Komatsu PC600-6, PC600LC-6 Hydraulic Excavator Shop Manual SEBM017111

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM017111

- Format: PDF

- Size: 83.8MB

- Number of Pages: 1041

Category: Komatsu Shop Manual PDF

-

Model List:

- PC600-6 Hydraulic Excavator

- PC600LC-6 Hydraulic Excavator

- 1. COVER PAGE

- 2. CONTENTS

- 2.1. LIST OF REVISED PAGES

- 3. GENERAL

- 3.1. SPECIFICATIONS

- 3.2. WEIGHT TABLE

- 3.3. FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. PARTS RELATED TO ENGINE

- 4.3. RADIATOR, OIL COOLER

- 4.4. POWER TRAIN

- 4.5. FINAL DRIVE

- 4.6. SWING CIRCLE

- 4.7. SWING MACHINERY

- 4.8. TRACK FRAME, RECOIL SPRING

- 4.9. TRACK SHOE

- 4.10. HYDRAULIC PIPING DRAWING

- 4.11. HYDRAULIC TANK, HYDRAULIC FILTER

- 4.12. HYDRAULIC PUMP (PISTON PUMP)

- 4.13. LINE OIL FILTER

- 4.14. CONTROL VALVE

- 4.15. SWING MOTOR

- 4.16. CENTRAL SWIVEL JOINT

- 4.17. TRAVEL MOTOR

- 4.18. VALVE CONTROL

- 4.19. WORK EQUIPMENT SWING PPC VALVE

- 4.20. TRAVEL PPC VALVE

- 4.21. SERVICE PPC VALVE

- 4.22. PPC SAFETY LOCK VALVE

- 4.23. PPC ACCUMULATOR

- 4.24. PPC SHUTTLE VALVE

- 4.25. SOLENOID VALVE

- 4.26. BOOM HOLDING VALVE

- 4.27. BOOM LOWER REGENERATION VALVE

- 4.28. AIR CONDITIONER

- 4.29. ACTUAL ELECTRIC WIRING DIAGRAM

- 4.30. ENGINE CONTROL

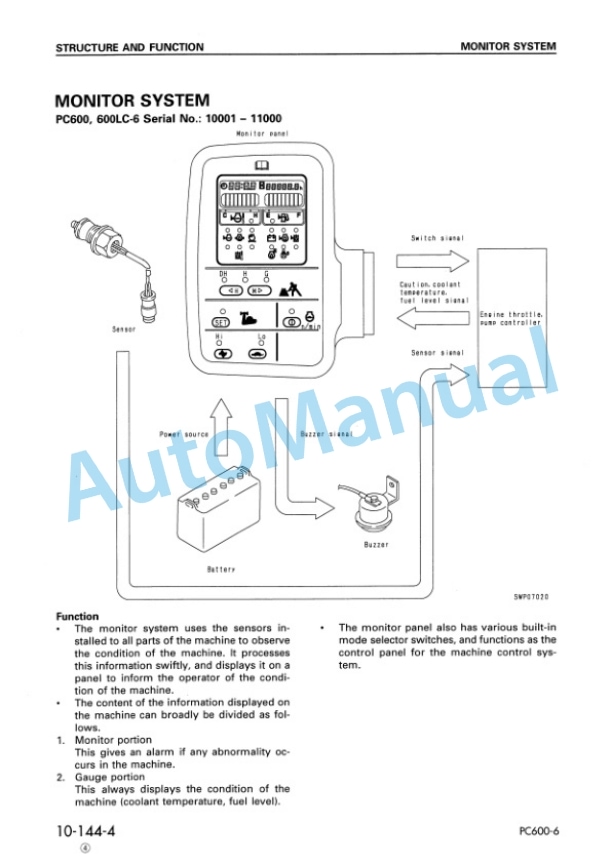

- 4.31. MACHINE CONTROL SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGING

- 5.2. TESTING AND ADJUSTING

- 5.3. TROUBLESHOOTING

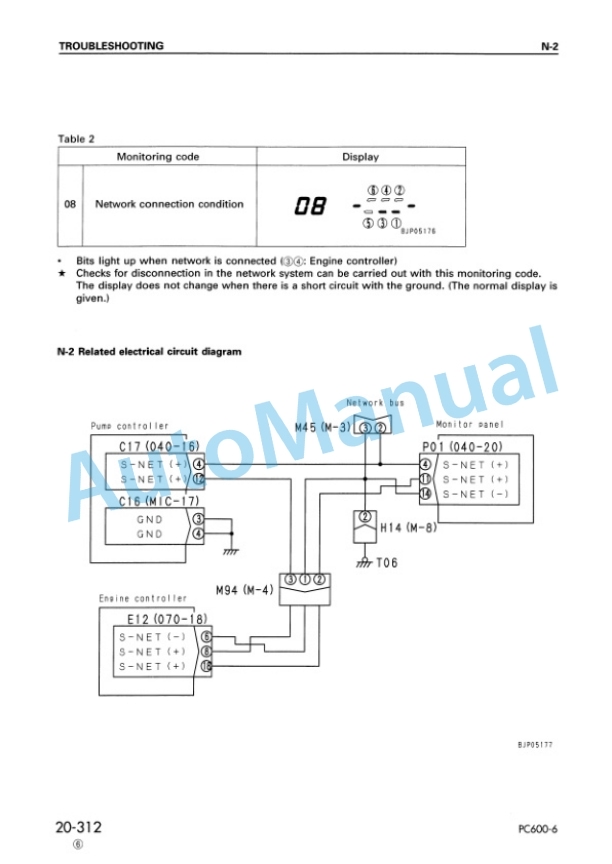

- 5.4. TROUBLESHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (n MODE)

- 5.5. TROUBLESHOOTING OF CUMMUNICATION ABNORMALITY SYSTEM (N MODE)

- 5.6. TROUBLESHOOTING OF ENGINE THROTTLE PUMP CONTROLLER (GOVERNOR CONTROL SYSTEM0, ENGING CONTROL SYSTEM (E MODE)

- 5.7. TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM (E MODE)

- 5.8. TROUBLESHOOTING OF ENGINE THROTTLE PUMP CONTROL SYSTEM) (C MODE)

- 5.9. TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM (C MODE)

- 5.10. TROUBLESHOOTING OF ENGINE THROTTLE PUMP CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)

- 5.11. TROUBLESHOOTING OF PUMP CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)

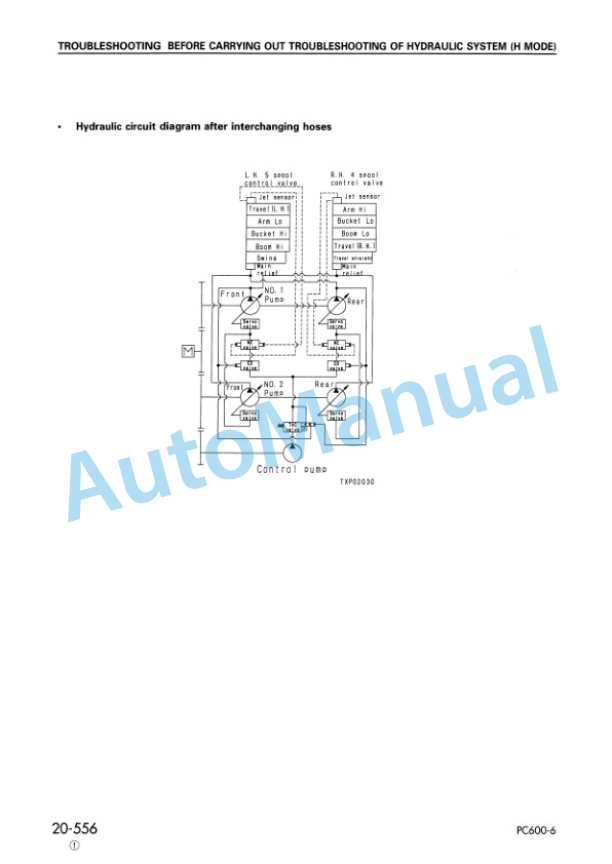

- 5.12. TROUBLESHOOTING OF HYDRAULIC MECHANICAL SYSTEM (H MODE)

- 5.13. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 5.14. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. REMOVAL OF RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 6.6. REMOVAL OF FUEL SUPPLY PUMP ASSEMBLY

- 6.7. INSTALLATION OF FUEL SUPPLY PUMP ASSEMBLY

- 6.8. REMOVAL OF FUEL INJECTOR ASSEMBLY

- 6.9. INSTALLATION OF FUEL INJECTOR ASSEMBLY

- 6.10. REMOVAL OF NOZZLE TIP

- 6.11. INSTALLATION OF NOZZLE TIP

- 6.12. REMOVAL OF ENGINE FRONT SEAL

- 6.13. INSTALLATION OF ENGINE FRONT SEAL

- 6.14. REMOVAL OF ENGINE REAR SEAL

- 6.15. INSTALLATION OF ENGINE REAR SEAL

- 6.16. REMOVAL OF CYLINDER HEAD ASSEMBLY

- 6.17. INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.18. REMOVAL OF RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 6.19. INSTALLATION OF RADIATOR, HYDRUALIC COOLER ASSEMBLY

- 6.20. REMOVAL OF RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 6.21. INSTALLATION OF RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 6.22. REMOVAL OF ENGINE, PTO, HYDRAULIC PUMP ASSEMBLY

- 6.23. INSTALLATION OF ENGINE, PTO, HYDRAULIC PUMP ASSEMBLY

- 6.24. REMOVAL OF ENGINE, PTO, HYDRAULIC PUMP ASSEMBLY

- 6.25. INSTALLATION OF ENGINE, PTO, HYDRAULIC PUMP ASSEMBLY

- 6.26. REMOVAL OF PTO ASSEMBLY

- 6.27. INSTALLATION OF ENGINE, PTO, HYDRAULIC PUMP ASSEMBLY

- 6.28. DISASSEMBLY OF PTO ASSEMBLY

- 6.29. ASSEMBLY OF PTO ASSEMBLY

- 6.30. REMOVAL OF FUEL TANK ASSEMBLY

- 6.31. INSTALLATION OF FUEL TANK

- 6.32. REMOVAL OF FUEL TANK ASSEMBLY

- 6.33. INSTALLATION OF FUEL TANK

- 6.34. DISASSEMBLY OF FINAL DRIVE ASSEMBLY

- 6.35. ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 6.36. REMOVAL OF REVOLVING FRAME ASSEMBLY

- 6.37. INSTALLATION OF REVOLVING FRAME ASSEMBLY

- 6.38. REMOVAL OF SWING MOTOR ASSEMBLY

- 6.39. INSTALLATION OF SWING MOTOR ASSEMBLY

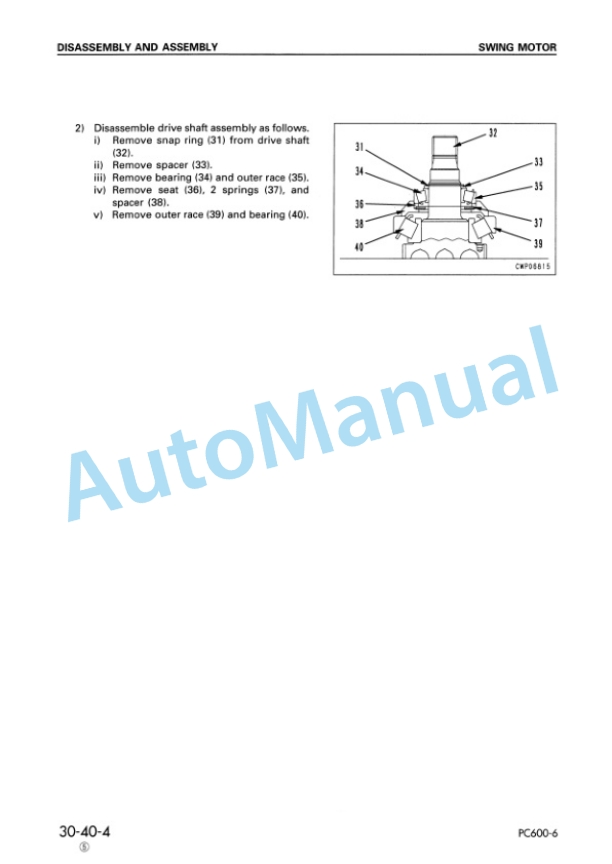

- 6.40. DISASSEMBLY OF SWING MOTOR ASSEMBLY

- 6.41. ASSEMBLY OF SWING MOTOR ASSEMBLY

- 6.42. REMOVAL OF SWING MACHINERY ASSEMBLY

- 6.43. INSTALLATION OF SWING MACHINERY ASSEMBLY

- 6.44. DISASSEMBLY OF SWING MACHINERY ASSEMBLY

- 6.45. ASSEMBLY OF SWING MACHINERY ASSEMBLY

- 6.46. REMOVAL OF SWING CIRCLE ASSEMBLY

- 6.47. INSTALLATION OF SWING CIRCLE ASSEMBLY

- 6.48. REMOVAL OF TRACK SHOE ASSEMBLY

- 6.49. INSTALLATION OF TRACK SHOE ASSEMBLY

- 6.50. DISASSEMBLY OF ONE LINK IN FIELD

- 6.51. ASSEMBLY OF ONE LINK IN FIELD

- 6.52. REMOVAL OF IDLER, RECOIL SPRING ASSEMBLY

- 6.53. INSTALLATION OF IDLER, RECOIL SPRING ASSEMBLY

- 6.54. DISASSEMBLY OF IDLER ASSEMBLY

- 6.55. ASSEMBLY OF IDLER ASSEMBLY

- 6.56. DISASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.57. ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.58. REMOVAL OF TRACK ROLLER ASSEMBLY

- 6.59. INSTALLATION OF TRACK ROLLER ASSEMBLY

- 6.60. DISASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.61. ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.62. REMOVAL OF CARRIER ROLLER ASSEMBLY

- 6.63. INSTALLATION OF CARRIER ROLLER ASSEMBLY

- 6.64. DISASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 6.65. ASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 6.66. REMOVAL OF HYDRAULIC TANK ASSEMBLY

- 6.67. INSTALLATION OF HYDRAULIC TANK ASSEMBLY

- 6.68. DISASSEMBLY OF MAIN RELIEF VALVE ASSEMBLY

- 6.69. ASSEMBLY OF MAIN RELIEF VALVE ASSEMBLY

- 6.70. REMOVAL OF MAIN CONTROL VALVE, SOLENOID VALVE ASSEMBLY

- 6.71. INSTALLATION OF MAIN CONTROL VALVE, SOLENOID VALVE ASSEMBLY

- 6.72. DISASSEMBLY OF MAIN CONTROL VALVE ASSEMBLY

- 6.73. ASSEMBLY OF MAIN CONTROL VALVE ASSEMBLY

- 6.74. REMOVAL OF NO. 1 AND NO. 2 PUMP ASSEMBLY

- 6.75. INSTALLATION OF NO. 1 AND NO. 2 PUMP ASSEMBLY

- 6.76. DISASSEMBLY OF HYDRAULIC PUMP ASSEMBLY

- 6.77. ASSEMBLY OF HYDRAULIC PUMP ASSEMBLY

- 6.78. REMOVAL OF CONTROL, PTO LUBRICATION PUMP ASSEMBLY

- 6.79. INSTALLATION OF CONTROL, PTO LUBRICATION PUMP ASSEMBLY

- 6.80. REMOVAL OF CENTER SWIVEL JOINT ASSEMBLY

- 6.81. INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY

- 6.82. DISASSEMBLY OF CENTER SWIVEL JOING ASSEMBLY

- 6.83. ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

- 6.84. DISASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 6.85. ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 6.86. DISASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 6.87. ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 6.88. REMOVAL OF BUCKET CYLINDER ASSEMBLY

- 6.89. INSTALLATION OF BUCKET CYLINDER ASSEMBLY

- 6.90. REMOVAL OF ARM CYLINDER ASSEMBLY

- 6.91. INSTALLATION OF ARM CYLINDER ASSEMBLY

- 6.92. REMOVAL OF BOOM CYLINDER ASSEMBLY

- 6.93. INSTALLATION OF BOOM CYLINDER ASSEMBLY

- 6.94. DISASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 6.95. ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 6.96. REMOVAL OF BUCKET ASSEMBLY

- 6.97. INSTALLATION OF BUCKET ASSEMBLY

- 6.98. REMOVAL OF ARM ASSEMBLY

- 6.99. INSTALLATION OF ARM ASSEMBLY

- 6.100. REMOVAL OF BOOM ASSEMBLY

- 6.101. INSTALLATION OF BOOM ASSEMBLY

- 6.102. REMOVAL OF OPERATORS CAB ASSEMBLY

- 6.103. INSTALLATION OF OPERATORS CAB ASSEMBLY

- 6.104. REMOVAL OF COUNTERWEIGHT ASSEMBLY

- 6.105. INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.3. SWING MACHINERY

- 7.4. SWING CIRCLE

- 7.5. FINAL DRIVE

- 7.6. TRACK FRAME AND RECOIL SPRING

- 7.7. HYDRAULIC PUMP

- 7.8. CONTROL AND PTO LUBRICATION PUMP

- 7.9. CONTROL VALVE

- 7.10. SWING MOTOR

- 7.11. TRAVEL MOTOR

- 7.12. WORK EQUIPMENT SWING PPC VALVE

- 7.13. TRAVEL PPC VALVE

- 7.14. SERVICE PPC VALVE

- 7.15. SOLENOID VALVE

- 7.16. CENTER SWIVEL JOINT

- 7.17. BOOM HOLDING VALVE

- 7.18. BOOM LOWER REGENERATION VALVE

- 7.19. HYDRAULIC CYLINDER

- 7.20. WORK EQUIPMENT

- 7.21. DIMENSIONS OF WORK EQUIPMENT

- 8. OTHERS

- 8.1. HYDRAULIC CIRCUIT DIAGRAM (2/2)

- 8.2. HYDRAULIC CIRCUIT DIAGRAM (1/2)

- 8.3. HYDRAULIC CIRCUIT DIAGRAM (2/2)

- 8.4. ELECTRIC CIRCUIT DIAGRAM (1/3)

- 8.5. ELECTRIC CIRCUIT DIAGRAM (2/3)

- 8.6. ELECTRIC CIRCUIT DIAGRAM (3/3)

- 8.7. ELECTRIC CIRCUIT DIAGRAM (1/4)

- 8.8. ELECTRIC CIRCUIT DIAGRAM (2/4)

- 8.9. ELECTRIC CIRCUIT DIAGRAM (3/4)

- 8.10. ELECTRIC CIRCUIT DIAGRAM (4/4)

Rate this product

You may also like