Komatsu PC200Z-6LE Hydraulic Excavator Shop Manual CEBM001700

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM001700

- Format: PDF

- Size: 10.4MB

- Number of Pages: 485

Category: Komatsu Shop Manual PDF

-

Model List:

- PC200Z-6LE Hydraulic Excavator

- 1. MAIN MENU

- 2. COVER

- 3. CONTENTS

- 4. GENERAL

- 4.1. GENERAL ASSEMBLY DRAWING

- 4.2. SPECIFICATIONS

- 4.3. WEIGHT TABLE

- 4.4. FUEL, COOLANT AND LUBRICANTS

- 4.5. ENGINE OIL SPECIFICATION

- 4.5.1. NORMAL OPERATION

- 4.5.2. ARCTIC OPERATION

- 4.6. COOLANT

- 5. STRUCTURE AND FUNCTION

- 5.1. ENGINE RELATED PARTS

- 5.1.1. SPECIFICATIONS

- 5.2. RADIATOR OIL COOLER

- 5.2.1. SPECIFICATIONS

- 5.3. ENGINE CONTROL SYSTEM

- 5.4. SWING MACHINERY

- 5.4.1. SPECIFICATIONS

- 5.5. TRACK FRAME RECOIL SPRING

- 5.5.1. SPECIFICATIONS

- 5.6. TRACK SHOE

- 5.6.1. STANDARD SHOE

- 5.6.2. SELECTION OF TRACK SHOE

- 5.7. HYDRAULIC PIPING DRAWING

- 5.8. HYDRAULIC CIRCUIT DIAGRAM

- 5.8.1. LS and PC valve

- 5.9. INLINE OIL FILTER

- 5.9.1. Outline

- 5.10. CONTROL VALVE

- 5.10.1. Outline

- 5.10.2. spool valve (standard)

- 5.11. SAFETYSUCTION VALVE FOR SERVICE VALVE

- 5.12. SELFREDUCING PRESSURE VALVE

- 5.12.1. Function

- 5.12.2. Operation

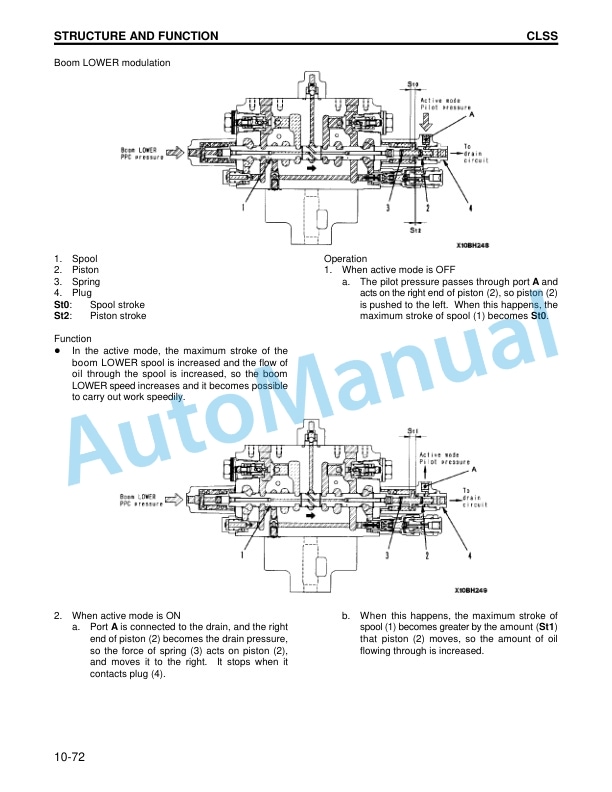

- 5.13. CLSS

- 5.13.1. Outline of CLSS

- 5.13.2. Operation for each function and valve

- 5.13.3. Operation of CLSS system as a whole

- 5.14. SWING MOTOR

- 5.14.1. BASIC MOTOR

- 5.14.2. Swing lock valve

- 5.14.3. Reverse prevention valve (swing dampening)

- 5.15. CENTER SWIVEL JOINT

- 5.16. TRAVEL MOTOR

- 5.16.1. Operation of parking brake

- 5.16.2. Operation of brake valve

- 5.17. VALVE CONTROL

- 5.18. WORK EQUIPMENT SWING PPC VALVE

- 5.18.1. Operation

- 5.19. TRAVEL PPC VALVE

- 5.19.1. Operation

- 5.20. SERVICE PPC VALVE

- 5.20.1. Operation

- 5.21. ACCUMULATOR

- 5.21.1. Function

- 5.21.2. Operation

- 5.22. STRAIGHTTRAVEL SYSTEM

- 5.22.1. Function

- 5.23. EPC SOLENOID VALVE

- 5.23.1. Operation

- 5.24. BOOM LOCK VALVE

- 5.24.1. Operation

- 5.25. ADDITIONAL FILTER FOR BREAKER

- 5.26. WORK EQUIPMENT

- 5.27. AIR CONDITIONER

- 5.28. ELECTRICAL WIRING DIAGRAM

- 5.29. ELECTRICAL CIRCUIT DIAGRAM

- 5.29.1. ELECTRICAL CIRCUIT DIAGRAM FOR AIR CONDITIONER

- 5.30. ELECTRIC CONTROL SYSTEM

- 5.30.1. TOTAL SYSTEM DIAGRAM

- 5.30.2. PUMP CONTROL FUNCTION

- 5.30.3. SWING LOCK, PPC LOCK FUNCTION

- 5.31. MACHINE MONITOR SYSTEM

- 5.31.1. FUNCTION

- 5.31.2. Monitor panel

- 5.32. SENSORS

- 5.32.1. Engine oil pressure sensor

- 5.32.2. Coolant temperature sensor

- 5.32.3. Fuel level sensor

- 6. TESTING, ADJUSTING AND TROUBLESHOOTING

- 6.1. TESTING AND ADJUSTING

- 6.1.1. STANDARD VALUE TABLE

- 6.1.2. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 6.1.3. MEASURING ENGINE SPEED

- 6.1.4. MEASURING EXHAUST GAS COLOR

- 6.1.5. ADJUSTING VALVE CLEARANCE

- 6.1.6. MEASURING COMPRESSION PRESSURE

- 6.1.7. MEASURING BLOWBY PRESSURE

- 6.1.8. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 6.1.9. MEASURE ENGINE OIL PRESSURE

- 6.1.10. TESTING AND ADJUSTING FAN BELT TENSION

- 6.1.11. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 6.1.12. ADJUSTING SPEED SENSOR

- 6.1.13. ADJUSTING FUEL CONTROL LEVER

- 6.1.14. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUIT

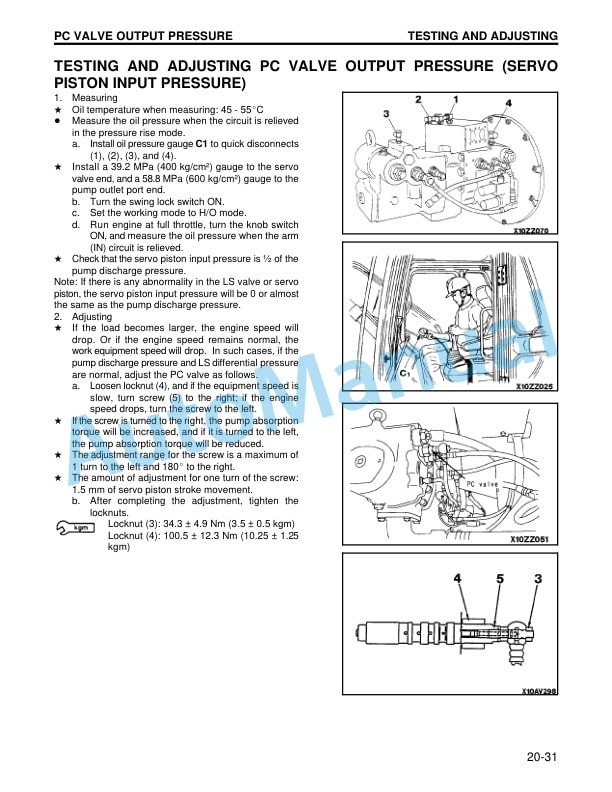

- 6.1.15. TESTING AND ADJUSTING PC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)

- 6.1.16. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE AND LS DIFFERENTIAL PRESSURE)

- 6.1.17. TESTING AND ADJUSTING CONTROL CIRCUIT OIL PRESSURE

- 6.1.18. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 6.1.19. MEASURING PPC VALVE OUTPUT PRESSURE

- 6.1.20. ADJUSTING WORK EQUIPMENT SWING PPC VALVE

- 6.1.21. TESTING TRAVEL DEVIATION

- 6.1.22. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 6.1.23. MEASURING OIL LEAKAGE

- 6.1.24. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 6.1.25. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 6.1.26. TESTING AND ADJUSTING TRACK SHOE TENSION

- 6.1.27. BLEEDING AIR

- 6.2. TROUBLESHOOTING

- 6.2.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 6.2.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 6.2.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 6.2.4. CHECKS BEFORE TROUBLESHOOTING

- 6.2.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 6.2.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 6.2.7. METHOD OF USING TROUBLESHOOTING CHARTS

- 6.2.8. TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)

- 6.2.9. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

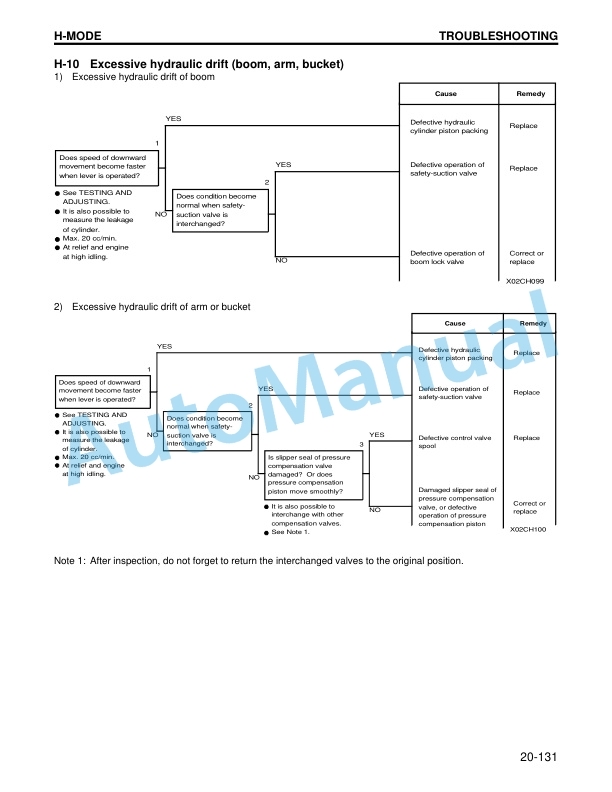

- 6.2.10. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 6.2.11. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. METHOD OF USING MANUAL

- 7.1.1. When removing or installing unit assemblies

- 7.1.2. General precautions

- 7.1.3. Listing of special tools

- 7.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 7.2.1. Precautions when carrying out removal work

- 7.2.2. Precautions when carrying out installation work

- 7.2.3. Precautions when completing the operations

- 7.3. SPECIAL TOOL LIST

- 7.4. SKETCHES OF SPECIAL TOOLS

- 7.5. AIR CONDITIONER COMPRESSOR

- 7.6. FUEL INJECTION PUMP

- 7.7. CYLINDER HEAD ASSEMBLY

- 7.7.1. Removal

- 7.7.2. Installation

- 7.8. RADIATOR, HYDRAULIC OIL COOLER ASSEMBLY

- 7.8.1. Removal

- 7.8.2. Installation

- 7.9. ENGINE, MAIN PUMP

- 7.10. CENTER SWIVEL JOINT

- 7.11. SWING MACHINERY

- 7.11.1. Removal

- 7.11.2. Installation

- 7.11.3. Disassembly

- 7.11.4. Assembly

- 7.12. REVOLVING FRAME

- 7.13. IDLER RECOIL SPRING

- 7.14. MAIN PUMP INPUT SHAFT OIL SEAL

- 7.15. PUMP MERGEDIVIDER VALVE

- 7.15.1. Disassembly

- 7.15.2. Assembly

- 7.16. MAIN RELIEF VALVE

- 7.17. WORK EQUIPMENT SWING PPC VALVE

- 7.17.1. Removal

- 7.17.2. Installation

- 7.17.3. Disassembly

- 7.17.4. Assembly

- 7.18. TRAVEL PPC VALVE

- 7.18.1. Removal

- 7.18.2. Installation

- 7.18.3. Disassembly

- 7.18.4. Installation

- 7.19. BOOM LOCK VALVE

- 7.20. BUCKET CYLINDER

- 7.20.1. Removal

- 7.20.2. Installation

- 7.21. HYDRAULIC CYLINDER

- 8. MAINTENANCE STANDARD

- 8.1. SWING MACHINERY

- 8.2. SWING CIRCLE

- 8.3. FINAL DRIVE

- 8.4. TRACK FRAME RECOIL SPRING

- 8.5. SAFETYSUCTION VALVE FOR SERVICE VALVE

- 8.6. SELFREDUCING PRESSURE VALVE

- 8.7. SWING MOTOR

- 8.8. TRAVEL MOTOR

- 8.9. WORK EQUIPMENT SWING PPC VALVE

- 8.10. TRAVEL PPC VALVE

- 8.11. SERVICE PPC VALVE

- 8.12. CENTER SWIVEL JOINT

- 8.13. BOOM LOCK VALVE

- 8.14. HYDRAULIC CYLINDER

- 8.14.1. Boom cylinder

- 8.14.2. Arm cylinder

- 8.14.3. Bucket cylinder

- 8.15. WORK EQUIPMENT

- 8.16. DIMENSION OF WORK EQUIPMENT

- 8.16.1. Arm portion

- 8.16.2. Bucket portion

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00