Komatsu GD510, GD520 Series Shop Manual SEBMG5250108

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBMG5250108

- Format: PDF

- Size: 36.4MB

- Number of Pages: 696

Category: Komatsu Shop Manual PDF

-

Model List:

- GD510 Series

- GD520 Series

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. TESTING AND ADJUSTING

- 3.1.1. TABLE OF JUDGEMENT STANDARD VALUE

- 3.1.2. TESTING AND ADJUSTING TOOL LIST

- 3.1.3. ADJUSTING VALVE CLEARANCE

- 3.1.4. MEASURING COMPRESSION PRESSURE

- 3.1.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.1.6. BLEEDING AIRFROM FUEL SYSTEM

- 3.1.7. ENGINE SPEED CONTROL

- 3.2. DISASSEMBLY AND ASSEMBLY

- 3.2.1. RADIATOR

- 3.2.2. RADIATOR ASSEMBLY

- 3.2.3. FUEL TANK(INCL.HYDRAULIC TANK)ASSEMBLY

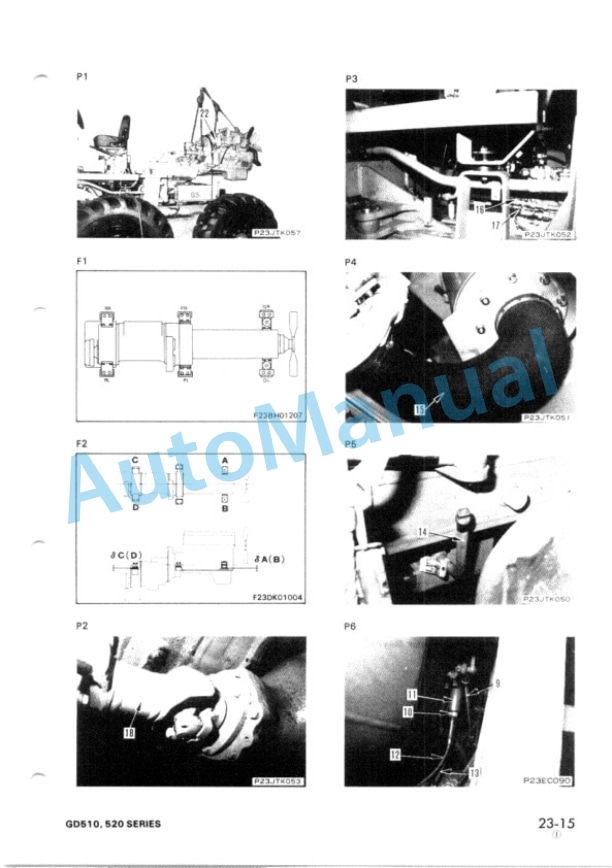

- 4. POWER TRAIN

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. GENERAL

- 4.1.2. POWER TRAIN

- 4.1.3. HYDROSHIFT TRANSMISSION PIPING

- 4.1.4. HYDROSHIFT TRANSMISSION CONTROL

- 4.1.5. POWER TRAIN HYDRAULIC CIRCUIT SCHEMATICS

- 4.1.6. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 4.1.8. HYDROSHIFT TRANSMISSION

- 4.1.9. TRANSFER

- 4.1.10. TRANSMISSION CONTROL VALVE

- 4.1.11. HYDROSHIFT TRANSMISSION PUMP

- 4.1.12. FINAL DRIVE

- 4.1.13. FINAL DRIVE,DIFFERENTIAL LOCK AND UNLOCK PIPING

- 4.1.14. TANDEM DRIVE

- 4.2. TESTING ADJUSTING

- 4.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 4.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 4.2.3. INCHING PEDAL TRAVEL AND OPERATING FORCE

- 4.2.4. MAIN CLUTCH

- 4.2.5. TRANSMISSION CONTROL LEVER TRAVEL AND OPERATING FORCE

- 4.2.6. CHECKING OIL PRESSURE

- 4.2.7. MACHINE TYPE AND INCHING PRESSURE

- 4.2.8. TRANSMISSION CONTROL LEVER TRAVEL AND OPERATING FORCE

- 4.2.9. CLEARANCE DIFFERENTIAL LOCKING DEVICE OIL PRESSURE

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. ENGINE(INCL.TRANSMISSION)ASSEMBLY

- 4.3.2. MAIN CLUTCH ASSEMBLY

- 4.3.3. MAIN CLUTCH CASE ASSEMBLY

- 4.3.4. MAIN CLUTCH ASSEMBLY

- 4.3.5. MAIN CLUTCH BOOSTER ASSEMBLY

- 4.3.6. TRANSMISSION ASSEMBLY

- 4.3.7. SHIFTING FORK COVER ASSEMBLY

- 4.3.8. TRANSMISSION

- 4.3.9. LOW SPEED ROTATING CLUTCH

- 4.3.10. INTERMEDIATE SHAFT ROTATING CLUTCH

- 4.3.11. CAGE AND CARRIER

- 4.3.12. TRANSMISSION CASE

- 4.3.13. PLANETARY GEAR

- 4.3.14. TRANSMISSION PUMP

- 4.3.15. TANDEM AND FINAL DRIVE

- 4.3.16. TANDEM,FINAL DRIVE ASSEMBLY

- 4.3.17. FINAL DRIVE

- 4.3.18. TANDEM,FINAL DRIVE ASSEMBLY

- 4.3.19. SIDE CASE ASSEMBLY

- 4.3.20. BEVEL GEAR ASSEMBLY

- 4.3.21. PINION ASSEMBLY

- 4.4. MAINTENANCE STANDARD

- 4.4.2. MAIN CLUTCH

- 4.4.3. TRANSMISSION

- 4.4.4. HYDROSHIFT TRANSMISSION

- 4.4.5. TRANSFER

- 4.4.6. HYDROSHIFT TRANSMISSION CONTROL VALVE

- 4.4.7. TRANSMISSION PUMP

- 4.4.8. FINAL DRIVE

- 4.4.9. TANDEM DRIVE

- 5. STEERING SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. STEERING PIPING

- 5.1.2. STEERING CIRCUIT DIAGRAM

- 5.1.3. STEERING CONTROL VALVE

- 5.1.4. FRONT AXLE

- 5.1.5. STEERING CYLINDER

- 5.1.6. WHEEL

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TABLE OF JUDGEMENT STANDARD

- 5.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 5.2.3. CHECKING STEERING WHEEL

- 5.2.4. CHECKING TIRE RUNOUT

- 5.2.5. CHECKING TIRE INFLATION PRESSURE

- 5.2.6. CHECKING TOEIN

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. FRONT AXLE ASSEMBLY

- 5.3.2. FRONT AXLE ASSEMBLY

- 5.3.3. STEERING VALVE

- 5.3.4. DOUBLE RELIEF VALVE

- 5.4. MAINTENANCE STANDARD

- 5.4.1. FRONT AXLE

- 5.4.2. STEERING CYLINDER

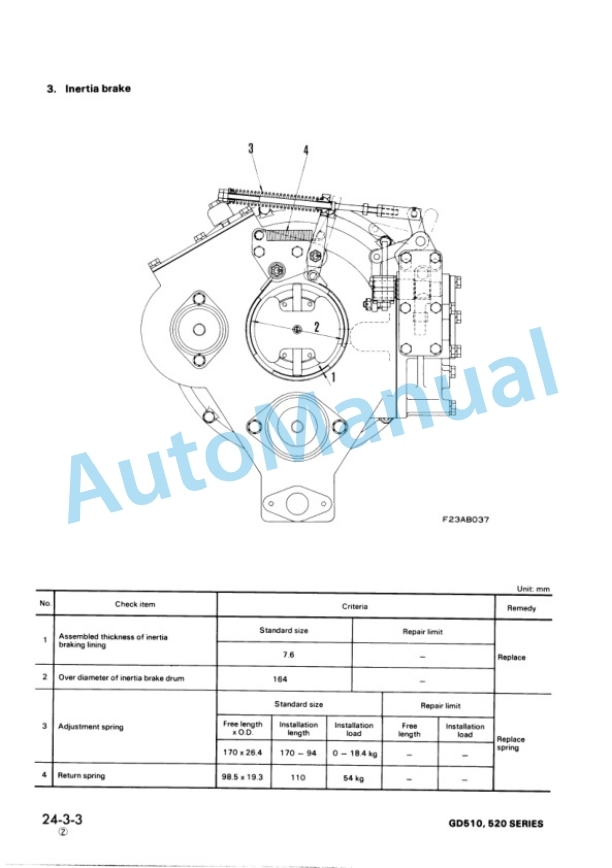

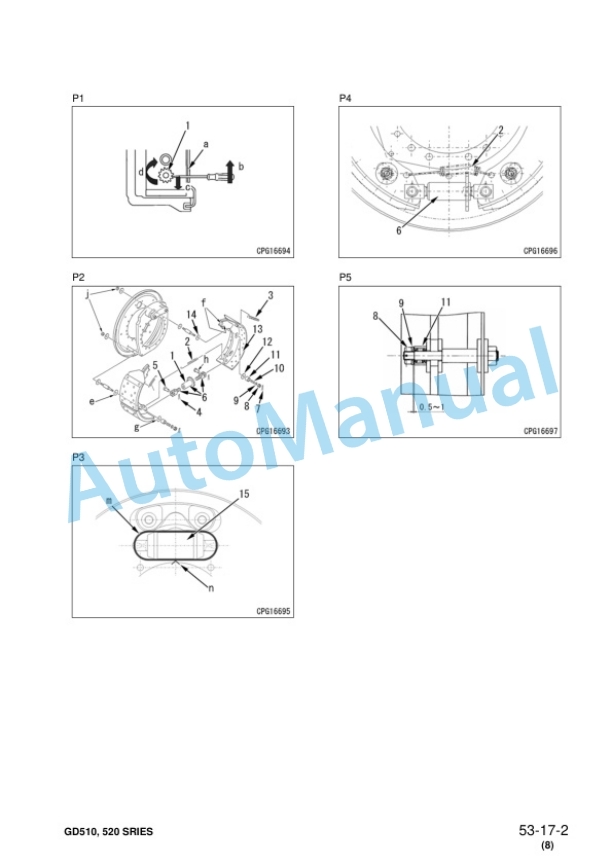

- 6. BRAKE SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. BRAKE PIPING

- 6.1.2. BRAKE CIRCUIT DIAGRAM

- 6.1.3. BOOST MASTER

- 6.1.4. BRAKE AIR PIPING

- 6.1.5. AIR BRAKE CIRCUIT SCHEMATICS

- 6.1.6. AIR BRAKE CIRCUIT DIAGRAM

- 6.1.7. AUTOMATIC DRAIN VALVE

- 6.1.8. AIR DRIER

- 6.1.9. WHEEL BRAKE

- 6.1.10. PARKING BRAKE

- 6.2. TESTING AND ADJUSTING

- 6.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 6.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 6.2.3. CHECKING BRAKE PEDAL

- 6.2.4. AIR BLEEDING FROM BRAKE CIRCUIT

- 6.2.5. CHECKING PARKING BRAKE LEVER

- 6.2.6. CHECKING WEAR OF BRAKE DISC

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. WHEEL BRAKE

- 6.3.2. WHEEL BRAKE ASSEMBLY

- 6.3.3. BOOST MASTER

- 6.3.4. PARKING BRAKE

- 6.4. MAINTENANCE STANDARD

- 6.4.1. WHEEL BRAKE

- 6.4.2. PARKING BRAKE

- 6.4.3. BOOST MASTER

- 7. HYDRAULIC SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. HYDRAULIC CONTROL PIPING

- 7.1.2. HYDRAULIC CONTROL LINKAGE

- 7.1.3. BLADE ACCUMULATOR SYSTEM

- 7.1.4. HYDRAULIC CIRCUIT DIAGRAM

- 7.1.5. FLOW DIVIDER

- 7.1.6. HYDRAULIC PUMP

- 7.1.7. CIRCLE ROTATION MOTOR

- 7.1.8. WORK EQUIPMENT CONTROL VALVE

- 7.1.9. PILOT CHECK VALVE

- 7.1.10. HYDRAULIC CYLINDER

- 7.2. DISASSEMBLY AND ASSEMBLY

- 7.2.1. HYDRAULIC PUMP(INCL.STEERING PUMP)

- 7.2.2. BLADE LIFT CYLINDER

- 7.2.3. DRAWBAR SHIFT CYLINDER

- 7.2.4. ARTICULATE CYLINDER

- 7.2.5. BLADE SIDE SHIFT CYLINDER

- 7.2.6. BLADE SIDE SHIFT CYLINDER ASSEMBLY

- 7.2.7. SCARIFIER CYLINDER ASSEMBLY

- 7.2.8. LEANING CYLINDER

- 7.2.9. POWER TILT CYLINDER

- 7.2.10. REAR MOUNT RIPPER CYLINDER ASSEMBLY

- 7.2.11. HYDRAULIC CYLINDER ASSEMBLY

- 7.2.12. CIRCLE ROTATION MOTOR

- 7.3. MAINTENANCE STANDARD

- 7.3.1. HYDRAULIC PUMP

- 7.3.2. HYDRAULIC CONTROL VALVE

- 7.3.3. HYDRAULIC CYLINDER

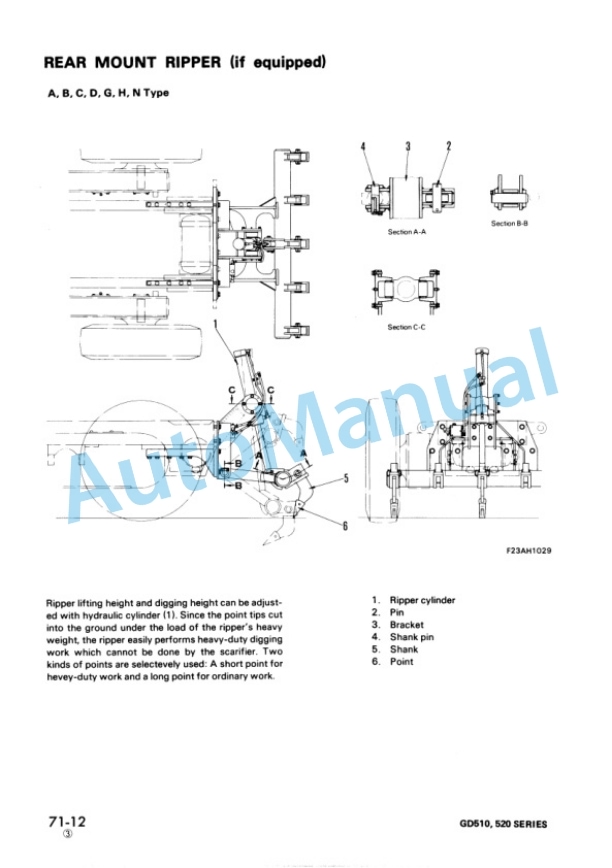

- 8. WORK EQUIPMENT

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. DRAWBAR AND LIFTER

- 8.1.2. BLADE

- 8.1.3. CIRCLE ROTATION GEAR

- 8.1.4. SCARIFIER

- 8.1.5. REAR MOUNT RIPPER

- 8.1.6. FRAME

- 8.2. TESTING AND ADJUSTING

- 8.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 8.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 8.2.3. CHECKING CONTROL LEVER

- 8.2.4. CHECKING HYDRAULIC OIL TRMPERATURE

- 8.2.5. CHECKING HYDRAULIC OIL PRESSURE

- 8.2.6. HYDRAULIC DRIFT

- 8.2.7. CHARGING BLADE ACCUMULATOR WITH GAS

- 8.2.8. ADJUSTMENT OF CIRCLE GUIDE

- 8.3. DISASSEMBLY AND ASSEMBLY

- 8.3.1. BLADE ASSEMBLY

- 8.3.2. CIRCLE ROTATION GEAR

- 8.3.3. REAR MOUNT RIPPER ASSEMBLY

- 8.4. MAINTENANCE STANDARD

- 8.4.1. DRAWBAR AND LIFTER

- 8.4.2. BLADE

- 8.4.3. CIRCLE ROTATION GEAR

- 8.4.4. SCARIFIER

- 8.4.5. REAR MOUNT RIPPER

- 9. ELECTRIC AND ELECTRONIC SYSTEM

- 9.1. STRUCTURE AND FUNCTION

- 9.1.1. ELECTRICAL CIRCUIT DIAGRAM

- 9.1.2. CIRCUIT DIAGRAM OF CAB

- 9.1.3. ELECTRONIC VEHICLE MONITORING SYSTEM(EVMS)

- 9.1.4. ADJUSTING SPEEDOMETER MODULE OF MACHINE MONITOR

- 9.2. TESTING AND ADJUSTING

- 9.2.1. TABLE OF MONITOR REFERENCE VALUES

- 9.2.2. ELECTRICAL WIRING DIAGRAM

- 9.2.3. POSITION OF CONNECTOR

- 9.2.4. CONNECTOR TERMINAL NUMBER

- 9.2.5. PRECAUTION WHEN HANDLING CONNECTOR

- 9.2.6. METHOD OF USING YESNO TROUBLESHOOTING FLOW CHART

- 9.2.7. TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM (D TYPE) (M1 TO M18)

- 9.2.8. TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM(M,N TYPE) (M1 TO M22)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00