Komatsu PC03-2 Hydraulic Excavator Shop Manual SEBM025000

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM025000

- Format: PDF

- Size: 12.3MB

- Number of Pages: 255

Category: Komatsu Shop Manual PDF

-

Model List:

- PC03-2 Hydraulic Excavator

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. STANDARD TIGHTENING TORQUE

- 0.4. COATING MATERIALS

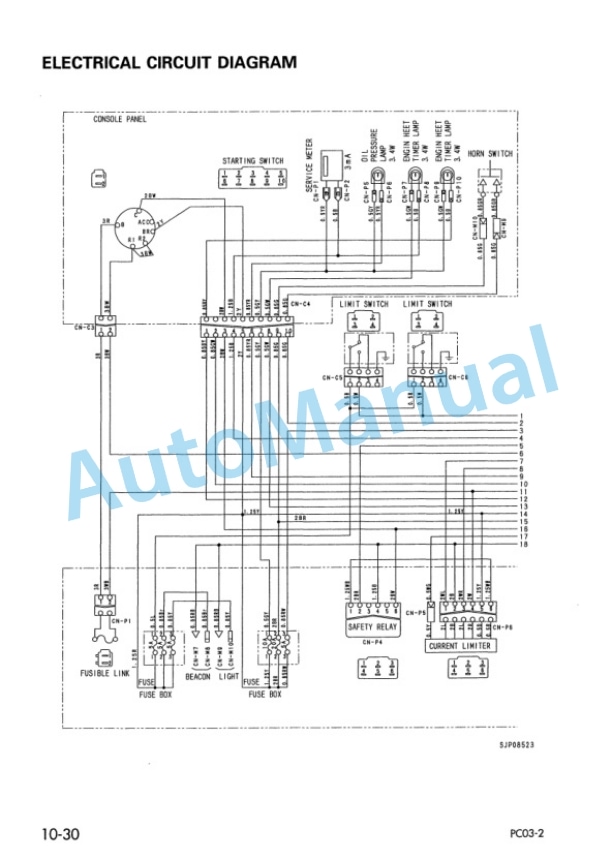

- 0.5. ELECTRIC WIRE CODE

- 0.6. COVERSION TABLE

- 1. GENERAL

- 1.1. GENERAL ASSEMBLY DRAWING

- 1.2. SPECIFICATIONS

- 1.3. WEIGHT TABLE

- 1.4. LIST OF LUBRICANT AND WATER

- 1.5. HYDRAULIC PIPING

- 1.6. HYDRAULIC DIAGRAM

- 1.7. HYDRAULIC TANK

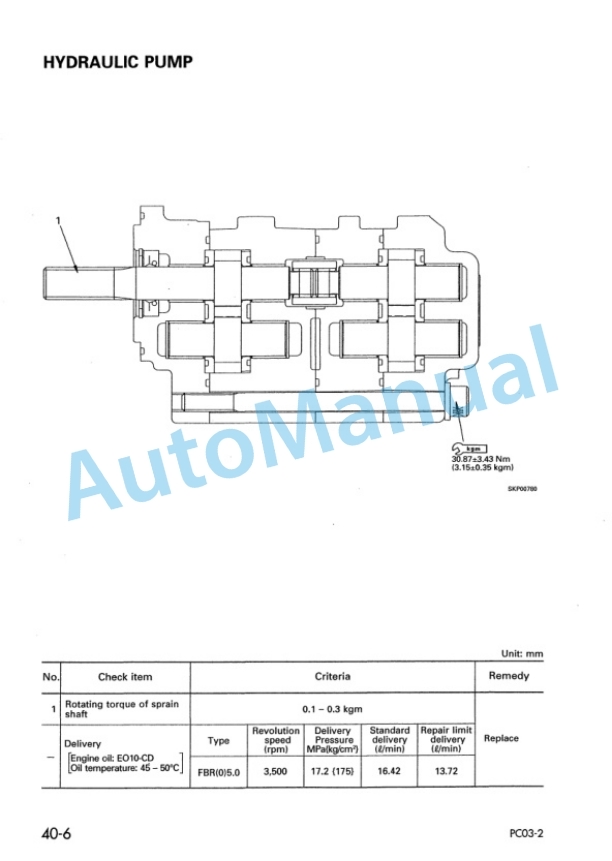

- 1.8. HYDRAULIC PUMP

- 1.9. SPOOL CONTROL VALVE

- 1.10. SWING MOTOR

- 1.11. CENTER SWIVEL JOINT

- 1.12. TRAVEL MOTOR

- 1.13. VALVE CONTROL

- 1.14. HYDRAULIC CYLINDER

- 1.15. WORK EQUIPMENT

- 1.16. ELECTRICAL CIRCUIT DIAGRAM

- 2. TESTING AND ADJUSTING

- 2.1. STANDARD VALVE TABLE FOR ENGINERELATED PARTS

- 2.2. STANDARD VALVE TABLE FOR CHASSISRELATED PARTS

- 2.3. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 2.4. MEASURING ENGINE SPEED

- 2.5. MEASURING ENGINE OIL PRESSURE

- 2.6. ADJUSTING VALVE CLEARANCE

- 2.7. MEASURING COMPRESSION PRESSURE

- 2.8. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 2.9. TESTING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS

- 2.10. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 2.11. BLEEDING AIR FROM HYDRAULIC CYLINDERS

- 2.12. TROUBLESHOOTING

- 2.12.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.12.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.12.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 2.12.4. CHECKS BEFORE TROUBLESHOOTING CHARTS

- 2.12.5. METHOD OF USING TROUBLESHOOTING CHARTS

- 2.12.6. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

- 2.12.6.1. H1 SPEEDS OF ALL WORK EQUIPMENT, TRAVELING, SWINGING ARE SLOW OR LACK POWER

- 2.12.6.2. H2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS WORK EQUIPMENT TRAVELING, SWINGING DO NOT FUNCTION OR ARE

- 2.12.6.3. H3 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)

- 2.12.6.4. H4 CONTROL LEVER IS HEAVY

- 2.12.6.5. H5 WORK EQUIPMENT (BOOM, ARM, BUCKET ) IS SLOW EXCESSIVE HYDRAULIC DRIFT

- 2.12.6.6. H6 WORK EQUIPMENT (BOOM, ARM, BUCKET ) LACKS POWER

- 2.12.6.7. H7 EXCESSIVE TIME LAG

- 2.12.6.8. H8 WHEN MACHINE IS TRAVELING, IT DEVIATES NATURALLY TO ONE SIDE

- 2.12.6.8.1. DEVIATES IN SAME DIRECTION IN BOTH FORWARD AND REVERSE

- 2.12.6.8.2. DEVIATES IN DIFFERENT DIRECTIONS IN BOTH FORWARD AND REVERSE

- 2.12.6.9. H9 TRAVEL LACKS POWER (OR SPEED IS SLOW

- 2.12.6.10. H10 MACHINE DOES NOT MOVE (ONE SIDE ONLY)

- 2.12.6.11. H11 DOES NOT SWING

- 2.12.6.12. H12 SWING SPEED IS SLOW OR ACCELERATION IS POOR

- 2.12.6.13. H13 EXCESSIVE OVERRUN WHEN STOPPING SWING

- 2.12.6.14. H14 EXCESSIVE SHOCK WHEN STOPPING SWING

- 2.12.6.15. H15 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING

- 2.12.6.16. H16 EXCESSIVE HYDRAULIC DRIFT OF SWING

- 2.12.6.17. H17 EXCESSIVE HYDRAULIC DRIFT OF BOOM SWING

- 2.12.6.18. TABLE OD FAILURE MODES AND CAUSES

- 2.12.7. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 2.12.7.1. M1 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), ENGINE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP

- 2.12.7.2. M2 WHEN ENGINE IS RUNNING, ENGINE OIL PRESSURE CAUTION LAMP LIGHTS UP (ENGINE OIL PRESSURE IS NORMAL)

- 2.12.7.3. M3 THE ENGINE COOLING WATER TEMPERATURE CASUTION LAMP WILL LIGHT ON, WHEN TURNING THE ENGINE STARTING SWITCH ON

- 2.12.7.4. M4 THE WORKING LAMP DOES NOT LIGHT ON, EVEN THOUGH THE LAMP SWITCH IS TURNED ON

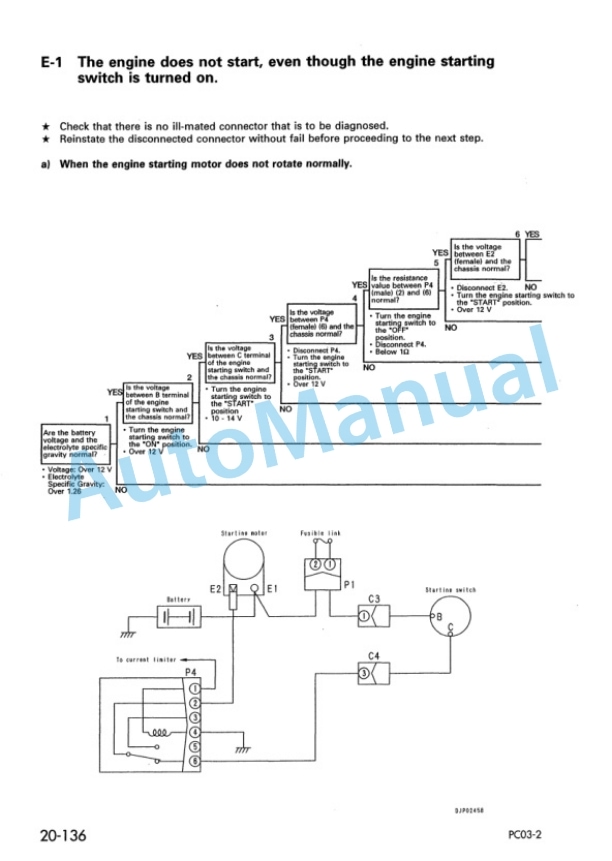

- 2.12.8. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 2.12.8.1. E1 THE ENGINE DOES NOT START, EVEN THOUGH THE ENGINE STARTING SWITCH IS TURNED ON

- 2.12.8.1.1. WHEN THE ENGINE STARTING MOTOR DOES NOT ROTATE NORMALLY

- 2.12.8.1.2. WHEN THE ENGINE STARTING MOTOR ROTATES NORMALLY

- 2.12.8.2. E2 THE ENGINE DOES NOT STOP, EVEN THOUGH THE ENGINE STARTING SWITCH IS TURNED OFF

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 3.3. SPECIAL TOOL LIST

- 3.4. RADIATOR

- 3.4.1. REMOVAL AND INSTALLATION

- 3.5. CENTER SWIVEL JOINT

- 3.5.1. DISASSEMBLY AND ASSEMBLY

- 3.6. BATTERY

- 3.6.1. REMOVAL AND INSTALLATION

- 3.7. ENGINE, MAIN PUMP

- 3.7.1. REMOVAL AND INSTALLATION

- 3.8. TRAVEL MOTOR

- 3.8.1. REMOVAL AND INSTALLATION

- 3.9. SPROCKET

- 3.9.1. REMOVAL AND INSTALLATION

- 3.10. SWING MOTOR

- 3.10.1. REMOVAL AND INSTALLATION

- 3.11. REVOLVING FRAME

- 3.11.1. REMOVAL AND INSTALLATION

- 3.12. SWING CIRCLE

- 3.12.1. REMOVAL AND INSTALLATION

- 3.13. IDLER

- 3.13.1. REMOVAL AND INSTALLATION

- 3.14. IDLER

- 3.14.1. DISASSEMBLY AND ASSEMBLY

- 3.15. TRACK ROLLER

- 3.15.1. REMOVAL AND INSTALLATION

- 3.16. TRACK ROLLER

- 3.16.1. DISASSEMBLY AND ASSEMBLY

- 3.17. RUBBER SHOE

- 3.17.1. REMOVAL AND INSTALLATION

- 3.18. MAIN PUMP

- 3.18.1. REMOVAL AND INSTALLATION

- 3.19. SPOOL CONTROL VALVE

- 3.19.1. REMOVAL AND INSTALLATION

- 3.20. SPOOL CONTROL VALVE

- 3.20.1. DISASSEMBLY

- 3.21. ARM CYLINDER

- 3.21.1. REMOVAL AND INSTALLATION

- 3.22. BUCKET CYLINDER

- 3.22.1. REMOVAL AND INSTALLATION

- 3.23. BOOM CYLINDER

- 3.23.1. REMOVAL AND INSTALLATION

- 3.24. BOOM SWING CYLINDER

- 3.24.1. REMOVAL AND INSTALLATION

- 3.25. BLADE CYLINDER

- 3.25.1. REMOVAL AND INSTALLATION

- 3.26. WORK EQIPMENT

- 3.26.1. REMOVAL AND INSTALLATION

- 3.27. BUCKET

- 3.27.1. REMOVAL AND INSTALLATION

- 3.28.1. REMOVAL AND INSTALLATION

- 3.29. BOOM

- 3.29.1. REMOVAL

- 3.29.2. INSTALLATION

- 3.30. BLADE

- 3.30.1. REMOVAL AND INSTALLATION

- 3.31. FUEL TANK

- 3.31.1. REMOVAL AND INSTALLATION

- 3.32. MACHINE COVER

- 3.32.1. REMOVAL

- 3.32.2. INSTALLATION

- 3.33. HYDRAULIC TANK

- 3.33.1. REMOVAL AND INSTALLATION

- 3.34. MONITOR PANEL

- 3.34.1. REMOVAL AND INSTALLATION

- 3.35. COUNTERWEIGHT

- 3.35.1. REMOVAL AND INSTALLATION

- 4. MAINTENANCE STANDARD

- 4.1. CENTER SWIVEL JOINT

- 4.2. SPOOL CONTROL VALVE

- 4.3. TRAVEL MOTOR

- 4.4. HYDRAULIC CYLINDER

- 4.5. WORK EQUIPMENT

- 5. ENGINE

- 5.1. CONTENTS

- 5.2. SPECIFICATIONS AND PERFORMANCE

- 5.3. CROSS SECTIONAL VIEWS

- 5.3.1. SPECIAL SWIRL PRECOMBUSTION CHAMBER SYSTEM

- 5.4. COOLING WATER, LUBRICATING OIL AND FUEL OIL

- 5.4.1. COOLING WATER

- 5.4.2. LUBRICATING OIL

- 5.4.3. FUEL OIL

- 5.5. TROUBLESHOOTING

- 5.5.1. TROUBLE CAUSES AND REMEDIES

- 5.5.2. TROUBLE DIAGNOSIS THROUGH MEASUREMENT OF COMPRESSION PRESSURE

- 5.6. SPECIAL SERVICE TOOLS

- 5.6.1. SPECIAL SERVICE TOOLS

- 5.6.2. MEASURING INSTRUMENTS

- 5.7. MEASUREMENT, INSPECTION AND ADJUSTMENT

- 5.7.1. MEASURING THE COMPRESSION PRESSURE

- 5.7.2. ADJUSTING THE VALVE HEAD

- 5.7.3. CHECKING THE VBELT TENSION

- 5.7.4. MEASURING AND CHECKING THE INJECTION PRESSURE AND SPRAY PATTERNS OF THE FUEL INJECTION VALVE

- 5.7.5. CHECKING AND ADJUSTIONG THE FUEL INJECTION TIMING

- 5.7.6. ADJUSTING THE NOLOAD MAXIMUM (OR MINIMUM) REVOLUTIONS

- 5.7.7. CHECKING THE COOLING WATER SYSTEM AND RADIATOR FOR LEAKAGE

- 5.7.8. CHECKING THE BATTERY

- 5.7.9. CHECKING SENSORS

- 5.7.10. CHECKING THE OIL COOLER

- 5.7.11. CHECKING THE PISTON COOLING NOZZLE

- 5.8. MEASURING PROCEDURES, SERVICE DATA AND CORRECTIVE ACTION

- 5.8.1. CYLINDER HEAD

- 5.8.2. CYLINDER BLOCK

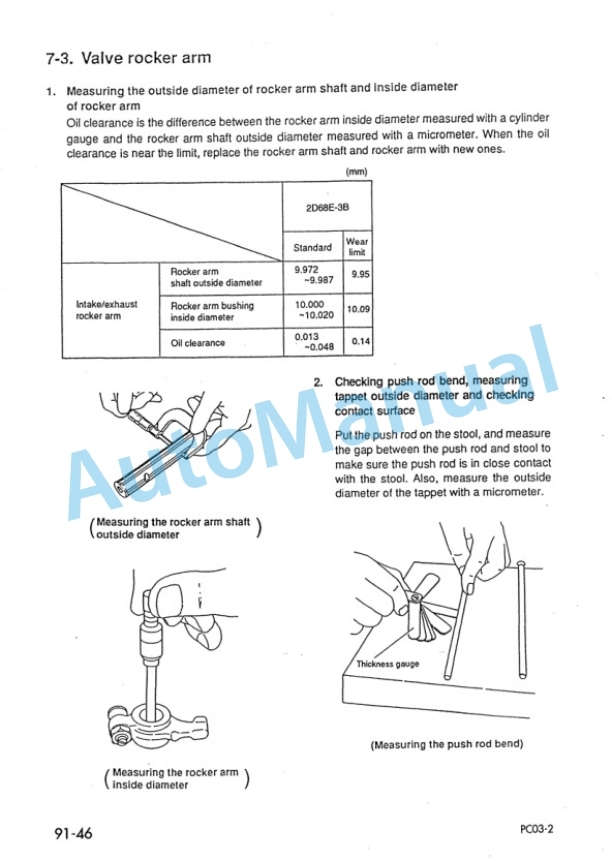

- 5.8.3. VALVE ROCKER ARM

- 5.8.4. PISTON AND PISTON RING

- 5.8.5. CONNECTING ROD

- 5.8.6. CAMSHAFT

- 5.8.7. CRANKSHAFT

- 5.8.8. GEARS

- 5.8.9. TROCHOID PUMP

- 5.9. DISASSEMBLY AND REASSEMBLY

- 5.9.1. DISASSEMBLY

- 5.9.2. PRECAUTIONS BEFORE AND DURING REASSEMBLY

- 5.10. SERVICE DATA

- 5.10.1. CYLINDER HEAD

- 5.10.2. CYLINDER BLOCK

- 5.10.3. VALVE ROCKER ARM

- 5.10.4. PISTON

- 5.10.5. PISTON RING

- 5.10.6. CONNECTING ROD

- 5.10.7. CAMSHAFT

- 5.10.8. CRANKSHAFT

- 5.10.9. SIDE GAP AND BACKLASH

- 5.10.10. OTHERS

- 5.11. TIGHENING TORQUJE

- 5.11.1. MAIN BOLT/NUT

- 5.11.2. STANDARD BOLT AND NUT

- 5.12. FUEL INJECTION PUMP FOR INDIRECT INJECTION SYSTEM

- 5.12.1. EXPLODED VIEWS (YPFR TYPE)

- 5.12.2. DISASSEMBLY

- 5.12.3. INSPECTION

- 5.12.4. REASSEMBLY

- 5.13. GOVERNOR

- 5.13.1. EXPLODED VIEWS OF GOVERNOR FOR INDIRECT INJECTION SYSTEM

- 5.13.2. DISASSEMBLY

- 5.13.3. INSPECTION

- 5.13.4. REASSEMBLY

- 5.14. ATTACHED DRAWING 1. EXPLODED VIEWS OF ENGINE COMPONENTS

- 5.15. ATTACHED DRAWING 2. EXPLODED VIEWS OF ENGINE COMPONENTS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00