Komatsu FG20-8, FG25-8, FG30-8, FD20-8, FD25-8, FD30-8, FD20-10, FD25-10, FD30-10, FG20S-4, FG25S-4, FG30S-4, FD20S Shop Manual

$40.00

- Type Of Manual: Shop Manual

- Format: PDF

- Size: 26.5MB

- Number of Pages: 539

Category: Komatsu Shop Manual PDF

-

Model List:

- FG20-8 Forklift Truck

- FG25-8 Forklift Truck

- FG30-8 Forklift Truck

- FD20-8 Forklift Truck

- FD25-8 Forklift Truck

- FD30-8 Forklift Truck

- FD20-10 Forklift Truck

- FD25-10 Forklift Truck

- FD30-10 Forklift Truck

- FG20S-4 Forklift Truck

- FG25S-4 Forklift Truck

- FG30S-4 Forklift Truck

- FD20S-4 Forklift Truck

- FD25S-4 Forklift Truck

- FD30S-4 Forklift Truck

- FD20S-5 Forklift Truck

- FD25S-5 Forklift Truck

- FD30S-5 Forklift Truck

- FG20H-8 Forklift Truck

- FG25H-8 Forklift Truck

- FG30H-8 Forklift Truck

- 1. ASFORE

- 1.1. FOREWORD

- 1.2. DISASSEMBLY AND ASSEMBLY DIAGRAM

- 1.3. DESCRIPTION OF THE SYMBOLS

- 2. ASGEN

- 2.1. GENERAL AND SPECIFICATIONS

- 2.1.1. General locations

- 2.1.2. Machine serial number

- 2.1.3. Engine serial number

- 2.1.4. Weight of main components

- 2.1.5. Specifications

- 2.1.6. Overall dimensions

- 2.1.7. Standard tightening torque

- 2.1.8. Periodic replacement

- 2.1.9. Precautions for maintenance

- 3. AGDIS

- 3.1. DISASSEMBLY AND ASSEMBLY

- 3.1.1. SERIES

- 3.1.1.1. General disassembly

- 3.1.1.2. General assembly

- 3.1.1.3. Tighteneing torque

- 3.1.2. SERIES

- 3.1.2.1. General disassembly

- 3.1.2.2. General assembly

- 3.1.2.3. Tightenening torque

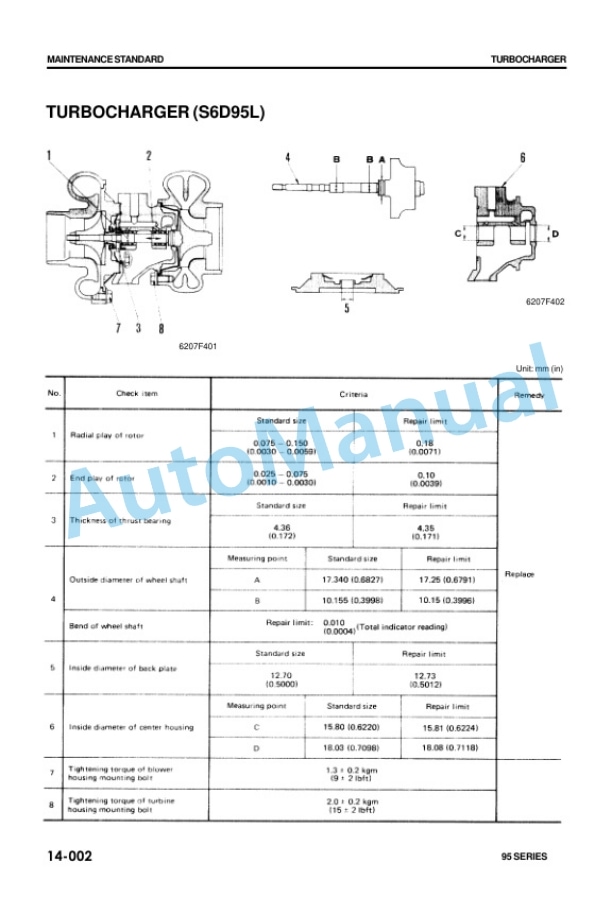

- 3.2. MAINTENANCE STANDARD

- 3.3. Turbocharger

- 3.4. Cylinder head

- 3.5. Valve and valve guide

- 3.6. Rocker arm shaft, push rod and tappet

- 3.7. Cylinder block

- 3.8. Crankshaft

- 3.9. Camshaft

- 3.10. Timing gear

- 3.11. Piston, piston ring and piston pin

- 3.12. Connecting rod

- 3.13. Flywheel and flywheel housing

- 3.14. Oil pump

- 3.15. Regulator valve

- 3.16. Water pump and thermostst

- 4. AGSERV

- 4.1. SERVICE INFORMATION

- 4.2. Procedure for selection and installation of pistons on 4D95S (L) and 6D95L engine

- 5. AGSTRUC

- 5.1. STRUCTURE AND FUNCTION

- 5.2. GENERAL STRUCTURE

- 5.3. INTAKE AND EXHAUST SYSTEM

- 5.3.1. Intake and exhaust system

- 5.3.2. Main circulation system

- 5.3.3. Timing gear

- 5.3.4. Valve system

- 5.3.5. Flywheel and flywheel housing

- 5.4. LUBRICATION SYSTEM

- 5.4.1. Lubrication system chart

- 5.4.2. Oil pump

- 5.4.3. Oil filter

- 5.5. FUEL SYSTEM

- 5.5.1. Fuel system chart

- 5.5.2. Fuel injection pump

- 5.5.3. Fuel injection nozzle

- 5.5.4. Fuel filter

- 5.6. COOLING SYSTEM

- 5.6.1. Cooling system chart

- 5.6.2. Water pump

- 5.6.3. Oil cooler (option)

- 5.6.4. Thermostat and fan drive

- 5.7. ELECTRICAL SYSTEM

- 5.7.1. Starting and charging circuit

- 5.7.2. Alternator

- 5.7.3. Starting motor

- 5.7.4. Electrical intake air heater

- 5.7.5. Fuel solenoid

- 6. AGTEST

- 6.1. TESTING AND ADJUSTING

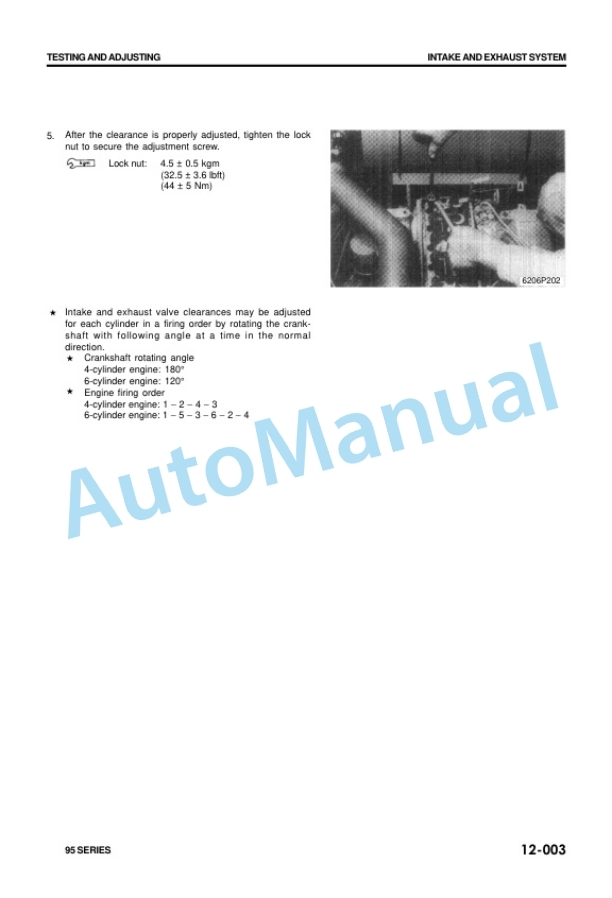

- 6.2. INTAKE AND EXHAUST SYSTEM

- 6.2.1. Adjusting valve clearance

- 6.2.2. Measuring exhaust gas color

- 6.3. ENGINE BODY

- 6.3.1. Measuring compression pressure

- 6.3.2. Measuring blowby pressure

- 6.4. FUEL SYSTEM

- 6.4.1. Checking and adjusting fuel injection timing

- 6.4.2. Adjustment of fuel injection pressure

- 6.4.3. Adjustment of fuel injection volume

- 6.4.4. Adjustment of governor

- 6.5. LUBRICATION SYSTEM

- 6.5.1. Measuring oil pressure

- 6.5.2. Measuring oil temperature

- 6.6. COOLING SYSTEM

- 6.6.1. Measuring water temperature

- 6.6.2. Testing and adjusting fan belt tension

- 6.7. PERFORMANCE TEST

- 6.7.1. Runin standard

- 6.7.2. Performance test criteria

- 6.7.3. Testing and adjusting tool list

- 6.7.4. Testing and adjusting data

- 6.8. TROUBLESHOOTING

- 6.8.1. Method of reading troubleshooting table

- 6.8.2. Troubleshooting table

- 7. ASAPPEN

- 7.1. APPENDIX

- 7.1.1. Change in structure of radiator mount

- 7.1.2. Change of TORQFLOW transmission control valve

- 7.1.3. Improved tilt valve

- 7.1.4. Quick on start system

- 7.1.5. Auto stop system

- 7.1.6. Local modification for full transisterized ignition system

- 8. ASDIS

- 8.1. DISASSEMBLY AND ASSEMBLY OF COMPONENTS

- 8.1.1. POWER TRAIN

- 8.1.1.1. General

- 8.1.1.2. Clutch

- 8.1.1.3. Transmission

- 8.1.1.4. Torque converter

- 8.1.1.5. TORQFLOW transmission

- 8.1.1.6. Front axle

- 8.1.1.7. Differential

- 8.1.1.8. Front wheel, Rear wheel

- 8.1.2. STEERING SYSTEM

- 8.1.2.1. General

- 8.1.2.2. Power steering pump

- 8.1.2.3. Steering gear box

- 8.1.2.4. Power steering cylinder

- 8.1.2.5. Rear axle

- 8.1.3. BRAKE SYSTEM

- 8.1.3.1. General

- 8.1.3.2. Master cylinder

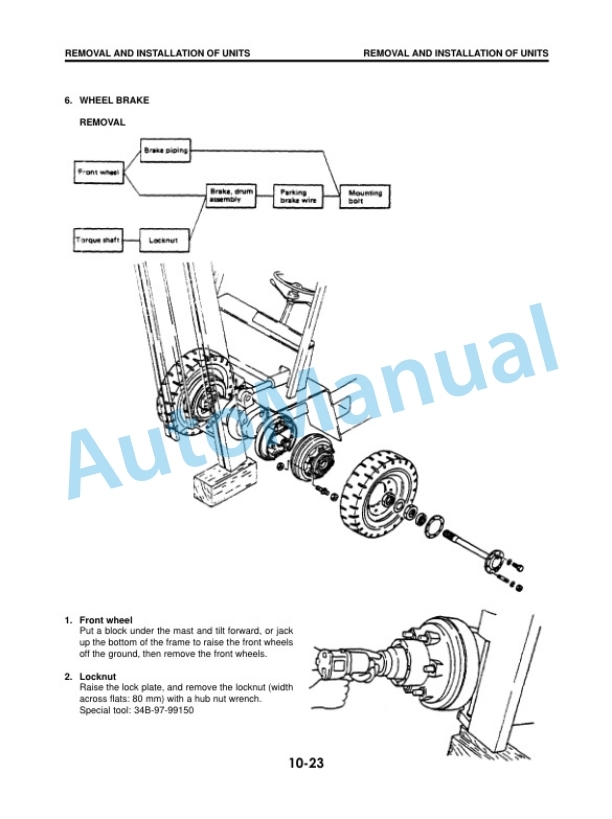

- 8.1.3.3. Wheel brake

- 8.1.4. HYDRAULIC SYSTEM

- 8.1.5. MAST AND RELATED PARTS

- 8.2. REMOVAL AND INSTALLATION OF UNIT

- 8.2.1. STRUCTURE

- 8.2.2. FLOW CHART

- 8.2.3. REMOVAL AND INSTALLATION OF UNIT

- 8.2.3.1. Mast

- 8.2.3.2. Lift cylinder

- 8.2.3.3. Torque converter (or clutch) Transmission Front axle

- 8.2.3.4. Engine

- 8.2.3.5. Muffler

- 8.2.3.6. Wheel brake

- 8.2.3.7. Rear axle

- 8.2.3.8. Power steering cylinder

- 8.2.3.9. Tightening torque

- 9. ASTEST

- 9.1. TESTING AND ADJUSTING

- 9.1.1. Engine

- 9.1.2. Drive system

- 9.1.3. Travel system

- 9.1.4. Steering system

- 9.1.5. Brake system

- 9.1.6. Work system

- 9.1.7. Hydraulic system

- 10. ASTROUB

- 10.1. TROUBLESHOOTING

- 10.1.1. Engine

- 10.1.2. Electrical system

- 10.1.3. Clutch and clutch transmission

- 10.1.4. TORQFLOW system

- 10.1.5. Steering system

- 10.1.6. Brake system

- 10.1.7. Hydraulic system

- 11. AWELEC

- 11.1. ENGINE ELECTRICAL SYSTEM

- 11.2. ENGINE LUBRICATION SYSTEM

- 11.3. OIL PUMP

- 12. AWMECH

- 12.1. ENGINE MECHANICAL

- 12.1.1. DISASSEMBLY

- 12.1.2. INSPECTION AND CORRECTION

- 12.1.3. ASSEMBLY

- 12.1.4. TIGHTENING TORQUE

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00