Komatsu GD530A, GD650A, GD670A, AW Series Shop Manual CEBMG65194

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBMG65194

- Format: PDF

- Size: 96.6MB

- Number of Pages: 1053

Category: Komatsu Shop Manual PDF

-

Model List:

- GD530A Series

- GD650A Series

- GD670A Series

- AW Series

- 1. MAIN MENU

- 2. CONTENTS FOR CEBMG65194

- 3. A01.50K ARTICULATION JOINT ASSEMBLY

- 3.1. TABLE OF CONTENTS

- 3.2. INTRODUCTION

- 3.3. SERVICING

- 4. A10.40K CHARLYNN ORBITROL UNIT

- 4.1. TABLE OF CONTENTS

- 4.2. INTRODUCTION

- 4.3. SERVICING

- 5. C11.40K R1 TRANSMISSION POWER SHIFT (FUNK 2263E130B)

- 5.1. TABLE OF CONTENTS

- 5.2. SPECIAL TOOLS

- 5.3. INTRODUCTION

- 5.4. TROUBLESHOOTING

- 5.5. FLYWHEEL DIMENSIONAL CHECKS

- 5.6. CONVERTER ASSEMBLY INSTALLATION INTO TRANSMISSION IF SEPARATED FROM TRANSMISSION

- 5.7. SERVICING

- 5.8. SERVICING MACHINE AFTER TRANSMISSION OVERHAUL

- 5.9. STARTUP PROCEDURE

- 6. E01.15K ALL WHEEL DRIVE PUMP (REXROTH)

- 6.1. TABLE OF CONTENTS

- 6.2. INTRODUCTION

- 6.3. INTERPRETATION OF TYPE CODES

- 6.4. DIAGNOSTIC PORTS

- 6.5. TROUBLESHOOTING

- 6.6. SERVICING

- 6.7. TESTS AND ADJUSTMENTS

- 7. E03.90K R1 CIRCLE REVERSE MOTOR (DANFOSS)

- 7.1. TABLE OF CONTENTS

- 7.2. LOCATION ON MACHINE

- 7.3. DESCRIPTION

- 7.4. SERVICING

- 8. E03.95K CIRCLE REVERSE MOTOR P/N 1435 598 H91 (CHARLYNN)

- 8.1. TABLE OF CONTENTS

- 8.2. TESTS AND ADJUSTMENTS

- 9. E04.60K STEERING BRAKE PUMP (EATON MODEL 70422 RDU)

- 9.1. TABLE OF CONTENTS

- 9.2. LOCATION ON MACHINE

- 9.3. DESCRIPTION

- 9.4. SPECIFICATIONS

- 9.5. SERVICE DIAGNOSIS

- 9.6. SERVICE/SPECIAL TOOLS

- 9.7. PRESSURES

- 9.8. SPECIAL TORQUES

- 9.9. TESTS AND ADJUSTMENTS

- 9.10. SERVICING

- 10. E13.30K HYDRAULIC MOTOR (VICKERS) (ALL WHEEL DRIVE)

- 10.1. TABLE OF CONTENTS

- 10.2. LOCATION ON MACHINE

- 10.3. DESCRIPTION

- 10.4. OPERATION

- 10.5. SPECIFICATIONS

- 10.6. SERVICE DIAGNOSIS

- 10.7. SERVICE/SPECIAL TOOLS

- 10.8. SERVICING

- 10.9. TESTS AND ADJUSTMENTS

- 11. E30.40K HYDRAULIC OIL SWIVEL BLOCK (FOURWAY)

- 11.1. TABLE OF CONTENTS

- 11.2. TESTING AND ADJUSTMENTS

- 12. E32.35K CONTROL VALVE MANIFOLDS (HUSCO 5000C SERIES)

- 12.1. TABLE OF CONTENTS

- 12.2. INTRODUCTION

- 12.3. TROUBLESHOOTING

- 12.4. SERVICING

- 13. E32.45K MAIN SYSTEM PUMP

- 13.1. TABLE OF CONTENTS

- 13.2. INTRODUCTION

- 13.3. TROUBLESHOOTING

- 13.4. SERVICING

- 14. E32.90K ALL WHEEL DRIVE HYDRAULIC INTEGRATED CIRCUIT (HIC) VALVE

- 14.1. TABLE OF CONTENTS

- 14.2. INTRODUCTION

- 14.3. TROUBLESHOOTING

- 14.4. SERVICING

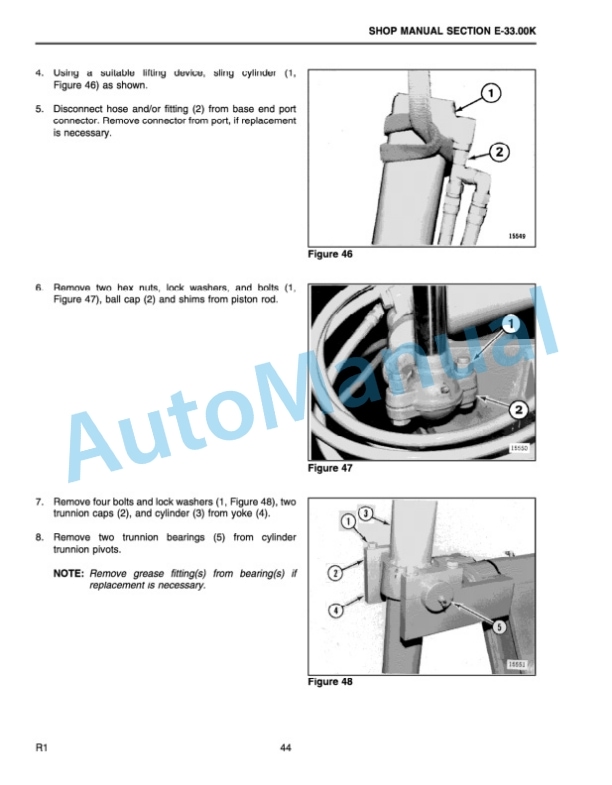

- 15. E33.00K R1 HYDRAULIC CYLINDERS

- 15.1. TABLE OF CONTENTS

- 15.2. INTRODUCTION

- 15.3. SERVICE DIAGNOSIS

- 15.4. SPECIAL TORQUES

- 15.5. TESTS AND ADJUSTMENTS

- 15.6. SERVICING

- 16. E33.10K ACCUMULATORS (P/N 1285 352 H91, 1279 537 H 1233 789 H91)

- 16.1. TABLE OF CONTENTS

- 16.2. LOCATION ON MACHINE

- 16.3. DESCRIPTION

- 16.4. OPERATION

- 16.5. SPECIFICATIONS

- 16.6. SERVICE/SPECIAL TOOLS

- 16.7. PRESSURES

- 16.8. SPECIAL TORQUES

- 16.9. TESTS AND ADJUSTMENTS

- 16.10. SERVICING

- 17. E33.80K TROUBLESHOOTING AND ADJUSTMENT MANUAL

- 17.1. TABLE OF CONTENTS

- 17.2. SPECIAL TOOLS

- 17.3. INTRODUCTION

- 17.4. SETTING RELIEF VALVES

- 17.5. GENERAL DIAGNOSIS PROCEDURE

- 17.6. HYDRAULIC TEST PORT CONNECTIONS

- 17.7. HYDRAULIC SYSTEM OVERVIEW

- 17.8. DETAILED HYDRAULIC SYSTEMS

- 17.9. STEERING AND BRAKE CIRCUIT (INCLUDES LOCK PIN)

- 17.10. ALL WHEEL DRIVE CIRCUIT

- 17.11. All Wheel Drive Pump Adjustment Procedure

- 17.12. Filtering Procedure for AWD Hydraulic System

- 18. E34.00K REAR AXLE COOLING AND LOCK/UNLOCK DIFFERENTIAL PUMP

- 18.1. TABLE OF CONTENTS

- 18.2. INTRODUCTION

- 18.3. SERVICING

- 18.4. TESTS AND ADJUSTMENTS

- 19. F01.20K R1 CIRCLE REVERSE SLIP CLUTCH

- 19.1. TABLE OF CONTENTS

- 19.2. RETROFITTING A STANDARD CIRCLE GEAR CASE WITH A SLIP CLUTCH

- 19.3. TESTS AND ADJUSTMENTS

- 20. F01.30K CIRCLE REVERSE GEAR CASE

- 20.1. TABLE OF CONTENTS

- 20.2. INTRODUCTION

- 20.3. SERVICING

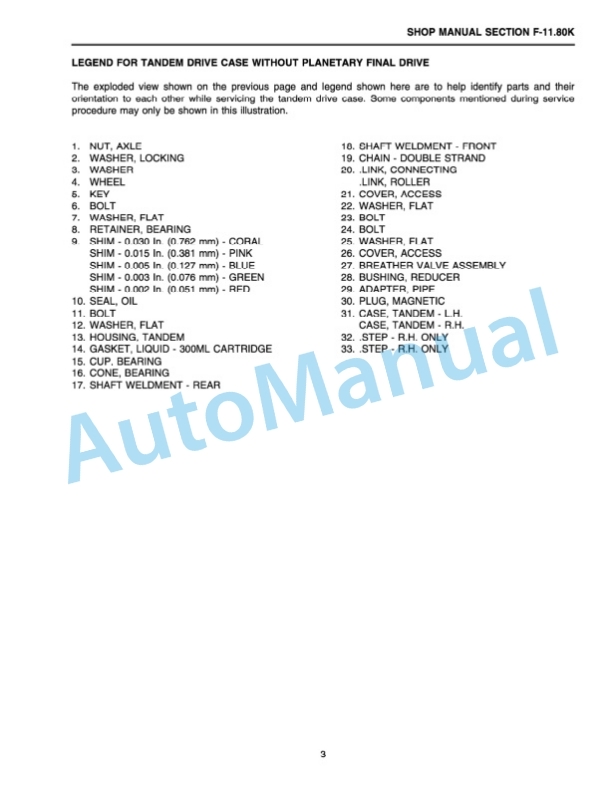

- 21. F11.80K R1 TANDEM CASE (SINGLE AND DOUBLE STRAND CHAINS)

- 21.1. TABLE OF CONTENTS

- 21.2. LOCATION ON MACHINE

- 21.3. DESCRIPTION

- 21.4. FINAL DRIVE PLANETARY/NONPLANETARY IDENTIFICATION

- 21.5. SPECIFICATIONS

- 21.6. SERVICE DIAGNOSIS

- 21.7. SERVICE/SPECIAL TOOLS

- 21.8. TOLERANCES

- 21.9. LUBRICANTS AND SEALANTS

- 21.10. SPECIAL TORQUES

- 21.11. TESTS AND ADJUSTMENTS

- 21.12. SERVICING

- 22. G01.13K R3 GEARBOX ASSEMBLY (ALL WHEEL DRIVE)

- 22.1. TABLE OF CONTENTS

- 22.2. DESCRIPTION

- 22.3. SERVICE/SPECIAL TOOLS

- 22.4. TESTS AND ADJUSTMENTS

- 22.5. SERVICING

- 23. G01.15K FRONT AXLE ASSEMBLY

- 23.1. TABLE OF CONTENTS

- 23.2. DESCRIPTION

- 23.3. FRONT AXLE TORQUE VALUES

- 23.4. TESTS AND ADJUSTMENTS

- 23.5. SERVICING

- 24. G09.30K R1 FINAL DRIVE ASSEMBLY (JOHN DEERE TeamMate II) WITH PLANETARY AND NONPLANETARY REDUCTION (NoSPIN LOCK/UNLOCK DIF

- 24.1. TABLE OF CONTENTS

- 24.2. LOCATION ON MACHINE

- 24.3. DESCRIPTION

- 24.4. SERVICE DIAGNOSIS

- 24.5. SERVICE/SPECIAL TOOLS

- 24.6. LUBRICANTS AND SEALANTS

- 24.7. SPECIAL TORQUES

- 24.8. TESTS AND ADJUSTMENTS

- 24.9. SERVICING

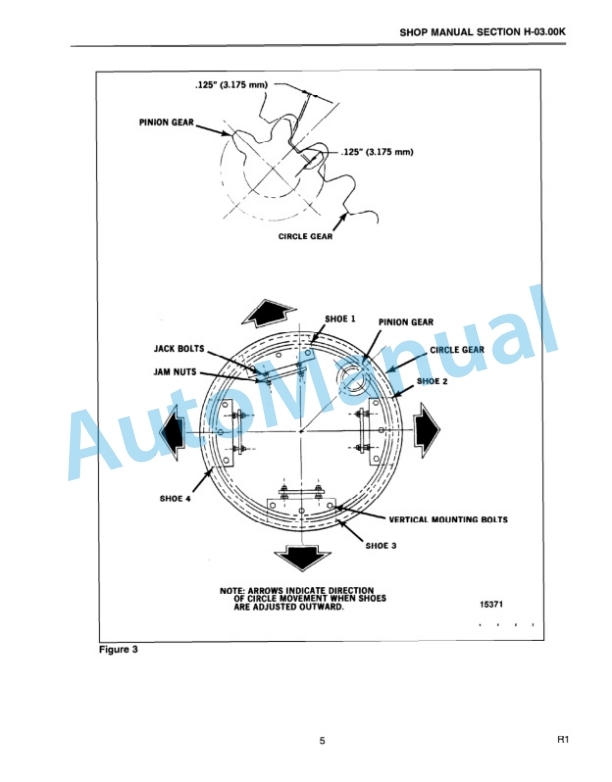

- 25. H03.00K R1 CIRCLE ADJUSTMENT (FOUR SHOE)

- 25.1. TABLE OF CONTENTS

- 25.2. INTRODUCTION

- 25.3. REBUILDING TEETH

- 25.4. VERTICAL ADJUSTMENT

- 25.5. PINION ADJUSTMENT

- 26. Y02.00K METRIC CONVERSIONS

- 26.1. TABLE OF CONTENTS

- 26.2. METRIC CONVERSIONS

- 27. K04.20K R1 PARKING BRAKE CALIPER (PERROT P/N 40 023 002)

- 27.1. TABLE OF CONTENTS

- 27.2. LOCATION ON MACHINE

- 27.3. DESCRIPTION

- 27.4. OPERATION

- 27.5. SERVICE DIAGNOSIS

- 27.6. LUBRICANTS AND SEALANTS

- 27.7. TESTS AND ADJUSTMENTS

- 28. K04.30K PARKING BRAKE CALIPER (MICO)

- 28.1. TABLE OF CONTENTS

- 28.2. INTRODUCTION

- 28.3. OPERATION

- 28.4. TROUBLESHOOTING

- 28.5. TESTS AND ADJUSTMENTS

- 29. K11.10K R2 BRAKE VALVE (REXROTH)

- 29.1. TABLE OF CONTENTS

- 29.2. LOCATION ON MACHINE

- 29.3. DESCRIPTION

- 29.4. OPERATION

- 29.5. LUBRICANTS AND SEALANTS

- 29.6. SPECIAL TORQUES

- 29.7. TESTS AND ADJUSTMENTS

- 29.8. SERVICING

- 30. K11.30K R1 BRAKE VALVE (MICO)

- 30.1. TABLE OF CONTENTS

- 30.2. TESTS AND ADJUSTMENTS

- 31. L01.45K WIRING DIAGRAMS

- 31.1. Foldout No. 1 Electrical Wiring Diagram 1 of 2

- 31.2. Foldout No. 1 Electrical Wiring Diagram 2 of 2

- 31.3. Foldout No. 2 Electrical Wiring Diagram 1 of 3

- 31.4. Foldout No. 2 Electrical Wiring Diagram 2 of 3

- 31.5. Foldout No. 2 Electrical Wiring Diagram 3 of 3

- 31.6. Foldout No. 3 Electrical Wiring Diagram 1 of 3

- 31.7. Foldout No. 3 Electrical Wiring Diagram 2 of 3

- 31.8. Foldout No. 3 Electrical Wiring Diagram 3 of 3

- 32. N01.35K R1 PREDELIVERY PROCEDURES

- 32.1. TABLE OF CONTENTS

- 32.2. PREUNLOADING CHECKS

- 32.3. RECORD SERIAL NUMBERS

- 32.4. GENERAL INSTRUCTIONS

- 32.5. LUBRICATION

- 32.6. TORQUES

- 32.7. ENGINE CHECKS

- 32.8. PRESSURE TESTS

- 32.9. CHECKS AND ADJUSTMENTS

- 32.10. TESTING

- 33. X01.00K SUSPENSION SEAT

- 33.1. TABLE OF CONTENTS

- 33.2. SERVICING

- 33.3. GENERAL

- 33.4. COMPLETE ASSEMBLY

- 33.5. LOWER SUSPENSION

- 33.6. SEAT ADJUSTER

- 34. Y01.00K GENERAL TORQUE VALUES

- 34.1. TABLE OF CONTENTS

- 34.2. INTRODUCTION

- 34.3. TORQUE VALUES FOR STANDARD ENGLISH FASTENERS

- 34.4. TORQUE VALUES FOR STANDARD METRIC FASTENERS

- 34.5. TORQUE VALUES FOR HOSE CLAMPS

- 34.6. TORQUE VALUES FOR SPLIT FLANGE CONNECTIONS

- 34.7. TORQUE VALUES FOR HYDRAULIC TUBES AND FITTINGS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00