Komatsu PC160LC-7 Hydraulic Excavator Shop Manual SEBM028606

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM028606

- Format: PDF

- Size: 38.2MB

- Number of Pages: 770

Category: Komatsu Shop Manual PDF

-

Model List:

- PC160LC-7 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DIMENSION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL,COOLANT,AND LUBRICANTS

- 4. STRUCTURE, FUNCTION, AND MAINTENANCE STANDARD

- 4.1. ENGINE RELATED PARTS

- 4.2. RADIATOROIL COOLERAFTERCOOLER

- 4.3. POWER TRAIN

- 4.4. SWING MACHINERY

- 4.5. SWING CIRCLE

- 4.6. FINAL DRIVE

- 4.7. TRACK FRAMERECOIL SPRING

- 4.8. IDLER

- 4.9. CARRIER ROLLER

- 4.10. TRACK ROLLER

- 4.11. TRACK SHOE

- 4.12. HYDRAULIC EQUIPMENT LAYOUT DRAWING

- 4.13. TRAVEL JUNCTION VALVE

- 4.14. SELFREDUCING PRESSURE VALVE

- 4.15. CENTER SWIVEL JOINT

- 4.16. SWING MOTOR

- 4.17. TRAVEL MOTOR

- 4.18. WORK EQUIPMENTSWING PPC VALVE

- 4.19. TRAVEL PPC VALVE

- 4.20. SERVICE PPC VALVE

- 4.21. SOLENOID VALVE

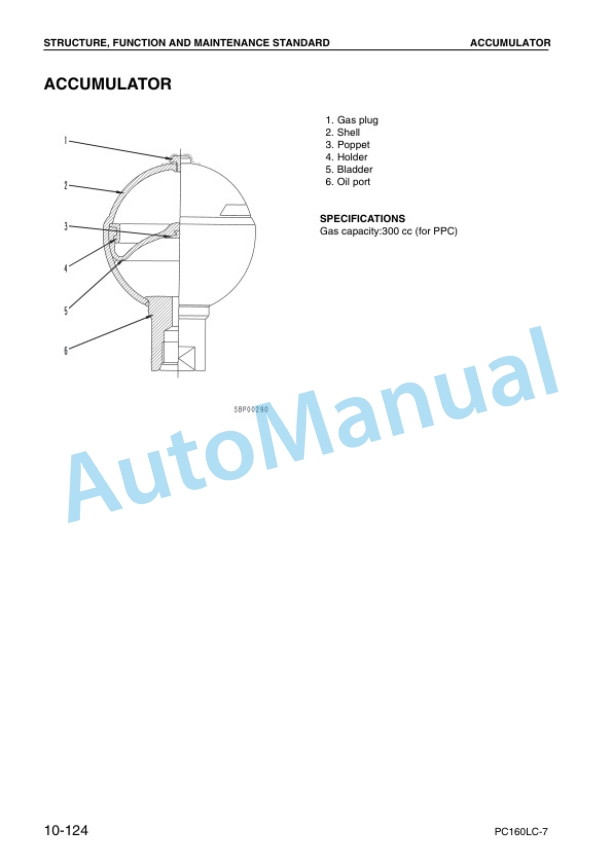

- 4.22. ACCUMULATOR

- 4.23. RETURN OIL FILTER

- 4.24. ATTACHMENT CIRCUIT SELECTOR VALVE

- 4.25. HYDRAULIC CYLINDER

- 4.26. WORK EQUIPMENT

- 4.27. AIR CONDITIONER

- 4.28. ENGINE CONTROL

- 4.29. ELECTRONIC CONTROL SYSTEM

- 4.30. MULTI MONITOR SYSTEM

- 4.31. SEGMENT MONITOR SYSTEM

- 4.32. SENSOR

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALVE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALVE TABLE FOR CHASSIS RELATED PARTS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. TOOLS FOR TESTING,ADJUSTING AND TROUBLESHOOTING

- 5.3.2. INSPECTION AND ADJUSTING OF ENGINE RPM

- 5.3.3. MEASUREMENT OF EXHAUST GAS COLOR

- 5.3.4. ADJUSTMENT OF VALVE CLEARANCE

- 5.3.5. MEASUREMENT OF COMPRESSION PRESSURE

- 5.3.6. MEASUREMENT OF BLOWBY PRESSURE

- 5.3.7. INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 5.3.8. MEASUREMENT OF ENGINE OIL PRESSURE

- 5.3.9. ADJUSTMENT OF ENGINE SPEED SENSOR

- 5.3.10. INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

- 5.3.11. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 5.3.12. INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

- 5.3.13. INSPECTION AND ADJUSTMENT OIL PRESSURE IN WORK EQUIPMENT,SWING, AND TRAVEL CIRCUITS

- 5.3.14. INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

- 5.3.15. INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE

- 5.3.16. INSPECTION AND ADJUSTMENT PUMP LS CONTROL CIRCUIT OIL PRESSURE

- 5.3.17. MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE

- 5.3.18. MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

- 5.3.19. ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

- 5.3.20. INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

- 5.3.21. TESTING AND ADJUSTING TRAVEL DEVIATION

- 5.3.22. RELEASE OF RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 5.3.23. MEASUREMENT OF OIL LEAKAGE

- 5.3.24. BLEEDING AIR FROM EACH PART

- 5.3.25. INSPECTION PROCEDURES FOR DIODE

- 5.3.26. SPECIAL FUNCTION OF MONITOR PANEL

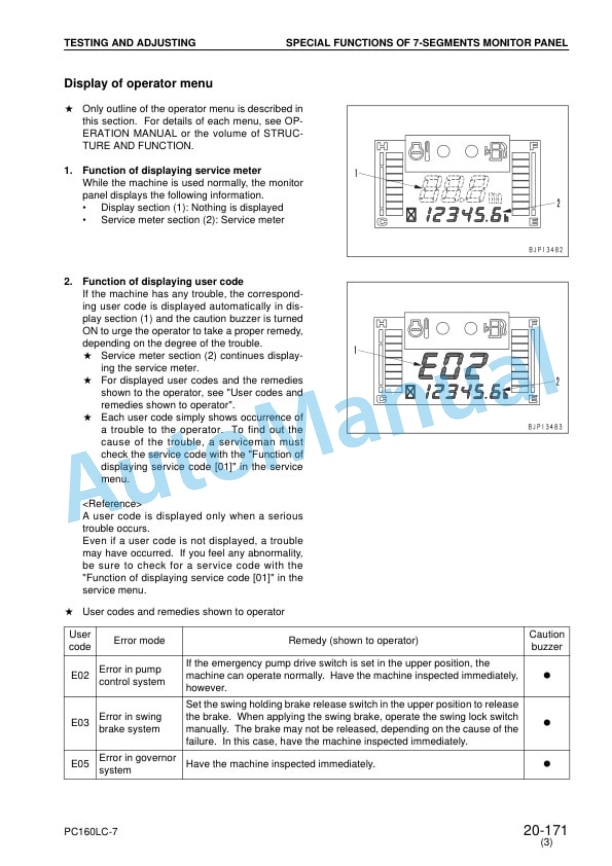

- 5.3.27. SPECIAL FUNCTIONS OF 7SEGMENTS MONITOR PANEL

- 5.3.28. PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

- 5.3.29. PMTUNE UP SERVICE

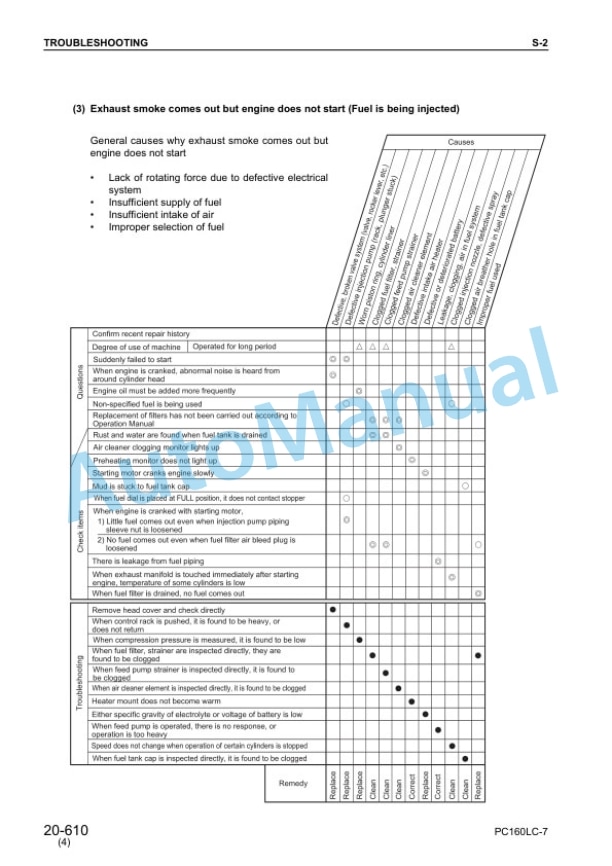

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 5.4.6. CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

- 5.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.4.8. TADAPTERBOXES AND TADAPTER TABLE

- 5.4.9. TROUBLESHOOTING ERROR CODE ELECTRICAL SYSTEM AND FAILURE CODE MECHANICAL SYSTEM ARE INDICATED

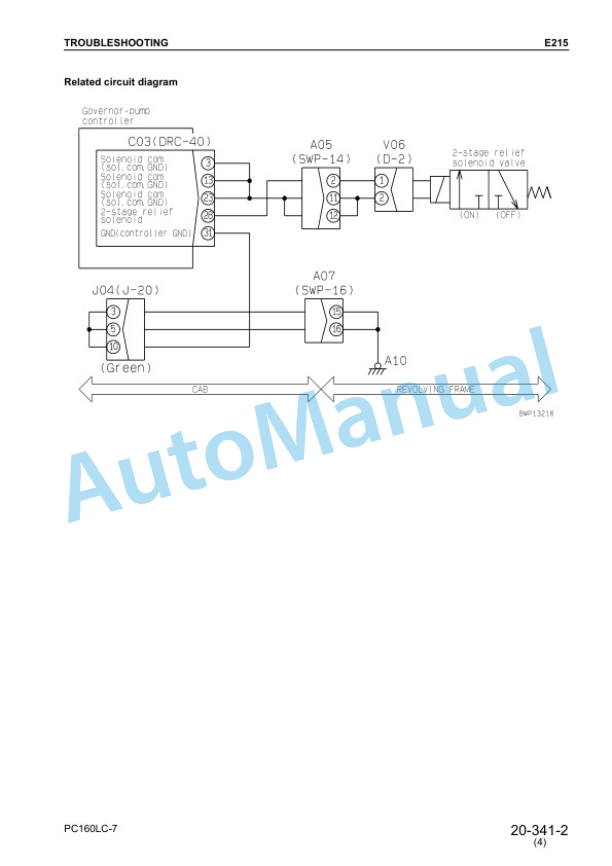

- 5.4.10. TROUBLESHOOTING OF ELECTRICAL SYSTEM(EMODE)

- 5.4.11. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 5.4.12. TROUBLESHOOTING OF ENGINE (SMODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO READ THIS MANUAL

- 6.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. STARTING MOTOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. FUEL INJECTION PUMP

- 6.6.1. SPECIAL TOOLS

- 6.6.2. REMOVAL

- 6.6.3. INSTALLATION

- 6.7. ENGINE FRONT SEAL

- 6.7.1. REMOVAL

- 6.7.2. INSTALLATION

- 6.8. ENGINE REAR SEAL

- 6.8.1. REMOVAL AND INSTALLATION

- 6.9. AFTERCOOLER

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. HYDRAULIC OIL COOLER

- 6.10.1. REMOVAL AND INSTALLATION

- 6.11. ENGINE AND HYDRAULIC PUMP

- 6.11.1. REMOVAL AND INSTALLATION

- 6.12. FINAL DRIVE

- 6.12.1. REMOVAL AND INSTALLATION

- 6.12.2. DISASSEMBLY AND ASSEMBLY

- 6.13. CARRIER ROLLER

- 6.13.1. SPECIAL TOOLS

- 6.13.2. DISASSEMBLY AND ASSEMBLY

- 6.14. SWING MOTOR AND SWING MACHINERY

- 6.14.1. REMOVAL AND INSTALLATION

- 6.15. CENTER SWIVEL JOINT

- 6.15.1. REMOVAL

- 6.15.2. INSTALLATION

- 6.15.3. SPECIAL TOOLS

- 6.15.4. DISASSEMBLY AND ASSEMBLY

- 6.16. WORK EQUIPMENT

- 6.16.1. SPECIAL TOOLS

- 6.16.2. REMOVAL

- 6.16.3. INSTALLATION

- 6.17. REVOLVING FRAME

- 6.17.1. REMOVAL

- 6.17.2. INSTALLATION

- 6.18. SWING CIRCLE

- 6.18.1. REMOVAL AND INSTALLATION

- 6.19. HYDRAULIC TANK

- 6.19.1. DISASSEMBLY AND ASSEMBLY

- 6.20. HYDRAULIC PUMP

- 6.20.1. SPECIAL TOOLS

- 6.20.2. REMOVAL

- 6.20.3. INSTALLATION

- 6.21. HYDRAULIC PUMP INPUT SHAFT OIL SEAL

- 6.21.1. SPECIAL TOOLS

- 6.21.2. REMOVAL AND INSTALLATION

- 6.22. WORK EQUIPMENT PPC VALVE

- 6.22.1. DISASSEMBLY AND ASSEMBLY

- 6.23. TRAVEL PPC VALVE

- 6.23.1. DISASSEMBLY AND ASSEMBLY

- 6.24. HYDRAULIC CYLINDER

- 6.24.1. SPECIAL TOOLS

- 6.24.2. DISASSEMBLY

- 6.24.3. ASSEMBLY

- 6.25. COUNTERWEIGHT

- 6.25.1. REMOVAL AND INSTALLATION

- 6.26. AIR CONDITIONER UNIT

- 6.26.1. SPECIAL TOOLS

- 6.26.2. REMOVAL

- 6.26.3. INSTALLATION

- 6.27. OPERATORS CAB

- 6.27.1. REMOVAL

- 6.27.2. INSTALLATION

- 6.28. OPERATORS CAB GLASS (STUCK GLASS)

- 6.28.1. REMOVAL AND INSTALLATION

- 6.29. GOVERNOR,PUMP CONTROLLER

- 6.29.1. REMOVAL AND INSTALLATION

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM

- 7.2. SERIAL NO.1000111000

- 7.2.1. ELECTRICAL CIRCUIT DIAGRAM (1/4)

- 7.2.2. ELECTRICAL CIRCUIT DIAGRAM (2/4)

- 7.2.3. ELECTRICAL CIRCUIT DIAGRAM (3/4)

- 7.2.4. ELECTRICAL CIRCUIT DIAGRAM (4/4)

- 7.3. SERIAL NO.11001 AND UP

- 7.3.1. ELECTRICAL CIRCUIT DIAGRAM (1/4)

- 7.3.2. ELECTRICAL CIRCUIT DIAGRAM (2/4)

- 7.3.3. ELECTRICAL CIRCUIT DIAGRAM (3/4)

- 7.3.4. ELECTRICAL CIRCUIT DIAGRAM (4/4)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00