Komatsu MPF15-1A Forklift Truck Service Manual

$30.00

- Type Of Manual: Service Manual

- Format: PDF

- Size: 3.1MB

- Number of Pages: 296

Category: Komatsu Service Manual PDF

-

Model List:

- MPF15-1A Forklift Truck

- 1. BVINTRO

- 1.1. Introduction, Service Manual

- 1.2. Introduction, Service Manual

- 1.3. Contents, Section M

- 1.3.1. Machine Information

- 1.4. General Product Information

- 1.4.1. Presentation of the MPF151A

- 1.4.2. Main Components

- 1.5. Inch (SAE) and Metric Fasteners

- 1.5.1. Introduction

- 1.5.2. Nomenclature, Threads

- 1.5.3. Strength Identification

- 1.5.4. Conversion of Metric and English Units

- 2. BVELECT

- 2.1. Electrical System with TX and TT Card

- 2.1.1. Electrical Schematic Part 1

- 2.1.2. Electrical Schematic Part 2

- 2.1.3. Basics Of Circuit Operation

- 2.1.4. Control Features

- 2.1.5. General Maintenance Instructions

- 2.1.6. Troubleshooting Instructions

- 2.2. Battery Controller / Hourmeter / Lift Interrupt

- 2.2.1. General Information

- 2.2.2. Electrical

- 2.2.3. Battery Controller (BC)

- 2.2.4. Troubleshooting

- 2.3. Dash Display

- 2.3.1. General Information

- 2.3.2. Location

- 2.3.3. Operational Checks

- 2.3.4. Status Codes

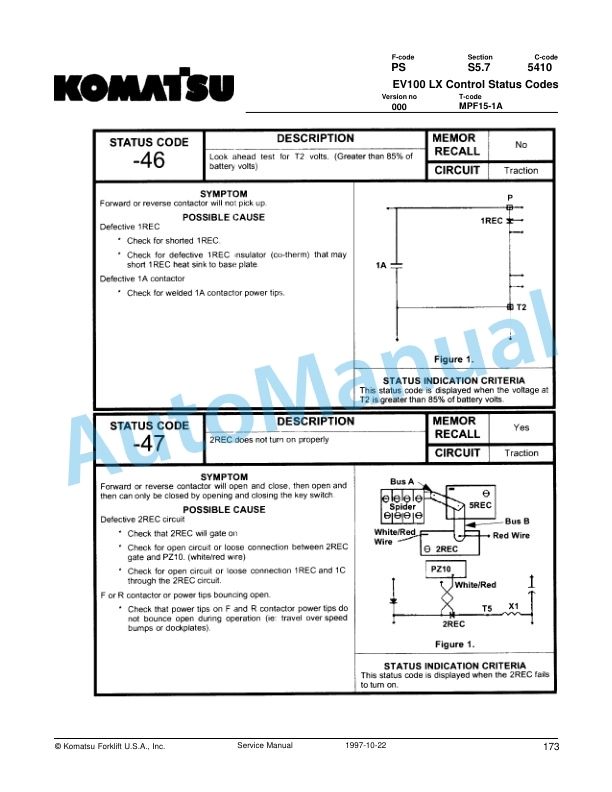

- 2.4. EV100 LX Control Status Codes

- 2.5. SCR Component Checks

- 2.5.1. Main Logic Card

- 2.5.2. Capacitor 1C

- 2.5.3. Contactors Forward, Rearward, 1A, Power Steering, and Pump

- 2.5.4. Potentiometer in Accelerator

- 2.5.5. SCRs (1REC, 2REC, 5REC)

- 2.5.6. Rectifiers (3REC, 4REC, Diode Blocks)

- 2.5.7. Thermal Protector (TP)

- 2.5.8. Filter Block (23FIL, etc.)

- 2.5.9. Filter Block (23FIL, etc.)

- 2.5.10. Choke and Reactor T3T4

- 2.5.11. Replacement of EV100 Components

- 2.5.12. Instructions EV100 Plugs

- 2.6. Direction Contactor

- 2.6.1. General Information

- 2.6.2. Remove / replace contact tips

- 2.7. Speed Contactor

- 2.7.1. General Information

- 2.7.2. Disassembly

- 2.7.3. Assembly

- 2.8. Electrical System Troubleshooting

- 2.8.1. Control Circuits and Power Circuits

- 2.9. Electrical System Troubleshooting Charts

- 2.10. Pump Contactor

- 2.10.1. General Information

- 2.10.2. Disassembly

- 2.10.3. Assembly

- 2.11. Steering Pump Contactor

- 2.11.1. General Information

- 2.11.2. Disassembly

- 2.11.3. Assembly

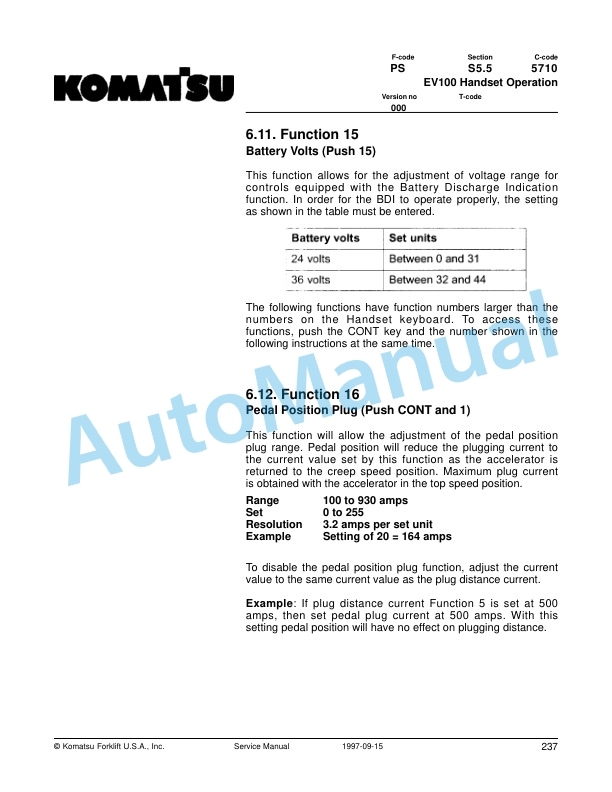

- 2.12. EV100 Handset Operation

- 2.12.1. General Information

- 2.12.2. Purpose

- 2.12.3. Operation

- 2.12.4. Function SetUp Procedures

- 2.12.5. Description and Location

- 2.12.6. Function Numbers for Controllers

- 3. BVHYDRA

- 3.1. Hydraulic System

- 3.1.1. Hydraulic Schematic

- 3.1.2. General Information

- 3.1.3. Maintenance

- 3.1.4. Adjustments

- 3.2. Hydraulic Troubleshooting

- 3.2.1. Troubleshooting Chart

- 3.3. Lift Pump Assembly

- 3.3.1. Shimming Mast on Truck.

- 3.3.2. Two Stage Mast

- 3.4. Mast, 3 Stage

- 3.4.1. Shimming Mast on Truck.

- 3.4.2. Three Stage Mast

- 3.5. Lift Cylinder, 2 Stage

- 3.5.1. Cylinder Repair

- 3.6. Freelift Cylinder, 3 Stage

- 3.6.1. Freelift Cylinder Repair

- 3.7. Staging Cylinder, 3 Stage

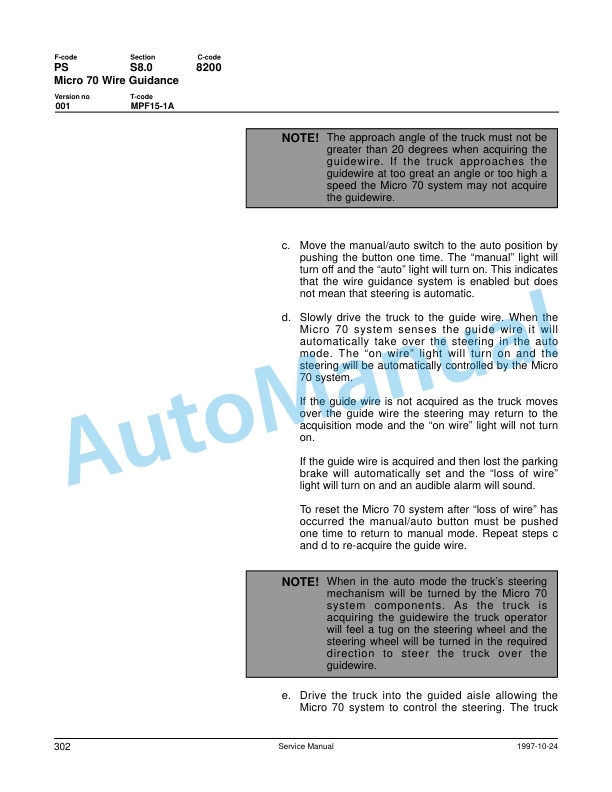

- 3.8. Micro 70 Wire Guidance Important Information

- 3.8.1. Powering Up

- 3.8.2. Powering Down

- 3.9. Micro 70 Wire Guidance

- 3.9.1. Electrical Schematic Part 1

- 3.9.2. Electrical Schematic Part 2

- 3.9.3. Electrical Schematic Part 3

- 3.9.4. Electrical Schematic Part 4

- 3.9.5. Cautions and Warnings

- 3.9.6. Operation Information

- 3.9.7. Component Function and Relationship

- 3.9.8. Truck Set Up On Site

- 3.9.9. Troubleshooting Information

- 3.9.10. Troubleshooting Charts

- 4. BVMAINT

- 4.1. Technical Service Data

- 4.2. Ordering Spare Parts

- 4.3. Introduction, Maintenance

- 4.3.1. Safe Jacking Procedure

- 4.4. Service Schedule

- 4.4.1. Planned Maintenance Schedule

- 4.5. Planned Maintenance Procedures

- 4.5.1. Services to be performed daily or at each 8 hour operating shift

- 4.5.2. Services to be performed monthly or every 250 operating hours

- 4.5.3. Services to be performed annually or every 1200 operating hours

- 4.6. Lubrication Chart

- 4.7. Oil and Grease Specifications

- 4.7.1. Approved Oils and Grease

- 4.8. Contents, Section S

- 4.8.1. Service Instructions

- 4.9. Inspection Covers

- 4.9.1. Removal Of Plastic Dash Panel

- 5. BVMOTORS

- 5.1. Drive Motor

- 5.1.1. General Information

- 5.1.2. Operating Conditions

- 5.1.3. Troubleshooting

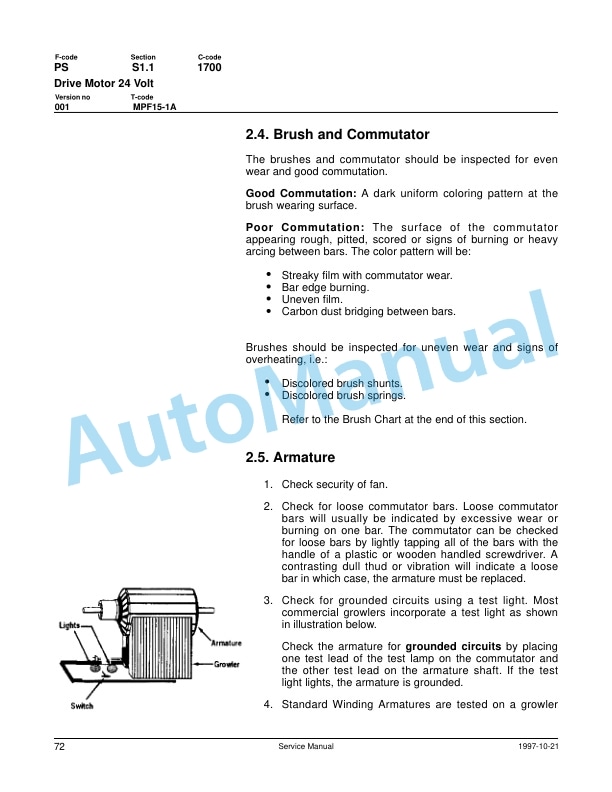

- 5.2. Drive Motor 24 Volt

- 5.2.1. Component Repair

- 5.2.2. Inspection and Troubleshooting

- 5.2.3. When changing brushes

- 5.3. Drive Motor 36 Volt

- 5.3.1. Component Repair

- 5.3.2. Inspection and Troubleshooting

- 5.3.3. When Changing Brushes

- 5.4. Transmission

- 5.4.1. System description

- 5.4.2. Troubleshooting

- 5.4.3. Removal

- 5.5. Transmission Disassembly Assembly

- 5.5.1. Disassembly

- 5.5.2. Installation

- 6. BVSAFETY

- 6.1. Standard Codes

- 6.2. Warning Symbols

- 6.2.1. Warning Levels

- 6.3. Prohibitory Symbols

- 6.3.1. Ordinance Symbols

- 7. BVSTEER

- 7.1. Torque Generator

- 7.1.1. Disassembly

- 7.1.2. Assembly

- 7.2. Steering System Pump

- 7.2.1. General Information

- 7.3. Steering System

- 7.3.1. General Information

- 7.4. Stabilizing Caster Spring Loaded

- 7.4.1. Removal

- 7.4.2. Inspection

- 7.4.3. Disassembly

Rate this product

You may also like

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu FR18S-2A, FR23S-2A, FR15DR-2A Forklift Truck Service Manual

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu ASX Stand-up Counterbalanced Electric Forklift Truck Service Manual SM401

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu 4D94E, 4D94L, 4D98E Diesel Engine Forklift Truck Service Manual 4D94E-BE4

$30.00