Komatsu FB22H-3R, FB25H-3R, FB25HG-3R, FB30H-3R Workshop Manual 40248042304EN

$40.00

- Type Of Manual: Workshop Manual

- Manual ID: 40248042304EN

- Format: PDF

- Size: 9.4MB

- Number of Pages: 286

Category: Komatsu Shop Manual PDF

-

Model List:

- FB22H-3R

- FB25H-3R

- FB25HG-3R

- FB30H-3R

- 1.1. Header

- 1.2. Table of contents

- 1.2.1. General information

- 1.2.1.1. Product information

- 1.2.1.1.1. Instruction and maintenance manual

- 1.2.1.1.2. Definition of Direction of Travel

- 1.2.1.1.3. General Forklift Description

- 1.2.1.1.4. Overall dimensions

- 1.2.1.1.5. Technical Data

- 1.2.1.1.6. Tyre characteristics

- 1.2.1.1.7. Forklift capacities Model 2200 kg Masts vertical with forks 1400 mm max.

- 1.2.1.1.8. Forklift capacities Model 2500 kg short pitch Masts vertical with forks 1400 mm max.

- 1.2.1.1.9. Forklift capacities Model 2500 kg long pitch Masts vertical with forks 1400 mm max.

- 1.2.1.1.10. Forklift capacities Model 3000 kg Masts vertical with forks 1400 mm max.

- 1.2.1.1.11. Alternative lift characteristics

- 1.2.1.1.12. Abbreviations key

- 1.2.1.1.13. Pneumatic tyre inflation pressure

- 1.2.1.1.14. Lamps

- 1.2.1.1.15. Battery dimensions and weights

- 1.2.1.1.16. Internal accessibility

- 1.2.1.1.17. Safety Devices

- 1.2.1.1.18. Transporting the Forklift

- 1.2.1.1.19. Forklift Towing

- 1.2.1.1.20. Loading and Unloading the Forklift

- 1.2.1.2. Safety precautions

- 1.2.1.2.1. Description of safety symbols

- 1.2.1.2.2. Operations Preliminary to Maintenance

- 1.2.1.2.3. To avoid accidents

- 1.2.1.2.4. General safety Regulations

- 1.2.1.2.5. Safety Regulations Relative to Operating Materials

- 1.2.2. Service

- 1.2.2.1. Maintenance

- 1.2.2.1.1. Preliminary operations before commissioning

- 1.2.2.1.2. Synoptic Table of Maintenance Operations

- 1.2.2.1.3. Supply Table

- 1.2.3. Diagnostics

- 1.2.3.1. Diagnostic software

- 1.2.3.1.1. Connection between the diagnostics PC and the forklift

- 1.2.3.1.2. Software

- 1.2.3.1.3. Description of the menus in the WINPCCONSOLE software

- 1.2.3.1.4. Description of the PARAMETER menu

- 1.2.3.1.5. Description of the TESTER menu

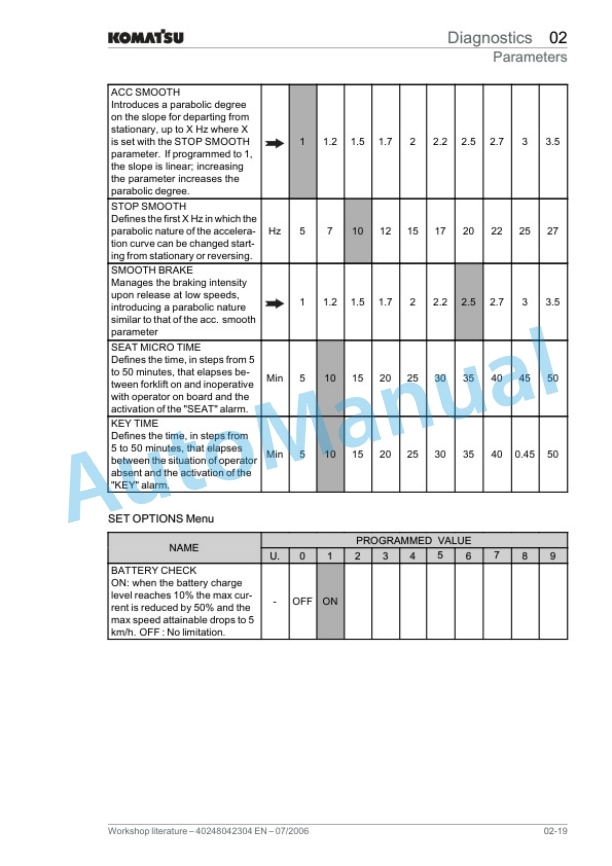

- 1.2.3.2. Parameters

- 1.2.3.2.1. Introduction

- 1.2.3.2.2. Parameters of the DUAL AC Master module

- 1.2.3.2.3. AC3 module parameters

- 1.2.3.2.4. Smart Display

- 1.2.3.2.5. TESTER Function

- 1.2.3.2.6. Speed reductions

- 1.2.3.3. Alarms

- 1.2.3.3.1. General information on the alarms

- 1.2.3.3.2. Alarms of the DUAL AC module

- 1.2.3.3.3. Alarms of the AC3 module

- 1.2.3.3.4. Alarms of the SMART DISPLAY module

- 1.2.3.4. Analogue signals

- 1.2.3.4.1. Analogue signal acquisition

- 1.2.4. Drive motor

- 1.2.4.1. Asynchronous motors

- 1.2.4.1.1. Features of the asynchronous motors

- 1.2.4.1.2. Checking the asynchronous motors

- 1.2.4.2. Front axle motors

- 1.2.4.2.1. Drive motor technical data

- 1.2.4.2.2. Drive motor checks

- 1.2.4.2.3. Motor temperature sensor

- 1.2.4.2.4. Drive motor decomposition

- 1.2.5. Gearbox

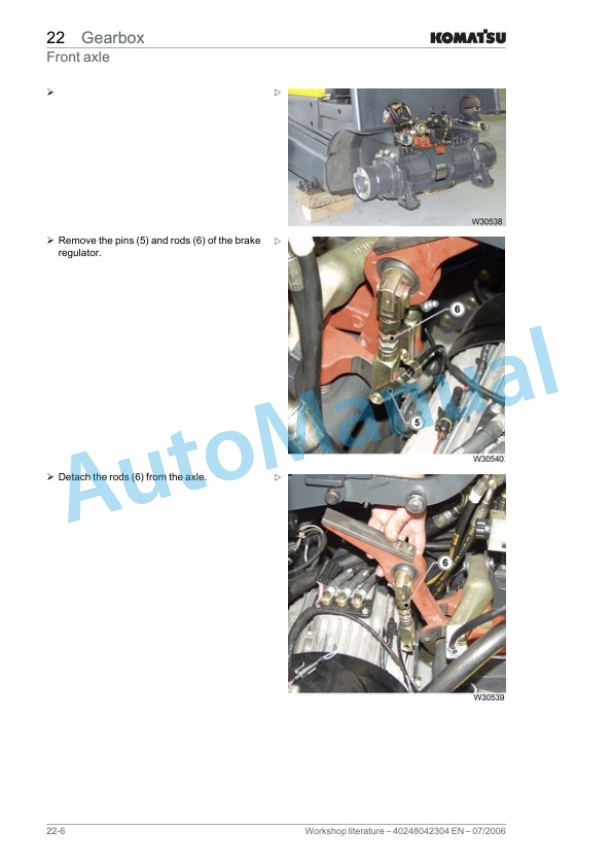

- 1.2.5.1. Front axle

- 1.2.5.1.1. Front axle technical data

- 1.2.5.1.2. Front axle layout

- 1.2.5.1.3. Removal of front axle with drive motors

- 1.2.5.1.4. Front axle reconnection

- 1.2.5.1.5. Front axle disassembly

- 1.2.5.1.6. Front axle reassembly

- 1.2.5.2. Reducer

- 1.2.5.2.1. Front axle reducer layout

- 1.2.5.2.2. Front axle reduction gear disassembly/reassembly

- 1.2.5.2.3. Reduction gear oil level check

- 1.2.5.2.4. Reducer oil change

- 1.2.6. Vehicle

- 1.2.6.1. Bonnets

- 1.2.6.1.1. Bonnet layout

- 1.2.6.1.2. Right side bonnet removal/reassembly

- 1.2.6.1.3. Left side bonnet removal/reassembly

- 1.2.6.1.4. Battery hood removal/reassembly

- 1.2.6.1.5. Electronic panel bonnet removal/reassembly

- 1.2.6.1.6. Distributor hood removal/reassembly

- 1.2.6.1.7. Removal/reassembly of the operator footboard

- 1.2.6.2. Counterweight

- 1.2.6.2.1. Counterweight disconnection

- 1.2.6.2.2. Counterweight reconnection

- 1.2.7. Drivers seat

- 1.2.7.1. Fairing

- 1.2.7.1.1. Fairing removal/reassembly

- 1.2.7.1.2. Steering column panels removal/reassembly

- 1.2.7.2. Protective roof

- 1.2.7.2.1. Removal of the protective roof

- 1.2.7.2.2. Protective roof refitting

- 1.2.7.2.3. Lamp changes

- 1.2.8. Steering system

- 1.2.8.1. Hydraulic steering circuit

- 1.2.8.1.1. Power steering circuit tube connection diagram

- 1.2.8.2. Steering solenoid valve

- 1.2.8.2.1. Steering distributor technical data

- 1.2.8.2.2. Steering distributor removal

- 1.2.8.2.3. Steering distributor reassembly

- 1.2.8.3. Steering column

- 1.2.8.3.1. Steering column removal/reassembly

- 1.2.8.3.2. Replacement of the steering column joint

- 1.2.8.4. Steering axle

- 1.2.8.4.1. Steering axle technical data

- 1.2.8.4.2. Steering axle disconnection

- 1.2.8.4.3. Steering axle reconnection

- 1.2.8.4.4. Steering axle lubrication

- 1.2.8.4.5. Replacement of the steering axle bearings

- 1.2.8.4.6. Steering axle potentiometer

- 1.2.8.4.7. Replacement of the steering axle potentiometer

- 1.2.8.5. Steering cylinder

- 1.2.8.5.1. Steering cylinder disconnection

- 1.2.8.5.2. Steering cylinder reconnection

- 1.2.8.5.3. Replacement of the steering cylinder gaskets

- 1.2.8.5.4. Replacement of the cylinder connecting rod ball joints

- 1.2.9. Wheel and tyres

- 1.2.9.1. Miscellaneous

- 1.2.9.1.1. Safety regulations for wheels and rims

- 1.2.9.1.2. General information for changing tyres

- 1.2.9.1.3. Tyrewear check

- 1.2.9.2. Changing wheels

- 1.2.9.2.1. Changing the front wheel

- 1.2.9.2.2. Changing the rear wheel.

- 1.2.9.3. Wheel disassembly

- 1.2.9.3.1. Disassembly/assembly of tyres on rims with movable flange

- 1.2.9.3.2. Quick tyres assembly/disassembly

- 1.2.9.4. Tightening torques

- 1.2.9.4.1. Tightening torques for single wheels

- 1.2.10. Brake system

- 1.2.10.1. Service brake

- 1.2.10.1.1. Brake pedal

- 1.2.10.1.2. Brake pedal potentiometer

- 1.2.10.1.3. Brake pedal removal/reassembly

- 1.2.10.1.4. Replacement of the brake pedal spring

- 1.2.10.1.5. Stop micro replacement

- 1.2.10.1.6. Replacement of the brake pedal potentiometer

- 1.2.10.1.7. Service brake adjustment

- 1.2.10.2. Parking brake

- 1.2.10.2.1. Microswitch features

- 1.2.10.2.2. Parking brake removal/reassembly

- 1.2.10.2.3. Parking brake wire replacement

- 1.2.10.2.4. Replacement of the parking brake microswitch

- 1.2.10.2.5. Parking brake adjustment

- 1.2.10.3. Brake group

- 1.2.10.3.1. Brake pad replacement

- 1.2.11. Controls

- 1.2.11.1. Accelerator pedal

- 1.2.11.1.1. Accelerator pedal

- 1.2.11.1.2. Accelerator pedal potentiometer

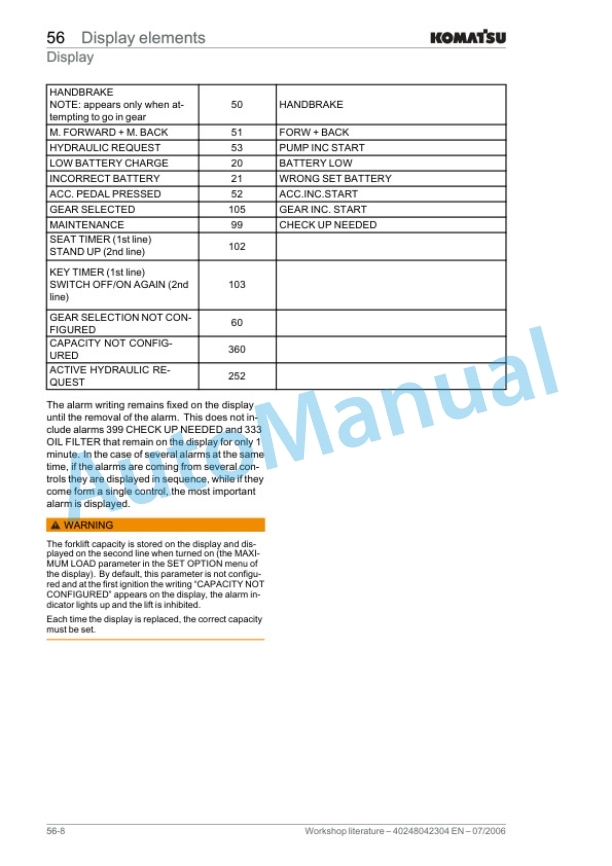

- 1.2.12. Display elements

- 1.2.12.1. Display

- 1.2.12.1.1. Multifunction panel

- 1.2.12.1.2. State of the display on ignition

- 1.2.12.1.3. State of the display during normal forklift operation

- 1.2.12.1.4. State of the display during an alarm situation

- 1.2.12.1.5. Plate data

- 1.2.12.1.6. Display operation

- 1.2.13. Electrical system

- 1.2.13.1. CAN BUS

- 1.2.13.1.1. CAN BUS

- 1.2.13.1.2. CAN BUS Application

- 1.2.13.1.3. Brake pedal potentiometer

- 1.2.13.2. Drive electrical system

- 1.2.13.2.1. Functions of the DUAL AC module

- 1.2.13.2.2. Plate data

- 1.2.13.2.3. DUAL AC connectors

- 1.2.13.2.4. Software program and parameterizations

- 1.2.13.3. Hydraulic functions electrical system

- 1.2.13.3.1. Functions of the AC3 module

- 1.2.13.3.2. Plate data

- 1.2.13.3.3. AC3 Connectors

- 1.2.13.3.4. Software program and parameterizations

- 1.2.13.4. Electrical system components

- 1.2.13.4.1. Contactors

- 1.2.13.4.2. Fuses

- 1.2.13.4.3. DC/DC Converter

- 1.2.13.4.4. Emergency pushbutton

- 1.2.13.4.5. Buzzer

- 1.2.13.4.6. Fans

- 1.2.13.4.7. Encoder description

- 1.2.13.4.8. Lamps

- 1.2.13.4.9. Protection of the electrical system

- 1.2.14. Hydraulic equipment

- 1.2.14.1. Solenoid valve

- 1.2.14.1.1. Lifting hall sensor

- 1.2.14.1.2. Reed contacts

- 1.3. Annex

- 1.3.1. A Diagrams

- 1.3.1.1. Circuit diagrams

- 1.3.1.1.1. Electrical circuit plan sheet 1/1

- 1.3.1.2. Hydraulic diagrams

- 1.3.1.2.1. Hydraulic system plan sheet 1/1

- 1.3.1.3. Flow diagrams

- 1.3.1.3.1. Flow chart of functions on display

Rate this product

You may also like