Komatsu PC30R-8, PC35R-8, PC40R-8, PC45R-8 Hydraulic Excavator Shop Manual SEBM012603

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM012603

- Format: PDF

- Size: 22.0MB

- Number of Pages: 426

Category: Komatsu Shop Manual PDF

-

Model List:

- PC30R-8 Hydraulic Excavator

- PC35R-8 Hydraulic Excavator

- PC40R-8 Hydraulic Excavator

- PC45R-8 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. PTO(COUPLING)

- 4.2. RADIATOR,OIL COOLER

- 4.3. ENGINE CONTROL

- 4.4. POWER TRAIN

- 4.5. SWING CIRCLE

- 4.6. SWING MACHINERY

- 4.7. TRACK FRAME,RECOIL SPRING

- 4.8. HYDRAULIC PIPING DRAWING

- 4.9. HYDRAULIC CIRCUIT DIAGRAM

- 4.10. HYDRAULIC PUMP

- 4.11. CENTER SWIVEL JOINT

- 4.12. SWING MOTOR

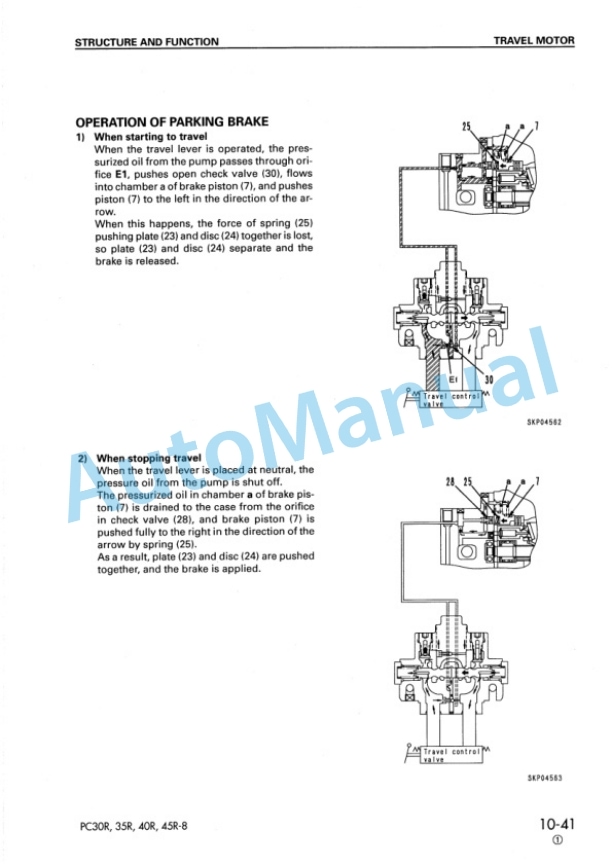

- 4.13. TRAVEL MOTOR

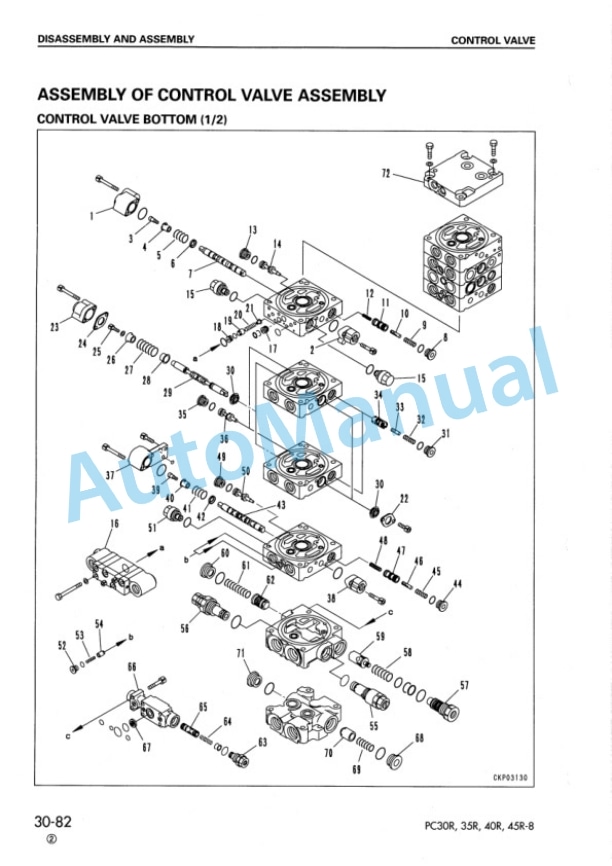

- 4.14. SPOOL CONTROL VALVE

- 4.15. CLSS

- 4.16. MULTICONTROL VALVE

- 4.17. ELECTRICAL WIRING DIAGRAM

- 4.18. VALVE CONTROL

- 4.19. WORK EQUIPMENT,SWING PPC VALVE

- 4.20. SOLENOID VALVE

- 4.21. WORK EQUIPMENT

- 4.22. MACHINE MONITOR SYSTEM

- 4.23. ELECTRICAL CIRCUIT DIAGRAM

- 4.24. HYDRAULIC CYLINDER

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.4. TESTING AND ADJUSTING

- 5.4.1. TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING

- 5.4.2. MEASURING ENGINE SPEED

- 5.4.3. MEASURING EXHAUST COLOR

- 5.4.4. ADJUSTING VALVE CLEARANCE

- 5.4.5. MEASURING COMPRESSION PRESSURE

- 5.4.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.4.7. MEASURING ENGINE OIL PRESSURE

- 5.4.8. TESTING AND ADJUSTING FAN BELT TENSION

- 5.4.9. ADJUSTING CONTROL LEVERS AND PEDALS

- 5.4.10. MEASURING SPROCKET WEAR

- 5.4.11. TESTING AND ADJUSTING TRACK SHOE TENSION

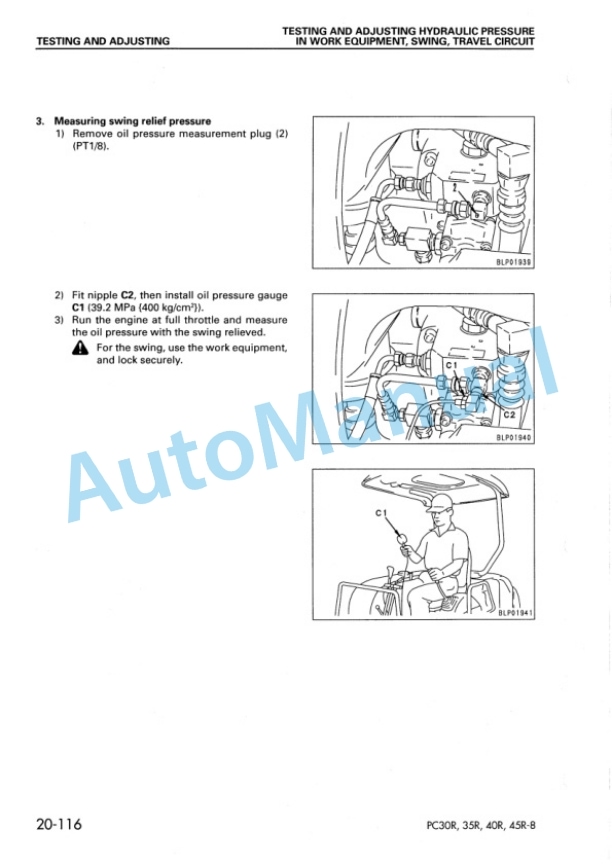

- 5.4.12. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT,SWING,TRAVEL CIRCUIT

- 5.4.13. TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE

- 5.4.14. ADJUSTING PC VALVE

- 5.4.15. TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE

- 5.4.16. TESTING OUTPUT PRESSURE OF SOLENOID VALVE

- 5.4.17. TESTING PPC VALVE OUTPUT PRESSURE AND SWING HOLDING BRAKE INLET PORT PRESSURE(PC20R)

- 5.4.18. ADJUSTING WORK EQUIPMENT,SWING PPC VALVE

- 5.4.19. TESTING AND ADJUSTING TRAVEL DEVIATION

- 5.4.20. TESTING OIL LEAKAGE

- 5.4.21. RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT

- 5.4.22. RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK

- 5.4.23. PRESSURIZING HYDRAULIC TANK

- 5.4.24. BLEEDING AIR

- 5.5. TROUBLESHOOTING

- 5.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.5.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.5.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.5.7. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.5.8. TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)

- 5.5.9. TROUBLESHOOTING OF HYDRAULIC,MECHANICAL SYSTEM(H MODE)

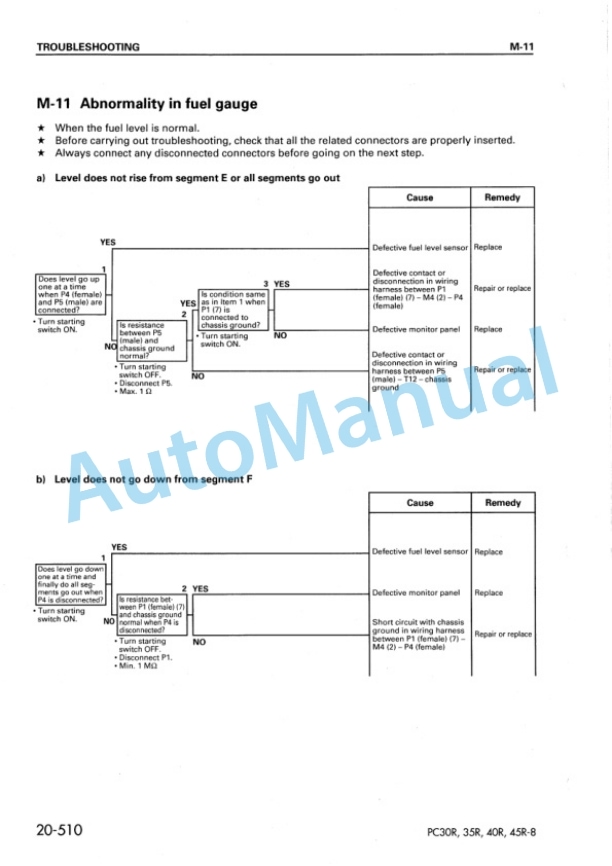

- 5.5.10. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM(M MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. STARTING MOTOR

- 6.4.1. REMOVAL AND INSTALLATION

- 6.5. ALTERNATOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. FUEL INJECTION PUMP

- 6.6.1. REMOVAL(PC30R,35R)

- 6.6.2. INSTALLATION(PC30R,35R)

- 6.6.3. REMOVAL(PC40R,45R)

- 6.6.4. INSTALLATION(PC40R,45R)

- 6.7. NOZZLE HOLDER

- 6.7.1. REMOVAL AND INSTALLATION

- 6.8. WATER PUMP

- 6.8.1. REMOVAL

- 6.8.2. INSTALLATION

- 6.9. THERMOSTAT

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. ENGINE FRONT SEAL

- 6.10.1. REMOVAL AND INSTALLATION

- 6.11. ENGINE REAR SEAL

- 6.11.1. REMOVAL

- 6.11.2. INSTALLATION

- 6.12. CYLINDER HEAD

- 6.12.1. REMOVAL(PC30R,35R)

- 6.12.2. INSTALLATION(PC30R,35R)

- 6.12.3. REMOVAL(PC40R,45R)

- 6.12.4. INSTALLATION(PC40R,45R)

- 6.13. RADIATOR,HYDRAULIC COOLER

- 6.13.1. REMOVAL

- 6.13.2. INSTALLATION

- 6.14. ENGINE,HYDRAULID PUMP

- 6.14.1. REMOVAL

- 6.14.2. INSTALLATION

- 6.15. FUEL TANK

- 6.15.1. REMOVAL AND INSTALLATION

- 6.16. DAMPER

- 6.16.1. REMOVAL AND INSTALLATION

- 6.17. CENTER SWIVEL JOINT

- 6.17.1. REMOVAL AND INSTALLATION

- 6.18. CENTER SWIVEL JOINT

- 6.18.1. DISASSEMBLY AND ASSEMBLY

- 6.19. TRAVEL MOTOR

- 6.19.1. REMOVAL AND INSTALLATION

- 6.20. SPROCKET

- 6.20.1. REMOVAL AND INSTALLATION

- 6.21. SWING MOTOR,SWING MACHINERY

- 6.21.1. REMOVAL

- 6.21.2. INSTALLATION

- 6.21.3. DISASSEMBLY

- 6.21.4. ASSEMBLY

- 6.22. REVOLVING FRAME

- 6.22.1. REMOVAL

- 6.22.2. INSTALLATION

- 6.23. SWING CIRCLE

- 6.23.1. REMOVAL AND INSTALLATION

- 6.24. IDLER

- 6.24.1. REMOVAL AND INSTALLATION

- 6.24.2. DISASSEMBLY

- 6.24.3. ASSEMBLY

- 6.25. RECOIL SPRING

- 6.25.1. REMOVAL AND INSTALLATION

- 6.25.2. DISASSEMBLY

- 6.25.3. ASSEMBLY

- 6.26. TRACK ROLLER

- 6.26.1. REMOVAL AND INSTALLATION

- 6.26.2. DISASSEMBLY

- 6.26.3. ASSEMBLY

- 6.27. CARRIER ROLLER

- 6.27.1. REMOVAL AND INSTALLATION

- 6.27.2. DISASSEMBLY AND ASSEMBLY

- 6.28. RUBBER SHOE

- 6.28.1. REMOVAL AND INSTALLATION

- 6.29. STEEL SHOE

- 6.29.1. REMOVAL AND INSTALLATION(PC30R,35R)

- 6.29.2. REMOVAL AND INSTALLATION(PC40R,45R)

- 6.30. HYDRAULIC TANK

- 6.30.1. REMOVAL AND INSTALLATION

- 6.31. HYDRAULIC COOLER

- 6.31.1. REMOVAL AND INSTALLATION

- 6.32. HYDRAULIC PUMP

- 6.32.1. REMOVAL AND INSTALLATION

- 6.33. SPOOL SOLENOID VALVE

- 6.33.1. REMOVAL AND INSTALLATION

- 6.34. LEFT PPC VALVE

- 6.34.1. REMOVAL AND INSTALLATION

- 6.35. RIGHT PPC VALVE

- 6.35.1. REMOVAL AND INSTALLATION

- 6.36. BUCKET CYLINDER

- 6.36.1. REMOVAL

- 6.36.2. INSTALLATION

- 6.37. BOOM SWING CYLINDER

- 6.38. HYDRAULIC CYLNDER

- 6.38.1. REMOVAL AND INSTALLATION

- 6.39. BOOM SWING BRACKET

- 6.39.1. REMOVAL AND INSTALLATION

- 6.40. CANOPY

- 6.40.1. REMOVAL AND INSTALLATION

- 6.41. FLOOR FRAME

- 6.41.1. REMOVAL

- 6.41.2. INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. SWING CIRCLE

- 7.2. SWING MACHINERY

- 7.3. SPROCKET

- 7.4. TRACK FRAME,RECOIL SPRING

- 7.5. IDLER

- 7.6. TRACK ROLLER

- 7.7. CARRIER ROLLER

- 7.8. TRACK SHOE

- 7.9. CENTER SWIVEL JOINT

- 7.10. HYDRAULIC PUMP

- 7.11. WORK EQUIPMENT,SWING PPC VALVE

- 7.12. SWING MOTOR

- 7.13. SPOOL CONTROL VALVE

- 7.14. HYDRAULIC CYLINDER

- 7.15. WORK EQUIPMENT

- 8. OTHER

- 8.1. HYDRAULIC CIRCUIT DIAGRAM(PC30R8)

- 8.2. HYDRAULIC CIRCUIT DIAGRAM(PC35R8)

- 8.3. HYDRAULIC CIRCUIT DIAGRAM(PC40R8)

- 8.4. HYDRAULIC CIRCUIT DIAGRAM(PC45R8)

- 8.5. ELECTRICAL CIRCUIT DIAGRAM

- 8.6. HYDRAULIC PIPING DRAWING

- 8.7. SYSTEM DIAGRAM DRAWING

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00