Komatsu HB365LC-3 Hydraulic Excavator Field Assembly Instruction GEN00146-04

$20.00

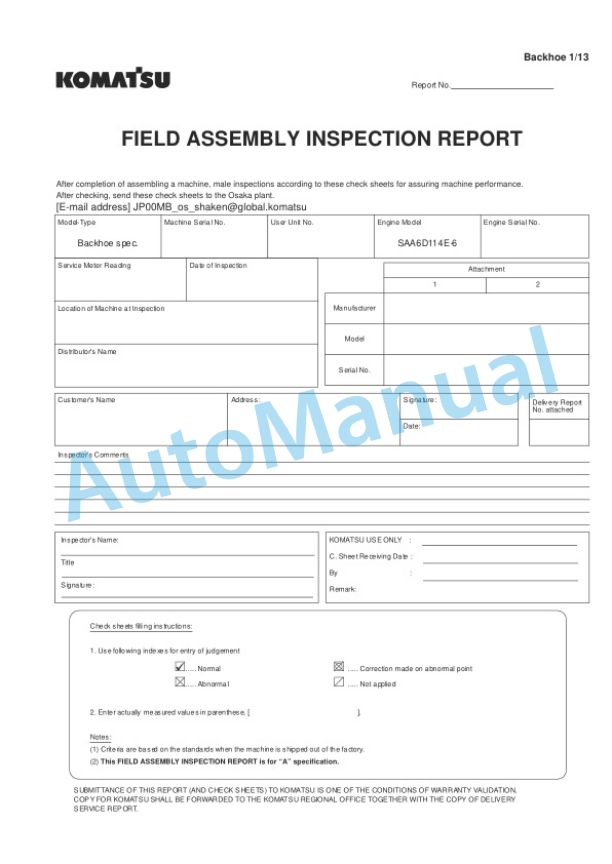

- Type Of Manual: Field Assembly Instruction

- Manual ID: GEN00146-04

- Format: PDF

- Size: 10.3MB

- Number of Pages: 132

-

Model List:

- HB365LC-3 Hydraulic Excavator

- 1. COVER

- 2. FOREWORD

- 3. CONTENTS

- 4. Specifications

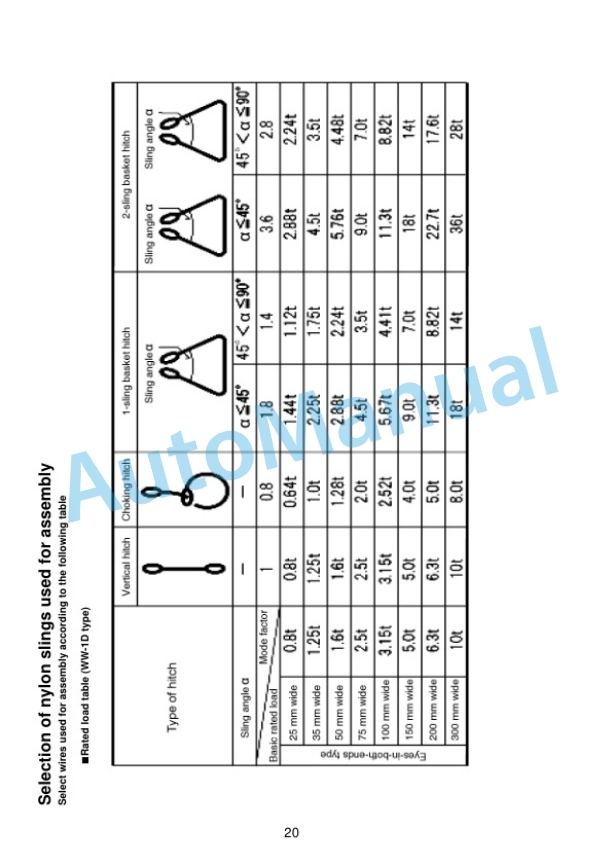

- 5. Precautions for field assembly

- 6. Disposal of Removed Parts

- 7. Assembling Procedures, Applicable Equipment and Schedule

- 8. Flow of field assembly

- 9. KIT Layout Diagram

- 10. Transportation

- 11. Tool list for field assembly

- 12. Tightening Torque

- 13. Coating Materials

- 14. Selection of wire ropes used for assembly

- 15. Selection of nylon slings used for assembly

- 16. ASSEMBLY OF CHASSIS

- 16.1. A1 Installation of handrail

- 16.2. A2 Installation of climbing grip

- 16.3. A3 Installation of mirror

- 17. ASSEMBLING OF WORK EQUIPMENT

- 17.1. B1 Installation of Boom Cylinder

- 17.2. B2 Releasing remaining pressure in hydraulic circuit

- 17.3. B3 Installation of Boom Cylinder Hoses

- 17.4. B4 Installation of boom cylinder top pin

- 17.5. B5 Installation of boom assembly

- 17.6. B6 Installation of Hoses from Chassis Along Top of Boom

- 17.7. B7 Connection of Boom Cylinder Head

- 17.8. B8 Installation of Arm Assembly

- 17.9. B9 Installation of Bucket Cylinder Hoses between Boom and Bucket Cylinder

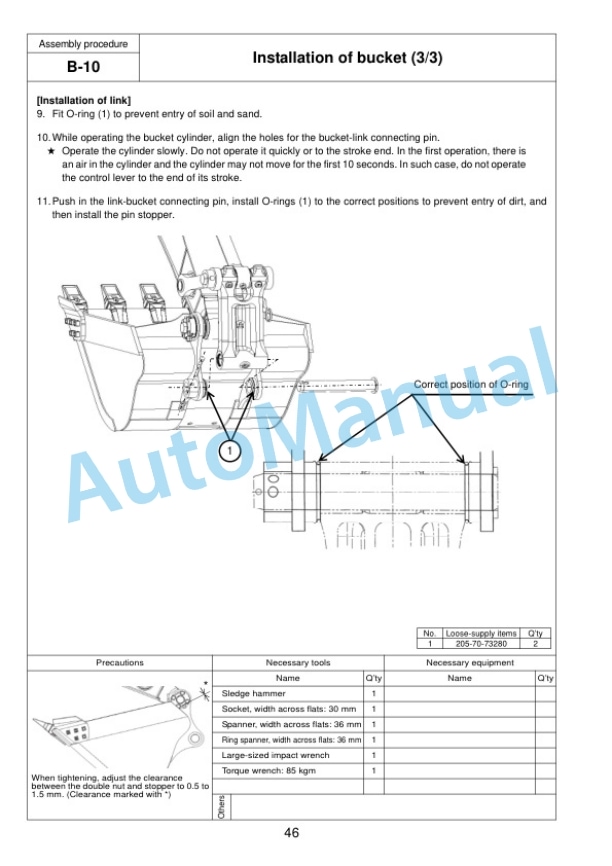

- 17.10. B10 Installation of Bucket

- 17.11. B11 Connection of Work Equipment Grease Piping

- 17.12. B12 Connection of Work Equipment Wiring

- 17.13. B13 Greasing after completion of work equipment

- 17.14. B14 Bleeding air from work equipment circuit

- 18. INCREASING AND DECREASING OF TRACK FRAME GAUGE,ASSEMBLING OF COUNTERWEIGHT

- 18.1. C1 Adjustment of track tension

- 18.2. C2 Sticking Sheet to Counterweight

- 18.3. C3 Installation of camera

- 18.4. C4 Sticking sheet to revolving frame

- 18.5. C5 Installation of counterweight

- 19. PROCEDURE FOR INSPECTION AND MAINTENANCE AFTERCOMPLETION OF ASSEMBLY

- 19.1. M1 Replacement of return filter(Standard filter to flushing filter)

- 19.2. M2 Flushing of hydraulic circuit

- 19.3. M3 Replacement of Return Filter (Flushing Filter to standard Filter) (1/2)

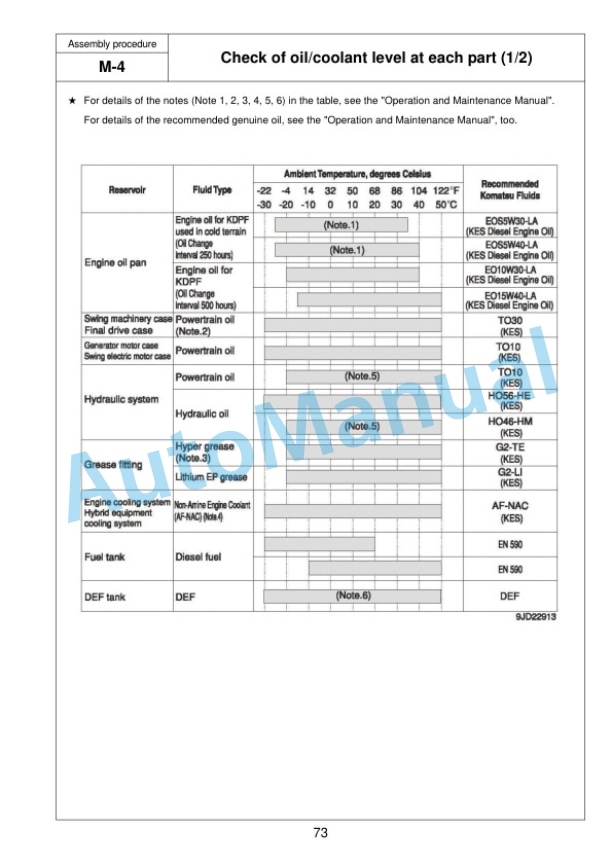

- 19.4. M4 Check of oil/coolant level at each part

- 19.5. M5 Inspection of oil level in hydraulic tank and refill

- 19.6. M6 Parts to be touched up after field assembly

- 19.7. M7 Error code

- 19.8. M8 ADJUST KomVision Camera angle (KomVision Spec.) (Camera calibration and 12 m visibility check)

- 20. Mounting bolt torque check sheet

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901