Komatsu PC15MR-1 Shop Manual SEBM019002

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM019002

- Format: PDF

- Size: 55.4MB

- Number of Pages: 261

Category: Komatsu Shop Manual PDF

-

Model List:

- PC15MR-1

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. SWING CIRCLE

- 4.2. TRACK FRAME, RECOIL SPRING

- 4.3. HYDRAULIC EQUIPMENT LAYOUT

- 4.4. HYDRAULIC TANK

- 4.5. HYDRAULIC PUMP

- 4.6. CONTROL VALVE

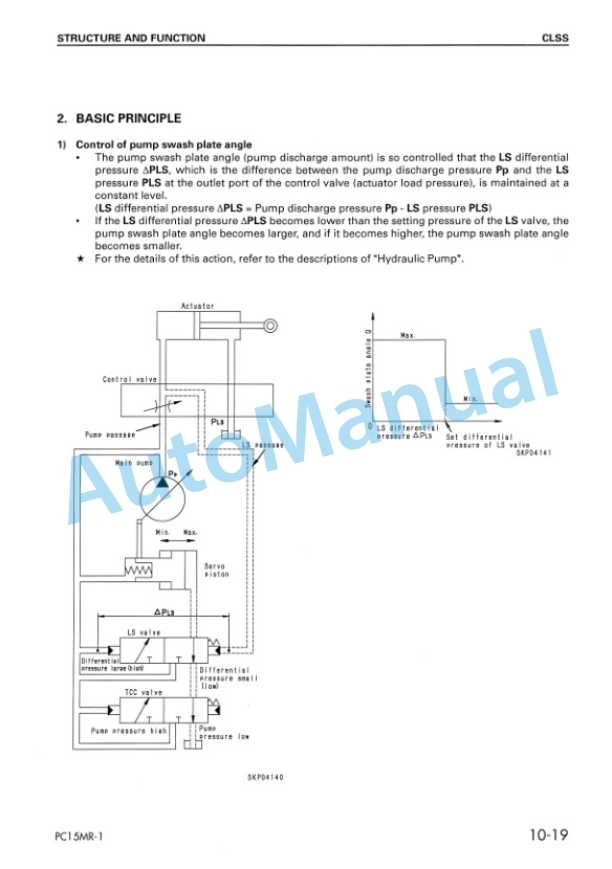

- 4.7. CLSS

- 4.8. CENTER SWIVEL JOINT

- 4.9. SWING MOTOR

- 4.10. TRAVEL MOTOR

- 4.11. VALVE CONTROL

- 4.12. PPC VALVE

- 4.13. PPC LOCK SOLENOID VALVE

- 4.14. TRAVEL 2SPEED SELECTER VALVE

- 4.15. ELECTRIC WIRING DIAGRAM

- 4.16. MONITOR SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.4. TESTING AND ADJUSTING

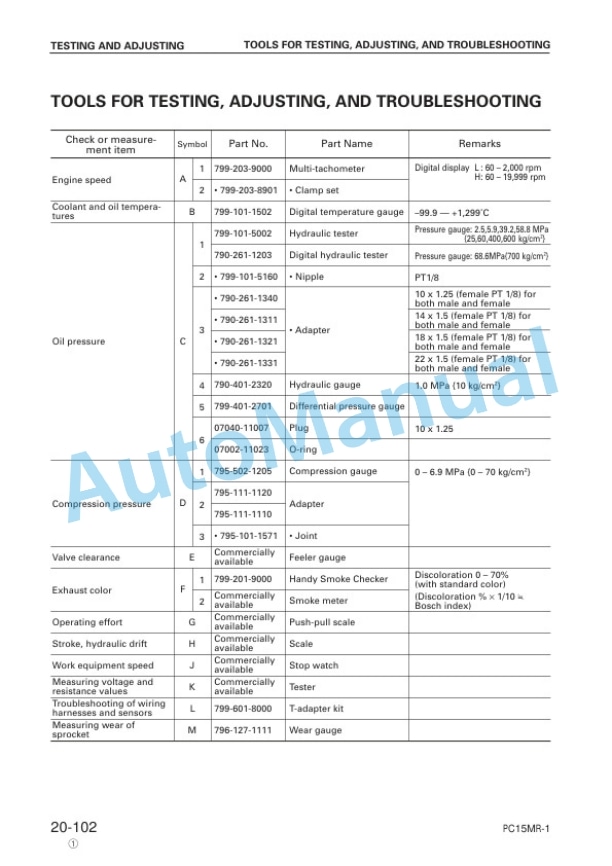

- 5.4.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.4.2. MEASURING ENGINE SPEED

- 5.4.3. MEASURING EXHAUST COLOR

- 5.4.4. ADJUSTING VALVE CLEARANCE

- 5.4.5. MEASURING COMPRESSION PRESSURE

- 5.4.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.4.7. MEASURING ENGINE OIL PRESSURE

- 5.4.8. TESTING AND ADJUSTING FAN BELT TENSION

- 5.4.9. ADJUSTING FUEL CONTROL LEVER

- 5.4.10. MEASURING SPROCKET WEAR

- 5.4.11. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.4.12. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 5.4.13. TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE

- 5.4.14. ADJUSTING PC VALVE SPRING

- 5.4.15. TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE

- 5.4.16. TESTING PPC LOCK VALVE

- 5.4.17. TESTING PPC VALVE OUTPUT PRESSURE AND SWING HOLDING BRAKE INLET PORT PRESSURE

- 5.4.18. ADJUSTING WORK EQUIPMENT, SWING PPC VALVE

- 5.4.19. TESTING AND ADJUSTING TRAVEL DEVIATION

- 5.4.20. MEASURING OIL LEAKAGE INSIDE WORK EQUIPMENT CYLINDER

- 5.4.21. RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT

- 5.4.22. RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK

- 5.4.23. PRESSURIZING HYDRAULIC TANK

- 5.4.24. BLEEDING AIR

- 5.5. TROUBLESHOOTING

- 5.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.5.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.5.6. CONNECTOR PIN ALLOCATION DRAWING

- 5.5.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

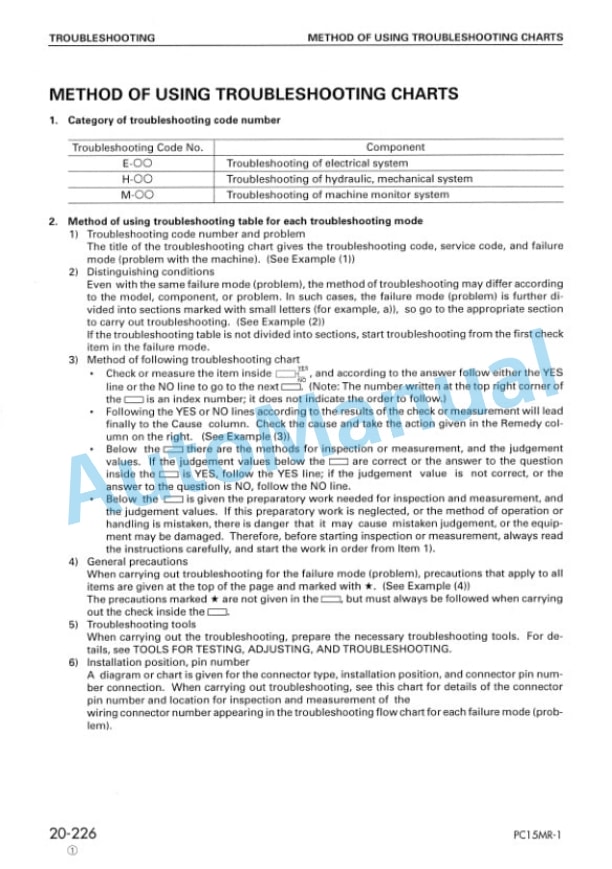

- 5.5.8. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.5.9. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 5.5.9.1. EMODE RELATED ELECTRICAL CIRCUIT DIAGRAM

- 5.5.9.2. E1 ENGINE DOES NOT START

- 5.5.9.2.1. WHEN STARTING MOTOR DOES NOT TURN (STARTING SYSTEM)

- 5.5.9.2.2. WHEN STARTING MOTOR TURNS (ENGINE STOP SOLENOID SYSTEM)

- 5.5.9.3. E2 ENGINE DOES NOT STOP

- 5.5.9.4. E3 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK LEVER IS CANCELED

- 5.5.9.5. E4 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED

- 5.5.9.6. E5 TRAVEL ALARM DOES NOT SOUND

- 5.5.10. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

- 5.5.10.1. TABLE OF FAILURE MODES AND CAUSES

- 5.5.10.2. H1 SPEEDS OF ALL WORK EQUIPMENT, SWING, TRAVEL ARE SLOW OR LACK POWER

- 5.5.10.3. H2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS

- 5.5.10.4. H3 NO WORK EQUIPMENT, TRAVEL, SWING MOVE

- 5.5.10.5. H4 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)

- 5.5.10.6. H5 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR

- 5.5.10.7. H6 BOOM IS SLOW OR LACKS POWER

- 5.5.10.8. H7 ARM IS SLOW OR LACKS POWER

- 5.5.10.9. H8 BUCKET IS SLOW OR LACKS POWER

- 5.5.10.10. H9 BOOM SWING IS SLOW OR LACKS POWER

- 5.5.10.11. H10 BLADE IS SLOW OR LACKS POWER

- 5.5.10.12. H11 BOOM, ARM, BUCKET DO NOT MOVE (BOOM SWING, BLADE, TRAVEL AND SWING ARE NORMAL)

- 5.5.10.13. H12 EXCESSIVE HYDRAULIC DRIFT (BOOM, ARM, BUCKET, BOOM SWING, BLADE)

- 5.5.10.13.1. BOOM, BUCKET, BOOM SWING, BLADE

- 5.5.10.14. H13 EXCESSIVE TIME LAG (ENGINE AT LOW IDLING)

- 5.5.10.14.1. BOOM, ARM

- 5.5.10.14.2. BUCKET

- 5.5.10.15. H14 IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW

- 5.5.10.16. H15 TRAVEL DEVIATION

- 5.5.10.16.1. DEVIATION IN NORMAL TRAVEL

- 5.5.10.16.2. DEVIATION WHEN STARTING

- 5.5.10.17. H16 TRAVEL SPEED IS SLOW OR LACKS POWER

- 5.5.10.18. H17 STEERING DOES NOT TURN EASILY

- 5.5.10.19. H18 TRAVEL SPEED DOES NOT SWITCH

- 5.5.10.20. H19 TRAVEL DOES NOT MOVE (ONE SIDE ONLY)

- 5.5.10.21. H20 SWING SPEED IS SLOW OR LACKS POWER

- 5.5.10.21.1. SPEED IS SLOW OR LACKS POWER IN BOTH DIRECTIONS

- 5.5.10.21.2. SPEED IS SLOW OR LACKS POWER IN ONE DIRECTION ONLY

- 5.5.10.22. H21 DOES NOT SWING

- 5.5.10.22.1. DOES NOT SWING IN EITHER DIRECTION

- 5.5.10.22.2. DOES NOT SWING IN ONE DIRECTION ONLY

- 5.5.10.23. H22 SWING ACCELERATION IS POOR

- 5.5.10.23.1. ACCELERATION IS POOR IN BOTH DIRECTIONS

- 5.5.10.23.2. ACCELERATION IS POOR IN ONE DIRECTION ONLY

- 5.5.10.24. H23 EXCESSIVE OVERRUN WHEN STOPPING SWING

- 5.5.10.24.1. OVERRUN WHEN STOPPING IS EXCESSIVE IN BOTH DIRECTIONS

- 5.5.10.24.2. OVERRUN WHEN STOPPING IS EXCESSIVE IN ONE DIRECTION ONLY

- 5.5.10.25. H24 EXCESSIVE SHOCK WHEN STOPPING SWING (IN ONE DIRECTION ONLY)

- 5.5.10.26. H25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING

- 5.5.10.27. H26 EXCESSIVE HYDRAULIC DRIFT OF SWING

- 5.5.11. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 5.5.11.1. ELECTRICAL CIRCUIT DIAGRAM FOR M MODE RELATED PARTS

- 5.5.11.2. M1 ABNORMALITY IN ENGINE OIL PRESSURE CAUTION LAMP SYSTEM

- 5.5.11.2.1. LAMP DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON

- 5.5.11.2.2. LAMP LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE OIL PRESSURE IS NORMAL)

- 5.5.11.3. M2 ABNORMALITY IN CHARGE CAUTION LAMP SYSTEM

- 5.5.11.3.1. LAMP DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON

- 5.5.11.3.2. LAMP LIGHTS UP WHEN ENGINE IS RUNNING (BATTERY CHARGE IS NORMAL)

- 5.5.11.4. M3 ABNORMALITY IN ENGINE WATER TEMPERATURE CAUTION LAMP SYSTEM

- 5.5.11.4.1. LAMP DOES NOT STAY LIGHTED UP FOR 3 SECONDS WHEN STARTING SWITCH IS TURNED ON

- 5.5.11.4.2. LAMP DOES NOT GO OUT AFTER STARTING SWITCH HAS BEEN AN ON FOR 3 SECONDS

- 5.5.11.4.3. LAMP LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE WATER TEMPERATURE IS NORMAL)

- 5.5.11.5. M4 ABNORMALITY IN PREHEATING PILOT LAMP

- 5.5.11.5.1. LAMP DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED TO HEAT

- 5.5.11.5.2. LAMP DOES NOT GO OUT WHEN STARTING SWITCH IS AT HEAT AND PREHEATING TIME (APPROX. 18 SEC.) IS COMPLETED

- 5.5.11.5.3. LAMP LIGHTS UP WHEN STARTING SWITCH IS AT POSITION OTHER THAN HEAT

- 5.5.11.6. M5 ABNORMALITY IN FUEL GAUGE SYSTEM

- 5.5.11.6.1. GAUGE DOES NOT GO UP FROM E WHEN FUEL IS ADDED TO FUEL TANK

- 5.5.11.6.2. GAUGE DOES NOT GO DOWN FROM F EVEN WHEN THERE IS NO FUEL IN FUEL TANK

- 5.5.11.6.3. FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY

- 5.5.11.7. M6 ABNORMALITY IN SERVICE METER SYSTEM

- 5.5.11.7.1. SERVICE METER DOES NOT ADVANCE WHEN STARTING SWITCH IS AT ON

- 5.5.11.7.2. SERVICE METER ADVANCES WHEN STARTING SWITCH IS AT OFF

- 5.5.11.7.3. PILOT LAMP DOES NOT FLASH WHEN SERVICE METER IS ADVANCING

- 5.5.11.8. M7 ABNORMALITY IN NIGHT LIGHTING SYSTEM

- 5.5.11.8.1. NIGHT LIGHTING DOES NOT LIGHT UP WHEN LAMP SWITCH IS TURNED ON

- 5.5.11.8.2. NIGHT LIGHTING LIGHTS UP WHEN LAMP SWITCH IS TURNED OFF

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

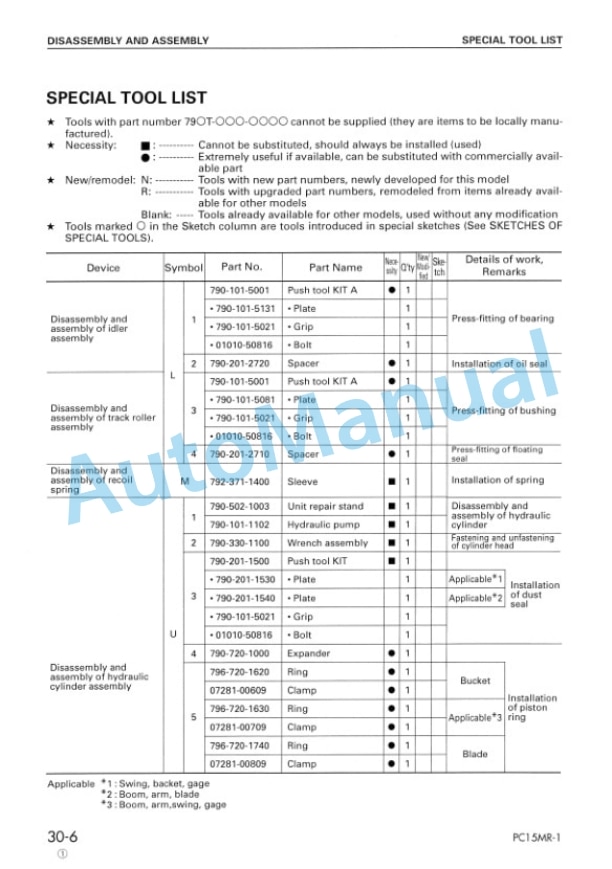

- 6.3. SPECIAL TOOL LIST

- 6.4. ENGINE AND HYDRAULIC PUMP

- 6.4.1. REMOVAL

- 6.4.2. INSTALLATION

- 6.5. CENTER SWIVEL JOINT

- 6.6. REVOLVING FRAME

- 6.7. HYDRAULIC CYLINDER

- 6.7.1. ASSEMBLY

- 7. MAINTENANCE STANDARD

- 7.1. SWING CIRCLE

- 7.2. TRACK FRAME, RECOIL SPRING

- 7.3. CENTER SWIVEL JOINT

- 7.4. SWING MOTOR

- 7.5. TRAVEL MOTOR

- 7.6. PPC VALVE

- 7.7. HYDRAULIC CYLINDER

- 7.8. WORK EQUIPMENT

- 8. OTHERS

- 8.1. HYDRAULIC CIRCUIT DIAGRAM (VARIABLE GAUGE TYPE)

- 8.2. HYDRAULIC CIRCUIT DIAGRAM (FIXED GAUGE TYPE)

- 8.3. ELECTRIC CIRCUIT DIAGRAM (SERIAL NO. 1000110634)

- 8.4. ELECTRIC CIRCUIT DIAGRAM (SERIAL NO. 10635 AND UP)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00