Komatsu PC200-6, PC200LC-6, PC210-6, PC210LC-6, PC220-6, PC220LC-6, PC230-6, PC230LC-6 Hydraulic Excavator Shop Manual SEBM010106

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM010106

- Format: PDF

- Size: 52.9MB

- Number of Pages: 1278

Category: Komatsu Shop Manual PDF

-

Model List:

- PC200-6 Hydraulic Excavator

- PC200LC-6 Hydraulic Excavator

- PC210-6 Hydraulic Excavator

- PC210LC-6 Hydraulic Excavator

- PC220-6 Hydraulic Excavator

- PC220LC-6 Hydraulic Excavator

- PC230-6 Hydraulic Excavator

- PC230LC-6 Hydraulic Excavator

- 1. GENERAL

- 1.1. Specification Dimension Drawings

- 1.2. Specifications

- 1.3. Weight Table

- 1.4. Fuel, Coolant and Lubricants

- 2. STRUCTURE AND FUNCTION

- 2.1. Engine Related Parts

- 2.2. Radiator, Oil Cooler, Aftercooler

- 2.3. Power Train

- 2.4. Final Drive

- 2.5. Swing Circle

- 2.6. Swing Machinery

- 2.7. Track Frame, Recoil Spring

- 2.8. Track Shoe

- 2.9. Hydraulic Piping Drawing

- 2.10. Hydraulic Circuit Diagram

- 2.11. Hydraulic Tank

- 2.12. Hydraulic Pump

- 2.13. Line Oil Filter

- 2.14. Control Valve

- 2.15. Selfreducing Pressure Valve

- 2.16. CLSS

- 2.17. Swing Motor

- 2.18. Center Swivel Joint

- 2.19. Travel Motor

- 2.20. Valve Control

- 2.21. Work Equipment, Swing PPC Valve

- 2.22. Travel PPC Valve

- 2.23. Service PPC Valve

- 2.24. Safety Lock Valve

- 2.25. PPC Accumulator

- 2.26. StraightTravel System

- 2.27. Solenoid Valve

- 2.28. Boom Holding Valve

- 2.29. Additional Filter for Breaker

- 2.30. Swivel Joint for Arm Rotation

- 2.31. Arm Rotation Motor

- 2.32. Work Equipment

- 2.33. Air Conditioner

- 2.34. Actual Electric Wiring Diagram

- 2.35. Electrical Circuit Diagram

- 2.36. Engine Control System

- 2.37. Electronic Control System for STD

- 2.38. Electronic Control System for Hyper GX

- 2.39. Machine Monitor System

- 2.40. Sensors

- 2.41. Front Window Auto Pullup System

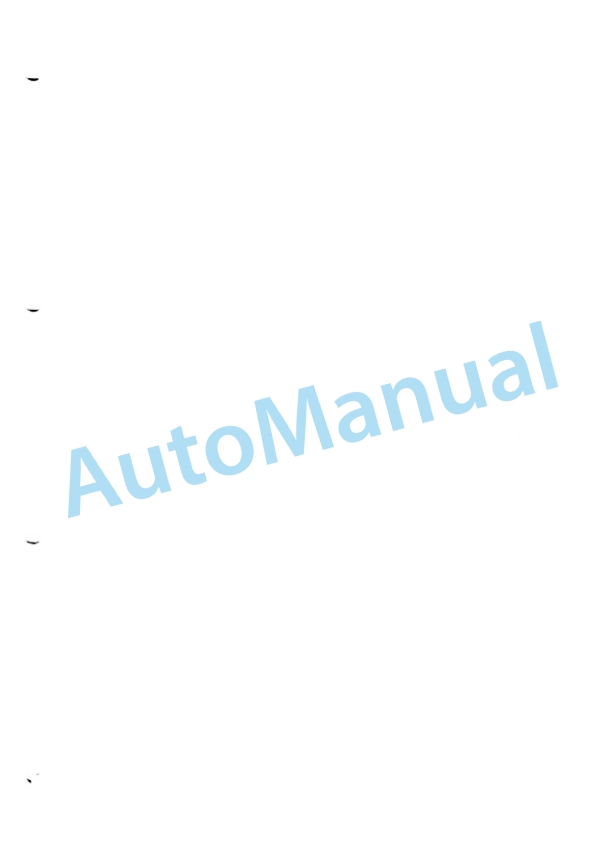

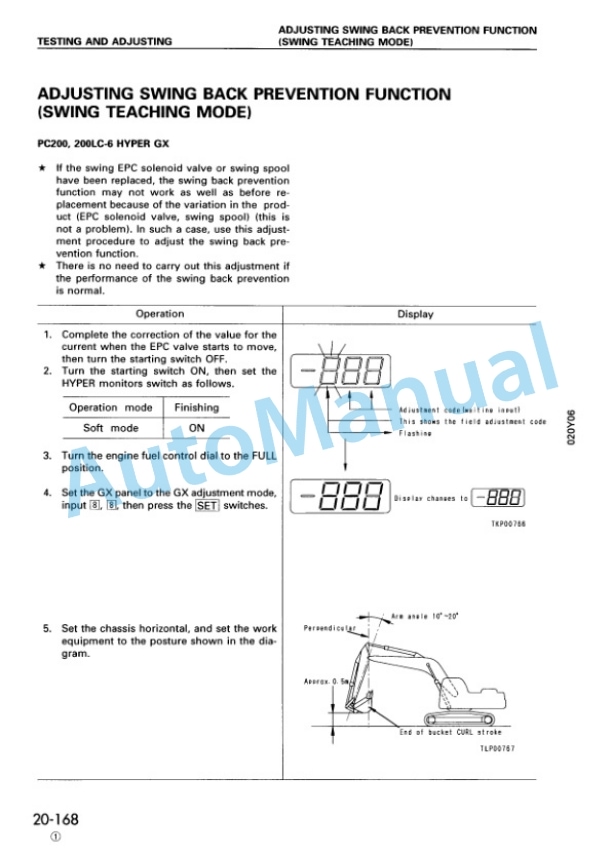

- 3. TESTING AND ADJUSTING

- 3.1. TABLE OF JUDGEMENT STANDARD VALUE

- 3.2. TESTING AND ADJUSTING

- 3.3. TROUBLESHOOTING

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. Method of Using Manual

- 4.2. Precautions When Carrying Out Operation

- 4.3. Special Tool List

- 4.4. Sketches of Special Tools

- 4.5. Starting Motor

- 4.6. Alternator

- 4.7. Air Conditioner Compressor

- 4.8. Condenser

- 4.9. Air Conditioner Condenser

- 4.10. Dry Receiver

- 4.11. Engine Oil Cooler Core

- 4.12. Fuel Injection Pump

- 4.13. Water Pump

- 4.14. Nozzle Holder

- 4.15. Turbocharger

- 4.16. Thermostat

- 4.17. Govenor Motor

- 4.18. Cylinder Head

- 4.19. Hydraulic Oil Cooler

- 4.20. Radiator Hydraulic Oil Cooler

- 4.21. Engine Main Pump

- 4.22. Damper

- 4.23. Fuel Tank

- 4.24. Center Swivel Joint

- 4.25. Final Drive

- 4.26. Travel Motor

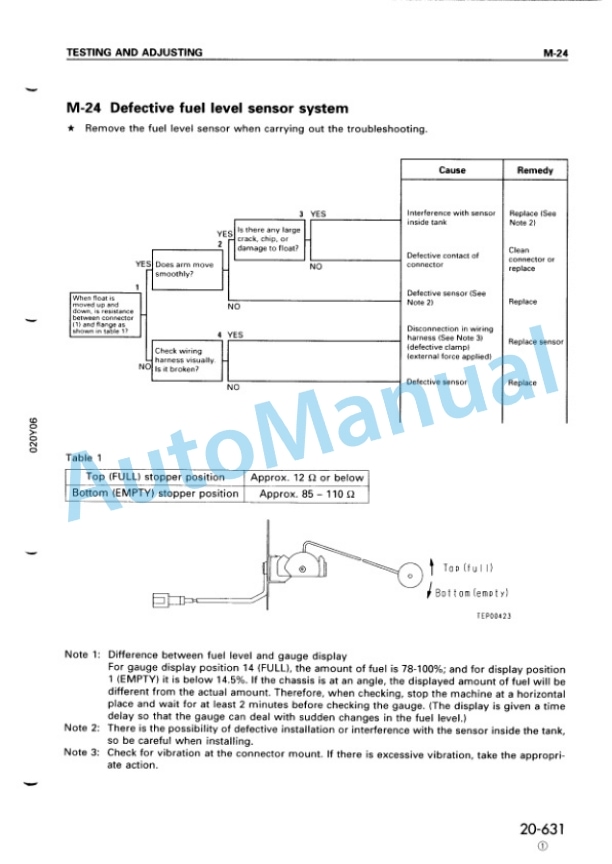

- 4.27. Sprocket

- 4.28. Swing Motor and Swing Machinery

- 4.29. Swing Motor

- 4.30. Revolving Frame

- 4.31. Swing Circle

- 4.32. Idler Recoil Spring

- 4.33. Recoil Spring

- 4.34. Idler

- 4.35. Track Roller

- 4.36. Carrier Roller

- 4.37. Track Shoe

- 4.38. Hydraulic Tank

- 4.39. Main Pump

- 4.40. Main Pump Input Shaft Oil Seal

- 4.41. Control Valve

- 4.42. Pump MergeDivider Valve

- 4.43. Main Relief Valve

- 4.44. Work Equipment EPC Valve

- 4.45. PC Valve

- 4.46. LS Valve

- 4.47. PC, LSEPC Valve

- 4.48. Solenoid Valve

- 4.49. Work Equipment Swing PPC Valve

- 4.50. Travel PPC Valve

- 4.51. Boom Lock Valve

- 4.52. Boom Cylinder

- 4.53. Arm Cylinder

- 4.54. Bucket Cylinder

- 4.55. Hydraulic Cylinder

- 4.56. Work Equipment

- 4.57. Bucket

- 4.59. Bucket Arm

- 4.60. Boom

- 4.61. Opeators Cab

- 4.62. Counterweight

- 4.63. Work Equipment Electric Lever Unit

- 4.64. Engine Throttle Pump Controller

- 4.65. Control Stand Case

- 4.66. Valve Controller

- 4.67. Monitor

- 4.68. ITERMS FOR HYPER GX

- 5. MAINTENANCE STANDARD

- 5.1. Swing Machinery

- 5.2. Swing Circle

- 5.3. Final Drive

- 5.4. Track Frame Recoil Spring

- 5.5. SafetySuction Valve (for Service Valve)

- 5.6. SelfReducing Pressure Valve

- 5.7. Swing Motor

- 5.8. Travel Motor

- 5.9. Work Equipment Swing PPC Valve

- 5.10. Work Equipment Swing EPC Valve

- 5.11. Tavel PPC Valve

- 5.12. Service PPC Valve

- 5.13. EPC Solenoid Valve

- 5.14. Center Swivel Joint

- 5.15. Boom Holding Valve

- 5.16. Hydraulic Cylinder

- 5.17. Work Equipment

- 5.18. Dimension of Work Equipment

- 6. OTHER

- 6.1. Hydraulic Circuit Diagram (pg. 903)

- 6.2. Hydraulic Circuit Diagram (pg. 905)

- 6.3. Hydraulic Circuit Diagram (pg. 907)

- 6.4. Hydraulic Circuit Diagram (pg. 909)

- 6.5. Hydraulic Circuit Diagram (pg. 90101)

- 6.6. Electrical Circuit Diagram 1/2 (pg. 9011)

- 6.7. Electrical Circuit Diagram 2/2 (pg. 9013)

- 6.8. Electrical Circuit Diagram 1/2 (pg. 9015)

- 6.9. Electrical Circuit Diagram 2/2 (pg. 9017)

- 6.10. Electrical Circuit Diagram 1/3 (pg. 9019)

- 6.11. Electrical Circuit Diagram 2/3 (pg. 9021)

- 6.12. Electrical Circuit Diagram 3/3 (pg. 9023)

- 6.13. Electrical Circuit Diagram (pg. 9025)

- 6.14. Electrical Circuit Diagram 1/3 (pg. 9027)

- 6.15. Electrical Circuit Diagram 2/3 (pg. 9029)

- 6.16. Electrical Circuit Diagram 3/3 (pg. 9031)

- 6.17. Electrical Circuit Diagram (pg 9033)

Rate this product

You may also like