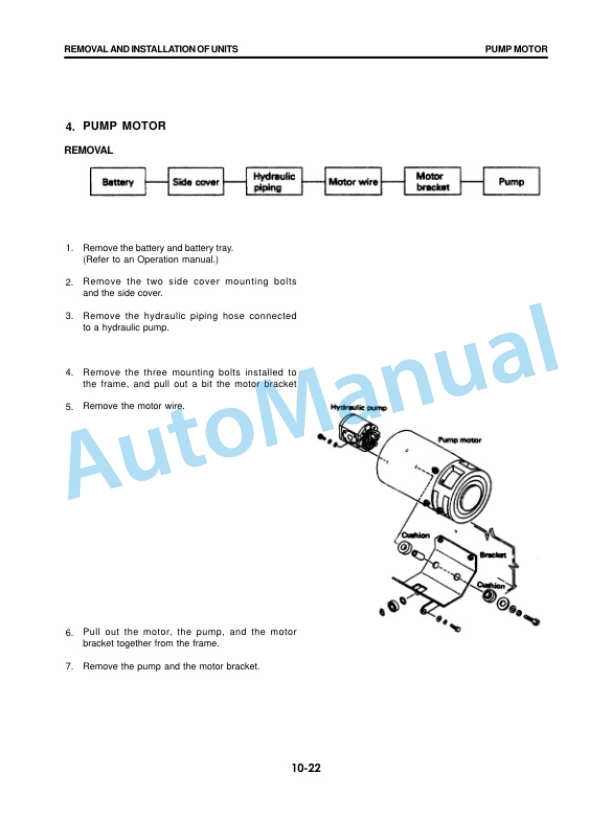

- 6.1.4.4. Pump motor

- 6.1.4.5. Power steering motor

- 6.1.4.6. Steering axle

- 6.1.4.7. power steering cylinder

- 7. AJTEST

- 7.1. TESTING AND ADJUSTING

- 7.2. Motor

- 7.3. Battery

- 7.4. Controller

- 7.5. Travel system

- 7.6. Steering system

- 7.7. Brake system

- 7.8. Work equipment system

- 7.9. Adjustment of parking brake lever

- 7.10. Adjustment of brake pedal

- 7.11. Adjustment of accelerator pedal

- 7.12. Adjustment of operators seat switch

- 8. AKSM016

- 8.1. GENERAL MAINTENANCE INSTRUCTIONS

- 8.2. A COMPARISON OF GE EV100LXT CONTROLLER WITH THE EXISTING CONTROLLER

- 8.3. HANDSET SETTINGS ON MACHINES SHIPPED FROM FACTORY

- 8.4. LIST OF FUNCTION, EV100LXT TRACTION CONTROLLER FOR BBX

- 8.5. MAIN SPECIFICATIONS OF MOTOR AND SERVICE DATA

- 8.6. BASICS OF CIRCUIT OPERATION

- 8.7. OUTLINE OF CONTROLLER

- 8.7.1. Description of Control Function

- 8.7.2. Dimensions

- 8.7.3. External View

- 8.7.4. Traction Control Panel

- 8.7.5. Contractor Panel for BBX

- 8.7.6. Accelerator

- 8.8. HYDRAULIC PUMP OPERATION (CONTRACTOR TYPE)

- 8.9. DEADMAN HORN ALARM CIRCUIT

- 8.10. GLOSSARY

- 8.11. ELEMENTARY DIAGRAM SYMBOLS

- 8.12. PROCEDURES FOR REPLACING CONTROLLER COMPONENT PARTS

- 8.12.1. Control Card

- 8.12.2. Stud Semiconductors

- 8.12.3. Capacitor

- 8.12.4. IL, 23FIL, 24FIL and 25FIL

- 8.12.5. Reactor/Choke

- 8.13. TROUBLESHOOTING

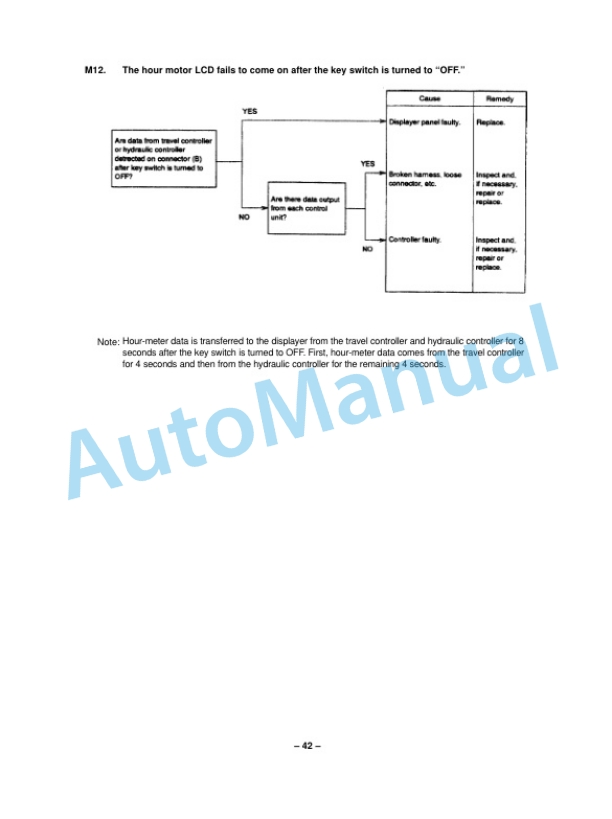

- 8.13.1. Digital Multifunction Displayer

- 8.13.2. Troubleshooting Instructions

- 8.13.3. Status Code Requiring Troubleshooting by Use of Meter Panel

- 8.13.4. Procedure for Setting Travel Characteristics with HANDSET

- 8.13.5. SEQUENCE OF OPERATION

- 8.13.6. List of Status Code

- 8.13.7. Troubleshooting for the Hydraulic Control with Contractor Type

- 8.13.7.1. The voltage reading at the terminals of PATD, PBTD and PAD, PBD wire in normal conditions

- 8.13.7.2. Troubleshooting of hydraulic pump motor

- 8.13.7.2.1. Contactor closes and the pump motor does not rotate

- 8.13.7.2.2. The contactor does not close

- 8.13.7.2.3. No time delay after the valve switch opens for the contractor tips chatters

- 8.13.8. Troubleshooting for the horn function

- 8.13.8.1. The voltage reading at the terminals of TMM2 normal conditions

- 8.13.8.2. Troubleshooting for the horn alarm function

- 8.13.8.2.1. The horn does not blow when the horn button is activated

- 8.13.8.2.2. The horn does not blow with the condition listed below

- 8.13.8.2.3. The horn blows continuously

- 8.13.9. Troubleshooting of Power Steering Motor

- 8.13.9.1. Troubleshooting

- 8.13.9.2. Disassembly

- 8.13.9.3. Reassembly

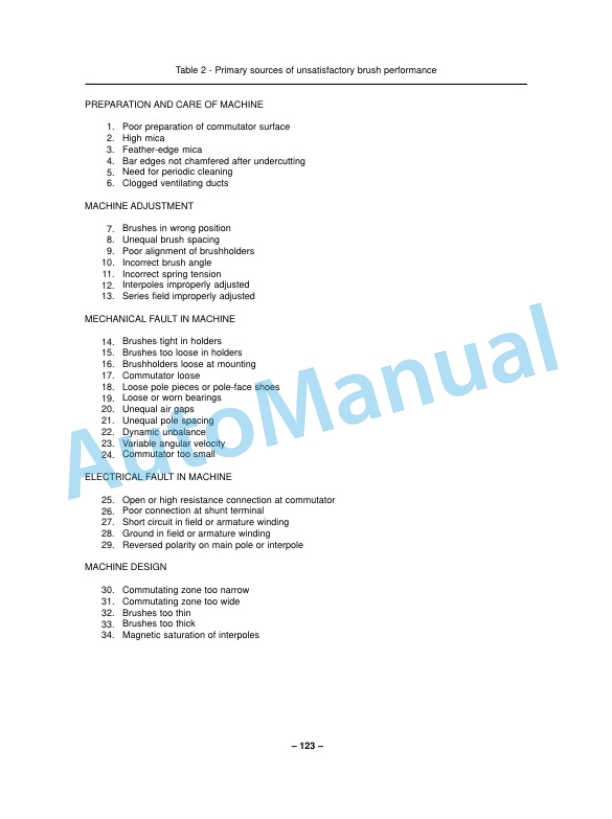

- 8.13.10. Troubleshooting of the Brush for Traction and Pump Motors

- 8.13.11. Troubleshooting without use of the Meter Panel for Traction SCR Controller

- 8.13.11.1. The voltage reading at the terminals in normal condition

- 8.13.11.2. Troubleshooting instructions

- 8.13.12. All Testing Should be Done with Truck Jacked Up

- 8.13.12.1. Failures that cause reduced or no motor torque with SCR control

- 8.13.12.2. Failures that cause full or no motor torque with SCR control

- 8.13.12.3. Misoperation of other features

- 8.13.13. Others Electrical Component Parts

- 8.13.13.1. Capacitor 1C

- 8.13.13.2. Contractors F, R, 1A, and P

- 8.13.13.3. Potentiometer in Accelerator

- 8.13.13.4. Coil driver module

- 8.13.13.5. SCRs (1REC, 2REC, 5REC)

- 8.13.13.6. Rectifiers (3REC, 4REC, diode blocks)

- 8.13.13.7. Thermal protector (TP)

- 8.13.13.8. Filter block (23FIL, etc.)

- 8.13.13.9. choke and reactor T3T4

- 8.13.13.10. TROUBLESHOOTING SYMPTOM CHART

- 8.13.14. Description of Newly Introduced Motor Control System

- 8.14. CIRCUIT DIAGRAM

- 8.15. Untitled

- 9. MSM003

- 9.1. MSM003 MAST SERVICE COVER

- 9.1.1. CONTENTS

- 9.1.2. UPRIGHT DESCRIPTION

- 9.1.3. MAST REMOVAL

- 9.1.4. INSPECTION ADJUSTMENTS

- 9.1.5. CYLINDER BLEEDING

- 9.1.6. CARRIAGE REMOVAL TRUCK

- 9.1.7. CARRIAGE REMOVAL FLOOR

- 9.1.8. CARRIAGE INSTALLATION

- 9.1.9. INTERNAL REEVING INSTALL

- 9.1.10. UPRIGHT DISASSEMBLY

- 9.1.11. UPRIGHT INSPECTION

- 9.1.11.1. UPRIGHT ASSEMBLY

- 9.1.11.2. MAST RACKING SKEWING

- 9.1.12. HOIST CHAINS

- 9.1.12.1. CHAIN STRETCH

- 9.1.12.2. CHAIN ADJUSTMENT

- 9.1.13. MAST INSTALLATION

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00