Komatsu PC20MR-2, PC27MR-2, PC30MR-2 Galeo Hydraulic Excavator Shop Manual WEBM006900

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WEBM006900

- Format: PDF

- Size: 91.1MB

- Number of Pages: 646

Category: Komatsu Shop Manual PDF

-

Model List:

- PC20MR-2 Galeo Hydraulic Excavator

- PC27MR-2 Galeo Hydraulic Excavator

- PC30MR-2 Galeo Hydraulic Excavator

- 1. Contents

- 2. General

- 2.1. Specification dimension drawing

- 2.2. Working range drawing

- 2.3. Specifications

- 2.4. Weight table

- 2.5. Lubricants, fuel and coolant specifications

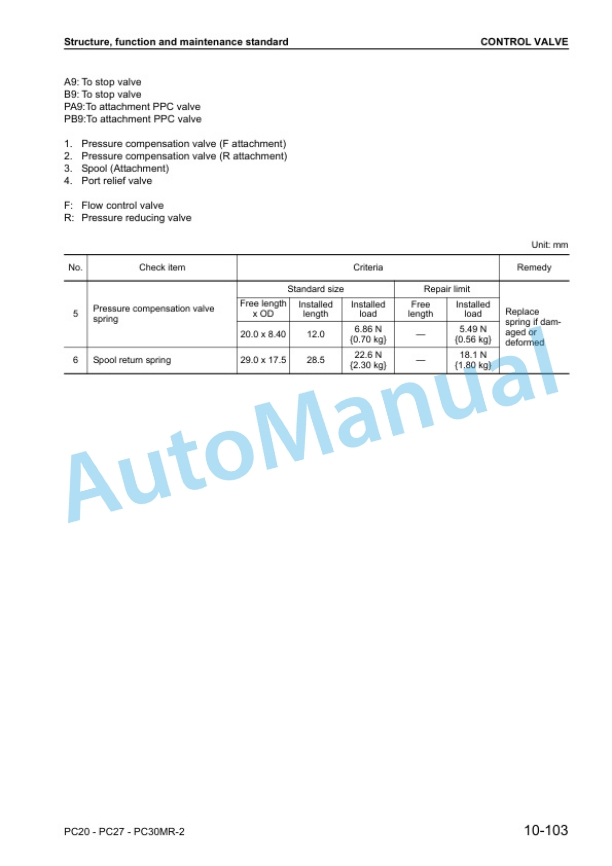

- 3. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 3.1. Swing machinery

- 3.2. Idler cushion

- 3.3. Idler

- 3.4. Hydraulic components layout drawing

- 3.5. Center swivel joint

- 3.6. Travel motor

- 3.7. Travel motor

- 3.8. Hydraulic cylinder

- 3.9. Operation for each function and valve

- 3.10. Swing motor

- 3.11. Swing motor

- 3.12. Ppc valve

- 3.13. Work equipment

- 3.14. Dimensions of each part of work equipment

- 3.15. Floor

- 3.16. Engine control

- 3.17. Electric control system

- 3.18. Component parts of system

- 3.19. Monitor system

- 3.20. Monitor panel

- 3.21. Sensors

- 4. TESTING AND ADJUSTING

- 4.1. Standard value table for engine related parts

- 4.2. Standard value table for chassis related parts

- 4.3. Testing and adjusting

- 4.3.1. List of testing, adjusting, and troubleshooting tools

- 4.3.2. Measuring engine speed

- 4.3.3. Measurement of exhaust gas color

- 4.3.4. Adjusting valve clearance

- 4.3.5. Adjusting valve clearance

- 4.3.6. Measuring compression pressure

- 4.3.7. Measuring compression pressure

- 4.3.8. Measuring engine oil pressure

- 4.3.9. Testing and adjusting fuel injection timing

- 4.3.10. Testing and adjusting fuel injection timing

- 4.3.11. Bleeding air from fuel circuit

- 4.3.12. Testing and adjusting alternator belt tension

- 4.3.13. Testing and adjusting alternator belt tension

- 4.3.14. Adjusting fuel control lever linkage

- 4.3.15. Measurement of clearance in swing circle bearings

- 4.3.16. Testing wear of sprocket

- 4.3.17. Testing and adjusting track shoe tension

- 4.3.18. Testing and adjusting oil pressures in work equipment, travel, swing, and blade circuits

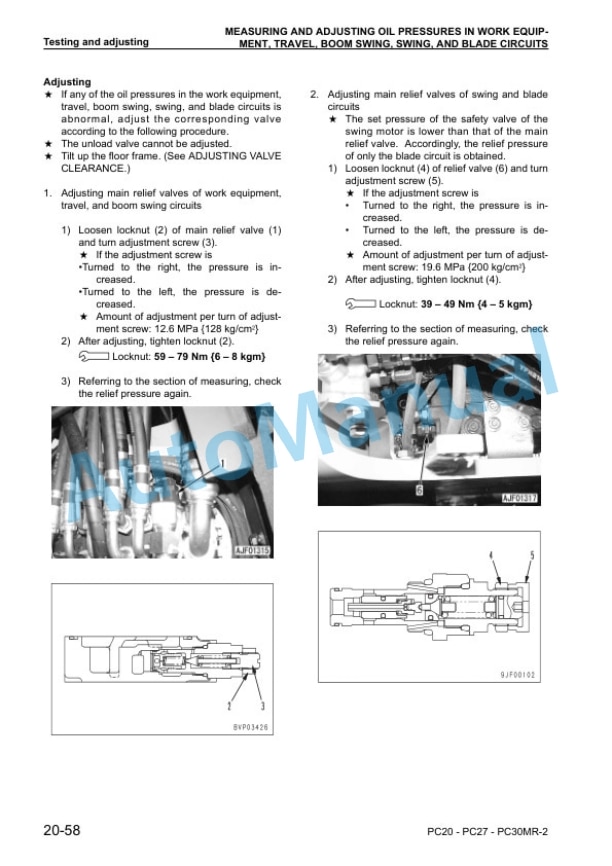

- 4.3.19. Measuring and adjusting oil pressures in work equipment, travel, boom swing, swing, and blade circuits

- 4.3.20. Measuring control circuit basic pressure

- 4.3.21. Testing and adjusting pump ls differential pressure

- 4.3.22. Measuring and adjusting ls differential pressure

- 4.3.23. Measuring solenoid valve output pressure

- 4.3.24. Measuring ppc valve output pressure

- 4.3.25. Adjusting play of work equipment and swing ppc valves

- 4.3.26. Measuring swing holding brake release pressure

- 4.3.27. Measuring swing holding brake release pressure

- 4.3.28. Testing and adjusting travel deviation

- 4.3.29. Measurement of oil leakage from cylinder

- 4.3.30. Releasing residual pressure from hydraulic circuit

- 4.3.31. Bleeding air from cylinder

- 4.3.32. Pressurizing hydraulic tank

- 4.3.33. Bleeding air from each part

- 4.3.34. How to open and close (tilt) floor

- 4.3.35. Inspection procedures for diode

- 4.3.36. Troubleshooting

- 4.4. Troubleshooting of electrical system PC20MR2 (Except monitor panel) (E mode)

- 4.4.1. Before starting emode troubleshooting

- 4.4.2. Information contained in troubleshooting table

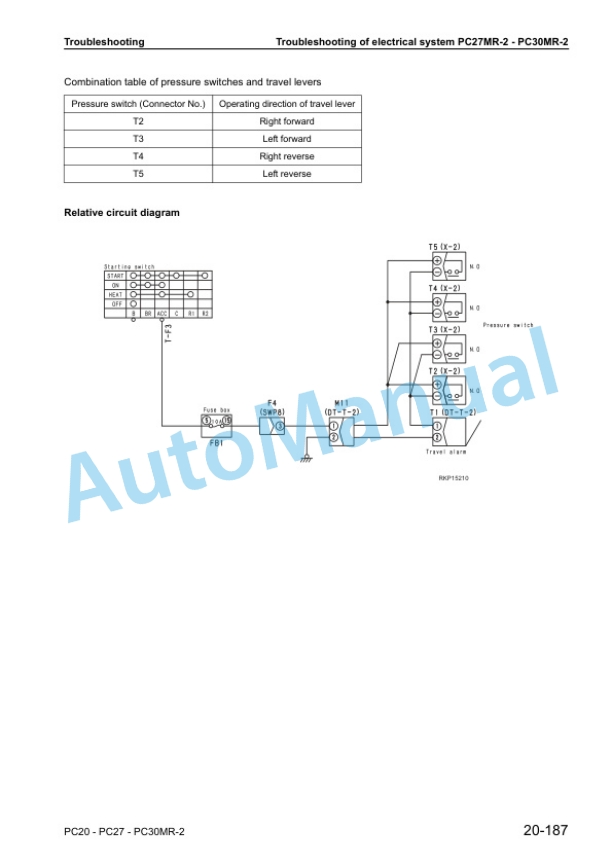

- 4.5. Troubleshooting of electrical system PC27MR2 PC30MR2 (Except monitor panel) (E mode)

- 4.5.1. Before starting emode troubleshooting

- 4.5.2. Information contained in troubleshooting table

- 4.6. Troubleshooting of hydraulic and mechanical system (PC20MR2) (H mode)

- 4.6.1. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 4.7. Troubleshooting of hydraulic and mechanical system (PC27MR2 PC30MR2) (H mode)

- 4.7.1. Information contained in troubleshooting table

- 4.8. Troubleshooting of monitor panel system (PC20MR2) (M mode)

- 4.8.1. Before starting Mmode troubleshooting

- 4.8.2. Information contained in troubleshooting table

- 4.9. Troubleshooting of monitor panel (PC2730MR2) system (Mmode)

- 4.9.1. Before starting Mmode troubleshooting

- 4.9.2. Information contained in troubleshooting table

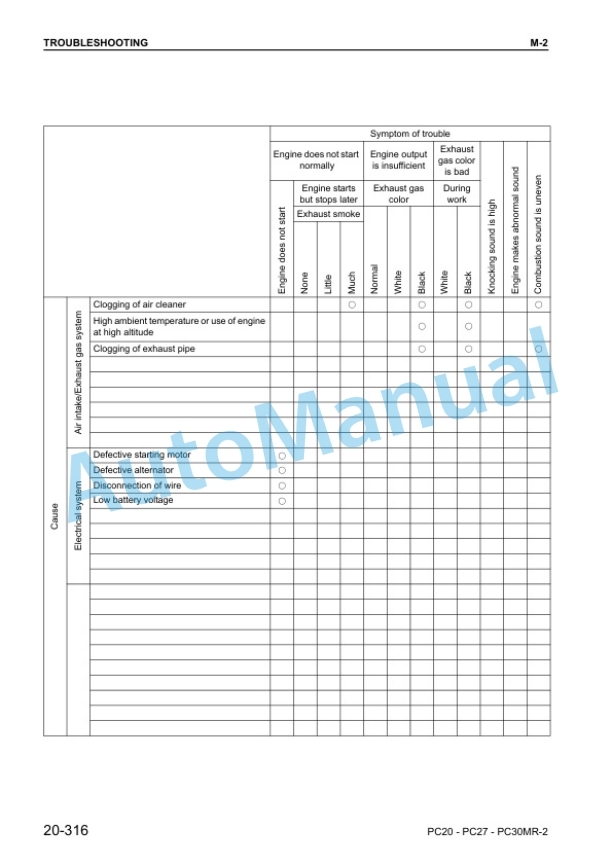

- 4.10. TROUBLESHOOTING OF ENGINE (PC20MR2) (SMODE)

- 4.10.1. Troubleshooting of engine (smode)

- 4.11. TROUBLESHOOTING OF ENGINE (PC2730MR2) (SMODE)

- 4.11.1. Method of using troubleshooting charts

- 5. Disassembly and assembly

- 5.1. How to read this manual

- 5.2. Precautions when performing operation

- 5.3. Special tool list

- 5.4. Removal and installation of fuel injection pump assembly

- 5.5. Removal and installation of fuel injection pump assembly

- 5.6. Removal and installation of radiator and hydraulic oil cooler assembly

- 5.7. Removal and installation of radiator and hydraulic oil cooler assembly

- 5.8. Removal and installation of engine and hydraulic pump assembly

- 5.9. Removal and installation of engine and hydraulic pump assembly

- 5.10. Removal and installation of track shoe assembly

- 5.11. Disassembly and assembly of idler assembly

- 5.12. Disassembly and assembly of recoil spring assembly

- 5.13. Disassembly and assembly of carrier roller assembly

- 5.14. Disassembly and assembly of track roller assembly

- 5.15. Removal and installation of center swivel joint assembly

- 5.16. Removal and installation of center swivel joint assembly

- 5.17. Disassembly and assembly of center swivel joint assembly

- 5.18. Removal and installation of floor frame assembly

- 5.19. Removal and installation of floor frame assembly

- 5.20. Removal and installation of swing motor and swing machinery assembly

- 5.21. Removal and installation of swing motor and swing machinery assembly

- 5.22. Disassembly and assembly of swing motor and swing machinery assembly

- 5.23. Removal and installation of work equipment assembly

- 5.24. Removal and installation of revolving frame assembly

- 5.25. Removal and installation of revolving frame assembly

- 5.26. Removal and installation of swing circle assembly

- 5.27. Disassembly and assembly of control valve assembly

- 5.28. Disassembly and assembly of hydraulic cylinder assembly

- 5.29. Disassembly and assembly of hydraulic cylinder assembly

- 5.30. Removal and installation of air conditioner unit assembly

- 5.31. Removal and installation of front window assembly

- 5.32. Removal and installation of operators cab glass (stuck glass)

- 6. OTHERS

- 6.1. Hydraulic circuit diagram (PC20MR2)

- 6.2. Hydraulic circuit diagram (PC27MR2)

- 6.3. Hydraulic circuit diagram (PC30MR2)

- 6.4. Electrical circuit diagram (PC20MR2)

- 6.5. Electrical circuit diagram (PC2730MR2)

Rate this product

You may also like