Komatsu HD1500-5 Dump Truck Operation and Maintenance Manual CEAM006100

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM006100

- Format: PDF

- Size: 1.8MB

- Number of Pages: 162

-

Model List:

- HD1500-5 Dump Truck

- 1. MAIN MENU

- 2. COVER

- 3. INTRODUCTION

- 3.1. FORWARD

- 3.2. ALERTS PAGEA DESCRIPTION OF THE DANGER, WARNING, AND CAUTION SYMBOLS USED IN THIS MANUAL

- 3.3. TABLE OF CONTENTS

- 3.4. TRUCK MODEL ILLUSTRATION

- 3.5. ABOUT THIS MANUAL

- 3.6. STANDARD CHARTS AND TABLES

- 4. SAFETY

- 4.1. GENERAL SAFETY

- 4.2. PRECAUTIONS DURING OPERATION

- 4.2.1. OPERATING MACHINE

- 4.2.2. BATTERY

- 4.2.3. TOWING

- 4.3. PRECAUTIONS FOR MAINTENANCE

- 4.3.1. BEFORE CARRYING OUT MAINTENANCE

- 4.3.2. DURING MAINTENANCE

- 4.3.3. TIRES

- 4.3.4. WHEN REPAIRS ARE NECESSARY

- 4.3.5. ADDITIONAL JOB SITE RULES

- 4.4. WARNING, CAUTION AND INSTRUCTION PLATES/DECALS

- 5. OPERATION

- 5.1. OPERATING INSTRUCTIONS

- 5.1.1. PREPARING FOR OPERATION

- 5.1.2. SAFETY IS THINKING AHEAD

- 5.1.3. AT THE TRUCK GROUND LEVEL WALK AROUND INSPECTION

- 5.2. ENGINE STARTUP SAFETY PRACTICES

- 5.3. AFTER ENGINE HAS STARTED

- 5.4. MACHINE OPERATION SAFETY PRECAUTIONS

- 5.5. LOADING

- 5.6. HAULING

- 5.6.1. RETARDER OPERATION

- 5.7. PASSING

- 5.8. DUMPING

- 5.9. SAFE PARKING PROCEDURES

- 5.10. SHUTDOWN PROCEDURE

- 5.11. TOWING

- 5.12. OPERATOR CAB AND CONTROLS

- 5.12.1. STEERING WHEEL AND CONTROLS

- 5.12.2. RETARDER CONTROL LEVER

- 5.12.3. SERVICE BRAKE PEDAL

- 5.12.4. THROTTLE PEDAL

- 5.12.5. INSTRUMENT PANEL

- 5.12.6. HEATER/AIR CONDITIONER COMPARTMENT AND CONTROLS

- 5.12.7. RETARDING CAPACITY CHART

- 5.12.8. RADIO SPEAKERS

- 5.12.9. MOM DISPLAY SCREEN

- 5.12.10. WARNING ALARM BUZZER

- 5.12.11. CAB RADIO

- 5.12.12. AIR CLEANER VACUUM GAUGES

- 5.12.13. PAYLOAD METER

- 5.12.14. WINSHIELD WIPERS

- 5.12.15. CENTER CONSOLE STRUCTURE

- 5.12.15.1. TRANSMISSION RANGE SELECTOR

- 5.12.15.2. CONTROL SWITCHES

- 5.12.15.3. SHIFT LIMITER SWITCH

- 5.12.15.4. F1 START SWITCH

- 5.12.15.5. HOIST CONTROL SWITCH

- 5.12.15.6. PARKING BRAKE SWITCH

- 5.12.15.7. BRAKE LOCK SWITCH

- 5.12.15.8. WINDOW CONTROL SWITCH

- 5.12.15.9. WINDOW CONTROL SWITCH

- 5.12.15.10. ASH TRAY

- 5.12.15.11. LIGHTER

- 5.12.15.12. PASSENGER SEAT W/SAFETY BELT

- 5.12.16. OPERATOR SEAT

- 5.13. INSTRUMENT PANEL AND INDICATORS

- 5.13.1. KEYSWITCH

- 5.13.2. EMERGENCY BRAKE SWITCH

- 5.13.3. CONTROL/INDICATOR PANEL (POD)

- 5.13.4. CENTER DISPLAY PANEL

- 5.13.5. CONTROL/INDICATOR PANEL (POD)

- 5.13.6. LADDER LIGHT SWITCH

- 5.13.7. HEADLIGHT SWITCH

- 5.13.8. BACK UP/DECK LIGHTS SWITCH

- 5.13.9. ELECTRONIC DISPLAY SWITCHES

- 5.14. CONTROL/INDICTOR PANEL (FIGURE 37)

- 5.14.1. DISCUSSION OF ITEMS 110, FIGURE 37

- 5.15. CENTER DISPLAY PANEL (FIGURE 38)

- 5.15.1. DISCUSSION OF ITEMS 129, FIGURE 38

- 5.16. CONTROL/INDICATOR PANEL (POD) (FIGURE 38)

- 5.16.1. DISCUSSION OF ITEMS 121 FIGURE 39

- 5.17. REAR OF OPERATOR CAB

- 5.18. CUMMINS ENGINE CENTRY FUEL SYSTEM DIAGNOSTICS

- 5.18.1. DETERMINING FAULT CODES

- 5.18.2. EXITING THE DIAGNOSTICS MODE

- 5.19. MESSAGES FOR OPERATION AND MAINTENANCE (MOM)

- 5.19.1. DISCUSSION OF SCREEN DISPLAYS

- 5.20. CENTER ELECTRONIC DISPLAY PANEL

- 5.20.1. DISCUSSION OF SCREEN DISPLAYS

- 6. MAINTENANCE

- 6.1. LUBRICATION AND SERVICE

- 6.1.1. LUBRICATION CHART

- 6.1.2. HOUR (SHIFT) LUBRICATION AND MAINTENANCE CHECKS

- 6.1.3. HOUR LUBRICATION MAINTENANCE CHECKS

- 6.1.4. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 6.1.5. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 6.1.6. HOUR LUBRICATION AND MAINTENANCE CHECKS

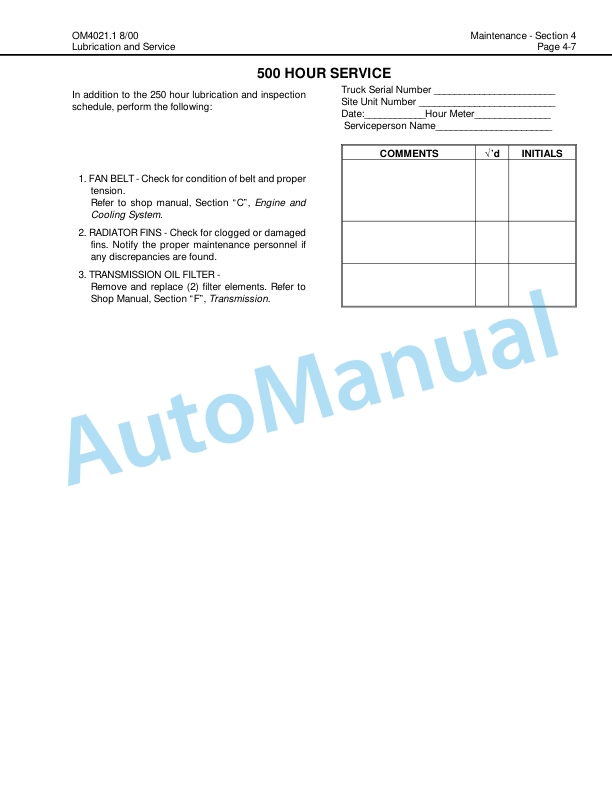

- 6.1.7. HOUR LUBRICATION AND MAINTENANCE CHECKS

- 6.2. HYDRAULIC TANK SERVICE

- 6.2.1. STEERING CIRCUIT FILTERS

- 6.2.2. HYDRAULIC TANK BREATHER SERVICE

- 6.3. LINCOLN AUTOMATIC LUBRICATION SYSTEM

- 6.3.1. SYSTEM COMPONTENTS

- 6.3.2. SYSTEM OPERATION

- 6.3.3. SYSTEM PRIMING

- 6.3.4. SYSTEM CHECKOUT

- 6.3.5. PRESSURE REDUCER AJUSTMENTS

- 6.3.6. DC SOLID STATE TIMER CHECK

- 6.3.6.1. DC SOLID STATE ADJUSTMENT

- 6.3.7. INJECTORS ADJUSTMENT

- 6.3.8. TROUBLESHOOTING CHART

- 6.3.9. PUMP CYCLE TIMER

- 6.3.10. PREVENTIVE MAINTENANCE PROCEDURES

- 7. SPECIFICATIONS

- 7.1. MAJOR COMPONENT DESCRIPTIONS

- 7.2. SPECIFICATIONS

- 8. OPTIONAL EQUIPMENT

- 8.1. PAYLOAD METER II (REFER TO SEPARATE PAYLOAD METER II INDEX)

- 8.1.1. PAYLOAD METER II ON BOARD WEIGHTING SYSTEM (OBWS)

- 8.1.2. GENERAL INFORMATION

- 8.1.3. LIGHTS, SWITCHES, AND COMPONENTS

- 8.1.4. TIPS FOR OPERATION

- 8.1.5. EXTERNAL DISPLAY LIGHTS

- 8.1.6. THEORY OF OPERATION

- 8.1.6.1. LINKAGE FACTOR

- 8.1.6.2. BRAKE LOCK

- 8.1.6.3. CALCULATION METHOD

- 8.1.6.4. SOURCES OF ERROR

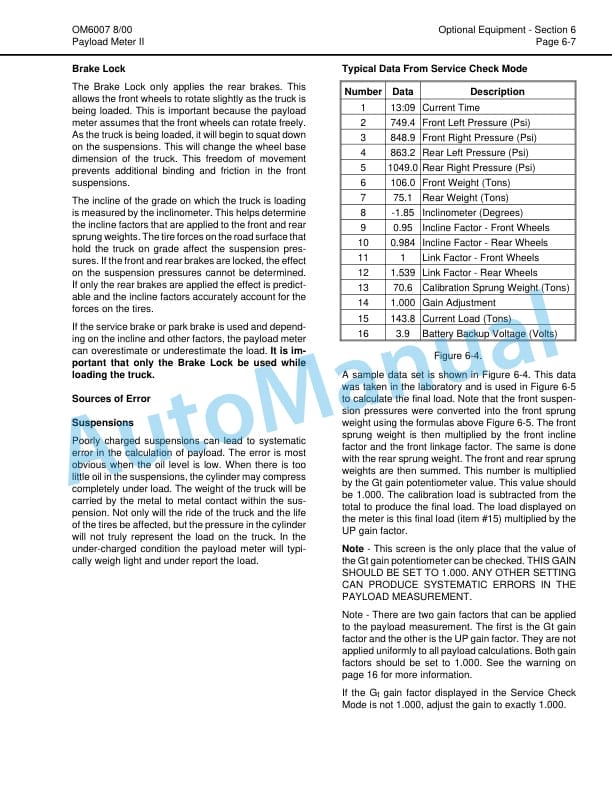

- 8.1.6.5. TYPICAL DATA FROM SERVICE CHECK MODE

- 8.1.6.6. EXAMPLE CALCULATION OF PAYLOAD

- 8.1.6.7. CALCULATION OF THE CALIBRATION LOAD

- 8.1.7. TYPES OF DATA STORED

- 8.1.7.1. CYCLE DATA

- 8.1.7.2. ENGINE ON/OFF DATA

- 8.1.7.3. FAULT CODES AND WARNING DATA

- 8.1.7.4. ENGINE OPERATION

- 8.1.7.5. TOTAL PAYLOAD AND TOTAL NUMBER OF CYCLES

- 8.1.7.6. OTHER DATA

- 8.1.8. OPERATOR FUNCTIONS

- 8.1.8.1. USING THE OPERATOR LOAD COUNTER

- 8.1.8.1.1. DESCRIPTION

- 8.1.8.1.2. VIEWING THE OPERATIOR LOAD COUTER

- 8.1.8.1.3. CLEARING THE OPERATOR LOAD COUNTER

- 8.1.8.2. DIMMING THE LIGHTS ON THE DISPLAY

- 8.1.9. INITIAL SETUP OF PAYLOAD METER

- 8.1.9.1. SWITCH SETTINGS

- 8.1.9.2. CHECKING THE OPERATOR CHECK MODE

- 8.1.9.3. CHECKING THE SERVICE CHECK MODE

- 8.1.9.3.1. SETTING THE UP00

- 8.1.9.3.2. SETTING THE PL00

- 8.1.9.4. CHECKING THE GT SETTING

- 8.1.9.5. CHECKING THE INCLINOMETER SETTINGS

- 8.1.9.6. CALIBRATING A TRUCK

- 8.1.10. DISPLAYS AT STARTUP

- 8.1.11. SETUP AND MAINTENANCE

- 8.1.11.1. SETTING THE SPEED LIMIT

- 8.1.11.2. SETTING THE OPTION CODE

- 8.1.11.3. SETTING THE MACHINE I.D. CODE

- 8.1.11.4. SETTING THE OPERATOR I.D. CODE

- 8.1.11.5. SETTING THE TIME AND DATE

- 8.1.12. DOWNLOAD OF INFORMATION

- 8.1.13. DISPLAY OF FAULT CODES

- 8.1.14. CHARTS OF ERROR CODES AND OTHER INFORMATION

- 8.1.15. SERVICE CHECK MODE

- 8.1.15.1. MONITORING INPUT SIGNALS

- 8.1.15.2. UP FACTOR PAYLOAD CALCULATION GAIN

- 8.1.15.3. PL MODE LOAD CALCULATION TIMING

- 8.1.16. FINAL GEAR RATIO SELECTION

- 8.1.17. BATTERY REPLACEMENT PROCEDURE

- 8.1.17.1. REPLACING THE BATTERY

- 8.1.17.2. AFTER REPLACING THE BATTERY

- 8.1.18. SUSPENSION PRESSURE SENSOR

- 8.1.18.1. MAKING CONNECTIONS

- 8.1.18.2. WIRING DIAGRAM

- 8.1.18.3. NORMAL OPERATION OF THE SCOREBOARD

- 8.1.19. PAYLOAD METER BACK PANEL

- 8.1.19.1. AMP PIN IDENTIFICATION

- 8.1.20. PAYLOAD CIRCUIT NUMBERS

- 8.1.21. PALOAD METER II REINITIALIZATION PROCEDURE

- 8.2. PAYLOAD METER II

- 8.3. RADIO, AM/FM STERO CASSETTE

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714