Komatsu PC340-6K, PC340LC-6K, PC340NLC-6K Hydraulic Excavator Shop Manual UEBM000901

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM000901

- Format: PDF

- Size: 28.0MB

- Number of Pages: 748

Category: Komatsu Shop Manual PDF

-

Model List:

- PC340-6K Hydraulic Excavator

- PC340LC-6K Hydraulic Excavator

- PC340NLC-6K Hydraulic Excavator

- 1. SAFETY

- 2. FOREWORD

- 3. HOW TO READ THE SHOP MANUAL

- 4. HOISTING INSTRUCTIONS

- 5. COATING MATERIALS

- 6. STANDARD TIGHTENING TORQUE

- 7. ELECTRIC WIRE CODE

- 8. CONVERSION TABLE

- 9. GENERAL

- 10. STRUCTURE AND FUNCTION

- 11. CLSS

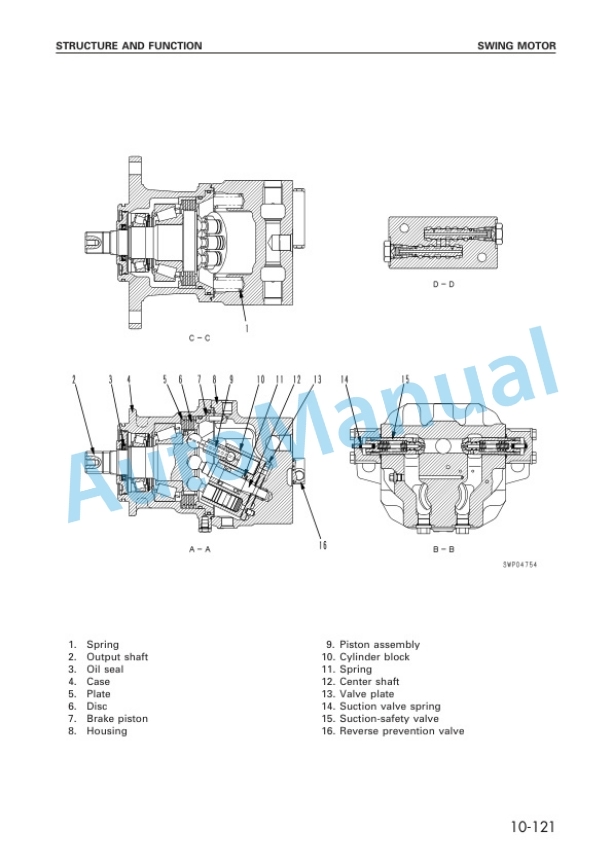

- 12. SWING MOTOR

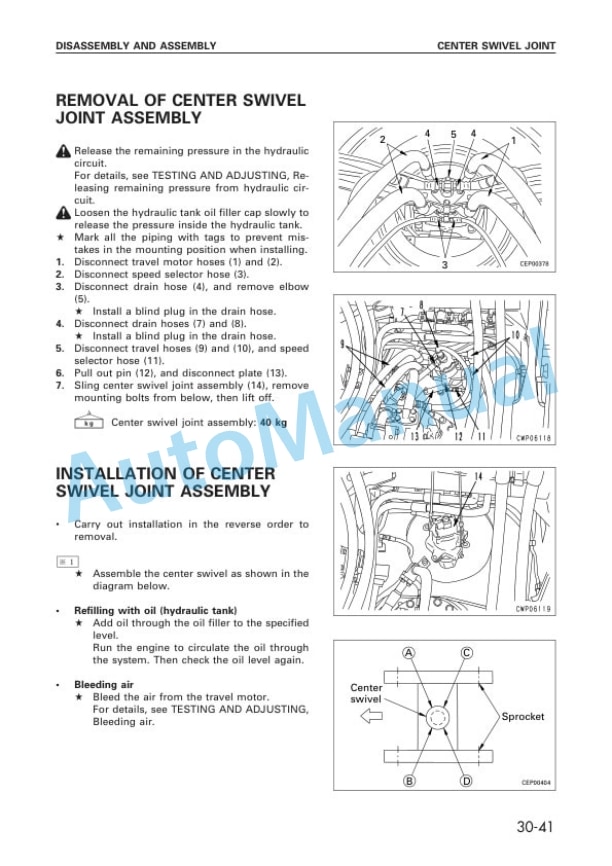

- 13. CENTER SWIVEL JOINT

- 14. TRAVEL MOTOR

- 15. VALVE CONTROL

- 16. WORK EQUIPMENT SWING PPC VALVE

- 17. TRAVEL PPC VALVE SERVICE PPC VALVE

- 18. PPC SAFETY LOCK VALVE

- 19. PPC ACCUMULATOR

- 20. PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE

- 21. LS EPC VALVE

- 22. SOLENOID VALVE

- 23. WORK EQUIPMENT

- 24. AIR CONDITIONER

- 25. ACTUAL ELECTRIC WIRING DIAGRAM

- 26. ELECTRIC CIRCUIT DIAGRAM

- 27. ENGINE CONTROL

- 28. ELECTRONIC CONTROL SYSTEM

- 29. MACHINE MONITOR SYSTEM

- 30. TESTING AND ADJUSTING

- 31. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 32. MEASURING ENGINE SPEED

- 33. MEASURING EXHAUST COLOR

- 34. ADJUSTING VALVE CLEARANCE

- 35. MEASURING COMPRESSION PRESSURE

- 36. MEASURING BLOW BY PRESSURE

- 37. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 38. MEASURING ENGINE OIL PRESSURE

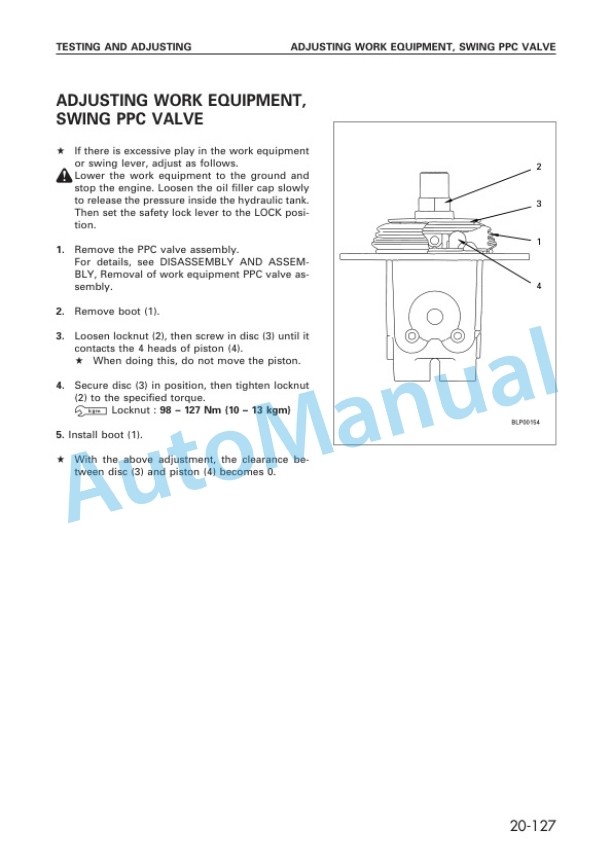

- 39. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 40. TESTING AND ADJUSTING WATER PUMP BELT TENSION

- 41. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 42. ADJUSTING ENGINE SPEED SENSOR

- 43. MEASURING AIR SUPPLY PRESSURE ( BOOST PRESSURE)

- 44. TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE

- 45. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 46. TESTING AND ADJUSTING TVC VALVE OUTPUT PRESSURE ( SERVO PISTON INPUT PRESSURE)

- 47. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE ( SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

- 48. TESTING CONTROL CIRCUIT OIL PRESSURE ( OIL PRESSURE WHEN SELF PRESSURE IS REDUCED)

- 49. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 50. MEASURING PPC VALVE OUTPUT PRESSURE AND TESTING PPC SHUTTLE VALVE

- 51. ADJUSTING WORK EQUIPMENT, SWING PPC VALVE

- 52. TESTING TRAVEL DEVIATION

- 53. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 54. MEASURING OIL LEAKAGE

- 55. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 56. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 57. TESTING WEAR OF SPROCKET

- 58. TESTING AND ADJUSTING TRACK SHOE TENSION

- 59. BLEEDING AIR

- 60. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 61. CHECKS BEFORE TROUBLESHOOTING

- 62. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 63. EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM

- 64. DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 65. METHOD OF USING JUDGEMENT TABLE

- 66. METHOD OF USING TROUBLESHOOTING CHARTS

- 67. DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

- 68. SERVICE CODE TABLE

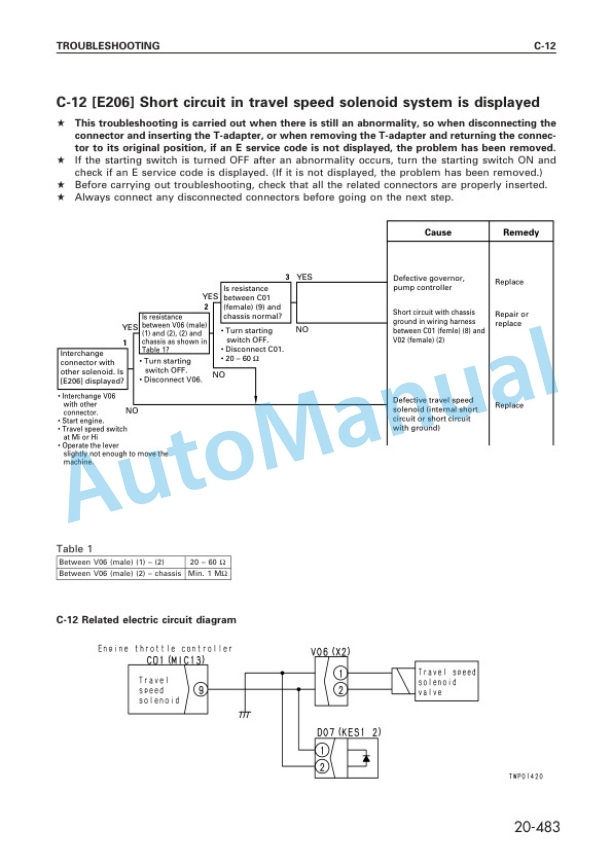

- 69. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER ( GOVERNOR CONTROL SYSTEM) ( E MODE)

- 70. JUDGEMENT TABLE FOR GOVERNOR, PUMP CONTROLLER ( GOVERNOR CONTROL SYSTEM) AND ENGINE RELATED PARTS

- 71. E 1 Abnormality in governor, pump controller power source ( controller LED is OFF)

- 72. E 2 E308 Abnormality in fuel control dial input value is displayed

- 73. E 3 E317 Abnormality ( disconnection) in motor drive system is displayed

- 74. E 4 E318 Abnormality ( short circuit) in motor drive system is displayed

- 75. E 5 E306 Abnormality in feedback potentiometer system is displayed

- 76. E 6 E315 Abnormality ( short circuit) in battery relay output system is displayed

- 77. E 7 E316 Abnormality ( step out) in motor is displayed

- 78. E 8 Engine does not start

- 79. E 9 Engine speed is irregular

- 80. E 10 Lack of output ( engine high idling speed is too low)

- 81. E 11 Engine does not stop

- 82. E 12 Defective operation of battery relay system ( engine does not stop)

- 83. TROUBLESHOOTING OF ENGINE SYSTEM ( S MODE)

- 84. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER ( PUMP CONTROL SYSTEM) ( C MODE)

- 85. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER ( INPUT SIGNAL SYSTEM) ( F MODE)

- 86. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM ( H MODE)

- 87. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM ( M MODE)

- 89. DISASSEMBLY OF TRAVEL MOTOR ASSEMBLY

- 90. ASSEMBLY OF TRAVEL MOTOR ASSEMBLY

- 91. DISASSEMBLY OF MAIN PUMP ASSEMBLY

- 92. ASSEMBLY OF MAIN PUMP ASSEMBLY

- 93. DISASSEMBLY OF PUMP MERGE/ DIVIDER VALVE ASSEMBLY

- 94. ASSEMBLY OF PUMP MERGE/ DIVIDER VALVE ASSEMBLY

- 95. DISASSEMBLY OF PRESSURE COMPENSATION VALVE ASSEMBLY

- 96. ASSEMBLY OF PRESSURE COMPENSATION VALVE ASSEMBLY

- 97. REMOVAL OF SERVO VALVE ASSEMBLY FOR FRONT PUMP

- 98. INSTALLATION OF SERVO VALVE ASSEMBLY FOR FRONT PUMP

- 99. REMOVAL OF SERVO VALVE ASSEMBLY FOR REAR PUMP

- 100. INSTALLATION OF SERVO VALVE ASSEMBLY FOR REAR PUMP

- 101. REMOVAL OF LS EPC SOLENOID VALVE ASSEMBLY

- 102. INSTALLATION OF LS EPC SOLENOID VALVE ASSEMBLY

- 103. REMOVAL OF SOLENOID VALVE ASSEMBLY

- 104. INSTALLATION OF SOLENOID VALVE ASSEMBLY

- 105. REMOVAL OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 106. INSTALLATION OF WORK EQUIPMENT, PPC VALVE ASSEMBLY

- 107. DISASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 108. ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 109. REMOVAL OF TRAVEL PPC VALVE ASSEMBLY

- 110. INSTALLATION OF TRAVEL PPC VALVE ASSEMBLY

- 111. DISASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 112. ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 113. REMOVAL OF PPC SHUTTLE VALVE ASSEMBLY

- 114. INSTALLATION OF PPC SHUTTLE VALVE ASSEMBLY

- 115. DISASSEMBLY OF PPC SHUTTLE VALVE ASSEMBLY

- 116. ASSEMBLY OF PPC SHUTTLE VALVE ASSEMBLY

- 117. REMOVAL OF BOOM CYLINDER ASSEMBLY

- 118. INSTALLATION OF BOOM CYLINDER ASSEMBLY

- 119. REMOVAL OF ARM CYLINDER ASSEMBLY

- 120. INSTALLATION OF ARM CYLINDER ASSEMBLY

- 121. REMOVAL OF BUCKET CYLINDER ASSEMBLY

- 122. INSTALLATION OF BUCKET CYLINDER ASSEMBLY

- 123. DISASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 124. ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 125. REMOVAL OF WORK EQUIPMENT ASSEMBLY

- 126. INSTALLATION OF WORK EQUIPMENT ASSEMBLY

- 127. REMOVAL OF BUCKET ASSEMBLY

- 128. INSTALLATION OF BUCKET ASSEMBLY

- 129. REMOVAL OF ARM ASSEMBLY

- 130. INSTALLATION OF ARM ASSEMBLY

- 131. REMOVAL OF BUCKET, ARM ASSEMBLY

- 132. INSTALLATION OF BUCKET, ARM ASSEMBLY

- 133. REMOVAL OF BOOM ASSEMBLY

- 134. INSTALLATION OF BOOM ASSEMBLY

- 135. REMOVAL OF COUNTERWEIGHT ASSEMBLY

- 136. INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 137. REMOVAL OF AIR CONDITIONER COMPRESSOR ASSEMBLY

- 138. INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY

- 139. REMOVAL OF AIR CONDITIONER CONDENSER ASSEMBLY

- 140. INSTALLATION OF CONDENSER ASSEMBLY

- 141. REMOVAL OF RECEIVER TANK ASSEMBLY

- 142. INSTALLATION OF RECEIVER TANK ASSEMBLY

- 143. REMOVAL OF AIR CONDITIONER UNIT ASSEMBLY

- 144. INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY

- 145. REMOVAL OF GOVERNOR, PUMP CONTROLLER ASSEMBLY

- 146. INSTALLATION OF GOVERNOR, PUMP CONTROLLER ASSEMBLY

- 147. REMOVAL OF MONITOR PANEL ASSEMBLY

- 148. INSTALLATION OF MONITOR PANEL ASSEMBLY

- 149. REMOVAL OF CONTROL STAND CASE

- 150. INSTALLATION OF CONTROL STAND CASE

- 151. MAINTENANCE STANDARD

Rate this product

You may also like