Komatsu PC200-6, PC200LC-6, PC220-6, PC220LC-6, PC220SE-6 Hydraulic Excavator Shop Manual YEAN200201

$40.00

- Type Of Manual: Shop Manual

- Manual ID: YEAN200201

- Format: PDF

- Size: 12.6MB

- Number of Pages: 287

Category: Komatsu Shop Manual PDF

-

Model List:

- PC200-6 Hydraulic Excavator

- PC200LC-6 Hydraulic Excavator

- PC220-6 Hydraulic Excavator

- PC220LC-6 Hydraulic Excavator

- PC220SE-6 Hydraulic Excavator

- 1. COVER

- 1.1. CONTENTS

- 1.1.1. FOREWORD

- 1.1.1.1. FOREWORD

- 1.1.1.2. SAFETY INFORMATION

- 1.1.1.3. INTRODUCTION

- 1.1.1.3.1. INTENDED USE

- 1.1.1.3.2. FEATURES

- 1.1.1.3.3. BREAKING IN THE MACHINE

- 1.1.1.4. LOCATION OF RLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.1.1.4.1. MACHINE SERIAL NO. PLATE POSITION

- 1.1.1.4.2. ENGINE SERIAL NO. PLATE POSITION

- 1.1.1.4.3. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.1.2. SAFETY

- 1.1.2.1. GENERAL PRECAUTIONS

- 1.1.2.2. PRECAUTIONS DURING OPERATION

- 1.1.2.2.1. BEFORE STARTING ENGINE

- 1.1.2.2.2. AFTER STARTING ENGINE

- 1.1.2.2.3. TRANSPORTATION

- 1.1.2.2.4. BATTERY

- 1.1.2.2.5. TOWING

- 1.1.2.2.6. THE BUCKET WITH HOOK

- 1.1.2.3. PRECAUTIONS FOR MAINTENANCE

- 1.1.2.3.1. BEFORE CARRYING OUT MAINTENANCE

- 1.1.2.3.2. DURING MAINTENANCE

- 1.1.2.4. POSITION FOR ATTACHING SAFETY LABELS

- 1.1.3. OPERATION

- 1.1.3.1. GENERAL VIEW

- 1.1.3.1.1. GENERAL VIEW OF MACHINE

- 1.1.3.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 1.1.3.2. EXPLANATION OF COMPONENTS

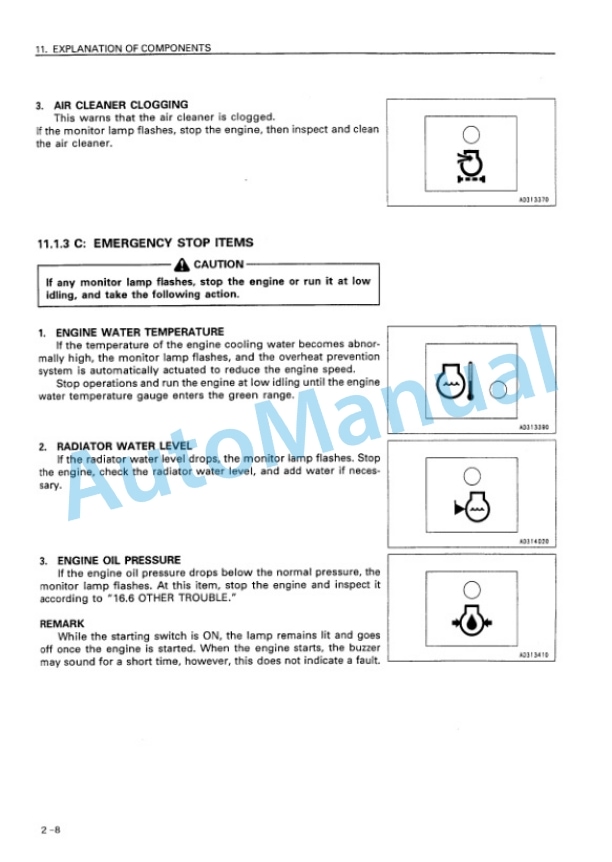

- 1.1.3.2.1. MACHINE MONITOR

- 1.1.3.2.2. SWITCHES

- 1.1.3.2.3. CONTROL LEVERS, PEDALS

- 1.1.3.2.4. CEILING WINDOW

- 1.1.3.2.5. FRONT WINDOW

- 1.1.3.2.6. DOOR LOCK

- 1.1.3.2.7. CAP, COVER WITH LOCK

- 1.1.3.2.8. HOT/COOL BOX

- 1.1.3.2.9. LUGGAGE BOX

- 1.1.3.2.10. ASHTRAY

- 1.1.3.2.11. AIR CONDITIONER

- 1.1.3.2.12. CAR RADIO

- 1.1.3.2.13. FUSE

- 1.1.3.2.14. FUSIBLE LINK

- 1.1.3.2.15. CONTROLLERS

- 1.1.3.2.16. TOOL BOX

- 1.1.3.2.17. GREASE PUMP HOLDER

- 1.1.3.2.18. HANDLING ACCUMULATOR

- 1.1.3.3. OPERATION

- 1.1.3.3.1. CHECK BEFORE STARTING ENGINE

- 1.1.3.3.2. STARTIMG EMGIME

- 1.1.3.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 1.1.3.3.4. MOVING MACHINE OFF

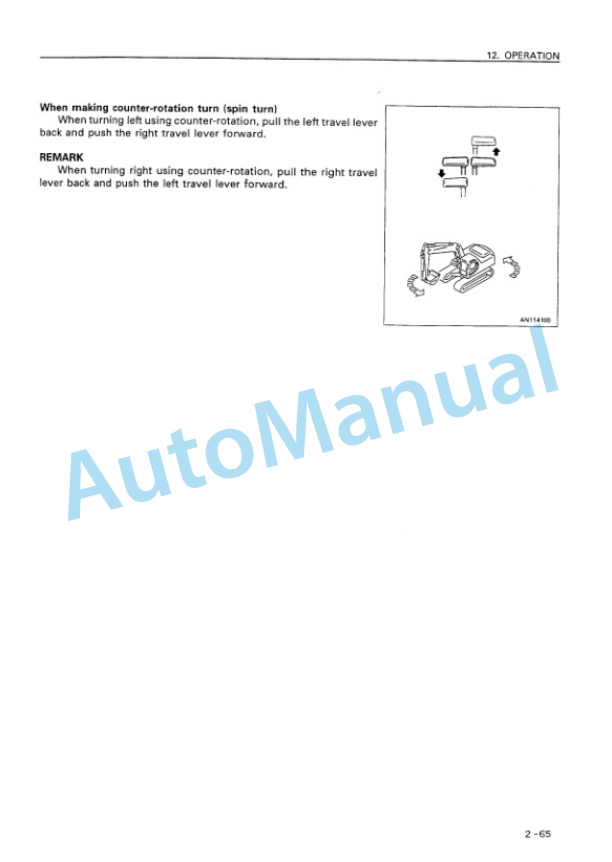

- 1.1.3.3.5. STEERING MACHINE

- 1.1.3.3.6. STOPPING MACHINE

- 1.1.3.3.7. SWINGING

- 1.1.3.3.8. OPERATION OF WORK EQUIPMENT

- 1.1.3.3.9. HANDLING ACTIVE MODE

- 1.1.3.3.10. WORKING MODE SELECTION

- 1.1.3.3.11. PROHIBITIONS FOR OPERATION

- 1.1.3.3.12. PRECAUTIONS FOR OPERATION

- 1.1.3.3.13. PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS

- 1.1.3.3.14. HOW TO ESCAPE FROM MUD

- 1.1.3.3.15. WORK POSSIBLE USING HYDRAULIC EXCAVATOR

- 1.1.3.3.16. REPLACEMENT AND INVERSION OF BUCKET

- 1.1.3.3.17. PARKING MACHINE

- 1.1.3.3.18. CHECK AFTER FINISHING WORK

- 1.1.3.3.19. STOPPING ENGINE

- 1.1.3.3.20. CHECK AFTER STOPPING ENGINE

- 1.1.3.3.21. LOCKING

- 1.1.3.4. TRANSPORTATION

- 1.1.3.4.1. LOADING, UNLOADING WORK

- 1.1.3.4.2. PRECAUTIONS FOR LOADING

- 1.1.3.4.3. PRECAUTIONS FOR TRANSPORTATION

- 1.1.3.4.4. THE WAY OF LIFTING THE MACHINE

- 1.1.3.5. COLD WEATHER OPERATION

- 1.1.3.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 1.1.3.5.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 1.1.3.5.3. AFTER COLD WEATHER

- 1.1.3.6. LONGTERM STORAGE

- 1.1.3.6.1. BEFORE STORAGE

- 1.1.3.6.2. DURING STORAGE

- 1.1.3.6.3. AFTER STORAGE

- 1.1.3.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 1.1.3.7. TROUBLESHOOTING

- 1.1.3.7.1. PHENOMENA THAT ARE NOT FAILURES

- 1.1.3.7.2. METHOD OF TOWING MACHINE

- 1.1.3.7.3. USING METHOD FOR LIGHTWEIGHT TOWING HOLE

- 1.1.3.7.4. PRECAUTIONS ON PARTICULAR JOBSITES

- 1.1.3.7.5. IF BATTERY IS DISCHARGED

- 1.1.3.7.6. OTHER TROUBLE

- 1.1.4. MAINTENANCE

- 1.1.4.1. GUIDES TO MAINTENANCE

- 1.1.4.2. OUTLINES OF SERVICE

- 1.1.4.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 1.1.4.2.2. OUTLINE OF ELECTRIC SYSTEM

- 1.1.4.2.3. OUTLINE OF HYDRAULIC SYSTEM

- 1.1.4.3. WEAR PARTS LIST

- 1.1.4.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 1.1.4.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 1.1.4.5.1. INTRODUCTION OF NECESSARY TOOLS

- 1.1.4.5.2. TORQUE LIST

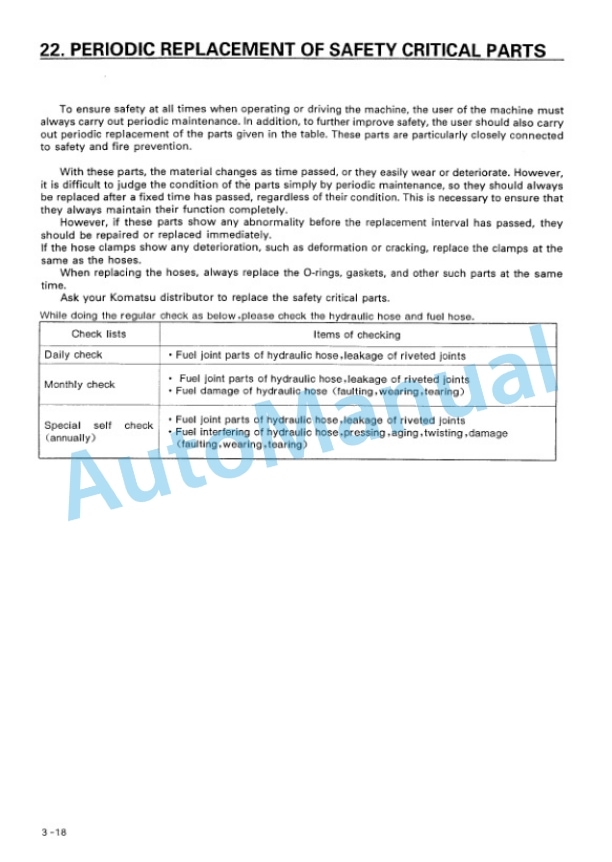

- 1.1.4.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 1.1.4.7. MAINTENANCE SCHEDULE CHART

- 1.1.4.7.1. MAINTENANCE SCHEDULE CHART

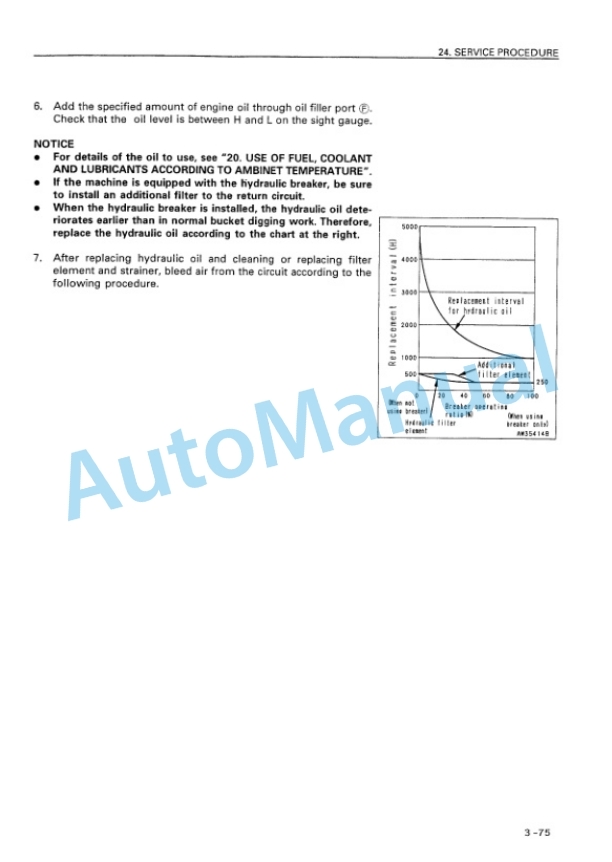

- 1.1.4.7.2. MAINTENANCE INTERVAL WHEN USING HYDRAULIC BREAKER

- 1.1.4.8. SERVICE PROCEDURE

- 1.1.4.8.1. INITIAL 250 HOURS SERVICE

- 1.1.4.8.2. WHEN REQUIRED

- 1.1.4.8.3. CHECK BEFORE STARTING

- 1.1.4.8.4. EVERY 100 HOURS SERVICE

- 1.1.4.8.5. EVERY 250 HOURS SERVICE

- 1.1.4.8.6. EVERY 500 HOURS SERVICE

- 1.1.4.8.7. EVERY 1000 HOURS SERVICE

- 1.1.4.8.8. EVERY 2000 HOURS SERVICE

- 1.1.4.8.9. EVERY 4000 HOURS SERVICE

- 1.1.4.8.10. EVERY 5000 HOURS SERVICE

- 1.1.5. SPECIFICATIONS

- 1.1.5.1. SPECIFICATIONS

- 1.1.6. OPTIONS, ATTACHMENTS

- 1.1.6.1. GENERAL PRECAUTIONS

- 1.1.6.1.1. PRECAUTIONS RELATED TO SAFETY

- 1.1.6.1.2. PRECAUTIONS WHEN INSTALLING ATTACHMENTS

- 1.1.6.2. HANDLING BUCKET WITH HOOK

- 1.1.6.2.1. CHECKING FOR DAMAGE TO BUCKET WITH HOOK

- 1.1.6.2.2. PROHIBITED OPERATIONS

- 1.1.6.2.3. PRECAUTIONS DURING OPERATIONS

- 1.1.6.3. USING SEAT BELT

- 1.1.6.3.1. SEAT BELT (OPTION)

- 1.1.6.4. HANDLING CAR HEATER

- 1.1.6.4.1. EXPLANATION OF COMPONENTS

- 1.1.6.4.2. PREPARING CAR HEATER

- 1.1.6.5. MACHINES READY FOR ATTACHMENTS

- 1.1.6.5.1. EXPLANATION OF COMPONENTS

- 1.1.6.5.2. HYDRAULIC CIRCUIT

- 1.1.6.5.3. ATTACHMENT MOUNTING/DISMOUNTING PROCEDURE

- 1.1.6.5.4. OPERATION

- 1.1.6.5.5. LONGTERM STORAGE

- 1.1.6.5.6. SPECIFICATIONS

- 1.1.6.6. INTRODUCTION OF ATTACHMENTS

- 1.1.6.6.1. SPECIFICATION, USE

- 1.1.6.6.2. ATTACHMENT INSTALLATION COMBINATION TABLE

- 1.1.6.6.3. SELECTION OF TRACK SHOES

- 1.1.6.6.4. SELECTION OF BUCKET TEETH

- 1.1.6.6.5. HANDLING RUBBER PAD SHOE

- 1.1.6.6.6. HANDLING TRAPEZOIDAL BUCKET

- 1.1.6.6.7. HANDLING EXTENSION ARM

- 1.1.6.6.8. HANDLING CLAMSHELL BUCKET

- 1.1.6.7. EXTENDING MACHINE SERVICE LIFE

- 1.1.6.7.1. HYDRAULIC BREAKER

- 1.1.6.7.2. POWER RIPPER

- 1.1.6.7.3. FORK GRAB

- 1.1.6.7.4. GRAPPLE BUCKET

- 1.1.6.7.5. SCRAP GRAPPLE

- 1.1.6.7.6. CRUSHER CUTTER

- 1.1.6.7.7. HYDRAULIC PILE DRIVER

- 1.1.6.7.8. HYDRAULIC EXCAVATOR WITH MULTIPURPOSE CRANE

- 1.1.6.8. AUTO GREASE SYSTEM

- 1.1.6.8.1. AUTO GREASE CONTROLLER (OPTION)

- 1.1.6.8.2. THE MEASURE TAKEN DURING ABNORMAL CONDITION

- 1.1.6.8.3. CHECK BEFORE START

- 1.1.6.8.4. EVERY 100 HOURS SERVICE

- 1.2. MEMO

- 2. UNDER COVER

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00