Komatsu PC200LC-6 Hydraulic Excavator Shop Manual SEBM010202

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM010202

- Format: PDF

- Size: 31.0MB

- Number of Pages: 540

Category: Komatsu Shop Manual PDF

-

Model List:

- PC200LC-6 Hydraulic Excavator

- 1. MAIN MENU

- 2. COVER

- 3. CONTENTS

- 4. GENERAL

- 4.1. SPECIFICATION DIMENSION DRAWINGS

- 4.2. SPECIFICATIONS

- 4.3. WEIGHT TABLE

- 4.4. FUEL, COOLANT AND LUBRICANTS

- 5. STRUCTURE AND FUNCTION

- 5.1. ENGINE RELATED PARTS

- 5.2. RADIATOR OIL COOLER AFTERCOOLER

- 5.3. ENGINE CONTROL

- 5.4. POWER TRAIN

- 5.5. FINAL DRIVE

- 5.6. SWING CIRCLE

- 5.7. SWING MACHINERY

- 5.8. TRACK FRAME RECOIL SPRING

- 5.9. TRACK SHOE

- 5.10. HYDRAULIC PIPING DRAWING

- 5.11. HYDRAULIC CIRCUIT DIAGRAM

- 5.12. HYDRAULIC TANK

- 5.13. HYDRAULIC PUMP

- 5.14. INLINE FILTER

- 5.15. CONTROL VALVE

- 5.16. SELFREDUCING PRESSURE VALVE

- 5.17. CLSS

- 5.18. SWING MOTOR

- 5.19. CENTER SWIVEL JOINT

- 5.20. TRAVEL MOTOR

- 5.21. VALVE CONTROL

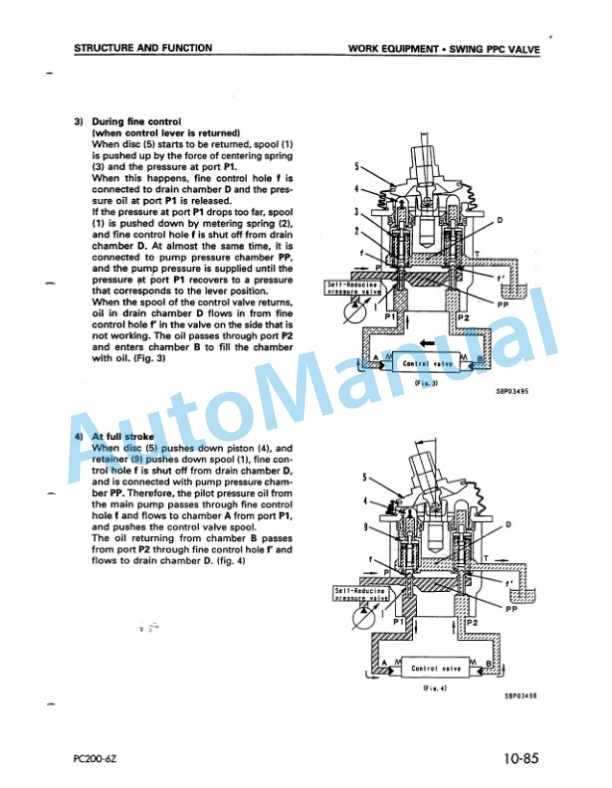

- 5.22. WORK EQUIPMENT SWING PPC VALVE

- 5.23. TRAVEL PPC VALVE

- 5.24. SERVICE PPC VALVE

- 5.25. ACCUMULATOR

- 5.26. STRAIGHTTRAVEL SYSTEM

- 5.27. EPC SOLENOID VALVE

- 5.28. BOOM HOLDING VALVE

- 5.29. ADDITIONAL FILTER FOR BREAKER

- 5.30. WORK EQUIPMENT

- 5.31. ACTUAL ELECTRICAL WIRING DIAGRAM

- 5.32. ELECTRIC CIRCUIT SYSTEM

- 5.33. ELECTRIC CONTROL SYSTEM

- 5.34. MACHINE MONITOR SYSTEM

- 5.35. SENSORS

- 6. TESTING AND ADJUSTING

- 6.1. STANDARD VALVE TABLE FOR ENGINE RELATED PARTS

- 6.2. STANDARD VALVE TABLE FOR ENGINE CHASSIS RELATED PARTS

- 6.3. STANDARD VALVE TABLE FOR ENGINE ELECTRICAL SYSTEM

- 6.4. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 6.5. MEASURING ENGINE SPEED

- 6.6. MEASURING EXHAUST COLOR

- 6.7. ADJUSTING VALVE CLEARANCE

- 6.8. MEASURING COMPRESSION PRESSURE

- 6.9. MEASURING BLOW BY PRESSURE

- 6.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 6.11. MEASURING ENGINE OIL PRESSURE

- 6.12. TESTING AND ADJUSTING FAN BELT TENSION

- 6.13. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 6.14. ADJUSTING ENGINE SPEED SENSOR

- 6.15. ADJUSTING FUEL CONTROL LEVER

- 6.16. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 6.17. TESTING AND ADJUSTING PC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)

- 6.18. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

- 6.19. TESTING AND ADJUSTING CONTROL CIRCUIT OIL PRESSURE

- 6.20. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 6.21. MEASURING PPC VALVE PUTPUT PRESSURE

- 6.22. ADJUSTING WORK EQUIPMENT, SWING PPC VALVE

- 6.23. TESTING TRAVEL DEVIATION

- 6.24. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 6.25. MEASURING OIL LEAKAGE

- 6.26. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 6.27. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 6.28. TESTING AND ADJUSTING TRACK SHOE TENSION

- 6.29. BLEEDING AIR

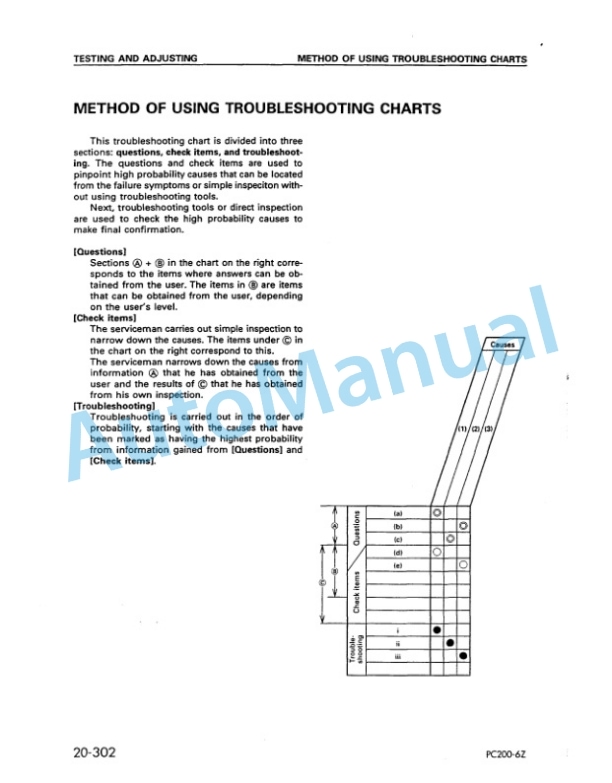

- 6.30. TROUBLESHOOTING

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. METHOD OF USING MANUAL

- 7.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 7.3. SPECIAL TOOL LIST

- 7.4. SKETCHES OF SPECIAL TOOLS

- 7.5. STARTING MOTOR ASSEMBLY

- 7.6. ALTERNATIVE ASSEMBLY

- 7.7. AIR CONDITIONER COMPRESSOR ASSEMBLY

- 7.8. CONDENSER ASSEMBLY

- 7.9. ENGINE OIL COOLER CORE ASSEMBLY

- 7.10. FUEL INJECTION PUMP ASSEMBLY

- 7.11. WATER PUMP ASSEMBLY

- 7.12. NOZZLE HOLDER ASSEMBLY

- 7.13. TURBOCHARGER ASSEMBLY

- 7.14. THERMOSTAT ASSEMBLY

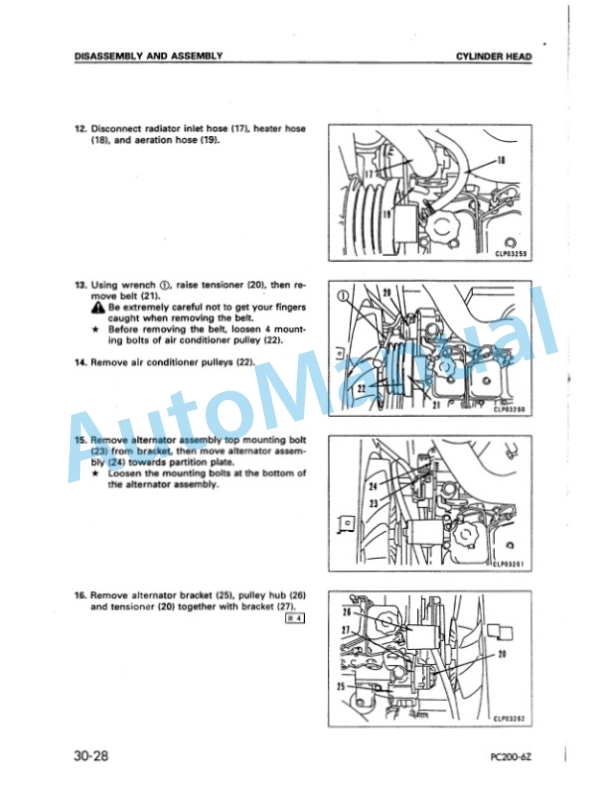

- 7.15. CYLINDER HEAD ASSEMBLY

- 7.16. RADIATOR HYDRAULIC COOLER ASSEMBLY

- 7.17. ENGINE MAIN PUMP ASSEMBLY

- 7.18. DAMPER ASSEMBLY

- 7.19. FUEL TANK ASSEMBLY

- 7.20. CENTER SWIVEL JOINT ASSEMBLY

- 7.21. FINAL DRIVE ASSEMBLY

- 7.22. SPROCKET

- 7.23. SWIMG MOTOR, SWING MACHINERY

- 7.24. REVOLVING FRAME ASSEMBLY

- 7.25. SWING CIRCLE ASSEMBLY

- 7.26. IDLER RECOIL SPRING ASSEMBLY

- 7.27. RECOIL SPRING ASSEMBLY

- 7.28. IDLER ASSEMBLY

- 7.29. TRACK ROLLER ASSEMBLY

- 7.30. CARRIER ROLLER ASSEMBLY

- 7.31. TRACK SHOE ASSEMBLY

- 7.32. HYDRAULAIC TANK ASSEMBLY

- 7.33. MAIN PUMP ASSEMBLY

- 7.34. MAIN PUMP INPUT SHAFT OIL SEAL

- 7.35. CONTROL VALVE ASSEMBLY

- 7.36. MAIN RELIEF VALVE ASSEMBLY

- 7.37. PC VALVE ASSEMBLY

- 7.38. LS VALVE ASSEMBLY

- 7.39. PCEPC VALVE ASSEMBLY

- 7.40. SOLENOID VALVE ASSEMBLY

- 7.41. WORK EQUIPMENT SWING PPC VALVE ASSEMBLY

- 7.42. TRAVEL PPC VALVE ASSEMBLY

- 7.43. BOOM LOCK VALVE ASSEMBLY

- 7.44. BOOM CYLINDER ASSEMBLY

- 7.45. ARM CYLINDER ASSEMBLY

- 7.46. BUCKET CYLINDER ASSEMBLY

- 7.47. HYDRAULIC CYLINDER ASSEMBLY

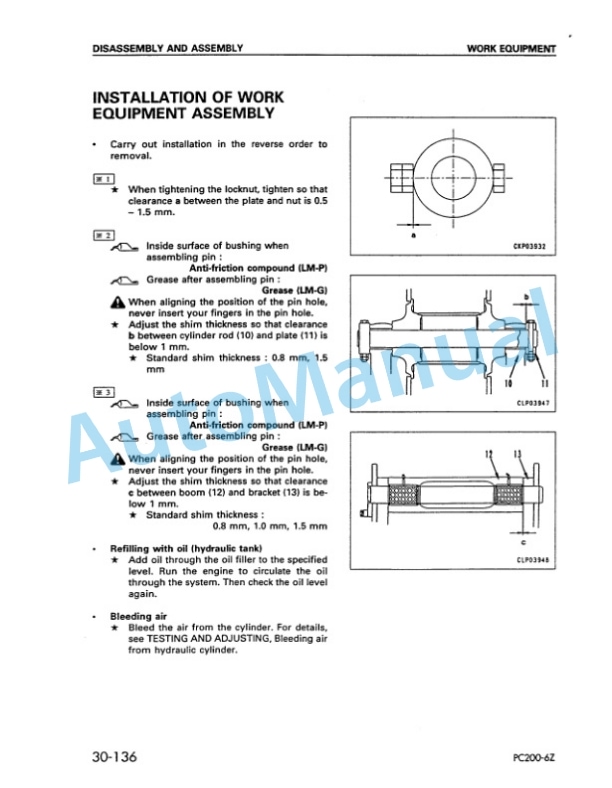

- 7.48. WORK EQUIPMENT ASSEMBLY

- 7.49. BUCKET ASSEMBLY

- 7.50. ARM ASSEMBLY

- 7.51. BUCKET ARM ASSEMBLY

- 7.52. BOOM ASSEMBLY

- 7.53. OPERATORS CAB ASSEMBLY

- 7.54. COUNTERWEIGHT ASSEMBLY

- 7.55. MONITOR ASSEMBLY

- 8. MAINTENANCE STANDARD

- 8.1. SWING MACHINERY

- 8.2. SWING CIRCLE

- 8.3. FINAL DRIVE

- 8.4. TRACK FRAME RECOIL SPRING

- 8.5. SELFREDUCING PRESSURE VALVE

- 8.6. SWING MOTOR

- 8.7. TRAVEL MOTOR

- 8.8. WORK EQUIPMENT SWING PPC VALVE

- 8.9. TRAVEL PPC VALVE

- 8.10. SERVICE PPC VALVE

- 8.11. CENTER SWIVEL JOINT

- 8.12. BOOM HOLDING VALVE

- 8.13. HYDRAULIC CYLINDER

- 8.14. WORK EQUIPMENT

- 8.15. DIMENSION OF WORK EQUIPMENT

- 9. OTHERS

- 9.1. HYDRAULIC PIPING DRAWING

- 9.2. HYDRAULIC CIRCUIT DIAGRAM

- 9.3. ACTUAL ELECTRICAL WIRING DIAGRAM (1/2)

- 9.4. ACTUAL ELECTRICAL WIRING DIAGRAM (2/2)

- 9.5. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 9.6. ELECTRICAL CIRCUIT DIAGRAM (2/2)

- 9.7. OPERATION OF CLSS SYSTEM AS A WHOLE

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00