Komatsu PC3000-6 Hydraulic Mining Shovel Service Manual SMPC30006208

$30.00

- Type Of Manual: Service Manual

- Manual ID: SMPC30006208

- Format: PDF

- Size: 12.6MB

- Number of Pages: 434

Category: Komatsu Service Manual PDF

-

Model List:

- PC3000-6 Hydraulic Mining Shovel

- 1. COVER

- 2. INTRODUCTION

- 3. II. SAFETY

- 4. III. SPECIFICATIONS

- 5. MAIN ASSEMBLY GROUPS

- 5.1. General layout

- 5.2. Superstructure

- 5.3. Power House

- 5.4. Hydraulic Oil Reservoir

- 5.5. Hydraulic Oil Cooler

- 5.6. Fuel tank (Fuel reservoir)

- 5.7. Counter weight

- 5.8. Cab support

- 5.9. Operators cab

- 5.10. Control blocks

- 5.11. Swing gears

- 5.12. Under carriage

- 6. DRIVE

- 6.1. Prime drive assembly

- 6.2. Engine and gearbox mount

- 6.3. Torque supports

- 6.4. Radiator fan Drive Assy.

- 6.5. Pump distributor gearbox (PTO)

- 6.5.1. Spline shaft housing

- 6.5.2. PTO lubrication and cooling

- 6.5.3. PTO valve adjustments

- 6.6. Coupling

- 6.7. Air Filter

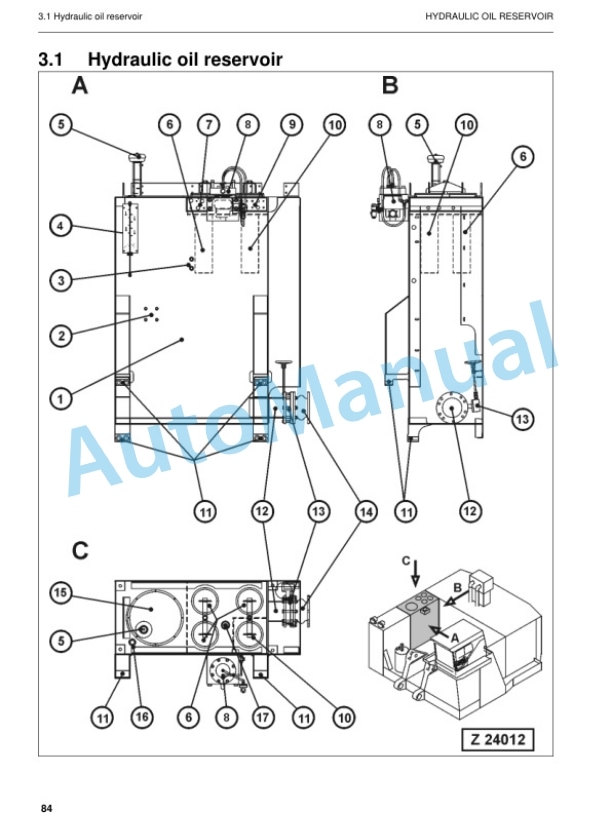

- 7. HYDRAULIC OIL RESERVOIR

- 7.1. Hydraulic oil reservoir

- 7.2. Return and leak oil filter

- 7.3. Breather Filter

- 7.4. Location of electrical components

- 8. HYDRAULIC OIL COOLING

- 8.1. General

- 8.2. Hydraulic oil cooling circuit

- 8.3. Back pressure valve adjustment

- 8.4. Fan drive

- 8.4.1. Fan pump

- 8.4.2. Pressure relieve valve

- 8.4.3. Temperature relay

- 8.5. Cooler fan drive adjustment

- 9. CONTROLLING

- 9.1. Pilot pressure supply and adjustment

- 9.1.1. Pilot control arrangement

- 9.1.2. Pilot pressure adjustment

- 9.1.3. Check of Control Pressure

- 9.2. Slew brakes

- 9.3. Travel parking brake

- 9.4. Check of the pilot control logic

- 9.4.1. Check sheet FSA Page 1

- 9.4.2. Check sheet BHA Page 1

- 10. COMPONENTS

- 10.1. Main control block and valve arrangement

- 10.1.1. FSA arrangement

- 10.1.2. BHA arrangement

- 10.2. Distributor manifold

- 10.2.1. Front shovel attachment FSA

- 10.2.2. Back hoe attachment BHA

- 10.2.3. SRV with throttle check valve

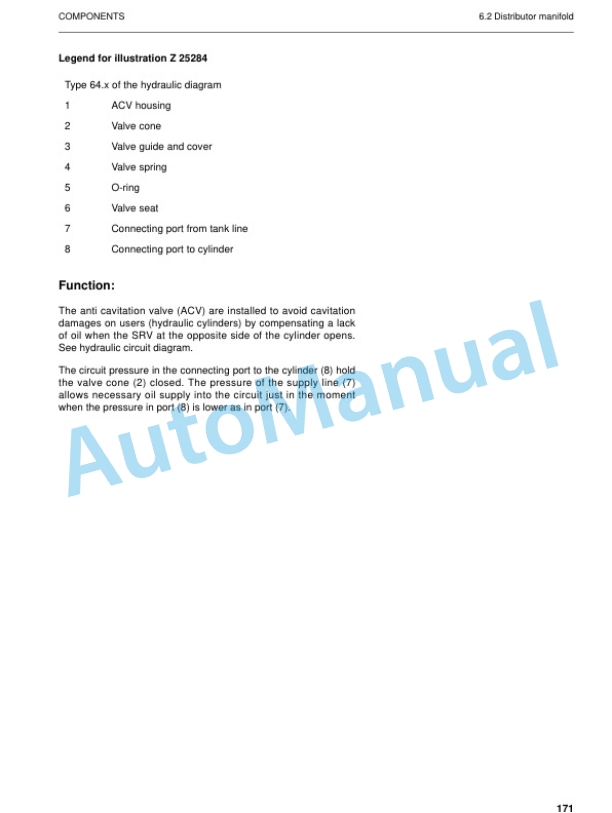

- 10.2.4. Anti cavitation valve (check valve)

- 10.3. Main control block

- 10.3.1. Load holding valve

- 10.3.2. High pressure filter

- 10.3.3. Pressure relieve valves and anticavitation valve

- 10.3.4. Pressure relieve valves and anticavitation valve

- 10.4. Compact valve blocks

- 10.5. Compact valve blocks

- 10.6. Auxiliary gear pumps

- 10.7. Hydraulic cylinder

- 10.8. Swing ring

- 11. MAIN HYDRAULIC PUMPS AND PUMP REGULATION

- 11.1. General

- 11.1.1. Pump location

- 11.2. Main pump operating principles

- 11.2.1. Main pump function

- 11.3. Main pump checks and adjustments

- 11.3.1. Peak point diesel engine test

- 11.3.2. Pressure transducer test

- 11.3.3. Cut off function

- 11.3.4. Pump regulation

- 11.3.5. Swing pump volume reduction

- 11.4. Electronic pump regulation

- 11.5. Pump Controller CR700

- 11.6. Multi Monitor

- 11.7. Multimonitor software instruction

- 11.7.1. Multimonitor main control

- 11.7.2. Service Menu screen

- 11.7.3. Monitoring (menu item 01)

- 11.7.4. Abnormality Record (menu item 02)

- 11.7.5. Default (menu item 03)

- 11.7.6. Adjustment (menu item 04)

- 11.7.7. Display Setup (menu item 05)

- 11.7.8. Table of fault messages and adjustments

- 11.8. Trouble shooting pump and pump regulation

- 12. OPERATING HYDRAULIC

- 12.1. General layout

- 12.2. Floating function of boom and stick only FSA

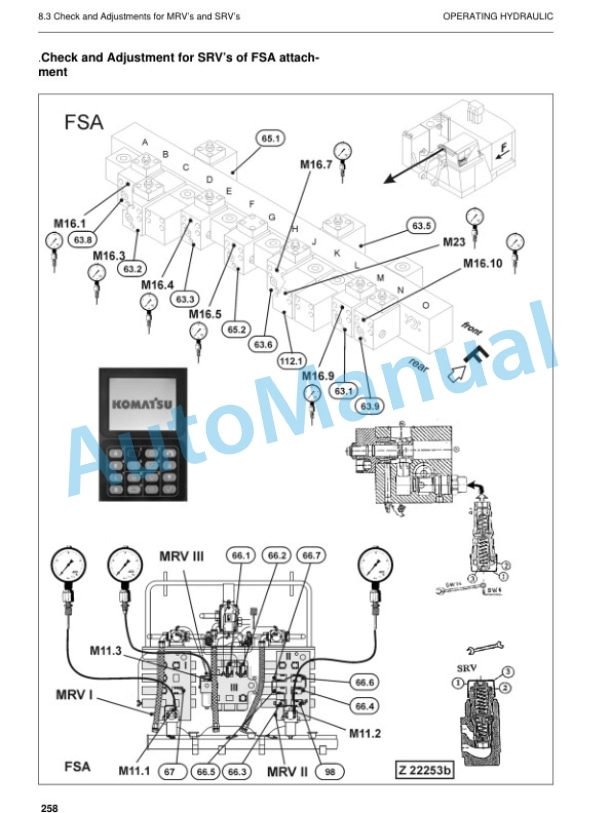

- 12.3. Check and Adjustments for MRVs and SRVs

- 12.3.1. Check and Adjustments for MRV

- 12.3.2. Check and Adjustment for SRVs

- 12.3.3. Check and adjustment of the throttle check valves

- 12.4. Hydraulic for the swing circuit

- 12.4.1. Hydraulic for the swing circuit

- 12.4.2. Slew gear box L S

- 12.4.3. Slew parking brake

- 12.4.4. Slew service brake valve

- 12.4.5. Checks and adjustment of the slew pressure valve

- 12.5. Travel circuit

- 12.5.1. Rotary joint

- 12.5.2. Travel motor A2FMt

- 12.5.3. Travel gear

- 12.5.4. Travel parking brake

- 12.5.5. Travel control function

- 12.5.6. Check and Adjustment SRV travel system

- 13. TRACK TENSION SYSTEM

- 13.1. General layout

- 13.2. Track tensioning function

- 13.2.1. Cushioning

- 13.2.2. Pressure Increasing valve PIV

- 13.3. Track tensioning adjustment

- 13.3.1. Track tensioning function check

- 14. ACCESS LADDER HYDRAULICALLY OPERATED

- 14.1. Access ladder

- 14.2. Access ladder functional description

- 15. CENTRAL REFILLING SYSTEM

- 15.1. Functional description

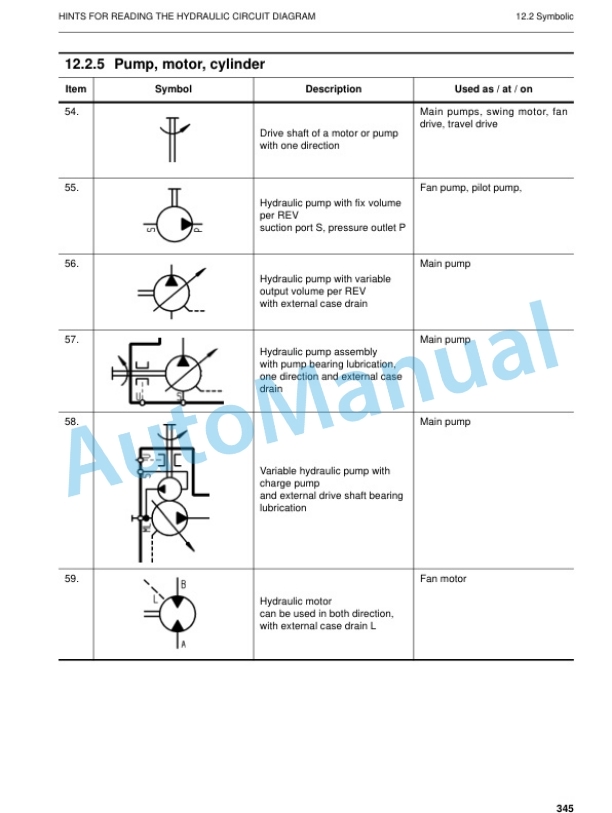

- 16. HINTS FOR READING THE HYDRAULIC CIRCUIT DIAGRAM

- 16.1. General

- 16.2. Symbolic

- 16.2.1. Lines, unions

- 16.2.2. Components, valves

- 16.2.3. Sensors

- 16.2.4. Valves, valve components

- 16.2.5. Pump, motor, cylinder

- 17. HINTS FOR READING THE ELECTRIC CIRCUIT DIAGRAM

- 17.1. Designation of electrical components

- 17.2. Electric symbols

- 17.3. Symbols

- 17.3.1. Drawing concept

- 17.3.2. Reading of the circuit diagram

- 18. ELECTRONIC TEXT MONITORING SYSTEM ETM

- 18.1. General Function

- 19. AUTOMATIC LUBRICATION SYSTEM

- 19.1. General Function

- 19.2. Function of a lubrication cycle

- 19.3. Lubrication pump drive

- 19.4. Lubrication pump

- 19.4.1. Adjustments lubricating pump speed

- 19.4.2. Adjustments lubricating pump pressure

- 19.5. Lubricant Injector (metering valve)

- 19.5.1. Connection of one or more injectors

- 19.5.2. Function lubrication injector (metering valve)

- 19.6. End line pressure switch

- 19.7. Lubricant in line filter

- 19.8. Lubricant level sensor

- 19.8.1. Capacitive digital type for machines with ETM

- 19.8.2. Capacitive analog type for machines with PLC

- 19.9. Lubrication system function and controlling

- 19.9.1. Central Lubrication System (CLS) function and controlling with ETM system (PC 3000)

- 19.9.2. Swing ring lubrication system (SLS) function and controlling with ETM system (PC3000)

- 19.10. Adjustment of the lubrication system with ETM

- 19.11. Trouble shooting lubricating system

- 19.11.1. Lubrication pump cylinder does not move

- 19.11.2. Lubricant pressure built up very slowly or not at all.

- 19.11.3. Insufficient lubricant supply to one or more attachment bearings

- 19.11.4. Insufficient lubricant at the swing ring gear

Rate this product

You may also like

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu FR15K-3, FR18K-3, FR23K-3 Electric AC-Powered Stand-Up Rider Service Manual SM151

$30.00

Komatsu Service Manual PDF

Komatsu G421, G422, G521, G522, G523 Transmission Service Manual 2975 413 M1

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu ASX Stand-up Counterbalanced Electric Forklift Truck Service Manual SM401

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

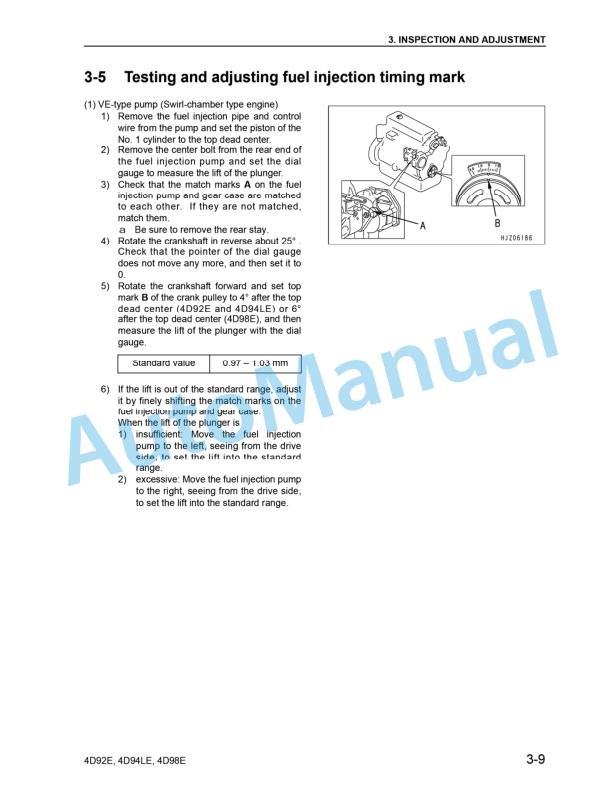

Komatsu 4D94E, 4D94L, 4D98E Diesel Engine Forklift Truck Service Manual 4D94E-BE4

$30.00

Komatsu Service Manual PDF

Komatsu FB10M-2, FB13M-2, FB15M-2, FB18M-2 Forklift Truck Service Manual SM018

$30.00