Komatsu PC360-7 Hydraulic Excavator Shop Manual SMEH3607M0

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SMEH3607M0

- Format: PDF

- Size: 74.6MB

- Number of Pages: 651

Category: Komatsu Shop Manual PDF

-

Model List:

- PC360-7 Hydraulic Excavator

- 0.1. SPECIFICATION DIMENSION DRAWINGS

- 0.2. SPECIFICATIONS

- 0.3. WEIGHT TABLE

- 0.4. FUEL, COOLANT AND LUBRICANTS

- 1. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 1.1. Engine Related Parts

- 1.2. Radiator Oil Cooler Aftercooler

- 1.3. Power Train

- 1.4. Final Drive

- 1.5. Swing Machinery

- 1.6. Swing Circle

- 1.7. Track Frame Recoil Spring

- 1.8. Idler

- 1.9. Carrier roller

- 1.10. Track roller

- 1.11. Track Shoe

- 1.12. Hydraulic Equipment Layout Drawing

- 1.13. Hydraulic Tank

- 1.14. Hydraulic Pump

- 1.15. Variable Volume Valve

- 1.16. Control Valve

- 1.17. CLSS

- 1.18. Self Pressure Reducing Valve

- 1.19. Swing Motor

- 1.20. Reverse Prevention Valve

- 1.21. Center Swivel Joint

- 1.22. Travel Motor

- 1.23. Travel Junction Valve

- 1.24. Travel PPC Shuttle Valve

- 1.25. Valve Control

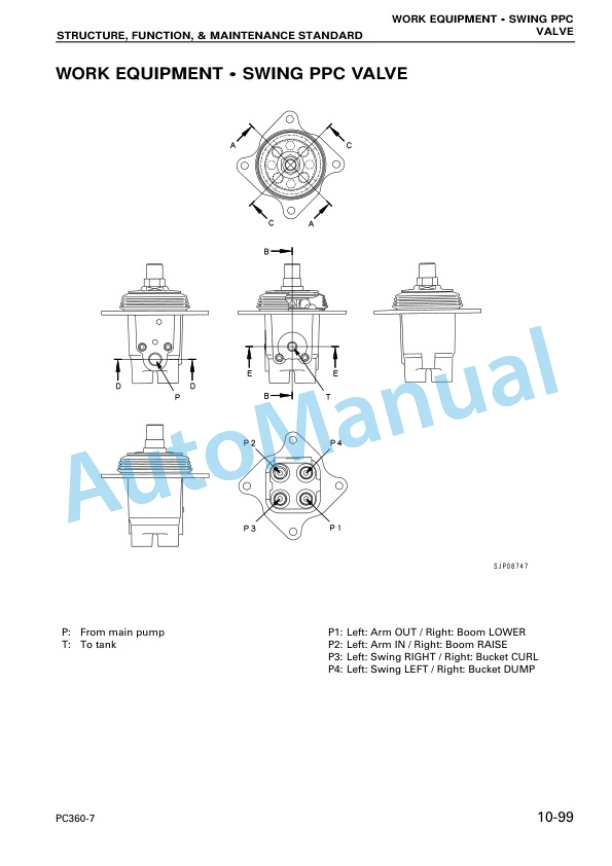

- 1.26. Work Equipment Swing PPC Valve

- 1.27. Travel PPC Valve

- 1.28. Service PPC Valve

- 1.29. Solenoid Valve

- 1.30. PPC Accumulator

- 1.31. Return Oil Filter

- 1.32. Boom Hydraulic Drift Prevention Valve

- 1.33. Quick Return Valve

- 1.34. Lift Check Valve

- 1.35. Attachment Circuit Selector Valve

- 1.36. Hydraulic Cylinder

- 1.37. Work Equipment

- 1.38. Air Conditioner

- 1.39. Engine Control.

- 1.40. Electronic Control System

- 1.41. Multi Monitor System

- 1.42. Segment Monitor System

- 1.43. Sensor

- 2. TESTING AND ADJUSTING

- 2.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 2.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS.

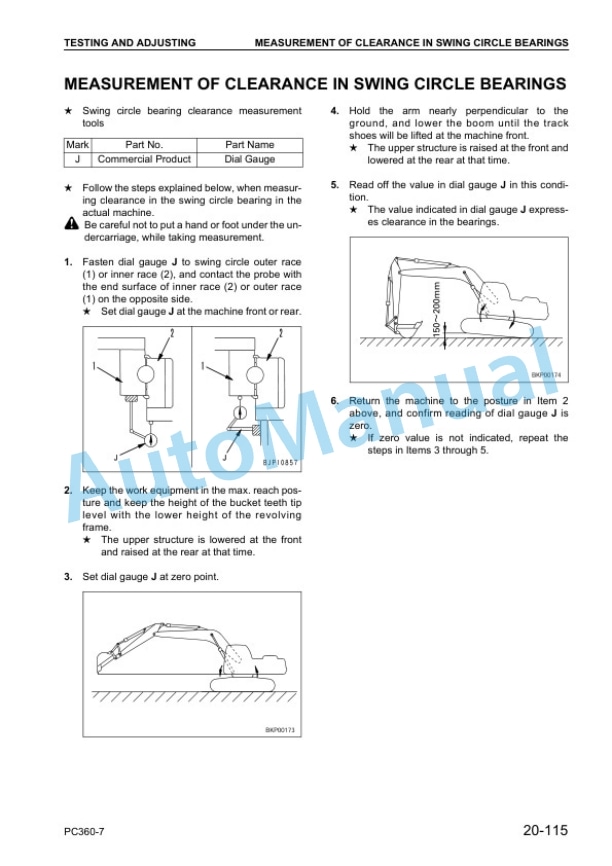

- 2.3. TESTING AND ADJUSTING

- 2.4. TROUBLESHOOTING.

- 2.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING.

- 2.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 2.4.4. CHECKS BEFORE TROUBLESHOOTING

- 2.4.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 2.4.6. CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

- 2.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 2.4.8. TROUBLESHOOTING WHEN SERVICE CODE ELECTRICAL SYSTEM AND FAILURE CODE MECHANICAL SYSTEM ARE INDICATED.

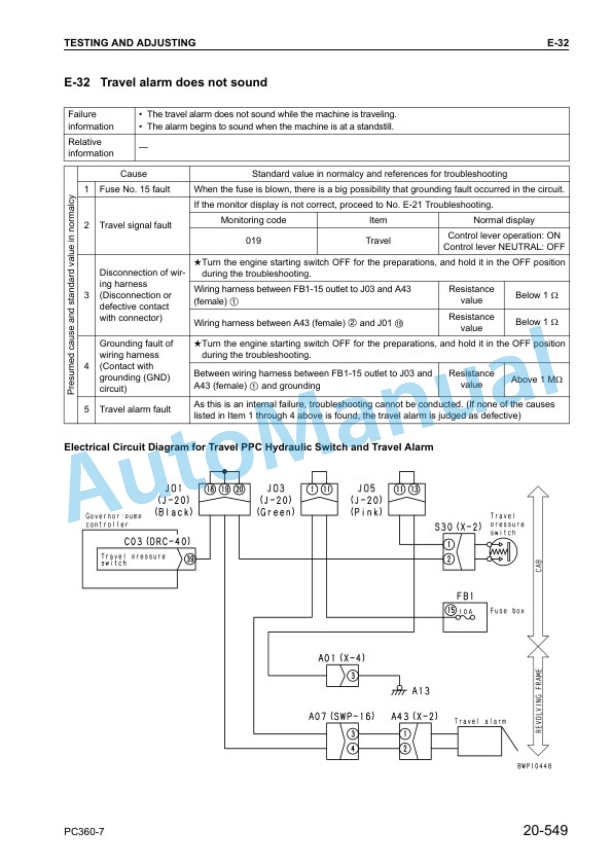

- 2.4.9. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EMODE)

- 2.4.10. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. HOW TO READ THIS MANUAL

- 3.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 3.3. SPECIAL TOOL LIST

- 3.4. STARTING MOTOR ASSEMBLY

- 3.5. FUEL INJECTION PUMP ASSEMBLY

- 3.6. ENGINE FRONT SEAL

- 3.7. ENGINE REAR SEAL

- 3.8. CYLINDER HEAD ASSEMBLY

- 3.9. RADIATOR ASSEMBLY

- 3.10. HYDRAULIC OIL COOLER ASSEMBLY

- 3.11. ENGINE AND HYDRAULIC PUMP ASSEMBLIES

- 3.12. FINAL DRIVE ASSEMBLY

- 3.13. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 3.14. SWING MOTOR, SWING MACHINERY ASSEMBLY

- 3.15. DISASSEMBLY AND ASSEMBLY OF SWING MOTOR, SWING MACHINERY ASSEMBLY

- 3.16. CARRIER ROLLER ASSEMBLY

- 3.17. TRACK ROLLER ASSEMBLY

- 3.18. IDLER ASSEMBLY

- 3.19. RECOIL SPRING ASSEMBLY

- 3.20. SPROCKET

- 3.21. TRACK SHOE ASSEMBLY

- 3.22. SWING CIRCLE ASSEMBLY

- 3.23. REVOLVING FRAME ASSEMBLY

- 3.24. CENTER SWIVEL JOINT ASSEMBLY

- 3.25. DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

- 3.26. HYDRAULIC TANK ASSEMBLY

- 3.27. CONTROL VALVE ASSEMBLY

- 3.28. DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY

- 3.29. HYDRAULIC PUMP ASSEMBLY

- 3.30. OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT

- 3.31. WORK EQUIPMENT PPC VALVE ASSEMBLY

- 3.32. TRAVEL PPC VALVE ASSEMBLY

- 3.33. HYDRAULIC CYLINDER ASSEMBLY

- 3.34. WORK EQUIPMENT ASSEMBLY

- 3.35. AIR CONDITIONER UNIT ASSEMBLY

- 3.36. COUNTERWEIGHT ASSEMBLY

- 3.37. OPERATORS CAB ASSEMBLY

- 3.38. MONITOR ASSEMBLY

- 3.39. GOVERNOR PUMP CONTROLLER ASSEMBLY

- 4. OTHERS

- 4.1. Hydraulic Circuit Diagram

- 4.2. Electrical Circuit Diagram (1/4)

- 4.3. Electrical Circuit Diagram (2/4).

- 4.4. Electrical Circuit Diagram (3/4)

- 4.5. Electrical Circuit Diagram (4/4)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00