Komatsu PC490LCi-11 Hydraulic Excavator Operation and Maintenance Manual CEAM032403

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM032403

- Format: PDF

- Size: 23.3MB

- Number of Pages: 382

-

Model List:

- PC490LCi-11 Hydraulic Excavator

- 1. OPERATION AND MAINTENANCE MANUAL PC490LCi11 HYDRAULIC EXCAVATOR

- 1.1. FOREWORD

- 1.1.1. READ THIS MANUAL

- 1.1.2. SAFETY INFORMATION

- 1.1.3. INTRODUCTION

- 1.1.3.1. intelligent Machine Control

- 1.1.3.2. MAIN USE OF MACHINE

- 1.1.4. CONTENTS

- 1.2. SAFETY

- 1.2.1. SAFETY

- 1.2.2. SAFETY LABELS

- 1.2.2.1. LOCATION OF SAFETY LABELS

- 1.2.2.2. SAFETY LABELS

- 1.2.3. PRECAUTIONS FOR OPERATION

- 1.2.3.1. START ENGINE

- 1.2.3.1.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 1.2.3.2. PRECAUTIONS RELATED TO CONTROL BOX

- 1.2.3.3. PRECAUTIONS RELATED TO SEMIAUTO MODE

- 1.2.3.4. PRECAUTIONS FOR TRANSPORTATION

- 1.2.3.4.1. PRECAUTIONS WHEN LOADING AND UNLOADING

- 1.2.3.5. PROTECTION AGAINST FALLING, FLYING OR INTRUDING OBJECTS

- 1.2.3.6. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 1.2.3.7. QUICK COUPLER ATTACHMENT

- 1.2.3.8. LARGE ATTACHMENTS AND COMBINATIONS

- 1.3. OPERATION

- 1.3.1. GENERAL VIEW

- 1.3.1.1. MACHINE EQUIPMENT NAME

- 1.3.1.2. CAB EQUIPMENT NAMES

- 1.3.2. EXPLANATION OF COMPONENTS

- 1.3.2.1. EXPLANATION OF MACHINE MONITOR EQUIPMENT

- 1.3.2.1.1. WARNING DISPLAY

- 1.3.2.1.2. ACTION LEVEL DISPLAY

- 1.3.2.1.3. Intelligent Machine Control EQUIPMENT STATE CAUTION LAMP

- 1.3.2.1.4. Intelligent Machine Control SYSTEM STATE CAUTION LAMP

- 1.3.2.1.5. CALIBRATION STATE CAUTION LAMP

- 1.3.2.1.6. IMU STATE CAUTION LAMP

- 1.3.2.1.7. CYLINDER FUNCTION STATE CAUTION LAMP

- 1.3.2.2. SWITCH

- 1.3.2.2.1. LAMP SWITCH

- 1.3.2.2.2. BOOM SECONDARY DRIVE SWITCH

- 1.3.2.2.3. AUTO/MANUAL SWITCH

- 1.3.2.3. CONTROL LEVERS AND PEDALS

- 1.3.2.3.1. LOCK LEVER

- 1.3.2.4. intelligent Machine Control SYSTEM

- 1.3.2.4.1. CONTROL BOX

- 1.3.2.4.2. NETWORK MODEM

- 1.3.2.5. OTHER EQUIPMENT

- 1.3.2.5.1. METHOD FOR OPENING AND CLOSING CAB FRONT WINDOW

- 1.3.2.5.2. CUP HOLDER

- 1.3.2.5.3. POWER SUPPLY OUTLET

- 1.3.2.5.4. FUSE

- 1.3.2.5.5. METHOD FOR REMOVING AND INSTALLING CONTROL BOX

- 1.3.3. MACHINE OPERATIONS AND CONTROLS

- 1.3.3.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 1.3.3.1.1. METHOD FOR WALKAROUND CHECK

- 1.3.3.1.2. METHOD FOR ADJUSTING

- 1.3.3.2. METHOD FOR STARTING ENGINE

- 1.3.3.2.1. METHOD FOR STARTING CONTROL BOX

- 1.3.3.2.2. METHOD FOR SHUTTING DOWN CONTROL BOX

- 1.3.3.3. METHOD FOR STOPPING ENGINE

- 1.3.3.4. DO NOT PERFORM THE WORK IF FOREIGN MATERIAL IS ACCUMULATED AROUND HYDRAULIC CYLINDER

- 1.3.3.5. METHOD FOR PARKING MACHINE

- 1.3.4. HANDLING RADIO

- 1.3.5. TRANSPORTATION

- 1.3.5.1. REMOVE AND INSTALL GNSS ANTENNA

- 1.3.5.1.1. METHOD FOR REMOVING GNSS ANTENNA

- 1.3.5.1.2. METHOD FOR INSTALLING GNSS ANTENNA

- 1.3.5.2. REMOVE AND INSTALL HANDRAIL

- 1.3.5.2.1. METHOD FOR REMOVING HANDRAIL

- 1.3.5.2.2. METHOD FOR INSTALLING HANDRAIL

- 1.3.5.3. REMOVE AND INSTALL GNSS ANTENNA AND ANTENNA FOR NETWORK MODEM

- 1.3.5.3.1. METHOD FOR REMOVING GNSS ANTENNA AND ANTENNA FOR NETWORK MODEM

- 1.3.5.3.2. METHOD FOR INSTALLING GNSS ANTENNA AND ANTENNA FOR NETWORK MODEM

- 1.3.6. PRECAUTIONS FOR LONGTERM STORAGE

- 1.3.6.1. STARTING MACHINE AFTER LONGTERM STORAGE

- 1.3.7. TROUBLES AND ACTIONS

- 1.3.7.1. IF ERROR INFORMATION IS DISPLAYED ON CONTROL BOX

- 1.3.7.1.1. IF Initializing IS DISPLAYED

- 1.3.7.2. OTHER TROUBLE

- 1.3.7.2.1. IF MACHINE MONITOR SHOWS WARNING DISPLAY

- 1.3.7.2.2. PHENOMENA AND ACTIONS FOR CONTROL BOX

- 1.4. MAINTENANCE

- 1.4.1. MAINTENANCE SCHEDULE

- 1.4.1.1. MAINTENANCE SCHEDULE TABLE

- 1.4.2. MAINTENANCE PROCEDURE

- 1.4.2.1. EVERY 500 HOURS MAINTENANCE

- 1.4.2.1.1. METHOD OF CHECKING LOOSENESS OF BUCKET CYLINDER STROKE SENSOR WIRING HARNESS CLAMP, HARDENING OF RUBBER

- 1.4.2.1.2. METHOD OF CHECKING AND CLEANING CYLINDER STROKE SENSOR CASE BOLT

- 1.4.2.2. METHOD FOR REPLACING HYDRAULIC TANK BREATHER ELEMENT

- 1.5. SPECIFICATIONS

- 1.5.1. SPECIFICATIONS

- 1.5.1.1. SPECIFICATIONSPC490LCI11

- 1.6. ATTACHMENTS AND OPTIONS

- 1.6.1. RECOMMENDED ATTACHMENT OPERATIONS

- 1.6.1.1. HYDRAULIC BREAKER

- 1.7. SETTING

- 1.7.1. INTELLIGENT MACHINE CONTROL SETTINGS

- 1.7.2. CONTROL BOX

- 1.7.2.1. METHOD FOR DISPLAYING MAIN MENU

- 1.7.2.1.1. MAIN MENU DISPLAY

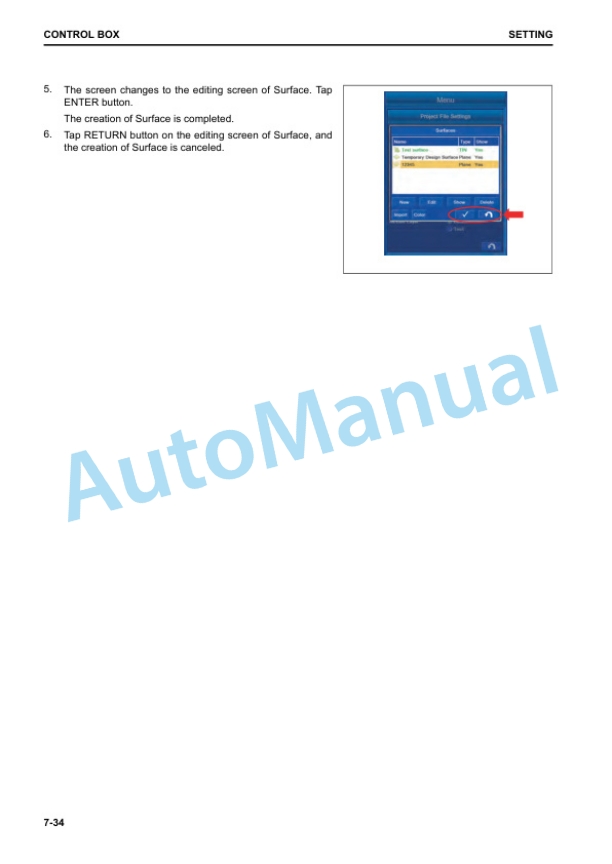

- 1.7.2.1.2. PROJECT FILE SETTING AND EDITING

- 1.7.2.1.3. GUIDANCE SETTINGS

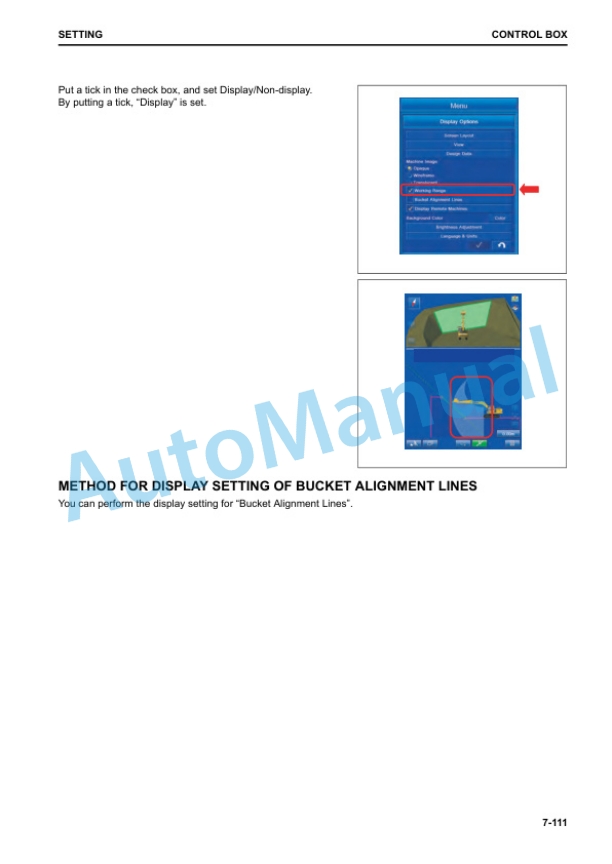

- 1.7.2.1.4. DISPLAY OPTIONS

- 1.7.2.1.5. SITE LINK TASK DETAIL MENU

- 1.7.2.1.6. SITE LINK

- 1.7.2.1.7. TOOLS

- 1.7.2.1.8. METHOD FOR SETTING GNSS RADIO DEVICE

- 1.7.2.1.9. PREPARATIONS FOR CALIBRATION

- 1.7.2.1.10. BUCKET CONFIGURATION

- 1.7.3. MACHINE MONITOR

- 1.7.3.1. MC SETTING

- 1.7.3.1.1. IMU ADJUSTMENT

- 1.7.3.1.2. BUCKET WEIGHT SETTING

- 1.7.3.1.3. BOOM FINE CONTROL ADJUSTMENT

- 1.7.3.1.4. SEMIAUTO ADJUSTMENT

- 1.8. EXECUTIONS

- 1.8.1. SEMIAUTO MODE

- 1.8.1.1. PRECAUTIONS FOR OPERATION

- 1.8.1.2. PRECAUTIONS FOR REPLACING PARTS AND FAILURES

- 1.8.1.3. WORKING MODE

- 1.8.1.4. SEMIAUTO MODE SETTINGS

- 1.8.1.4.1. METHOD FOR SWITCHING TO SEMIAUTO MODE

- 1.8.1.4.2. LIST OF RESTRICTED ITEMS DURING SEMIAUTO MODE

- 1.8.1.4.3. METHOD FOR ADJUSTING CONTROL SURFACE OFFSET

- 1.8.1.4.4. METHOD FOR SWITCHING TO MANUAL MODE

- 1.8.2. TRAVEL MODE

- 1.8.2.1. TRAVEL MODE SETTINGS

- 1.8.2.2. DISPLAY OF TRAVEL MODE

- 1.8.2.3. OFFSET MENU OF SURFACE

- 1.8.2.4. TEMPORARY DESIGN MENU

- 1.8.2.4.1. METHOD FOR CREATING TEMPORARY DESIGN SURFACE

- 1.8.2.5. TARGET SURFACE SETTINGS

- 1.8.2.5.1. METHOD FOR SETTING TARGET SURFACE

- 1.8.2.5.2. METHOD FOR RESETTING TARGET SURFACE

- 1.8.3. ROUGH DIGGING MODE

- 1.8.3.1. METHOD FOR SETTING ROUGH DIGGING SCREEN

- 1.8.4. FINE DIGGING MODE

- 1.8.4.1. METHOD FOR SETTING FINE DIGGING MODE SCREEN

- 1.8.5. TARGET SURFACE SETTINGS

- 1.8.5.1. TARGET SURFACE SETTING MENU

- 1.8.5.2. METHOD FOR SETTING TARGET SURFACE

- 1.8.6. BUCKET EDGE POSITION

- 1.8.6.1. DISPLAY BUCKET EDGE POSITION

- 1.8.6.1.1. METHOD FOR SETTING MEASURED BUCKET EDGE POSITION

- 1.8.6.1.2. DISPLAY BUCKET EDGE COORDINATES

- 1.8.6.1.3. DISPLAY DISTANCE BETWEEN BUCKET EDGE AND DESIGN SURFACE

- 1.8.6.1.4. DISPLAY BUCKET EDGE POSITION ALGNMENT STATION

- 1.8.6.1.5. DISPLAY DISTANCE BETWEEN CENTER LINE AND BUCKET EDGE POSITION

- 1.8.6.1.6. METHOD FOR MEASURING BUCKET EDGE POSITION

- 1.8.6.1.7. METHOD FOR SAVING MEASURED DATA

- 1.8.6.2. METHOD FOR COMPARING WITH BENCHMARK

- 1.8.6.3. METHOD FOR CORRECTING BUCKET EDGE POSITION

- 1.8.7. DAILY CALIBRATION

- 1.8.7.1. WALKAROUND CHECKS OF INTELLIGENT MACHINE CONTROL EQUIPMENT

- 1.8.7.1.1. METHOD FOR CHECKING GNSS ANTENNA AND CABLE

- 1.8.7.1.2. METHOD FOR CHECKING GNSS RADIO DEVICE

- 1.8.7.1.3. METHOD FOR CHECKING LOOSENESS OF CONTROL BOX

- 1.8.7.1.4. METHOD FOR CHECKS BEFORE STARTING ON intelligent Machine Control EQUIPMENT

- 1.8.7.1.5. METHOD FOR CHECKING PROJECT FILE

- 1.8.7.1.6. METHOD FOR CHECKING GNSS COMMUNICATION STATUS

- 1.8.7.1.7. METHOD FOR CHECKING CONTROL BOX SCREEN DISPLAY

- 1.8.7.1.8. METHOD FOR CHECKING AND ADJUSTING BUCKET EDGE ACCURACY

- 1.8.7.1.9. METHOD FOR CALIBRATING BUCKET TOOTH

- 1.8.8. CHECK GNSS COMMUNICATION STATUS

- 1.8.8.1. METHOD FOR CHECKING GNSS COMMUNICATION STATUS

- 1.8.8.2. METHOD FOR CHECKING NUMBER OF SATELLITES AND ERROR OF POSITIONING

- 1.8.8.3. METHOD FOR DISPLAYING BUCKET EDGE COORDINATES

- 1.8.8.4. METHOD FOR SETTING SATELLITE POSITION DISPLAY AND ELEVATION ANGLE

- 1.8.8.5. METHOD FOR DISPLAYING GNSS RECEIVER INFORMATION

- 1.8.8.6. METHOD FOR CHEKING EXPECTANCY OF EDGE ACCURANCY

- 1.8.8.7. METHOD FOR SETTING GLONASS SATELLITE

- 1.8.8.8. METHOD FOR SETTING TILT SENSOR

- 1.8.9. USE OF TOPO SURVEY

- 1.8.9.1. METHOD FOR PERFORMING TOPO SURVEY MANUALLY

- 1.8.9.1.1. CREATE NEW LAYER TO RECORD DATA

- 1.8.9.1.2. METHOD FOR INPUTTING NEW POSITION DETAILS NAME

- 1.8.9.2. METHOD FOR PERFORMING AUTOTOPO SURVEY

- 1.8.9.2.1. METHOD FOR CREATING NEW LAYER TO RECORD DATA

- 1.8.9.2.2. METHOD FOR INPUTTING NEW POSITION DETAILS NAME

- 1.8.9.3. METHOD FOR CANCELING TOPOGRAPHIC SURVEYS

- 1.8.10. TROUBLESHOOTING

- 1.8.10.1. CONTROL BOX SCREEN DISPLAY

- 1.8.10.2. SEMIAUTO MODE

- 1.8.10.3. WORKING ACCURACY

- 1.9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual