Komatsu HD465-10, HD605-10 Dump Truck Shop Manual SEN06976-00

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06976-00

- Format: PDF

- Size: 24.5MB

- Number of Pages: 532

Category: Komatsu Shop Manual PDF

-

Model List:

- HD465-10 Dump Truck

- HD605-10 Dump Truck

- 1. Cover

- 1.1. Index and Foreword

- 1.1.1. Index

- 1.1.2. Foreword, Safety, Basic Information

- 1.1.2.1. How to Read the Shop Manual

- 1.1.2.2. Safety Notice for Operation

- 1.1.2.3. Precautions to Prevent Fire

- 1.1.2.4. Procedures If Fire Occurs

- 1.1.2.5. Precautions When You Dispose of Waste Materials

- 1.1.2.6. Engine Technology to Conform Exhaust Gas Emission

- 1.1.2.7. Precautions When You Handle Hydraulic Equipment

- 1.1.2.8. Precautions When You Disconnect and Connect Pipings

- 1.1.2.9. Precautions When You Handle Electrical Equipment

- 1.1.2.10. Precautions When You Handle Fuel System Equipment

- 1.1.2.11. Precautions When You Handle Intake System Equipment

- 1.1.2.12. Practical Use of KOMTRAX

- 1.1.2.13. Disconnect and Connect PushPull Type Coupler

- 1.1.2.14. Precautions for Disconnection and Connection of Connectors

- 1.1.2.15. How to Disconnect and Connect Deutsch Connector

- 1.1.2.16. How to Disconnect and Connect Slide Lock Type Connector

- 1.1.2.17. How to Disconnect and Connect Connector with Lock to Pull

- 1.1.2.18. How to Disconnect and Connect Connector with Lock to Push

- 1.1.2.19. How to Disconnect and Connect Connector with Housing to Rotate

- 1.1.2.20. How to Read the Codes for Electric Cable

- 1.1.2.21. Explanation of Terms for Maintenance Standard

- 1.1.2.22. Standard Tightening Torque Table

- 1.1.2.23. Conversion Table

- 1.1.2.24. Abbreviation List

- 1.2. Specifications

- 1.2.1. Table of Contents

- 1.2.2. Specifications

- 1.2.2.1. Specification Drawing

- 1.2.2.2. Specifications

- 1.2.2.3. Weight Table

- 1.2.2.4. Fuel, Coolant, Lubricant

- 1.3. Structure and Function

- 1.3.1. Table of Contents

- 1.3.2. Bootup System

- 1.3.2.1. Layout Drawing of Bootup System

- 1.3.2.2. System Operating Lamp System

- 1.3.2.3. Battery Disconnect Switch

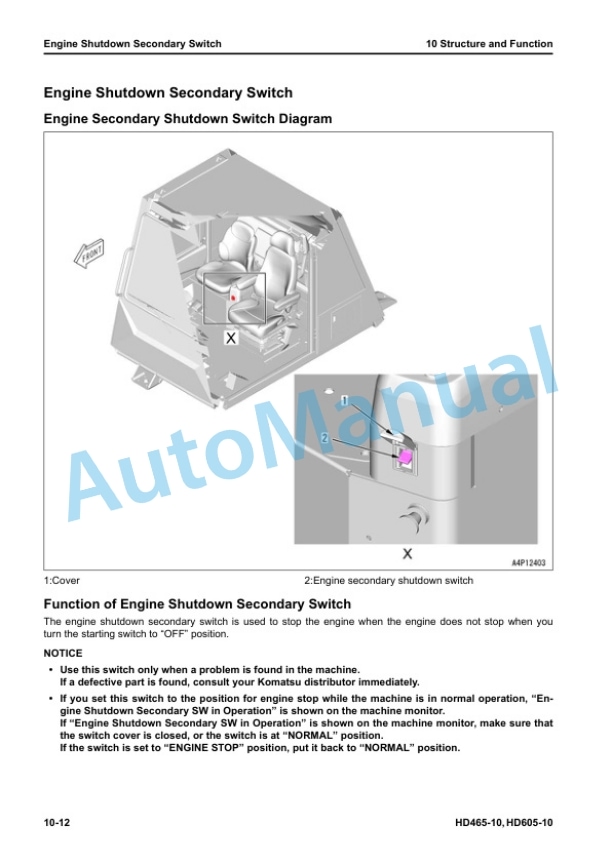

- 1.3.2.4. Engine Shutdown Secondary Switch

- 1.3.3. Engine System

- 1.3.3.1. Layout Drawing of Engine System

- 1.3.3.2. Engine Control System

- 1.3.3.3. Engine Power Mode Selector System

- 1.3.3.4. Automatic Idle Stop System

- 1.3.3.5. Component Parts of Engine System

- 1.3.4. Cooling System

- 1.3.4.1. Layout Drawing of Cooling System

- 1.3.4.2. Radiator Fan Control System

- 1.3.4.3. Component Parts of Cooling System

- 1.3.5. Control System

- 1.3.5.1. Layout Drawing of Control System

- 1.3.5.2. Layout Drawing of Control System (Machine with Mobile Communication Terminal)

- 1.3.5.3. Retarder and Hoist Control System

- 1.3.5.4. Machine Monitor System

- 1.3.5.5. Rearview Monitor System

- 1.3.5.6. KOMTRAX Plus System

- 1.3.5.7. Payload Meter System

- 1.3.5.8. Machine Lockout System

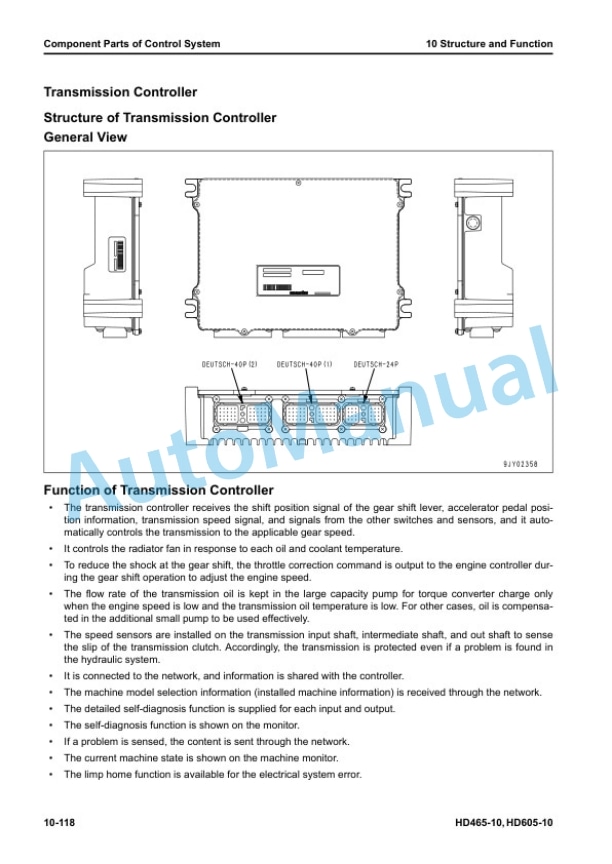

- 1.3.5.9. Component Parts of Control System

- 1.3.6. Hydraulic System

- 1.3.6.1. Layout Drawing of Hydraulic System

- 1.3.6.2. Component Parts of Hydraulic System

- 1.3.7. Power Train System

- 1.3.7.1. Layout Drawing of Power Train System

- 1.3.7.2. Transmission Control System

- 1.3.7.3. Gear Shift Control System

- 1.3.7.4. Direction Control System

- 1.3.7.5. Komatsu Traction Control System (KTCS)

- 1.3.7.6. Travel Speed Limitation System

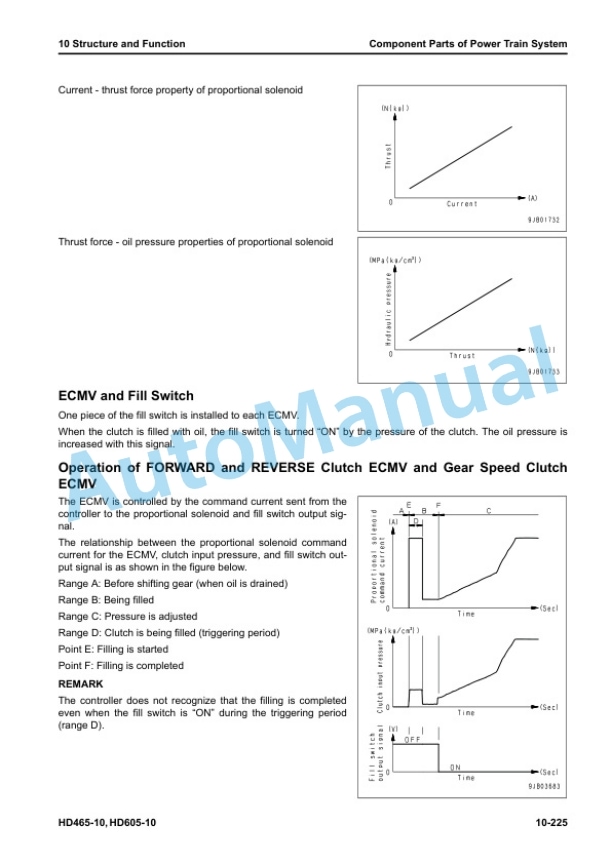

- 1.3.7.7. Component Parts of Power Train System

- 1.3.8. Work Equipment System

- 1.3.8.1. Work Equipment Control

- 1.3.8.2. Hoist Control

- 1.3.8.3. Component Parts of Work Equipment System

- 1.3.9. Steering System

- 1.3.9.1. Layout Drawing of Steering System

- 1.3.9.2. Secondary Steering System

- 1.3.9.3. Steering Column

- 1.3.9.4. Steering Linkage

- 1.3.9.5. Component Parts of Steering System

- 1.3.10. Brake System

- 1.3.10.1. Layout Drawing of Brake System

- 1.3.10.2. Retarder Control

- 1.3.10.3. ARSC System

- 1.3.10.4. Component Parts of Brake System

- 1.3.11. KOWA Oil Sampling System

- 1.3.11.1. Layout Drawing of KOWA Oil Sampling System

- 1.3.11.2. Function of KOWA Oil Sampling System

- 1.3.12. Undercarriage and Frame

- 1.3.12.1. Suspension

- 1.3.12.2. Front Suspension

- 1.3.12.3. Rear Suspension

- 1.3.12.4. Suspension Cylinder

- 1.3.13. Work Equipment

- 1.3.13.1. Structure of Work Equipment

- 1.3.13.2. Function of Work Equipment

- 1.3.14. CAB Related Parts

- 1.3.14.1. ROPS CAB

- 1.3.14.2. CAB Mount

- 1.4. Maintenance Standard

- 1.4.1. Table of Contents

- 1.4.2. Explanation of Terms for Maintenance Standard

- 1.4.3. Engine and Cooling System

- 1.4.3.1. Maintenance Standard for Engine Mount

- 1.4.3.2. Maintenance Standard for Damper

- 1.4.3.3. Maintenance Standard for Cooling Fan Pump

- 1.4.3.4. Maintenance Standard for Servo Valve for Cooling Fan Pump

- 1.4.3.5. Maintenance Standard for Cooling Fan Motor

- 1.4.4. Power Train

- 1.4.4.1. Maintenance Standard for Drive Shaft

- 1.4.4.2. Maintenance Standard for Torque Converter and Transmission Mount

- 1.4.4.3. Maintenance Standard for Torque Converter and PTO

- 1.4.4.4. Maintenance Standard for Torque Converter Valve

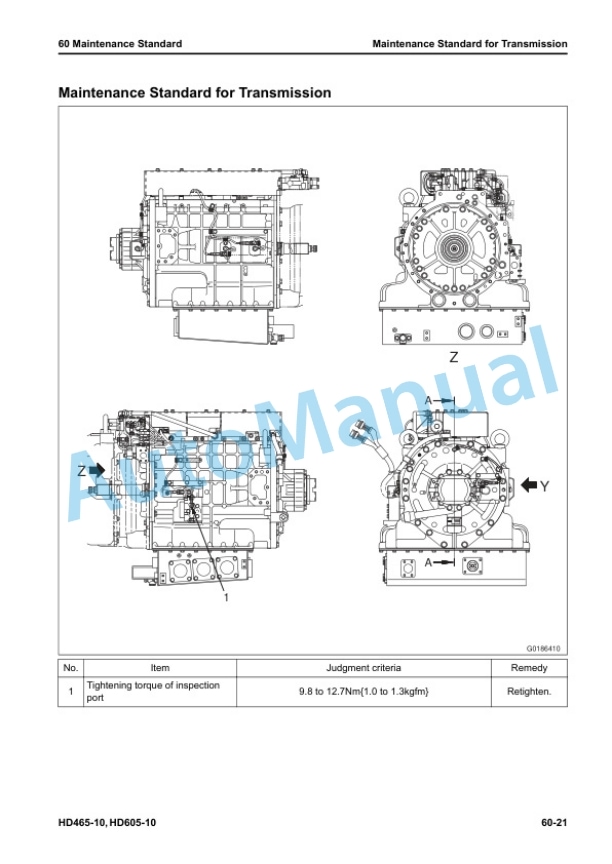

- 1.4.4.5. Maintenance Standard for Transmission

- 1.4.4.6. Maintenance Standard for Transmission Control Valve

- 1.4.4.7. Maintenance Standard for H, L, 4th, 3rd, R, 2nd, and 1st ECMV

- 1.4.4.8. Maintenance Standard for Lockup Clutch ECMV

- 1.4.4.9. Maintenance Standard for Front Axle

- 1.4.4.10. Maintenance Standard for Rear Axle

- 1.4.4.11. Maintenance Standard for Differential

- 1.4.4.12. Maintenance Standard for Final Drive

- 1.4.5. Steering System

- 1.4.5.1. Maintenance Standard for Steering Column

- 1.4.5.2. Maintenance Standard for Steering Linkage

- 1.4.5.3. Maintenance Standard for Demand Valve

- 1.4.5.4. Maintenance Standard for Steering Cylinder

- 1.4.6. Brake System

- 1.4.6.1. Maintenance Standard for Slack Adjuster

- 1.4.6.2. Maintenance Standard for Front Brake

- 1.4.6.3. Maintenance Standard for Rear Brake

- 1.4.7. Undercarriage and Frame

- 1.4.7.1. Maintenance Standard for Front Suspension Cylinder

- 1.4.7.2. Maintenance Standard for Rear Suspension Cylinder

- 1.4.8. Hydraulic System

- 1.4.8.1. Maintenance Standard for Pump Assembly (Steering, Hoist)

- 1.4.8.2. Maintenance Standard for Servo Valve of Pump Assembly (Steering, Hoist)

- 1.4.8.3. Maintenance Standard of Pump Assembly (Power Train and Brake Cooling)

- 1.4.8.4. Maintenance Standard of Pump Assembly (Brake Cooling and Control)

- 1.4.8.5. Maintenance Standard for Hoist Valve

- 1.4.9. Work Equipment

- 1.4.9.1. Maintenance Standard for Hoist Cylinder

- 1.4.10. CAB Related Parts

- 1.4.10.1. Maintenance Standard for CAB Mount

- 1.5. Circuit Diagrams

- 1.5.1. Table of Contents

- 1.5.2. How to Read the Codes for Electric Cable

- 1.5.3. Hydraulic Circuit Diagram

- 1.5.3.1. Symbols Used in Hydraulic Circuit Diagram

- 1.5.3.2. Hydraulic Circuit Diagram (1/3)

- 1.5.3.3. Hydraulic Circuit Diagram (2/3)

- 1.5.3.4. Hydraulic Circuit Diagram (3/3)

- 1.5.3.5. Power Train Hydraulic Circuit Diagram

- 1.5.4. Electrical Circuit Diagram

- 1.5.4.1. Symbols Used in Electric Circuit Diagram

- 1.5.4.2. Electrical Circuit Diagram of Inside of CAB (1/10)

- 1.5.4.3. Electrical Circuit Diagram of Inside of CAB (2/10)

- 1.5.4.4. Electrical Circuit Diagram of Inside of CAB (3/10)

- 1.5.4.5. Electrical Circuit Diagram of Inside of CAB (4/10)

- 1.5.4.6. Electrical Circuit Diagram of Inside of CAB (5/10)

- 1.5.4.7. Electrical Circuit Diagram of Inside of CAB (6/10)

- 1.5.4.8. Electrical Circuit Diagram of Inside of CAB (7/10)

- 1.5.4.9. Electrical Circuit Diagram of Inside of CAB (8/10)

- 1.5.4.10. Electrical Circuit Diagram of Inside of CAB (9/10)

- 1.5.4.11. Electrical Circuit Diagram of Inside of CAB (10/10)

- 1.5.4.12. Electrical Circuit Diagram of Machine (1/7)

- 1.5.4.13. Electrical Circuit Diagram of Machine (2/7)

- 1.5.4.14. Electrical Circuit Diagram of Machine (3/7)

- 1.5.4.15. Electrical Circuit Diagram of Machine (4/7)

- 1.5.4.16. Electrical Circuit Diagram of Machine (5/7)

- 1.5.4.17. Electrical Circuit Diagram of Machine (6/7)

- 1.5.4.18. Electrical Circuit Diagram of Machine (7/7)

- 1.5.4.19. Electrical Circuit Diagram of Engine (1/2)

- 1.5.4.20. Electrical Circuit Diagram of Engine (2/2)

- 1.6. Index

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00