Komatsu PC350LL-7E0 Logging Road Builer Excavator Shop Manual CEBM024301

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM024301

- Format: PDF

- Size: 117.3MB

- Number of Pages: 1014

Category: Komatsu Shop Manual PDF

-

Model List:

- PC350LL-7E0 Logging Road Builer Excavator

- 1. CEBM024301 PC350LL7E0 s/n A50001 and up

- 1.1. CONTENTS

- 1.2. REVISED PAGES

- 1.3. SAFETY

- 1.4. GENERAL

- 1.5. HOW TO READ THE SHOP MANUAL

- 1.6. HOISTING INSTRUCTIONS

- 1.7. PUSH PULL COUPLER

- 1.8. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.9. STANDARD TIGHTENING TORQUE

- 1.10. ELECTRIC WIRE CODE

- 1.11. CONVERSION TABLES

- 1.12. COATING MATERIALS

- 2. GENERAL

- 2.1. SPECIFICATIONS

- 2.2. WEIGHT TABLE

- 2.3. FUEL, COOLANT, AND LUBRICANTS

- 3. STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD

- 3.1. ENGINE RELATED PARTS

- 3.2. RADIATOR . OIL COOLER . AFTERCOOLER

- 3.3. POWER TRAIN

- 3.4. FINAL DRIVE

- 3.5. SPROCKET

- 3.6. SWING MACHINERY

- 3.7. TRACK FRAME . RECOIL SPRING

- 3.8. IDLER

- 3.9. TRACK ROLLER/CARRIER ROLLER

- 3.10. TRACK SHOE

- 3.11. TRIPLE GROUSER SHOE

- 3.12. DOUBLE GROUSER SHOE

- 3.13. HYDRAULIC EQUIPMENT

- 3.14. HYDRAULIC TANK AND FILTER

- 3.15. HYDRAULIC PUMP

- 3.16. CONTROL VALVE

- 3.17. CLSS

- 3.18. VALVE FUNCTIONS AND OPERATION

- 3.19. UNLOADER VALVE

- 3.20. INTRODUCTION OF LS PRESSURE

- 3.21. LS BYPASS VALVE

- 3.22. PRESSURE COMPENSATION VALVE

- 3.23. MERGEDIVIDER VALVE

- 3.24. LS SELECT VALVE

- 3.25. SELF PRESSURE REDUCING VALVE

- 3.26. TRAVEL JUNCTION VALVE

- 3.27. TRAVEL PPC SHUTTLE VALVE

- 3.28. BOOM DRIFT PREVENTION VALVE

- 3.29. ARM DRIFT PREVENTION VALVE

- 3.30. QUICK RETURN VALVE

- 3.31. LIFT CHECK VALVE

- 3.32. MAIN RELIEF VALVE

- 3.33. STAGE SAFETYSUCTION VALVE

- 3.34. VARIABLE PRESSURE COMPENSATION VALVE

- 3.35. CONTROL VALVE

- 3.36. PPC VALVE

- 3.37. PRESSURE REDUCING VALVE

- 3.38. SOLENOID VALVE

- 3.39. ATTACHMENT SOLENOID VALVE

- 3.40. CENTER SWIVEL JOINT

- 3.41. TRAVEL MOTOR

- 3.42. PARKING BRAKE

- 3.43. SAFETY VALVE

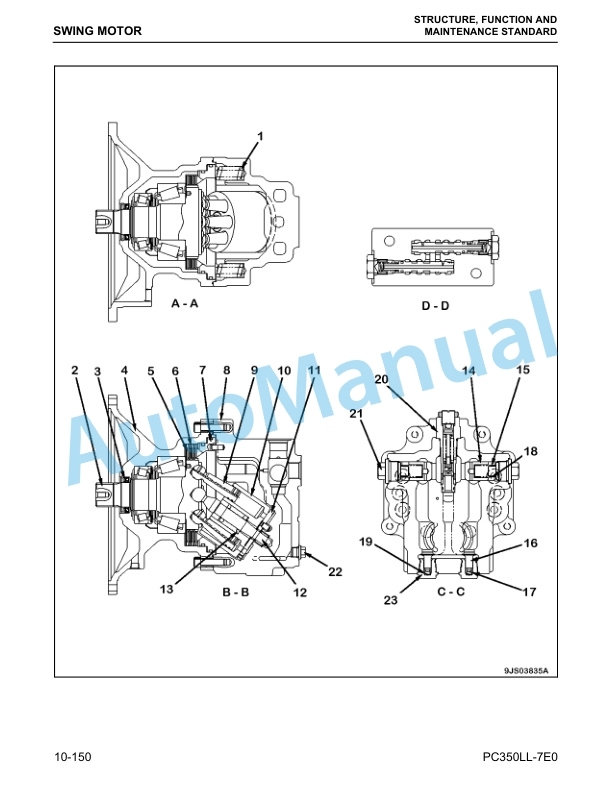

- 3.44. SWING MOTOR

- 3.45. REVERSE PREVENTION VALVE

- 3.46. HYDRAULIC CYLINDERS EXCAVATOR WORK EQUIPMENT

- 3.47. WORK EQUIPMENT PIVOT POINT MEASUREMENTS

- 3.48. CAB AND ATTACHMENTS

- 3.49. ELECTRICAL SYSTEM

- 3.50. ELECTRONIC COMPONENTS

- 3.51. ELECTRONIC CONTROL SYSTEM

- 3.52. SYSTEM COMPONENTS

- 3.53. MONITOR SYSTEM

- 3.54. MONITOR CONTROL AND DISPLAY

- 3.55. SWITCHES

- 3.56. SENSOR

- 3.57. KOMTRAX TERMINAL SYSTEM

- 4. STANDARD VALUE TABLES

- 4.1. STANDARD VALUE TABLES

- 5. TESTING AND ADJUSTING

- 5.1. SERVICE TOOLS

- 5.2. ENGINE

- 5.3. AIR COMPRESSOR BELT TENSION

- 5.4. FAN BELT

- 5.5. ALTERNATOR BELT

- 5.6. ENGINE FUNCTIONS

- 5.7. REFRIGERANT COMPRESSOR BELT

- 5.8. SWING CIRCLE BEARING CLEARANCE

- 5.9. TRACK SHOE TENSION

- 5.10. OIL PRESSURE IN WORK EQUIPMENT

- 5.11. OIL PRESSURE IN SWING

- 5.12. OIL PRESSURE IN TRAVEL CIRCUIT

- 5.13. CONTROL CIRCUIT OIL PRESSURE

- 5.14. PUMP PC CONTROL CIRCUIT OIL PRESSURE

- 5.15. PUMP LS CONTROL CIRCUIT OIL PRESSURE

- 5.16. SOLENOID VALVE OUTPUT PRESSURE

- 5.17. ATTACHMENT SOLENOID VALVE OUTPUT

- 5.18. PPC VALVE OUTPUT

- 5.19. ATTACHMENT PPC VALVE OUTPUT

- 5.20. WORK EQUIPMENT AND SWING PPC VALVES

- 5.21. HYDRAULIC DRIFT IN WORK EQUIPMENT

- 5.22. RELEASE REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.23. BLEEDING AIR FROM VARIOUS SYSTEMS

- 5.24. DIODE INSPECTION PROCEDURES

- 5.25. MACHINE MONITOR SPECIAL FUNCTIONS

- 5.26. SERVICE MENU OPERATION AND DISPLAY

- 5.27. HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER

- 5.28. PROCEDURE FOR TURNING ON KOMTRAX TERMINAL

- 5.29. KOMTRAX TERMINAL LAMP INDICATIONS

- 5.30. TROUBLESHOOTING ELECTRICAL SYSTEM

- 5.31. PMCLINIC INSPECTION TABLE

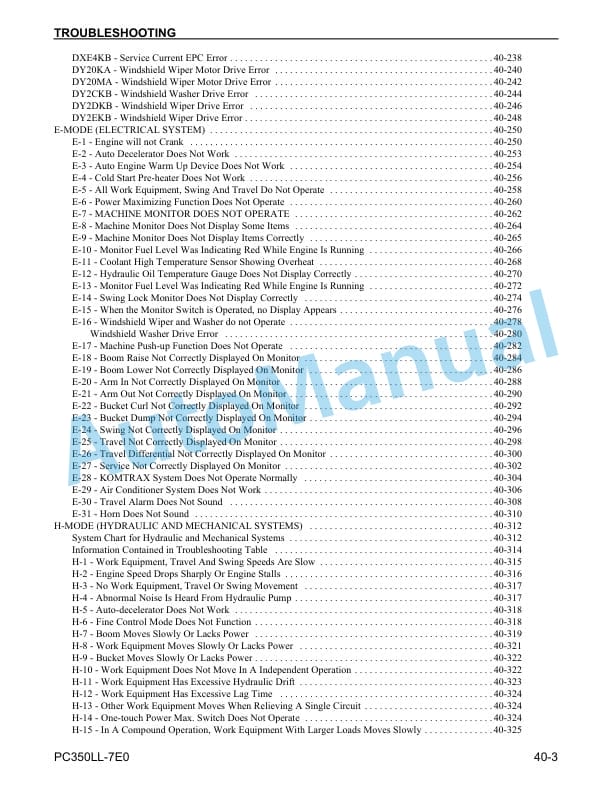

- 6. TROUBLESHOOTING

- 6.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 6.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 6.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 6.4. POSSIBLE PROBLEMS WHEN TROUBLESHOOTING A MODE

- 6.5. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 6.6. TADAPTER TABLE

- 6.7. CONNECTOR TYPES AND LOCATIONS

- 6.8. CONNECTOR LAYOUT DRAWINGS

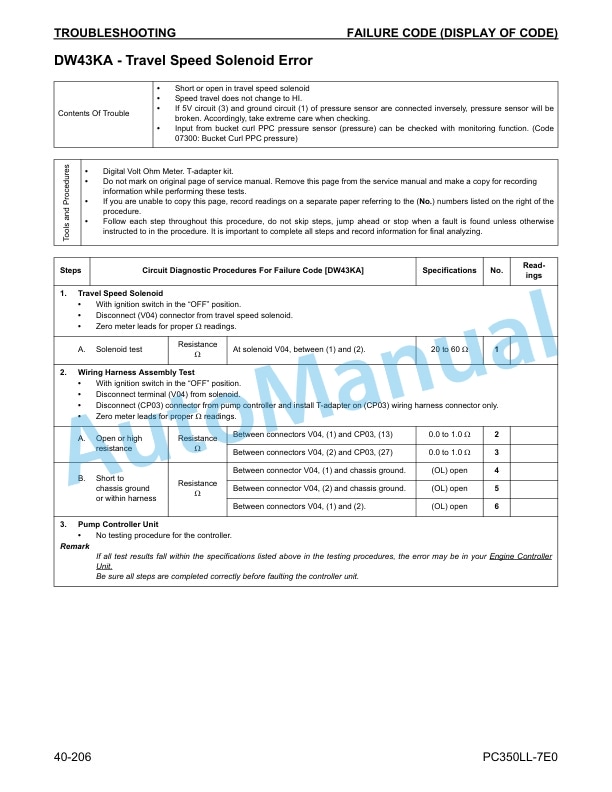

- 6.9. TROUBLESHOOTING BY FAILURE CODE

- 6.10. INFORMATION CONTAINED IN TESTING PROCEDURES

- 6.11. FAILURE CODE (DISPLAY OF CODE)

- 6.12. EMODE (ELECTRICAL SYSTEM)

- 6.13. HMODE (HYDRAULIC AND MECHANICAL SYSTEMS)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. HOW TO READ THIS MANUAL

- 7.2. SPECIAL TOOLS LIST

- 7.3. CONNECTOR REPAIR PROCEDURES

- 7.4. ENGINE COMPONENTS

- 7.5. ENGINE AND COOLING SYSTEM

- 7.6. UNDERCARRIAGE AND FRAME

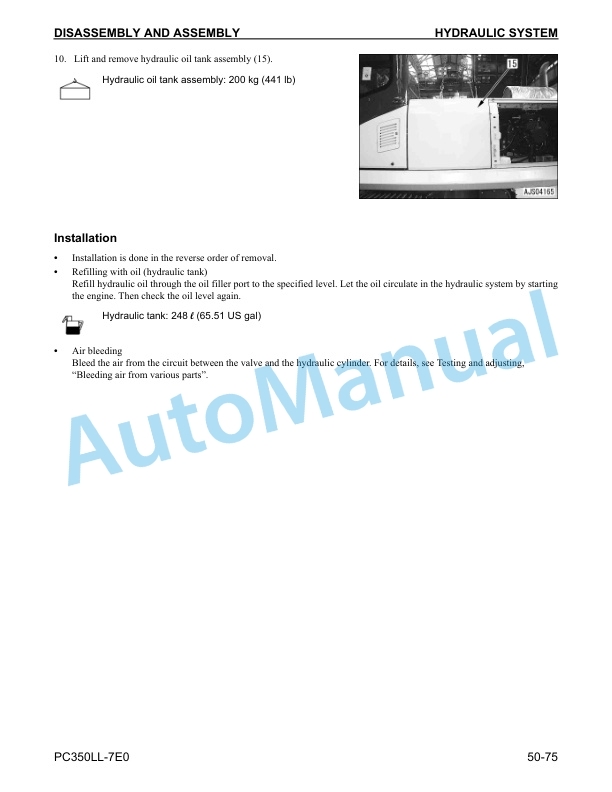

- 7.7. HYDRAULIC SYSTEM

- 7.8. WORK EQUIPMENT

- 7.9. CAB AND ITS ATTACHMENTS

- 7.10. ELECTRICAL SYSTEM

- 8. AIR CONDITIONER

- 8.1. STRUCTURE AND FUNCTION

- 8.2. TESTING AND ADJUSTING

- 8.3. TROUBLESHOOTING

- 9. OTHERS

- 9.1. ELECTRICAL CIRCUIT DIAGRAMS

- 9.2. HYDRAULIC CIRCUIT DIAGRAMS

Rate this product

You may also like