Komatsu PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Hydraulic Excavator Shop Manual UEN00084-07

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEN00084-07

- Format: PDF

- Size: 56.8MB

- Number of Pages: 1204

Category: Komatsu Shop Manual PDF

-

Model List:

- PC210-8 Hydraulic Excavator

- PC210LC-8 Hydraulic Excavator

- PC210NLC-8 Hydraulic Excavator

- PC230NHD-8 Hydraulic Excavator

- PC240LC-8 Hydraulic Excavator

- PC240NLC-8 Hydraulic Excavator

- 1. Index and foreword

- 1.1. Index

- 1.1.1. Organization list of the shop manual

- 1.1.2. Table of contents

- 2. Index and foreword

- 2.1. Foreword and general information

- 2.1.1. Foreword and general information

- 3. Specification

- 3.1. Specification and technical data

- 3.1.1. Specification and technical data

- 4. Structure, function and maintenance standard

- 4.1. Engine and cooling system

- 4.1.1. Engine and cooling system

- 4.1.2. Diesel Particulate Filter

- 5. Structure, function and maintenance standard

- 5.1. Power train

- 5.1.1. Power train

- 6. Structure, function and maintenance standard

- 6.1. Undercarriage and frame

- 6.1.1. Undercarriage and frame

- 7. Structure, function and maintenance standard

- 7.1. Hydraulic system, Part 1

- 7.1.1. Hydraulic system, Part 1

- 7.1.2. Hydraulic tank and filter

- 8. Structure, function and maintenance standard

- 8.1. Hydraulic system, Part 2

- 8.1.1. Hydraulic system, Part 2

- 9. Structure, function and maintenance standard

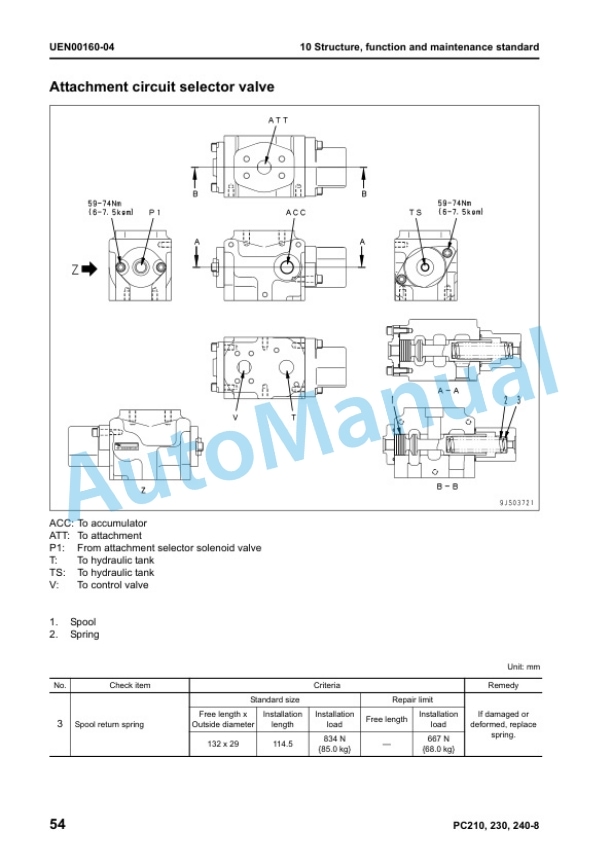

- 9.1. Hydraulic system, Part 3

- 9.1.1. Hydraulic system, Part 3

- 10. Structure, function and maintenance standard

- 10.1. Work equipment

- 10.1.1. Work equipment

- 11. Structure, function and maintenance standard

- 11.1. Cab and its attachments

- 11.1.1. Cab and its attachments

- 12. Structure, function and maintenance standard

- 12.1. Electrical system

- 12.1.1. Electrical system

- 13. Structure, function and maintenance standard

- 13.1. Auto Grease system

- 13.1.1. Outline of Auto Grease System

- 14. Standard value table

- 14.1. Standard service value table

- 14.1.1. Standard service value table

- 15. Testing and adjusting

- 15.1. Testing and adjusting, Part 1

- 15.1.1. Testing and adjusting, Part 1

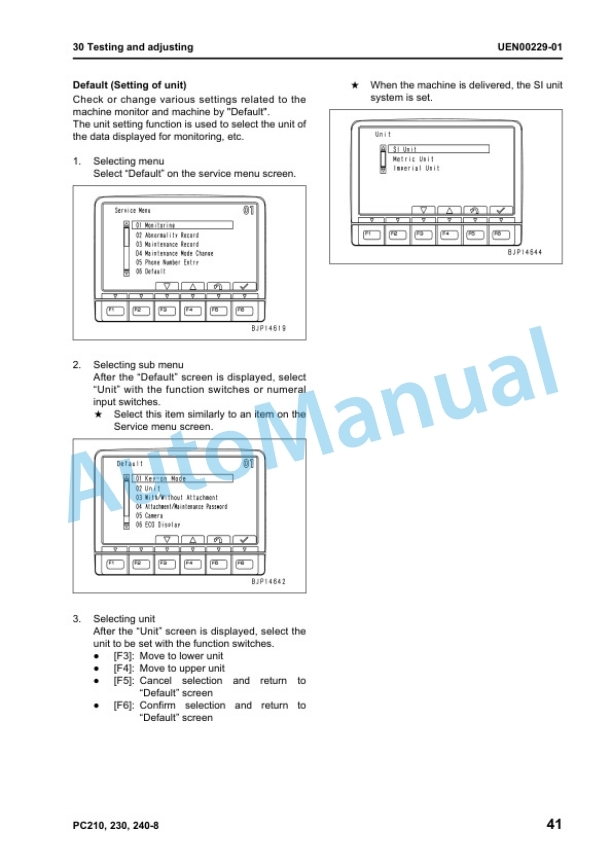

- 16. Testing and adjusting

- 16.1. Testing and adjusting, Part 2

- 16.1.1. Testing and adjusting, Part 2

- 17. Testing and adjusting

- 17.1. Testing and adjusting, Part 3

- 17.1.1. Testing and adjusting, Part 3

- 18. Troubleshooting

- 18.1. General information on troubleshooting

- 18.1.1. General information on troubleshooting

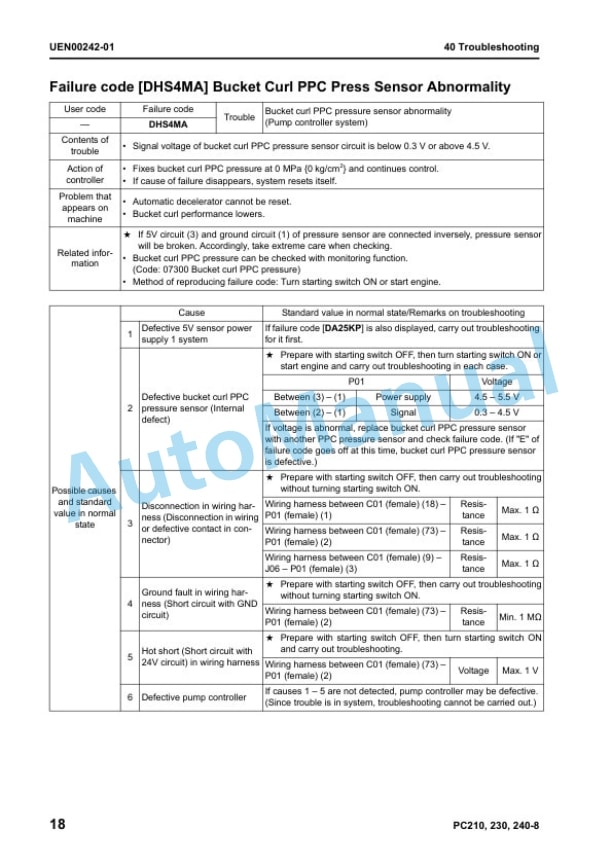

- 19. Troubleshooting

- 19.1. Troubleshooting by failure code (Display of code), Part 1

- 19.1.1. Troubleshooting by failure code (Display of code), Part 1

- 20. Troubleshooting

- 20.1. Troubleshooting by failure code (Display of code), Part 2

- 20.1.1. Troubleshooting by failure code (Display of code), Part 2

- 21. Troubleshooting

- 21.1. Troubleshooting by failure code (Display of code), Part 3

- 21.1.1. Troubleshooting by failure code (Display of code), Part 3

- 22. Troubleshooting

- 22.1. Troubleshooting by failure code (Display of code), Part 4

- 22.1.1. Troubleshooting by failure code (Display of code), Part 4

- 23. Troubleshooting

- 23.1. Troubleshooting of electrical system (Emode)

- 23.1.1. Troubleshooting of electrical system (Emode)

- 23.1.2. Before carrying out troubleshooting of electrical system

- 23.1.3. Troubleshooting of electrical system (Emode)

- 23.1.4. Information in troubleshooting table

- 23.1.5. E1 When starting switch turned ON, machine monitor displays nothing

- 23.1.6. E2 When starting switch turned ON (before starting engine), basic check item lights up

- 23.1.7. E3 Engine does not start (Engine does not turn)

- 23.1.8. E4 Preheater does not operate

- 23.1.9. E5 Automatic warmup system does not operate (in cold season)

- 23.1.10. E6 All work equipment, swing, and travel mechanism do not move or cannot be locked

- 23.1.11. E7 Precaution lights up while engine is running

- 23.1.12. E8 Emergency stop item lights up while engine is running

- 23.1.13. E9 Engine coolant temperature gauge does not indicate normally

- 23.1.14. E10 Hydraulic oil temperature gauge does not indicate normally

- 23.1.15. E11 Fuel level gauge does not indicate normally

- 23.1.16. E12 Contents of display by machine monitor are different from applicable machine

- 23.1.17. E13 Machine monitor does not display some items

- 23.1.18. E14 Function switch does not work

- 23.1.19. E15 Autodecelerator does not operate normally

- 23.1.20. E16 Working mode does not change

- 23.1.21. E17 Travel speed does not change

- 23.1.22. E18 Alarm buzzer cannot be stopped

- 23.1.23. E18 Alarm buzzer cannot be stopped

- 23.1.24. E19 Windshield wiper and window washer do not operate

- 23.1.25. E20 Power maximising function does not operate normally

- 23.1.26. E20 Power maximising function does not operate normally

- 23.1.27. E21 Swing holding brake does not operate normally

- 23.1.28. E22 Travel alarm does not sound or does not stop sounding

- 23.1.29. E23 Air conditioner does not operate normally (including air conditioner abnormality record)

- 23.1.30. E24 When starting switch is turned OFF, service meter is not displayed

- 23.1.31. E25 Machine monitor cannot be set in service mode

- 23.1.32. E26 Monitoring function does not display lever control signal normally

- 23.1.33. E27 KOMTRAX system does not operate normally

- 24. Troubleshooting

- 24.1. Troubleshooting of hydraulic and mechanical system (Hmode)

- 24.1.1. Troubleshooting of hydraulic and mechanical system (Hmode)

- 25. Troubleshooting

- 25.1. Troubleshooting of engine (Smode)

- 25.1.1. Troubleshooting of engine (Smode)

- 26. Troubleshooting

- 26.1. Troubleshooting of Auto Grease system

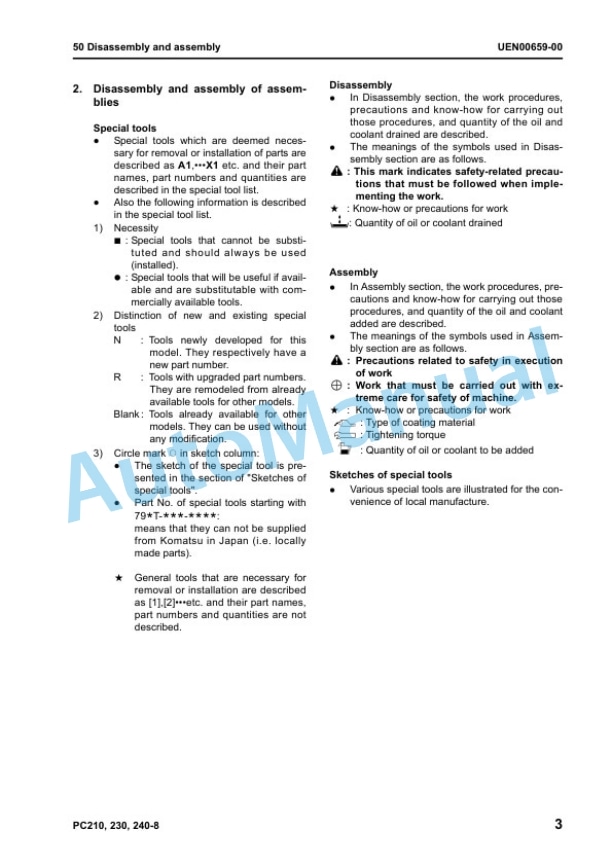

- 27. Disassembly and assembly

- 27.1. Disassembly and assembly related information

- 27.1.1. Disassembly and assembly related information

- 28. Disassembly and assembly

- 28.1. Engine cooling related

- 28.1.1. Engine cooling related

- 29. Disassembly and assembly

- 29.1. Power train

- 29.1.1. Power train

- 30. Disassembly and assembly

- 30.1. Under carriage and frame

- 30.1.1. Under carriage and frame

- 31. Disassembly and assembly

- 31.1. Hydraulic system

- 31.1.1. Hydraulic system

- 32. Disassembly and assembly

- 32.1. Work equipment

- 32.1.1. Work equipment

- 33. Disassembly and assembly

- 33.1. Cab related

- 33.1.1. Cab related

- 34. Disassembly and assembly

- 34.1. Electric components

- 34.1.1. Electric components

- 35. Diagrams and drawings

- 35.1. Hydraulic diagrams and drawings

- 35.1.1. Hydraulic diagrams and drawings (for PC210 K50001K51094, PC230 K50001K50113 and PC240 K50001K50303)

- 35.1.2. Hydraulic diagrams and drawings (For PC210 K51095 and up, PC230 K50114 and up and PC240 K50304 and up)

- 36. Diagrams and drawings

- 36.1. Electrical diagrams and drawings

- 36.1.1. Electrical diagrams and drawings (for PC210 K50001K51094, PC230 K50001K50113 and PC240 K50001K50303)

- 36.1.2. Electrical diagrams and drawings (For PC210 K51095 K52292, PC230 K50114 K50200 and PC240 K50304 K50595)

- 36.1.3. Electrical diagrams and drawings (for PC210 K52293 and up, PC230 K50201 and up and PC240 K50596 and up)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00