Komatsu PC390LL-10 Log Loader Shop Manual CEBM027500

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM027500

- Format: PDF

- Size: 11.8MB

- Number of Pages: 332

Category: Komatsu Shop Manual PDF

-

Model List:

- PC390LL-10 Log Loader

- 1. CEBM027500 PC390LL10 S/N A50601

- 1.1. CONTENTS

- 1.2. FOREWORD

- 1.2.1. SAFETY

- 1.2.1.1. Safety Notice

- 1.2.2. GENERAL

- 1.2.3. HOW TO READ THE SHOP MANUAL

- 1.2.3.1. Volumes

- 1.2.3.2. Distribution and Updating

- 1.2.3.3. Filing Method

- 1.2.3.4. Revised Edition Mark

- 1.2.3.5. Revisions

- 1.2.3.6. Symbols

- 1.2.4. HOISTING INSTRUCTIONS

- 1.2.4.1. Hoisting

- 1.2.4.2. Making Signs

- 1.2.4.3. Precautions

- 1.2.4.4. Selecting Wire Ropes

- 1.2.5. HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS

- 1.2.5.1. Points to Remember When Handling Electric Equipment

- 1.2.5.2. Points to Remember When Handling Hydraulic Equipment

- 1.2.6. PUSH PULL COUPLER

- 1.2.7. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.2.8. HANDLING OF FUEL SYSTEM DEVICES

- 1.2.9. HANDLING OF INTAKE SYSTEM PARTS

- 1.2.10. STANDARD TIGHTENING TORQUE

- 1.2.10.1. Bolts And Nuts

- 1.2.10.2. Tightening Torque Of Hose Nuts

- 1.2.10.3. Tightening Torque Of Split Flange Bolts

- 1.2.10.4. Tightening Torque For Flared Nuts

- 1.2.10.5. Tightening Torques for Split Flanged Bolts

- 1.2.10.6. Tightening Torques For Oring Boss Piping Joints

- 1.2.10.7. Table Of Tightening Torques For Oring Boss Plugs

- 1.2.10.8. Tightening Torque For Hoses (Taper Seal Type And Face Seal Type)

- 1.2.11. ELECTRIC WIRE CODE

- 1.2.11.1. Classification By Thickness

- 1.2.11.2. Classification By Color And Code

- 1.2.11.3. How To Read Electric Wire Code

- 1.2.12. PRECAUTIONS FOR OPERATIONS

- 1.2.12.1. Precautions When Carrying Out Removal Work

- 1.2.12.2. Precautions When Carrying Out Installation Work

- 1.2.12.3. Precautions When Completing the Operation

- 1.2.13. CONVERSION TABLES

- 1.2.13.1. Method Of Using The Conversion Table

- 1.2.14. COATING MATERIALS

- 1.2.15. LIST OF ABBREVIATIONS

- 1.2.15.1. List of Abbreviations Used in the Shop Manual

- 1.2.15.2. List of Abbreviations Used in the Circuit Diagrams

- 1.3. GENERAL

- 1.3.1. SPECIFICATIONS

- 1.3.1.1. Dimension Drawings

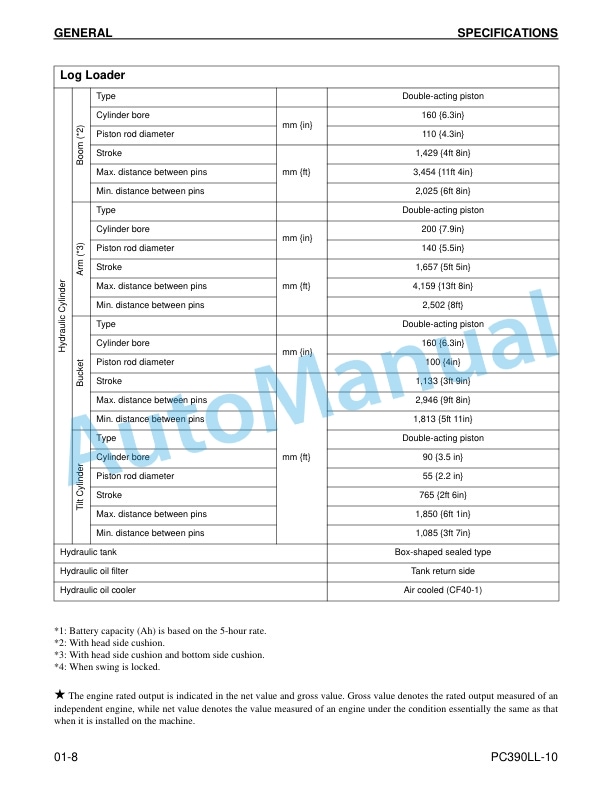

- 1.3.1.2. Hydraulic System

- 1.3.2. WEIGHT TABLE

- 1.3.3. FUEL, COOLANT AND LUBRICANTS

- 1.3.3.1. Lubrication Chart

- 1.4. STRUCTURE AND FUNCTION

- 1.4.1. ENGINE AND COOLING SYSTEM

- 1.4.1.1. Engine Related Parts

- 1.4.1.2. Cooling System

- 1.4.2. POWERTRAIN SYSTEM

- 1.4.2.1. Powertrain

- 1.4.2.2. Swing Circle

- 1.4.2.3. Final Drive

- 1.4.3. TRACK FRAME . RECOIL SPRING

- 1.4.4. HYDRAULIC SYSTEM

- 1.4.4.1. Hydraulic Component Layout

- 1.4.4.2. Valve Control

- 1.4.4.3. Hydraulic Tank

- 1.4.4.4. Oil Filler Cap

- 1.4.4.5. CLSS

- 1.4.4.6. Main Pump

- 1.4.4.7. Control Valve

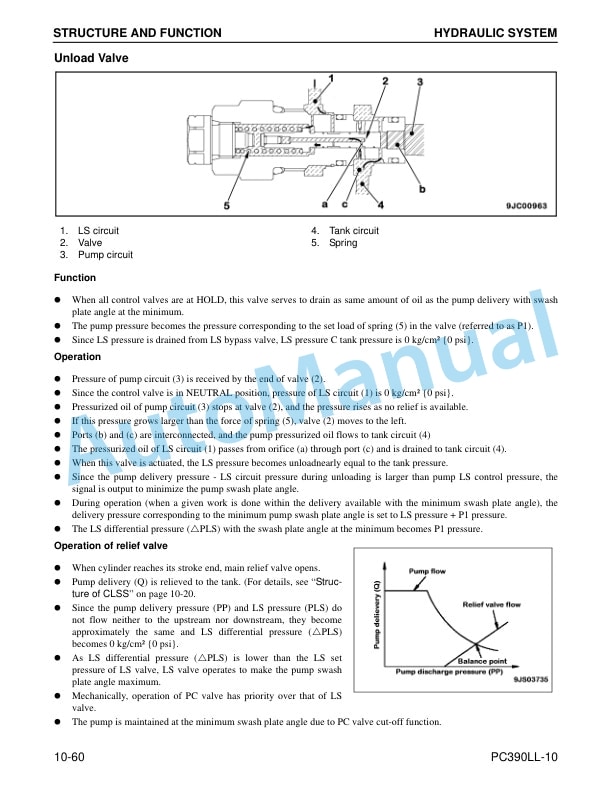

- 1.4.4.8. Functions and Operation by Valve

- 1.4.4.9. Swing Motor

- 1.4.4.10. Travel Motor Type KMV200ADT2

- 1.4.4.11. PPC Valve

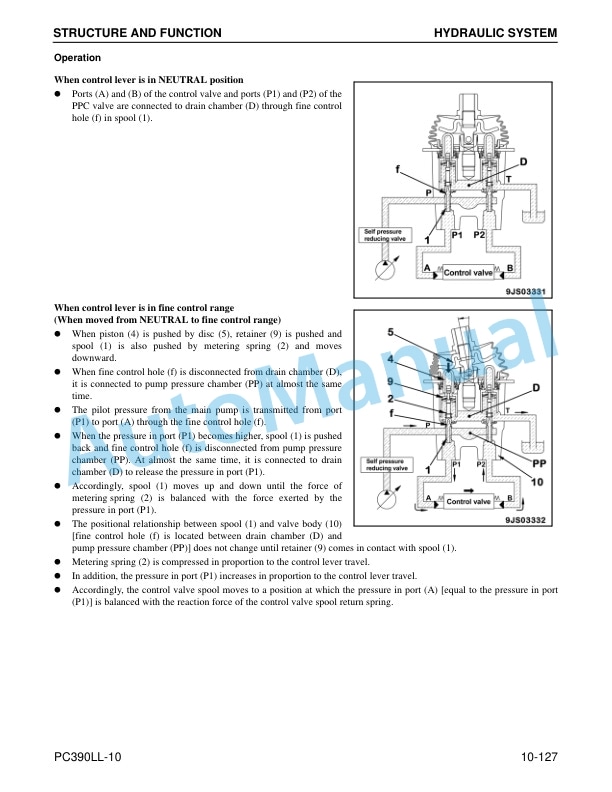

- 1.4.4.12. Solenoid Valve

- 1.4.4.13. Attachment Solenoid Valve

- 1.4.4.14. Center Swivel Joint

- 1.4.4.15. Accumulator

- 1.4.5. WORK EQUIPMENT

- 1.4.5.1. Work Equipment Road Builder

- 1.4.5.2. Work Equipment Log Loader

- 1.4.5.3. Work Equipment Shim

- 1.4.5.4. Bucket Play Adjustment Shim

- 1.4.6. ELECTRICAL SYSTEM

- 1.4.6.1. Electrical Control System

- 1.4.6.2. System Component Part

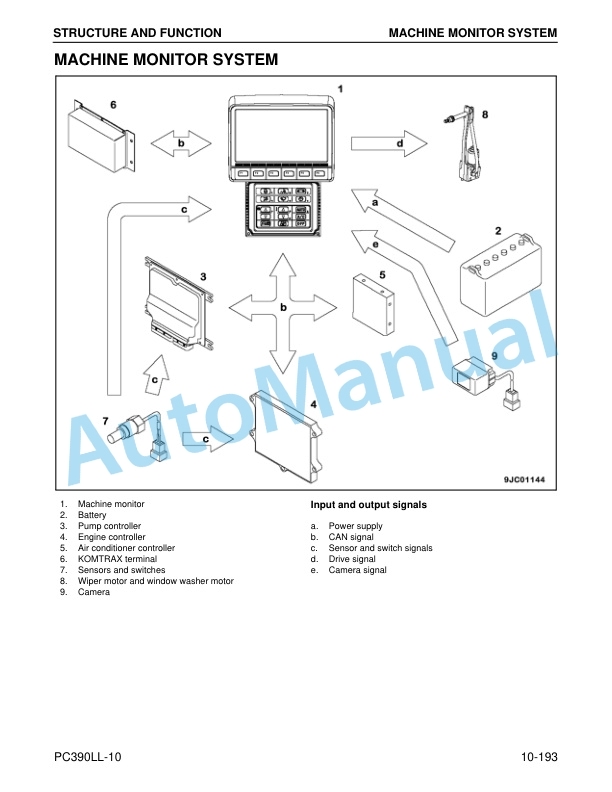

- 1.4.7. MACHINE MONITOR SYSTEM

- 1.4.7.1. Machine Monitor

- 1.4.7.2. Switches

- 1.4.8. KOMTRAX SYSTEM

- 1.4.8.1. KOMTRAX terminal

- 1.4.8.2. Input and Output Signals

- 1.4.9. SENSORS

- 1.4.9.1. Ambient Pressure Sensor

- 1.4.9.2. Charge (Boost) Pressure and Temperature Sensor

- 1.4.9.3. Coolant Temperature Sensor

- 1.4.9.4. Ne (Crankshaft) Speed Sensor

- 1.4.9.5. Bkup (Camshaft) Speed Sensor

- 1.4.9.6. Common Rail Pressure Sensor

- 1.4.9.7. Exhaust Manifold Pressure Sensor

- 1.4.9.8. EGR Orifice Temperature Sensor

- 1.4.9.9. EGR Valve Lift Sensor

- 1.4.9.10. Turbo Speed Sensor

- 1.4.9.11. KVGT Position Sensor

- 1.4.9.12. Mass Air Flow and Temperature Sensor

- 1.4.9.13. KDPF Differential Pressure and Outlet Pressure Sensor

- 1.4.9.14. KDOC Inlet Temperature Sensor

- 1.4.9.15. KDOC Outlet Temperature Sensor

- 1.4.9.16. KDPF Outlet Temperature Sensor

- 1.4.9.17. Crankcase Pressure Sensor

- 1.4.9.18. Engine Oil Level Sensor

- 1.4.9.19. Fuel Level Sensor

- 1.4.9.20. Coolant Level Sensor

- 1.4.9.21. Hydraulic Oil Temperature Sensor

- 1.4.9.22. Front Pump Oil Pressure Sensor

- 1.4.9.23. Rear Pump Oil Pressure Sensor

- 1.4.9.24. PPC Oil Pressure Sensor

- 1.4.9.25. Air Cleaner Clogging Sensor

- 1.4.9.26. Front Pump Swash Plate Sensor

- 1.4.9.27. Rear Pump Swash Plate Sensor

- 1.4.9.28. WaterInFuel Sensor

- 1.5. STANDARD VALUE TABLES

- 1.5.1. STANDARD SERVICE VALUE TABLES

- 1.5.1.1. Standard Value Table for Engine Related Parts

- 1.5.1.2. Standard Value Table for Chassis Related Parts

- 1.5.1.3. Posture of Machine for Measuring Performance and Measurement Procedure

Rate this product

You may also like