Komatsu JV100A-1, JV100WA-1, JV100WP-1 Shop Manual SEBM02650103K

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM02650103K

- Format: PDF

- Size: 30.7MB

- Number of Pages: 303

Category: Komatsu Shop Manual PDF

-

Model List:

- JV100A-1

- JV100WA-1

- JV100WP-1

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. ACCEL,FUEL TANK AND PIPING

- 3.1.2. RADIATOR,ENGINE MOUNT AND AIR CLEANER

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TESTING AND ADJUSTING TOOL LIST

- 3.2.2. TESTING AND ADJUSTING DATA

- 3.2.3. ADJUSTMENT OF VALVE CLEARANCE

- 3.2.4. MEASURING COMPRESSION PRESSURE

- 3.2.5. MEASURING BLOWBY

- 3.2.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.2.7. TESTING AND ADJUSTING FAN BELT TENSION

- 3.2.8. TROUBLESHOOTING

- 3.2.8.1. STARTING MOTOR DOES NOT ROTATE AT ALL WHEN STARTING SWITCH IS PLACED IN START(IN COLD WEATHER)

- 3.2.8.2. STARTING MOTOR DOES NOT ROTATE

- 3.2.8.3. ROTATION OF STARTING MOTOR IS TOO SLOW TO START THE ENGINE

- 3.2.8.4. WHEN THE STARTING SWITCH IS PUT IN START POSITION,THE SOUND OF THE PINION GOING IN AND OUT CAN BE HEARD,BUT THE STARTING MOTOR DOES NOT ROTATE

- 3.2.8.5. HEATER SIGNAL DOES NOT COME ON,EVEN WHEN THE STARTING SWITCH IS IN PREHEAT POSITION

- 3.2.8.6. BATTERY IS OFTEN INSUFFICIENTLY CHARGED

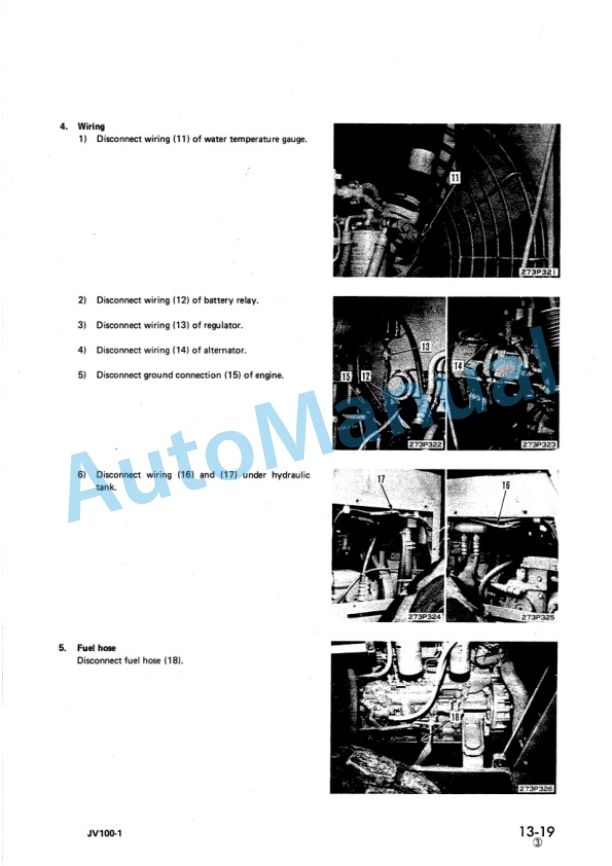

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. STARTING MOTOR

- 3.3.1.1. REMOVAL AND INSTALLATION

- 3.3.2. ALTERNATOR

- 3.3.2.1. REMOVAL AND INSTALLATION

- 3.3.3. FUEL INJECTION PUMP

- 3.3.3.1. REMOVAL AND INSTALLATION

- 3.3.4. WATER PUMP

- 3.3.4.1. REMOVAL INSTALLATION

- 3.3.5. NOZZLE HOLDER

- 3.3.5.1. REMOVAL AND INSTALLATION

- 3.3.6. TURBOCHARGER

- 3.3.6.1. REMOVAL AND INSTALLATION

- 3.3.7. RADIATOR AND OIL COOLER

- 3.4. STRUCTURE AND FUNCTION

- 3.4.1. POWER TRAIN

- 3.4.2. PTO(POWER TAKEOFF)

- 3.4.3. HYDROSTATIC TRANSMISSION(H.S.T.)

- 3.4.4. RANGE TRANSMISSION

- 3.4.5. TRANSMISSION CONTROL LEVERS

- 3.4.6. UNIVERSAL JOINT

- 3.4.7. DIFFERENTIAL

- 3.4.8. NONSPIN DIFFERENTIAL

- 3.4.9. FINAL DRIVE

- 3.4.10. WHEEL

- 3.5. TESTING AND ADJUSTING

- 3.5.1. TRAVEL AND OPERATING FORCE OF GEAR SHIFT LEVER

- 3.5.2. TRAVEL AND OPERATING FORCE OF TRAVEL LEVER

- 3.5.3. TESTING HYDRAULIC PRESSURE OF TRAVEL

- 3.6. DISASSEMBLY AND ASSEMBLY

- 3.6.1. TRAVEL PUMP ASSEMBLY

- 3.6.1.1. REMOVAL AND INSTALLATION

- 3.6.2. FRONT ROLLER TRAVEL MOTOR(JV100WA,WP)

- 3.6.2.1. REMOVAL

- 3.6.2.2. INSTALLATION

- 3.6.3. TRAVEL MOTOR ASSEMBLY

- 3.6.3.1. REMOVAL

- 3.6.3.2. INSTALLATION

- 3.6.4. RANGE TRANSMISSION ASSEMBLY

- 3.6.4.1. REMOVAL

- 3.6.4.2. INSTALLATION

- 3.6.4.3. DISASSEMBLY

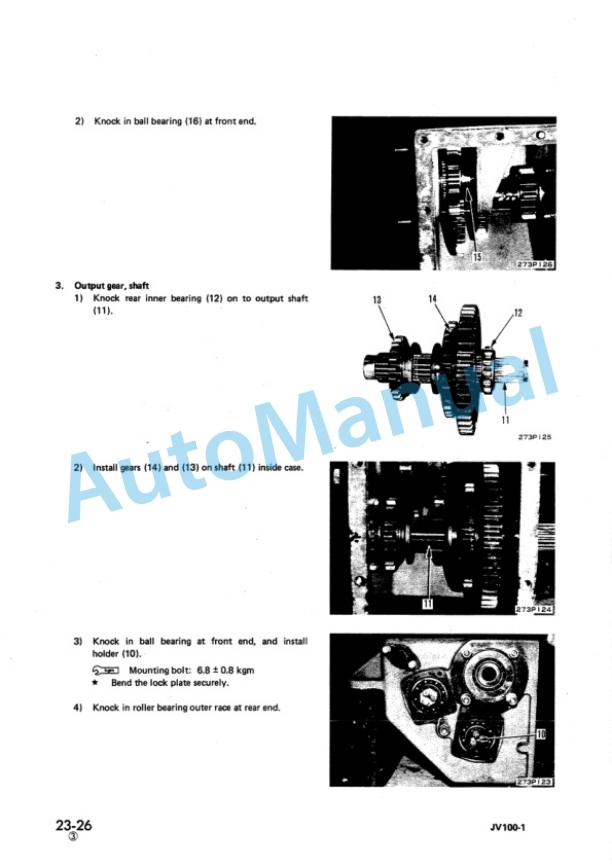

- 3.6.4.4. ASSEMBLY

- 3.6.5. SHIFTER COVER ASSEMBLY

- 3.6.5.1. DISASSEMBLY

- 3.6.5.2. ASSEMBLY

- 3.6.6. REAR AXLE HOUSING ASSEMBLY

- 3.6.6.1. REMOVAL

- 3.6.6.2. INSTALLATION

- 3.6.7. BEVEL GEAR ASSEMBLY

- 3.6.7.1. DISASSEMBLY

- 3.6.7.2. ASSEMBLY

- 3.6.8. FINAL DRIVE ASSEMBLY

- 3.6.8.1. DISASSEMBLY

- 3.6.8.2. ASSEMBLY

- 3.6.9. PLANETARY GEAR

- 3.6.9.1. DISASSEMBLY AND ASSEMBLY

- 3.7. MAINTENANCE STANDARD

- 3.7.2. RANGE TRANSMISSION

- 3.7.3. DIFFERENTIAL

- 3.7.4. FINAL DRIVE

- 4. STEERING SYSTEM

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. STEERING PIPING

- 4.1.2. FLOW CONTROL VALVE

- 4.1.3. STEERING VALVE

- 4.1.4. STEERING PUMP

- 4.1.5. STEERING CYLINDER

- 4.2. TESTING AND ADJUSTING

- 4.2.1. CHECKING STEERING WHEEL PLAY

- 4.2.2. CHECKING STEERING WHEEL OPERATING FORCE

- 4.2.3. CHECKING RUNOUT OF TIRES

- 4.2.4. TESTING TIRE INFLATION PRESSURE

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. STEERING PUMP ASSEMLBY

- 4.3.1.1. REMOVAL AND INSTALLATION

- 4.3.2. STEERING CYLINDER ASSEMBLY

- 4.3.2.1. REMOVAL

- 4.3.2.2. INSTALLATION

- 4.3.3. FLOW CONTROL VALVE ASSEMBLY

- 4.3.3.1. REMOVAL AND INSTALLATION

- 4.4. MAINTENANCE STANDARD

- 4.4.1. STEERING CYLINDER

- 5. BRAKE SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. BRAKE PIPING

- 5.1.2. BRAKE PIPING DIAGRAM

- 5.1.3. HYDROMASTER

- 5.1.4. MASTER CYLINDER

- 5.1.5. WHEEL BRAKE

- 5.1.6. PARKING BRAKE

- 5.2. TESTING AND ADJUSTING

- 5.2.1. CHECKING AND ADJUSTING BRAKE PEDAL HEIGHT

- 5.2.2. CHECKING AND ADJUSTING BRAKE PEDAL PLAY

- 5.2.3. CHECKING BRAKE PEDAL DEPRESSION HEIGHT

- 5.2.4. CHECKING BRAKE PEDAL OPERATING FORCE

- 5.2.5. CHECKING AND ADJUSTING WHEEL BRAKE

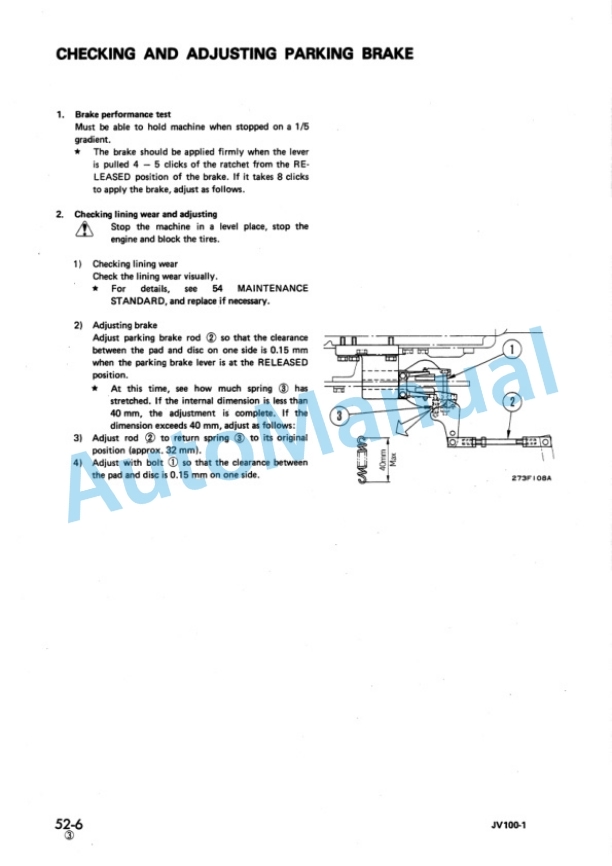

- 5.2.6. CHECKING AND ADJUSTING PARKING BRAKE

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. WHEEL BRAKE ASSEMBLY

- 5.3.1.1. REMOVAL AND INSTALLATION

- 5.3.2. BRAKE MASTER CYLINDER ASSEMBLY

- 5.3.2.1. REMOVAL AND INSTALLATION

- 5.3.3. HYDROMASTER

- 5.3.3.1. REMOVAL AND INSTALLATION

- 5.3.3.2. DISASSEMBLY

- 5.3.3.3. ASSEMBLY

- 5.3.4. PARKING BRAKE ASSEMBLY

- 5.3.4.1. REMOVAL(DISASSEMBLY)

- 5.3.4.2. INSTALLATION(ASSEMBLY)

- 5.4. MAINTENANCE STANDARD

- 5.4.1. WHEEL BRAKE

- 5.4.2. PARKING BRAKE

- 6. HYDRAULIC SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. HYDRAULIC PIPING

- 6.1.2. HYDRAULIC SYSTEM

- 6.1.3. HYDRAULIC CIRCUIT

- 6.1.4. HYDROSTATIC TRANSMISSION(HST)

- 6.2. TESTING AND ADJUSTING

- 6.2.1. MEASURING HYDRAULIC OIL TEMPERATURE

- 6.2.2. TROUBLESHOOTING

- 6.2.2.1. TROUBLESHOOTING TOOL TABLE

- 6.2.2.2. METHOD OF READING TROUBLESHOOTING TABLE

- 6.2.2.3. EXCESSIVE TIME LAG WHEN MACHINE STARTS OFF

- 6.2.2.4. MACHINE DOES NOT START

- 6.2.2.5. TRAVEL SPEED IS TOO SLOW,OR MACHINE DOES NOT TRAVEL(IN ALL SPEED RANGES)

- 6.2.2.6. BRAKES DO NOT WORK,OR BRAKING EFFECT IS POOR

- 6.2.2.7. BRAKE CANNOT BE RELEASED,OR BRAKE DRAGS

- 6.2.2.8. STEERING IS HEAVY,OR WILL NOT TURN

- 6.2.2.9. ROLLER DOES NOT VIBRATE

- 6.2.2.10. VIBRATING FORCE IS TOO SMALL,OR THERE IS AN EXCESSIVE TIME LAG WHEN VIBRATING

- 6.2.2.11. MACHINE VIBRATES ABNORMALLY

- 6.2.2.12. AMPLITUDE CANNOT BE SWITCHED

- 6.2.2.13. VIBRATION FREQUENCY CANNOT BE ADJUSTED

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. VIBRATOR PUMP ASSEMBLY

- 6.3.1.1. REMOVAL

- 6.3.1.2. INSTALLATION

- 6.3.2. VIBRATOR MOTOR ASSEMBLY

- 6.3.2.1. REMOVAL AND INSTALLATION

- 6.3.3. HYDRAULIC TANK ASSEMBLY

- 6.3.3.1. REMOVAL

- 6.3.3.2. INSTALLATION

- 6.3.4. OPERATORS PLATFORM

- 6.3.4.1. REMOVAL

- 6.3.4.2. INSTALLATION

- 7. WORK EQUIPMENT

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. VIBRATION CONTROL

- 7.1.2. DRUM

- 7.2. TESTING AND ADJUSTING

- 7.2.1. TRAVEL AND OPERATING FORCE OF VIBRATION LEVER

- 7.2.2. TESTING HYDRAULIC PRESSURE OF VIBRATOR

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. ARTICULATING ASSEMBLY(DISASSEMBLY)

- 7.3.1.1. REMOVAL(DISASSEMBLY)

- 7.3.1.2. INSTALLATION(ASSEMBLY)

- 7.3.2. VIBRATORY ROLLER ASSEMBLY

- 7.3.2.1. REMOVAL

- 7.3.2.2. INSTALLATION

- 7.3.2.3. DISASSEMBLY(JV100A1)

- 7.3.2.4. ASSEMBLY(JV100A1)

- 7.3.2.5. DISASSEMBLY(JV100WA1,JV100WP1)

- 7.3.2.6. ASSEMBLY(JV100WA1,JV100WP1)

- 7.3.3. FRONT AXLE ASSEMBLY

- 7.3.3.1. DISASSEMBLY

- 7.3.3.2. ASSEMBLY

- 8. ELECTRICAL SYSTEM

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. VIBRATION SWITCH

- 8.1.2. ELECTRICAL WIRING DIAGRAM

- 8.1.3. ELECTRICAL CIRCUIT DIAGRAM

- 8.2. TESTING AND ADJUSTING

- 8.2.1. TROUBLESHOOTING

- 8.2.1.1. EVEN IF THE VACUUM PRESSURE IN THE VACUUM TANK DROPS,THE ALARM BUZZE DOES NOT BUZZ

- 8.2.1.2. ELECTRICAL EQUIPMENT DOES NOT WORK

- 8.2.1.3. THE TURN SIGNAL LAMP DOES NOT FLASH

- 8.2.1.4. LIGHTING DEVICES SUCH AS HEAD LAMPS AND GAUGE LAMPS DO NOT LIGHT

- 8.2.1.5. EVEN IF THE VIBRATORY SWITCH IS PUT IN OFF POSITION,THE MACHINE STILL VIBRATES

- 8.2.1.6. EVEN IF THE VIBRATORY SWITCH IS PUT IN ON POSITON,THE MACHINE DOES NOT VIBRATE

- 9. OTHERS

- 9.1. TESTING AND ADJUSTING

- 9.1.1. INSPECTION TABLE

- 9.1.1.1. POWER TRAIN

- 9.1.1.2. TRAVEL AND STEERING SYSTEM

- 9.1.1.3. HYDRAULIC SYSTEM,WORK EQUIPMENT

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00