Komatsu PC20MR-2 Hydraulic Excavator Shop Manual SEBM037001

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM037001

- Format: PDF

- Size: 54.1MB

- Number of Pages: 408

Category: Komatsu Shop Manual PDF

-

Model List:

- PC20MR-2 Hydraulic Excavator

- 0.1. HOISTING INSTRUCTIONS

- 0.2. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.3. COATING MATERIALS

- 0.4. STANDARD TIGHTENING TORQUE

- 0.5. ELECTRIC WIRE CODE

- 0.6. CONVERSION TABLE

- 0.7. UNITS

- 1. GENERAL

- 1.1. SPECIFICATION DIMENSION DRAWING

- 1.2. WORKING RANGE DRAWING

- 1.3. SPECIFICATIONS

- 1.4. WEIGHT TABLE

- 1.5. LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS

- 2. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 2.1. HYDRAULIC COMPONENTS LAYOUT DRAWING

- 2.2. HYDRAULIC TANK

- 2.3. CENTER SWIVEL JOINT

- 2.4. TRAVEL MOTOR

- 2.5. HYDRAULIC CYLINDER

- 2.6. SOLENOID VALVE

- 2.7. MULTICONTROL VALVE (IF EQUIPPED)

- 2.8. HYDRAULIC PUMP

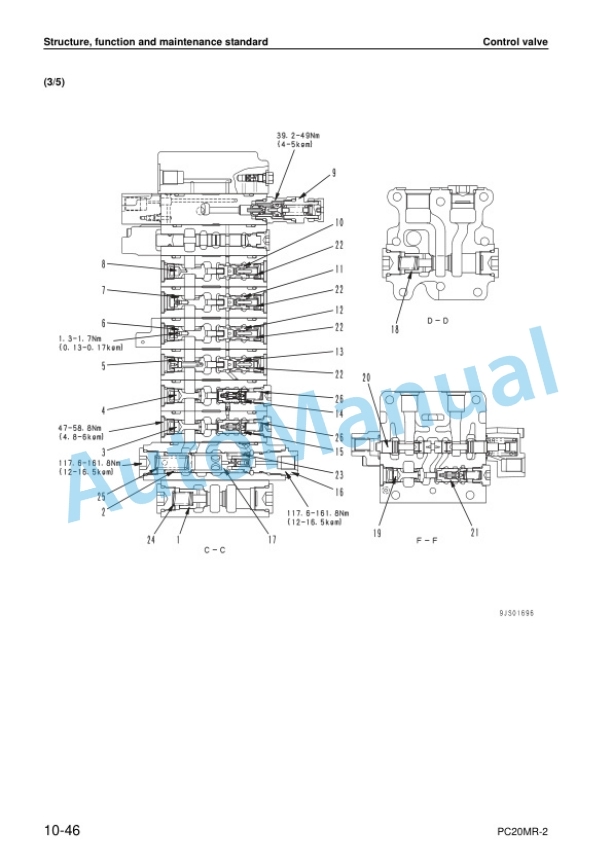

- 2.9. CONTROL VALVE

- 2.10. CLSS

- 2.11. OPERATION FOR EACH FUNCTION AND VALVE

- 2.12. SWING MOTOR

- 2.13. PPC VALVE

- 2.14. WORK EQUIPMENT

- 2.15. DIMENSIONS OF EACH PART OF WORK EQUIPMENT

- 2.16. FLOOR

- 2.17. ENGINE CONTROL

- 2.18. ELECTRIC CONTROL SYSTEM

- 2.19. COMPONENT PART OF SYSTEM

- 2.20. MONITOR SYSTEM

- 2.21. MONITOR PANEL

- 2.22. SENSORS

- 3. TESTING AND ADJUSTING

- 3.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 3.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 3.3. TESTING AND ADJUSTING

- 3.3.1. LIST OF TESTING, ADJUSTING, AND TROUBLESHOOTING TOOLS

- 3.3.2. MEASURING ENGINE SPEED

- 3.3.3. MEASUREMENT OF EXHAUST GAS COLOR

- 3.3.4. ADJUSTING VALVE CLEARANCE

- 3.3.5. MEASURING COMPRESSION PRESSURE

- 3.3.6. MEASURING ENGINE OIL PRESSURE

- 3.3.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.3.8. BLEEDING AIR FROM FUEL CIRCUIT

- 3.3.9. TESTING AND ADJUSTING FAN BELT TENSION

- 3.3.10. ADJUSTING FUEL CONTROL LEVER LINKAGE

- 3.3.11. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 3.3.12. TESTING AND ADJUSTING TRACK SHOE TENSION

- 3.3.13. TESTING AND ADJUSTING OIL PRESSURES IN WORK EQUIPMENT, TRAVEL, SWING, AND BLADE CIRCUITS

- 3.3.14. MEASURING CONTROL CIRCUIT BASIC PRESSURE

- 3.3.15. TESTING AND ADJUSTING PUMP LS DIFFERENTIAL PRESSURE

- 3.3.16. MEASURING SOLENOID VALVE OUTPUT PRESSURE

- 3.3.17. MEASURING PPC VALVE OUTPUT PRESSURE

- 3.3.18. ADJUSTING PLAY OF WORK EQUIPMENT AND SWING PPC VALVES

- 3.3.19. MEASURING SWING HOLDING BRAKE RELEASE PRESSURE

- 3.3.20. MEASURING OF OIL LEAKAGE FROM CYLINDER

- 3.3.21. RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 3.3.22. BLEEDING AIR FROM CYLINDER

- 3.3.23. PRESSURIZING HYDRAULIC TANK

- 3.3.24. HOW TO OPEN AND CLOSE (TILT) FLOOR

- 3.3.25. INSPECTION PROCEDURES FOR DIODE

- 3.4. TROUBLESHOOTING

- 3.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 3.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 3.4.4. CHECKS BEFORE TROUBLESHOOTING

- 3.4.5. CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING

- 3.4.6. CONNECTORS LIST AND STEREOGRAM

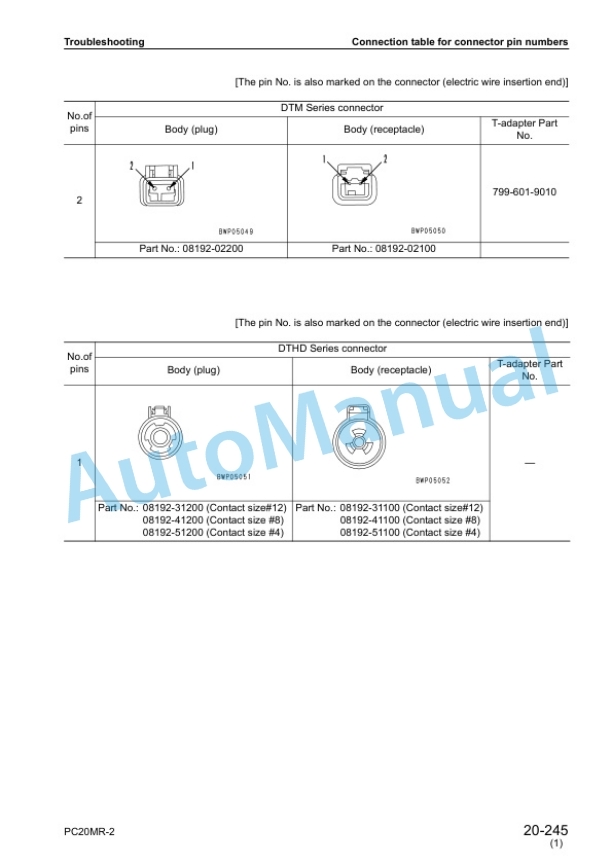

- 3.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 3.4.8. TADAPTERBOXES AND TADAPTER TABLE

- 3.4.9. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EXCEPT MONITOR PANEL EMODE)

- 3.4.9.1. BEFORE STARTING EMODE TROUBLESHOOTING

- 3.4.9.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 3.4.9.3. E1 ENGINE DOES NOT START

- 3.4.9.4. E2 ENGINE DOES NOT STOP

- 3.4.9.5. E3 WHEN SAFETY LOCK LEVER IS IN FREE POSITION, WHOLE WORK EQUIPMENT, TRAVEL, SWING, AND BLADE SYSTEMS DO NOT WORK

- 3.4.9.6. E4 WHEN SAFETY LOCK LEVER IS IN LOCK POSITION, WHOLE WORK EQUIPMENT, TRAVEL, SWING AND BLADE SYSTEMS WORK

- 3.4.9.7. E5 WHEN MACHINE STARTS TRAVELING, TRAVEL ALARM DOES NOT SOUND

- 3.4.9.8. E6 WHEN MACHINE STOPS TRAVELING, TRAVEL ALARM DOES NOT STOP SOUNDING

- 3.4.9.9. E7 WINDSHIELD WIPER DOES NOT OPERATE CAB SPECIFICATION

- 3.4.9.10. E8 WINDSHIELD WASHER DOES NOT OPERATE CAB SPECIFICATION

- 3.4.9.11. E9 HEATER DOES NOT OPERATE

- 3.4.10. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

- 3.4.10.1. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 3.4.10.2. H1 SPEED OR POWER OF WHOLE WORK EQUIPMENT, TRAVEL, SWING, AND BLADE IS LOW

- 3.4.10.3. H2 ENGINE SPEED LOWERS EXTREMELY OR ENGINE STALLS

- 3.4.10.4. H3 WHOLE WORK EQUIPMENT, TRAVEL SYSTEM, SWING SYSTEM, AND BLADE DO NOT WORK

- 3.4.10.5. H4 ABNORMAL SOUND COMES OUT FROM AROUND HYDRAULIC PUMP

- 3.4.10.6. H5 FINE CONTROL PERFORMANCE OR RESPONSE IS LOW

- 3.4.10.7. H6 SPEED OR POWER OF BOOM IS LOW

- 3.4.10.8. H7 SPEED OR POWER OF ARM IS LOW

- 3.4.10.9. H8 SPEED OR POWER OF BUCKET IS LOW

- 3.4.10.10. H9 SPEED OR POWER OF BOOM SWING IS LOW

- 3.4.10.11. H10 WORK EQUIPMENT DOES NOT MOVE SINGLY

- 3.4.10.12. H11 WORK EQUIPMENT HYDRAULIC DRIFT IS LARGE

- 3.4.10.13. H12 TIME LAG OF WORK EQUIPMENT IS LARGE

- 3.4.10.14. H13 IN COMPOUND OPERATION OF WORK EQUIPMENT, SPEED OF PART LOADED MORE IS LOW

- 3.4.10.15. H14 MACHINE DEVIATES DURING TRAVEL

- 3.4.10.16. H15 TRAVEL SPEED OR TRAVEL POWER IS LOW

- 3.4.10.17. H16 MACHINE IS NOT STEERED WELL OR STEERING POWER IS LOW

- 3.4.10.18. H17 TRAVEL SPEED DOES NOT CHANGE

- 3.4.10.19. H18 TRAVEL MOTOR DOES NOT WORK (ONE SIDE ONLY)

- 3.4.10.20. H19 SPEED OR POWER OF SWING IS LOW

- 3.4.10.21. H20 MACHINE DOES NOT SWING

- 3.4.10.22. H21 SWING ACCELERATION PERFORMANCE IS LOW

- 3.4.10.23. H22 MACHINE OVERRUNS WHEN IT STOPS SWINGING

- 3.4.10.24. H23 LARGE SHOCK IS MADE WHEN MACHINE STOPS SWINGING

- 3.4.10.25. H24 WHEN UPPER STRUCTURE STOPS SWINGING, IT MAKES LARGE SOUND

- 3.4.10.26. H25 HYDRAULIC DRIFT OF SWING IS LARGE

- 3.4.10.27. H26 SPEED OR POWER OF BLADE IS LOW

- 3.4.10.28. H27 BLADE DOES NOT MOVE

- 3.4.10.29. H28 HYDRAULIC DRIFT OF BLADE IS LARGE

- 3.4.11. TROUBLESHOOTING OF MONITOR PANEL SYSTEM (M MODE)

- 3.4.11.1. BEFORE STARTING MMODE TROUBLESHOOTING

- 3.4.11.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 3.4.11.3. M1 WHEN STARTING SWITCH IS TURNED ON, NO MONITOR/GAUGE OPERATES

- 3.4.11.4. M2 WHEN STARTING SWITCH IS TURNED ON, SOME MONITORS/GAUGES DO NO OPERATE

- 3.4.11.5. M3 CAUTION BUZZER DOES NOT SOUND OR DOES NOT STOP SOUNDING

- 3.4.11.6. M4 WHILE ENGINE IS RUNNING, ENGINE OIL PRESSURE MONITOR FLASHES

- 3.4.11.7. M5 WHILE ENGINE IS RUNNING, CHARGE LEVEL MONITOR FLASHES

- 3.4.11.8. M6 PREHEATING SYSTEM DOES NOT OPERATE

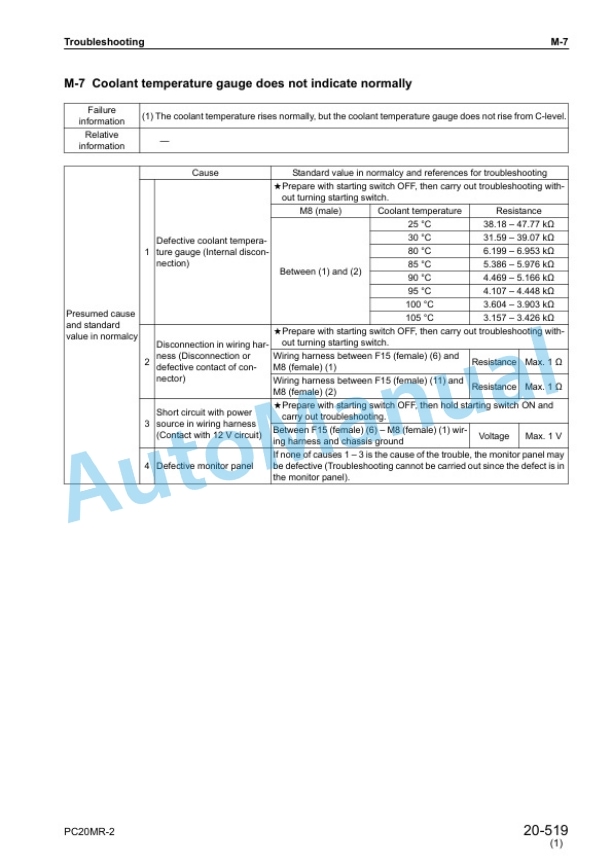

- 3.4.11.9. M7 COOLANT TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY

- 3.4.11.10. M8 FUEL LEVEL GAUGE DOES NOT INDICATE NORMALLY

- 3.4.11.11. M9 SERVICE METER DOES NOT OPERATE WHILE ENGINE IS RUNNING

- 3.4.11.12. M10 TRAVEL SPEED SHIFTING SYSTEM DOES NOT OPERATE NORMALLY

- 3.4.11.13. M11 MONITOR PANEL NIGHT LAMP AND WORKING LAMP DO NOT LIGHT UP

- 3.4.12. TROUBLESHOOTING OF ENGINE (S MODE)

- 3.4.12.1. TROUBLESHOOTING OF ENGINE (SMODE)

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. HOW TO READ THIS MANUAL

- 4.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 4.3. SPECIAL TOOL LIST

- 4.4. REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 4.5. REMOVAL AND INSTALLATION OF RADIATOR AND HYDRAULIC OIL COOLER ASSEMBLY

- 4.6. REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP ASSEMBLY

- 4.7. REMOVAL AND INSTALLATION TRACK SHOE ASSEMBLY

- 4.8. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 4.9. DISASSEMBLY AND ASSEMBLYOF RECOIL SPRING ASSEMBLY

- 4.10. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 4.11. REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY

- 4.12. DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

- 4.13. REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY

- 4.14. REMOVAL AND INSTALLATION OF SWING MOTOR AND SWING MACHINERY ASSEMBLY

- 4.15. REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY

- 4.16. REMOVAL AND INSTALLATION OF REVOLVING FRAME ASSEMBLY

- 4.17. REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY

- 4.18. DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY

- 4.19. DISASSEMBLY AND ASSEMBLY OF HDYRAULIC CYLINDER ASSEMBLY

- 4.20. REMOVAL AND INSTALLATION OF FRONT WINDOW ASSEMBLY

- 4.21. REMOVAL AND INSTALLATION OF OPERATORS CAB GLASS (STUCK GLASS)

- 5. OTHERS

- 5.1. HYDRAULIC CIRCUIT DIAGRAM

- 5.2. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 5.3. ELECTRICAL CIRCUIT DIAGRAM (2/2)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00