Komatsu PC340LC-7K, PC340NLC-7K Hydraulic Excavator Shop Manual UEBM001501

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM001501

- Format: PDF

- Size: 112.4MB

- Number of Pages: 630

Category: Komatsu Shop Manual PDF

-

Model List:

- PC340LC-7K Hydraulic Excavator

- PC340NLC-7K Hydraulic Excavator

- 1. PC340LC7

- 2. PC340NLC7

- 3. AND UP

- 4. AND UP

- 5. PC340_07_section01.pdf

- 5.1. SPECIFICATION DIMENSION DRAWINGS

- 5.1.1. PC340LC7, PC340NLC7

- 5.2. WEIGHT TABLE

- 5.2.1. PC340LC7, PC340NLC7

- 5.3. FUEL, COOLANT, AND LUBRICANTS

- 6. PC340_7_Section10.pdf

- 6.1. ENGINE RELATED PARTS

- 6.2. RADIATOR OIL COOLER AFTERCOOLER

- 6.3. POWER TRAIN

- 6.4. FINAL DRIVE

- 6.5. SWING MACHINERY

- 6.6. SWING CIRCLE

- 6.7. TRACK FRAME RECOIL SPRING

- 6.8. IDLER

- 6.9. CARRIER ROLLER

- 6.10. TRACK ROLLER

- 6.11. TRACK SHOE

- 6.11.1. TRIPLE GROUSER SHOE

- 6.12. hydraulic equipment layout drawing

- 6.12.1. LS(pc)EPC VALVE

- 6.13. variable volume valve

- 6.14. CONTROL VALVE

- 6.14.1. MAIN RELIEF VALVE

- 6.14.2. Variable pressure compensation valve

- 6.15. CLSS

- 6.15.1. OUTLINE OF CLSS

- 6.16. SELF PRESSURE REDUCING VALVE

- 6.17. SWING MOTOR

- 6.18. REVERSE PREVENTION VALVE

- 6.19. CENTER SWIVEL JOINT

- 6.20. TRAVEL MOTOR

- 6.21. TRAVEL JUNCTION VALVE

- 6.22. TRAVEL PPC SHUTTLE VALVE

- 6.23. VALVE CONTROL

- 6.24. WORK EQUIPMENT SWING PPC VALVE

- 6.25. TRAVEL PPC VALVE

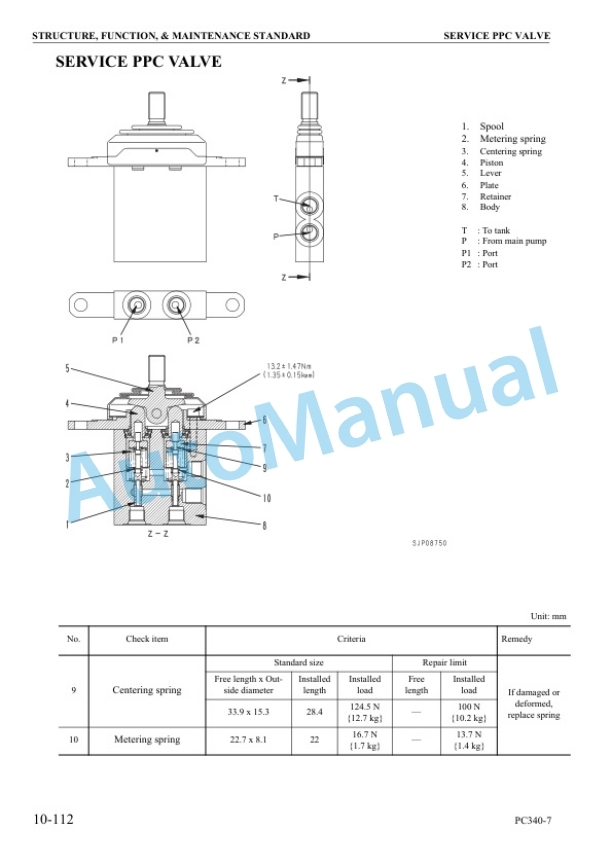

- 6.26. SERVICE PPC VALVE

- 6.27. SOLENOID VALVE

- 6.28. PPC ACCUMULATOR

- 6.29. return oil filter

- 6.29.1. For Breaker

- 6.30. BOOM HYDRAULIC DRIFT PREVENTION VALVE

- 6.31. quick return valve

- 6.32. LIFT CHECK VALVE

- 6.33. attachment circuit selector valve

- 6.34. HYDRAULIC CYLINDER

- 6.34.1. BOOM CYLINDER

- 6.34.2. ARM CYLINDER

- 6.34.3. BUCKET CYLINDER

- 6.35. work equipment

- 6.35.1. Dimension of bucket

- 6.36. air conditioner

- 6.36.1. air conditioner piping

- 6.37. ENGINE CONTROL

- 6.37.1. Governor motor

- 6.37.2. Engine throttle and pump controller

- 6.38. ELECTRONIC CONTROL SYSTEM

- 6.38.1. Total system diagram

- 6.39. mULTI MONITOR SYSTEM

- 6.40. SENSOR

- 7.1. The standard value for a new machine given in the table is the value used when shipping the ma…

- 7.2. The service limit value given in the tables is the estimated value for the shipped machine bas…

- 7.3. These standard values are not the standards used in dealing with claims.

- 7.4. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 7.5. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 8. _101.pdf

- 8.1. INSPECTION AND ADJUSTMENT OF ENGINE RPM

- 8.2. MEASUREMENT OF AIR BOOST PRESSURE

- 8.3. MEASUREMENT OF EXHAUST GAS COLOR

- 8.4. ADJUSTMENT OF VALVE CLEARANCE

- 8.5. MEASUREMENT OF COMPRESSION PRESSURE

- 8.6. MEASUREMENT OF BLOWBY PRESSURE

- 8.7. INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 8.8. MEASUREMENT OF ENGINE OIL PRESSURE

- 8.9. ADJUSTMENT OF ENGINE SPEED SENSOR

- 8.10. INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

- 8.11. EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM

- 8.12. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 8.13. INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

- 8.14. INSPECTION OF WEAR ON SPROCKET

- 8.15. INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWIN…

- 8.16. INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

- 8.17. INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE

- 8.18. INSPECTION AND ADJUSTMENT OF PUMP LS CONTROL CIRCUIT OIL PRESSURE

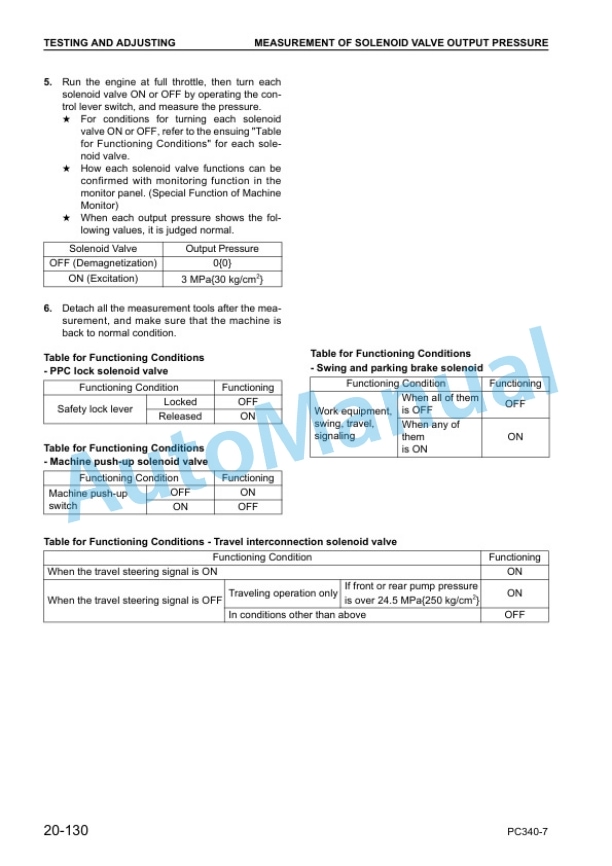

- 8.19. MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE

- 8.20. MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

- 8.21. ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

- 8.22. INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

- 8.23. RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 8.24. MEASUREMENT OF OIL LEAKAGE AMOUNT

- 8.25. AIR BLEEDING OF VARIOUS PARTS

- 8.26. INSPECTION PROCEDURES FOR DIODE

- 8.27. SPECIAL FUNCTION OF MULTIMONITOR PANEL

- 8.28. DISPLAY METHOD AND SPECIAL FUNCTIONS OF 7SEGMENT MONITOR PANEL

- 8.29. PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

- 9. _201.pdf

- 9.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 9.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 9.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 9.4. CHECKS BEFORE TROUBLESHOOTING

- 9.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 9.6. CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

- 9.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 10. _301.pdf

- 10.1. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 11. _501.pdf

- 11.1. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 12.1. HOW TO READ THIS MANUAL

- 12.1.1. REMOVAL AND INSTALLATION OF ASSEMBLIES

- 12.1.2. DisassemblY and assemblY OF assemblIES

- 12.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 12.3. REMOVAL AND INSTALLATION OF STARTING MOTOR ASSEMBLY

- 12.3.1. REMOVAL

- 12.3.2. INSTALLATION

- 12.4. REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 12.5. REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL

- 12.6. REMOVAL AND INSTALLATION OF ENGINE REAR SEAL

- 12.7. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 12.8. REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY

- 12.9. REMOVAL AND INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY

- 12.10. REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP ASSEMBLIES

- 12.11. REMOVAL AND INSTALLATION OF FINAL DRIVE ASSEMBLY

- 12.12. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 12.12.1. SKETCHES OF SPECIAL TOOLS

- 12.13. REMOVAL AND INSTALLATION OF SWING MOTOR, SWING MACHINERY ASSEMBLY

- 12.14. DISASSEMBLY AND ASSEMBLY OF SWING MOTOR, SWING MACHINERY ASSEMBLY

- 12.14.1. SKETCHES OF SPECIAL TOOLS

- 12.15. DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 12.16. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 12.17. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 12.18. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 12.19. REMOVAL AND INSTALLATION OF TRACK SHOE ASSEMBLY

- 12.19.1. EXPANSION OF TRACK SHOE

- 12.20. REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY

- 12.21. REMOVAL AND INSTALLATION OF REVOLVING FRAME ASSEMBLY

- 12.22. REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY

- 12.23. DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

- 12.24. REMOVAL AND INSTALLATION OF HYDRAULIC TANK ASSEMBLY

- 12.25. REMOVAL AND INSTALLATION OF CONTROL VALVE ASSEMBLY

- 12.26. DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY

- 12.27. REMOVAL AND INSTALLATION OF HYDRAULIC PUMP ASSEMBLY

- 12.28. REMOVAL AND INSTALLATION OF OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT

- 12.29. DISASSEMBLY AND ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 12.30. DISASSEMBLY AND ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 12.31. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 12.32. REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY

- 12.33. REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY

- 12.34. REMOVAL AND INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 12.35. REMOVAL AND INSTALLATION OF OPERATORS CAB ASSEMBLY

- 12.36. REMOVAL AND INSTALLATION OF MONITOR ASSEMBLY

- 12.37. REMOVAL AND INSTALLATION OF GOVERNOR PUMP CONTROLLER ASSEMBLY

- 13. _601.pdf

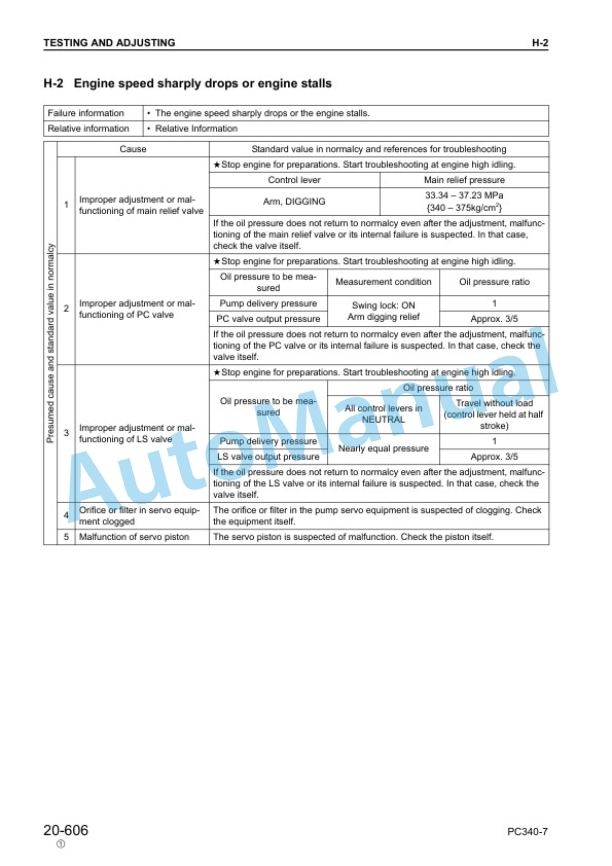

- 13.1. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 13.1.1. SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS

- 13.1.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 14. PC340_A2.pdf

- 14.1. hydraulic circuit diagram

- 14.2. electrical circuit diagram (1/4)

- 14.2.1. FOR multi monitor

- 14.3. electrical circuit diagram (2/4)

- 14.3.1. FOR multi monitor

- 14.4. electrical circuit diagram (3/4)

- 14.4.1. FOR multi monitor

- 14.5. electrical circuit diagram (4/4)

- 14.5.1. FOR multi monitor

Rate this product

You may also like