Komatsu PC60-5, PC60L-5, PC60U-5 Hydraulic Excavator Shop Manual SEBM02010505

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM02010505

- Format: PDF

- Size: 39.7MB

- Number of Pages: 417

Category: Komatsu Shop Manual PDF

-

Model List:

- PC60-5 Hydraulic Excavator

- PC60L-5 Hydraulic Excavator

- PC60U-5 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. ENGINE MOUNT

- 3.1.2. RADIATOR

- 3.1.4. FUEL TANK AND PIPING

- 3.1.5. ENGINE CONTROL

- 3.1.6. AUTODECELERATION SYSTEM (IF EQUIPPED)

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TESTING AND ADJUSTING DATA

- 3.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 3.2.3. ADJUSTING VALVE CLEARANCE

- 3.2.4. MEASURING EXHAUST GAS COLOR

- 3.2.5. MEASURING COMPRESSION PRESSURE

- 3.2.6. MEASURING BLOWBY PRESSURE

- 3.2.7. ADJUSTING FUEL INJECTION TIMING

- 3.2.8. TESTING AND ADJUSTING FAN BELT TENSION

- 3.2.9. ADJUSTING FUEL CONTROL LEVER

- 3.2.10. ADJUSTING AUTODECELERATION SYSTEM (IF EQUIPPED)

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. AUTODECELERATION CYLINDER

- 3.3.1.1. REMOVAL

- 3.3.1.2. INSTALLATION

- 3.3.2. FUEL INJECTION PUMP

- 3.3.2.1. REMOVAL

- 3.3.2.2. INSTALLATION

- 3.3.3. ENGINE OIL COOLER

- 3.3.3.1. REMOVAL

- 3.3.3.2. INSTALLATION

- 3.3.4. FAN AND FAN PULLEY

- 3.3.4.1. REMOVAL

- 3.3.4.2. INSTALLATION

- 3.3.5. HYDRAULIC OIL COOLER

- 3.3.5.1. REMOVAL

- 3.3.5.2. INSTALLATION

- 3.3.6. RADIATOR AND HYDRAULIC OIL COOLER

- 3.4. STRUCTURE AND FUNCTION

- 3.4.1. POWER TRAIN

- 3.4.2. TRAVEL SYSTEM

- 3.4.3. TRAVEL CONTROL CIRCUIT SCHEMATICS

- 3.4.4. TRAVEL CONTROL CIRCUIT

- 3.4.5. TRAVEL MOTOR (WITH REDUCTION GEAR AND PARKING BRAKE)

- 3.4.6. CENTER SWIVEL JOINT

- 3.4.7. STRAIGHT TRAVEL SYSTEM

- 3.4.8. TRAVEL CONTROL

- 3.4.9. SWING SYSTEM

- 3.4.10. SWING CONTROL CIRCUIT SCHEMATICS

- 3.4.11. SWING CONTROL CIRCUIT

- 3.4.12. SWING MOTOR AND BRAKE VALVE

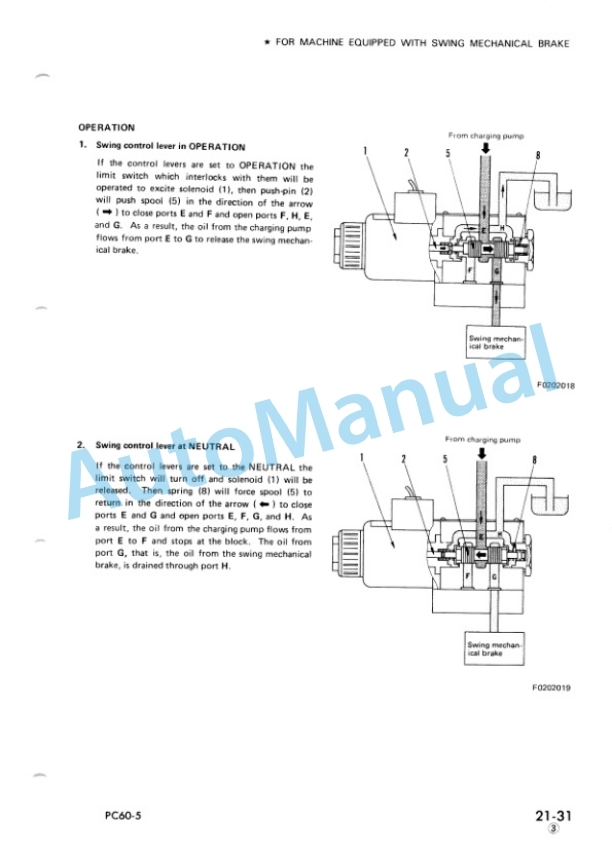

- 3.4.13. SWING MECHANICAL BRAKE

- 3.4.14. SWING PRIORITY CIRCUIT

- 3.4.15. SWING MACHINERY

- 3.4.16. SWING CIRCLE

- 3.4.17. SPROCKET

- 3.5. DISASSEMBLY AND ASSEMBLY

- 3.5.1. CENTER SWIVEL JOINT

- 3.5.2. SWING MACHINERY

- 3.6. MAINTENANCE STANDARD

- 3.6.1. SWING MACHINERY

- 3.6.2. SWING CIRCLE

- 3.6.3. SWING MOTOR

- 3.6.4. SPROCKET

- 4. UNDERCARRIAGE

- 4.1. STRUCTURE AND FUNCTION

- 4.2. DISASSEMBLY AND ASSEMBLY

- 4.3. MAINTENANCE STANDARD

- 4.3.1. TRACK FRAME AND RECOIL SPRING

- 4.3.2. IDLER

- 4.3.3. CARRIER ROLLER

- 4.3.4. TRACK ROLLER

- 4.3.5. TRACK SHOE

- 5. HYDRAULIC SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. OUTLINE

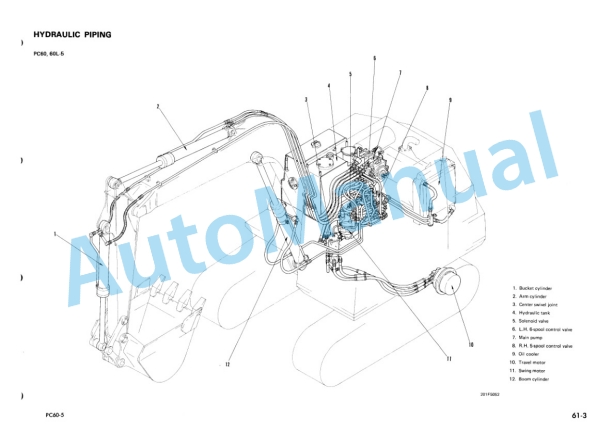

- 5.1.2. HYDRAULIC PIPING

- 5.1.3. HYDRAULIC SCHEMATICS

- 5.1.4. HYDRAULIC CIRCUIT

- 5.1.5. HYDRAULIC TANK (WITH FUEL TANK)

- 5.1.6. HYDRAULIC PUMP

- 5.1.7. PC CONTROL SYSTEM

- 5.1.8. MODE SELECTION TYPE PC CONTROL SYSTEM (IF EQUIPPED)

- 5.1.9. OLSS SYSTEM (IF EQUIPPED)

- 5.1.10. CONTROL VALVE

- 5.1.11. WORK EQUIPMENT SWIVEL JOINT

- 5.1.12. SAFETY SUCTION VALVE (FOR BOOM SWING)

- 5.1.13. HYDRAULIC CYLINDER

- 5.1.14. WORK EQUIPMENT CONTROL

- 5.1.15. WORK EQUIPMENT

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TABLE OF JUDGEMENT STANDARD VALUE

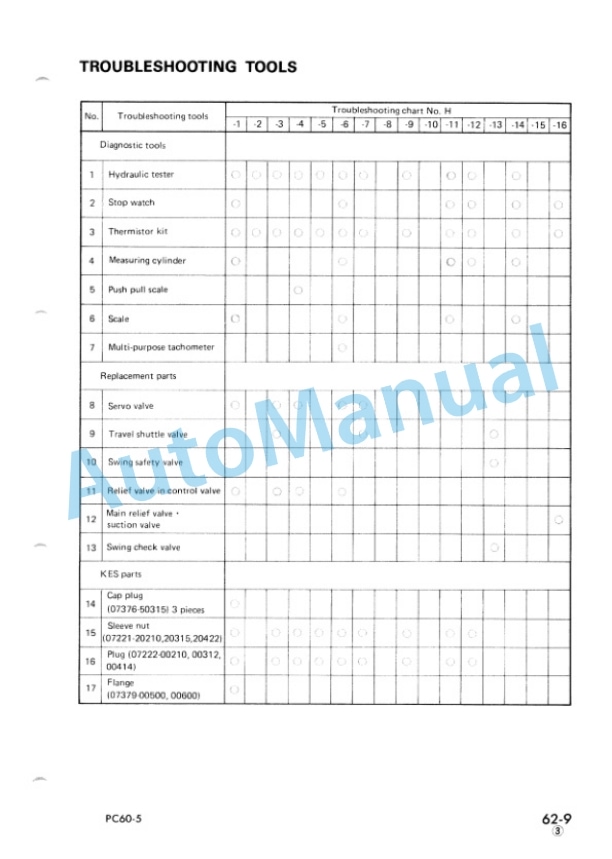

- 5.2.2. TROUBLESHOOTING TOOLS

- 5.2.3. MEASURING HYDRAULIC OIL TEMPERATURE

- 5.2.4. TESTING OPERATING FORCE OF CONTROL LEVERS

- 5.2.5. TESTING TRAVEL CONTROL LEVERS

- 5.2.6. TESTING TRAVEL CONTROL VALVE SPOOLS

- 5.2.7. TESTING AND ADJUSTING MAIN RELIEF VALVE

- 5.2.8. TESTING AND ADJUSTING CHARGING PUMP RELIEF VALVE

- 5.2.9. TESTING CONTROL CIRCUIT PRESSURE

- 5.2.10. MEASURING SWING AND BUCKET RELIEF PRESSURE

- 5.2.11. MEASURING DELIVERY OF PISTON PUMP

- 5.2.12. CHECKING PERFORMANCE OF WORK EQUIPMENT

- 5.2.13. AIR BLEEDING

- 5.2.14. CHECKING TRAVEL MOTOR PERFORMANCE

- 5.2.15. CHECKING PERFORMANCE OF SWING MOTORS

- 5.2.16. MEASURING OIL LEAKAGE FROM SWING AND TRAVEL MOTORS

- 5.2.17. CHECKING FOR OIL LEAKAGE FROM SWIVEL JOINT

- 5.2.18. ADJUSTING BOOM SWING KICKOUT (ON PC60U5)

- 5.2.19. CHECKING VISUALLY OR BY FEEL

- 5.2.20. TROUBLESHOOTING

- 5.2.20.1. ELECTRICAL CIRCUIT

- 5.2.20.2. POSITION OF CONNECTORS FOR TROUBLESHOOTING

- 5.2.20.3. CONNECTION TABLE FOR CONNECTOR PINS

- 5.2.20.4. TROUBLESHOOTING PROCEDURE

- 5.2.20.5. CHECKS BEFORE TROUBLESHOOTING

- 5.2.20.6. JUDGEMENT TABLE

- 5.2.20.7. TROUBLESHOOTING CHART

- 5.2.20.7.1. E1 WORK EQUIPMENT, SWING, TRAVEL SPEEDS EXTREMELY SLOW, OR LACK OF POWER, NO CHANGE IN OUTPUT WHEN MODE SELECTOR SWITCH IS OPERATED

- 5.2.20.7.2. E2 MACHINE DEVIATES EXCESSIVELY (DURING COMPOUND OPERATIONS)

- 5.2.20.7.3. E2 MACHINE DEVIATES EXCESSIVELY (DURING COMPOUND OPERATIONS) (WHEN STARTING)

- 5.2.20.7.4. E3 HYDRAULIC DRIFT OF SWING IS EXCESSIVE, OR UPPER STRUCTURE DOES NOT SWING

- 5.2.20.7.5. E4 AUTODECELERATION DOES NOT WORK

- 5.2.20.7.6. H1 MACHINE DEVIATES EXCESSIVELY (DEVIATES MORE THAN STANDARD WHEN ONLY TRAVEL SYSTEM IS USED, TRAVEL LEVER IS PULLED FAULLY)

- 5.2.20.7.7. H1 MACHINE DEVIATES EXCESSIVELY (DEVIATES MORE THAN STANDARD WHEN ONLY TRAVEL SYSTEM IS USED, TRAVEL LEVER AT FULL TRAVEL)

- 5.2.20.7.8. H2 MACHINE DEVIATES EXCESSIVELY DURING COMPOUND OPERATION

- 5.2.20.7.9. H3 MACHINE DEVIATES EXCESSIVELY WHEN STARTING

- 5.2.20.7.10. H4 CONTROL LEVERS ARE EXTREMELY HEAVY

- 5.2.20.7.11. H5 WORK EQUIPMENT, TRAVEL AND SWING START SUDDENLY DURING FINE CONTROL OPERATIONS

- 5.2.20.7.12. H6 SPEEDS FOR WORK EQUIPMENT, SWING, AND TRAVEL ARE ALL EXTREMELY SLOW, OR THERE IS NO POWER

- 5.2.20.7.13. H6 SPEEDS FOR WORK EQUIPMENT, SWING, AND TRAVEL ARE ALL EXTREMELY SLOW, OR THERE IS NO POWER (NO ABNORMALITY IN AUTODECELERATION)

- 5.2.20.7.14. H7 SPEEDS FOR BOOM, ARM AND BUCKET ARE SLOW, OR THERE IS NO POWER (NO ABNORMALITY IN AUTODECELERATION)

- 5.2.20.7.15. H8 ENGINE STALLS OR ENGINE SPEED DROPS DURING OPERATIONS

- 5.2.20.7.16. H9 NO CHANGE IN OUTPUT WHEN MODE SELECTOR SWITCH OPERATED

- 5.2.20.7.17. H10 AUTODECELERATION DOES NOT COME ON, OR DOES NOT GO OFF

- 5.2.20.7.18. H11 ABNORMAL NOISE COMES FROM AROUND PUMP

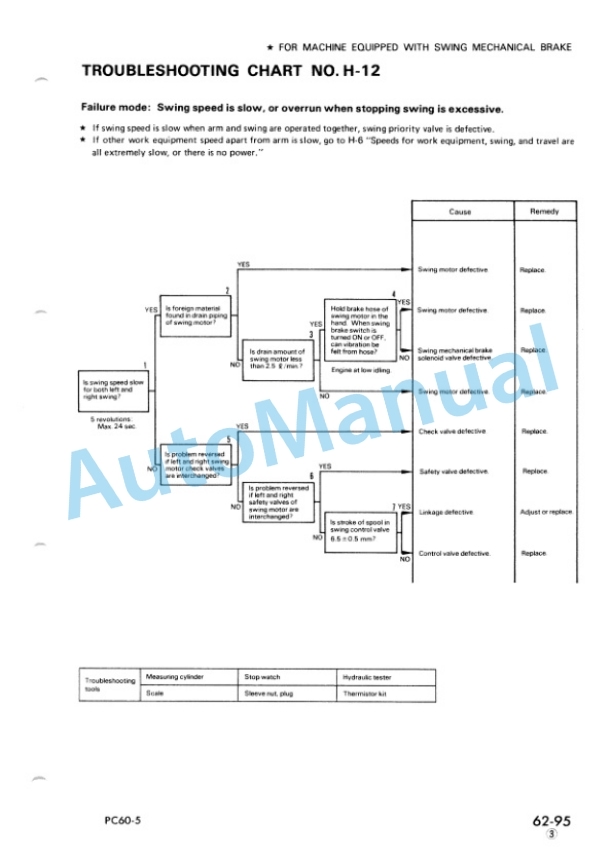

- 5.2.20.7.19. H12 SWING SPEED IS SLOW, OR OVERRUN WHEN STOPPING SWING IS EXCESSIVE

- 5.2.20.7.20. H13 UPPER STRUCTURE DOES NOT SWING

- 5.2.20.7.21. H14 EXCESSIVE HYDRAULIC DRIFT OF SWING

- 5.2.20.7.22. H15 EXCESSIVE HYDRAULIC DRIFT OF WORK EQUIPMENT

- 5.2.20.7.23. H16 EXCESSIVE TIME LAG FOR WORK EQUIPMENT

- 5.2.20.8. FAILURE MODE AND COMPONENTS

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.0.1. REMOVAL (WITH OLSS)

- 5.3.0.2. INSTALLATION (WITH OLSS)

- 5.3.0.3. DISASSEMBLY

- 5.3.0.4. ASSEMBLY

- 5.3.1. TVC VALVE AND FRONT CONC VALVE (IF EQUIPPED)

- 5.3.1.1. REMOVAL

- 5.3.1.2. INSTALLATION

- 5.3.2. REAR CONC VALVE (IF EQUIPPED)

- 5.3.3. MAIN PUMP INPUT SHAFT OIL SEAL

- 5.3.3.1. REMOVAL

- 5.3.3.2. INSTALLATION

- 5.3.4. SPOOL CONTROL VALVE

- 5.3.4.1. REMOVAL

- 5.3.4.2. INSTALLATION

- 5.3.5. SPOOL CONTROL VALVE

- 5.3.6. BUCKET CYLINDER

- 5.3.6.1. REMOVAL

- 5.3.6.2. INSTALLATION

- 5.3.7. HYDRAULIC CYLINDER

- 5.3.7.1. DISASSEMBLY

- 5.3.7.2. ASSEMBLY

- 5.4. MAINTENANCE STANDARD

- 5.4.1. CHARGING PUMP (BAR 16)

- 5.4.2. SPOOL CONTROL VALVE

- 5.4.3. SPOOL CONTROL VALVE

- 5.4.4. SPOOL CONTROL VALVE

- 5.4.5. HYDRAULIC CYLINDER

- 5.4.6. WORK EQUIPMENT

- 6. WORK EQUIPMENT

- 6.1. DISASSEMBLY AND ASSEMBLY

- 7. ELECTRICAL SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. ELECTRICAL SYSTEM

- 7.1.2. ELECTRICAL CIRCUIT DIAGRAM

- 7.2. TESTING AND ADJUSTING

- 7.2.1. ELECTRICAL CIRCUIT

- 7.2.2. TROUBLESHOOTING CHART

- 7.2.2.1. M1 BATTERY CHARGING PILOT LAMP DOES NOT GO OFF

- 7.2.2.2. M2 FUEL GAUGE DOES NOT DISPLAY OR DISPLAYS ABNORMALLY

- 7.2.2.3. M3 WATER TEMPERATURE GAUGE DOES NOT OPERATE OR DISPLAYS ABNORMALLY

Rate this product

You may also like